EP1405809A1 - Dispositif pour former des colis de produits empilés - Google Patents

Dispositif pour former des colis de produits empilés Download PDFInfo

- Publication number

- EP1405809A1 EP1405809A1 EP02405851A EP02405851A EP1405809A1 EP 1405809 A1 EP1405809 A1 EP 1405809A1 EP 02405851 A EP02405851 A EP 02405851A EP 02405851 A EP02405851 A EP 02405851A EP 1405809 A1 EP1405809 A1 EP 1405809A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- stack

- support

- stacking

- package

- support element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H33/00—Forming counted batches in delivery pile or stream of articles

- B65H33/02—Forming counted batches in delivery pile or stream of articles by moving a blade or like member into the pile

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/421—Forming a pile

- B65H2301/4214—Forming a pile of articles on edge

- B65H2301/42146—Forming a pile of articles on edge by introducing articles from above

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/422—Handling piles, sets or stacks of articles

- B65H2301/4223—Pressing piles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/422—Handling piles, sets or stacks of articles

- B65H2301/4224—Gripping piles, sets or stacks of articles

- B65H2301/42242—Gripping piles, sets or stacks of articles by acting on the outermost articles of the pile for clamping the pile

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2301/00—Handling processes for sheets or webs

- B65H2301/40—Type of handling process

- B65H2301/42—Piling, depiling, handling piles

- B65H2301/426—Forming batches

- B65H2301/4263—Feeding end plate or end sheet before formation or after completion of a pile

Definitions

- the invention relates to a device for the production of Stack packages from continuously a horizontally extending Stack support fed, lined up vertically a stack of printed sheets consisting of a die Feeding printed sheets in a stream of shingles to the stacking support Conveyor and one to form a stack multi-part support device engaging in the stack from below, from a waiting position along the stacking surface in a transfer position in which the stack package to a Transfer movable pressing device into a strapping device is drivable and a first and second support element has, which can be raised from below over the stack support and each of the rear resp. the front end of a stack assigned.

- pole booms sold by Muller Martini with the designation Avanti include described in EP'0'623'542 A1.

- this object is achieved in that the Support device a third, the front in the paper direction End of the stack resp. Stackable assigned liftable Has support element.

- the third support element is advantageous regardless of that first and second support element along the stack support driven driven, which creates more freedom of action, which has a positive effect on higher production output.

- the first and the second support element can be raised together in the separation gap and cause a exact separation between two printed sheets.

- the stack packages on the stack support expediently between one in the paper running direction the front End of the stack package associated press part and a spaced associated with the rear end of the stack Press part transferred to the pressing device and from the latter in transports the strapping device, resulting in short cycle times arise.

- the support elements of the support device are expedient on a common, parallel to the stack support extending guide adjustable so that a simple guide construction arises.

- End plate feed device for the production of ends stack packages reinforced with end plates, one for the rear end of a stack package specific end plate on the Transfer position of the stack between the second the rear end of the stack package supporting element and the press part associated with the rear end of the stack package fed to the stacking support, with which a reliable end plate positioning is guaranteed on the stack support.

- one is for the front end of one Endplate in a stack package determined by the second and the third support element formed space on the stack support transported against the paper feed direction.

- the feed device for end plates between is advantageous the pressed parts of those in the transfer position Pressing device arranged, whereby stack packages each have the desired length produced.

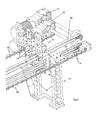

- 1 a to 1 l show a device 1 for producing stack packs 2 from printing sheets 4 fed continuously in a shingled stream 3.

- the printing sheets 4 are, as described in EP 0'623'542 A1, via a conveyor device (not visible) in one Scale stream 3 is fed to a horizontal stack support 5 after it has been previously aligned and placed in the desired scale shape, ie the scale formation must be turned laterally by 180 ° after the printing press. If the scale formation is to be processed by one wrap, it is initially essential to wrap it around another wrap.

- 1a to 1l further show that the device 1 is designed to be mobile and can thus be connected to the display of various printing machines of a company.

- FIG. 1 a shows the device 1 in the empty state with an incoming scale flow 3 and the first support element 6 of a multi-part support device 7 raised above the stack support 5.

- This further consists of a second support element 8, which is also illustrated in the raised state.

- the two support elements 6, 8 are assigned a third support element 9, which is also shown in the ejected position.

- the support elements 6, 8, 9 forming the support device 7 are driven on a guide 10 arranged below the stack support 5, parallel to this, along the stack support 5.

- the support elements 6, 8, 9 are connected, for example, to traction means, such as toothed belts or chains, which are driven along the stack support 5 in the paper running direction and back and can be raised and lowered by controlled adjusting means.

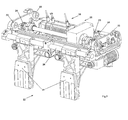

- FIG. 2 An embodiment of the drive arrangement for the support device 7, in particular support element 9, is shown in FIG. 2.

- the latter provides a lateral guide 10, which is fastened to a frame of the device 1 and on which a carriage 11 which is movable along the stack support 5 and on which the support element 9 can be raised and lowered is arranged.

- two columns 12 are provided, on which the support element 9, which has three support plates 13, can be driven vertically by a pneumatic cylinder (not shown).

- the support element 9 is driven along the stack support 5 by toothed belts 14, of which both the upper and the lower run can be seen.

- the drive motor for toothed belt 14 is located at the opposite end of the stack support 5. Toothed belt 15 is provided for driving support element 6 and toothed belt 16 for support element 8.

- the toothed belts 15 to 17 are each deflected around pulleys, one of which is connected to a drive motor, toothed belt 16 being associated with a geared motor 17 and toothed belt 15 with a geared motor 18.

- the support elements 6, 8, like the support element 9, are fastened to their own undercarriage (not illustrated in FIG. 2) and, like the support element 9, are actuated by a pneumatic cylinder.

- a pressing device 19 which can be moved along the stack support 5, is arranged above the stack support 5 and detects a stack package 2 produced on the stack support 5 and transports it into a subsequent strapping device 20.

- 3 shows a supporting structure 21 with a pressing part 22 viewed from the pressing device 19 in the opposite direction of the paper travel.

- the supporting structure extends transversely to the paper running direction and is arranged to be movable on both sides by two rollers 23 in a stationary C-shaped running rail (not visible).

- the running rail 27 is provided with a toothed rack (not shown) with which a toothed wheel 24 of a travel drive 25 meshes.

- the press part 22 consists of two press plates 26 which can be adjusted to the format of the printed sheets to be processed on a guide rod 26 arranged above them, transversely to the paper running direction.

- the area of action of the pressing device 19 extends from the stacking support 5 into the strapping device 20.

- the support elements 6, 9 of the support device 7 are raised via the stack support 5 in the concept of taking over an end plate 29 which is displaced from the side of the device 1 from a plate magazine between the spaced support elements 8, 9.

- an end plate 29 which, for the front end of a stack in the paper travel direction.

- Stack package 2 is provided. The (front) end plate 29 is now guided between the support elements 8, 9 via the stack support 5 to the front stack end of a stack which is held upright by the support element 6.

- the second support element 8 has now moved downward from the stacking support 5 and the end plate 29 is now held between the support elements 6 and 9.

- the collecting process is maintained and the first support element 6 of the support device 7 can now also be moved downwards, so that the end plate 29 comes to rest on the front end of the stack, supported by the support element 9 (see FIG. 1c).

- the support elements 6, 8 move into their starting position in front of the rear end of the stack (see FIG. 1d). In the situation according to FIG.

- the stack package 2 is located between two pressing parts 22, 28 of the pressing device 19, so that an end plate 30 can be fed from the side end plate magazine to the rear end of the stack package 2, ie the end plate magazine is between the pressing parts 22, 28, approximately arranged pressing part for the rear stack end.

- Pressed part 22 and the rear end of the stacking package or the supporting element 8 supporting this form a gap into which the rear end plate 30 is inserted.

- Both end plates 29 and 30 have the same dimensions (see Fig. 1g). Subsequently, as shown in FIG.

- the front pressed part 28 and the rear pressed part 22 with the end plate 29 and 30 in between are placed against the ends of the stacking package 2 and at the same time the support elements 8 and 9 are moved out of the stacking area. Meanwhile, stacking continues at the end of the shingled stream.

- the stack of packs 2 gripped by the pressed parts 22, 28 is now transferred to the strapping device 20 on the running rails 27 and the support elements 8, 9 have arrived at the end plate magazine for taking over a front end plate 29. While the front end plate 29 is being moved to the front stack end of the continuously increasing stack, the stack package 2 is finally pressed off in the strapping device 20 and then strapped or bound together.

- the front end plate 29 is supported by the support element 9 at the front end of the stack, the support elements 6, 8 are extended and the strapping is completed.

- the support elements 6, 8 return to the starting position, where, according to FIG. 1d, a new stacking process has already started.

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02405851A EP1405809B1 (fr) | 2002-10-02 | 2002-10-02 | Dispositif pour former des colis de produits empilés |

| DE50213650T DE50213650D1 (de) | 2002-10-02 | 2002-10-02 | Einrichtung zur Herstellung von Stapelpaketen |

| JP2003337963A JP4860103B2 (ja) | 2002-10-02 | 2003-09-29 | 堆積体パッケージを製造するための装置 |

| US10/676,043 US7021035B2 (en) | 2002-10-02 | 2003-10-02 | Apparatus for producing stack bundles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP02405851A EP1405809B1 (fr) | 2002-10-02 | 2002-10-02 | Dispositif pour former des colis de produits empilés |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1405809A1 true EP1405809A1 (fr) | 2004-04-07 |

| EP1405809B1 EP1405809B1 (fr) | 2009-07-01 |

Family

ID=31985174

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02405851A Expired - Lifetime EP1405809B1 (fr) | 2002-10-02 | 2002-10-02 | Dispositif pour former des colis de produits empilés |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7021035B2 (fr) |

| EP (1) | EP1405809B1 (fr) |

| JP (1) | JP4860103B2 (fr) |

| DE (1) | DE50213650D1 (fr) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2159177A1 (fr) | 2008-08-29 | 2010-03-03 | Müller Martini Holding AG | Procédé et dispositif de fabrication de piles de feuilles imprimées |

| EP2316767A1 (fr) | 2009-11-03 | 2011-05-04 | Müller Martini Holding AG | Dispositif et procédé de fabrication de piles de produits d'impression |

| DE102011084469A1 (de) * | 2011-10-13 | 2013-04-18 | Robert Bosch Gmbh | Separiervorrichtung |

| DE102011088625A1 (de) | 2011-12-14 | 2013-06-20 | Müller Martini Holding AG | Einrichtung zum Herstellen von Stapelpaketen |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7200976B2 (en) * | 2002-07-19 | 2007-04-10 | Ferag Ag | Method and device for forming horizontal stacks of printed products and securing said stacks with straps |

| ITMI20040927A1 (it) * | 2004-05-07 | 2004-08-07 | Omet Srl | Procedimento e dispositivo per separare e trasferire verso l'impacchettamento un predeterminato numero di oggetti piatti quali fogli di carta in particolare tovaglioli |

| EP1816098B1 (fr) * | 2006-02-02 | 2010-03-31 | Müller Martini Holding AG | Procédé et dispositif pour former des piles |

| US20090112675A1 (en) * | 2007-10-31 | 2009-04-30 | Jeff Servais | Automated order fulfillment system and method |

| EP2520525B1 (fr) * | 2011-05-03 | 2018-05-23 | Müller Martini Holding AG | Procédé de fabrication de tiges constituées de produits d'impression |

| EP2537786B1 (fr) | 2011-06-22 | 2018-07-18 | Müller Martini Holding AG | Tige et procédé de fabrication de cette tige à partir de produits d'impression |

| EP3590850B1 (fr) * | 2018-07-02 | 2021-05-05 | H+H GmbH & Co. KG | Procédé et dispositif d'empilement et d'emballage de produits pliés |

| DE102020101506A1 (de) * | 2020-01-23 | 2021-07-29 | MM Engineering GmbH | Vorrichtung und Verfahren zur Durchführung von Verpackungsschritten von flächigen Kartongütern |

| CN113928903A (zh) * | 2021-10-18 | 2022-01-14 | 东莞市浩信精密机械有限公司 | 一种用于捆书机的不停机分纸机构 |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57112266A (en) * | 1980-12-27 | 1982-07-13 | Yamada Kikai Kogyo Kk | Classification device for folded book |

| US4772003A (en) * | 1987-02-24 | 1988-09-20 | Dainihon Insatsu Kabushiki Kaisha | Apparatus for stacking signatures or the like |

| JPH0432459A (ja) * | 1990-05-25 | 1992-02-04 | Toppan Printing Co Ltd | 刷本類の自動区分け装置における区分けフォーク駆動制御方法 |

| JPH06219622A (ja) * | 1993-01-20 | 1994-08-09 | Dainippon Printing Co Ltd | 刷本集積装置 |

| US5393196A (en) * | 1991-05-28 | 1995-02-28 | Winkler & Duennebier Maschinenfabrik Und Eisengiesserei Kg | Method and apparatus for stacking of envelopes or the like |

| EP0741101A2 (fr) * | 1995-05-05 | 1996-11-06 | CIVIEMME S.r.l. | Méthode pour séparer une pile de cahiers dans un empileur et empileur pour la mise en oeuvre de cette méthode |

| FR2777876A1 (fr) * | 1998-04-24 | 1999-10-29 | Realisations Etudes Et Commerc | Dispositif d'empilage et de transfert de cahiers imprimes sous forme de cartouches |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4641489A (en) * | 1984-09-28 | 1987-02-10 | World Color Press, Inc. | Machine for handling signatures |

| US4723883A (en) * | 1985-08-09 | 1988-02-09 | Stacker Machine Co., Inc. | Stacker bundler shuttle system |

| US4824093A (en) * | 1988-05-06 | 1989-04-25 | Baldwin Technology Corporation | Handling signatures |

| DE4202540A1 (de) * | 1992-01-30 | 1993-08-05 | Giebeler Gmbh & Co Kg Robert | Verfahren und vorrichtung zur herstellung definierter stapel gefalzter oder ungefalzter blaetter oder blattfoermiger gegenstaende |

| JP4318322B2 (ja) | 1993-05-07 | 2009-08-19 | グラプハ−ホルディング・アクチエンゲゼルシヤフト | 並列して起立している刷紙に対して垂直方向で指向して堆積体を形成するための装置 |

| DE59806580D1 (de) * | 1997-03-18 | 2003-01-23 | Grapha Holding Ag | Vorrichtung zur Bildung eines sich senkrecht zu den stehend aneinandergereihten Druckbogen erstreckenden Teilstapels |

-

2002

- 2002-10-02 EP EP02405851A patent/EP1405809B1/fr not_active Expired - Lifetime

- 2002-10-02 DE DE50213650T patent/DE50213650D1/de not_active Expired - Lifetime

-

2003

- 2003-09-29 JP JP2003337963A patent/JP4860103B2/ja not_active Expired - Fee Related

- 2003-10-02 US US10/676,043 patent/US7021035B2/en not_active Expired - Fee Related

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS57112266A (en) * | 1980-12-27 | 1982-07-13 | Yamada Kikai Kogyo Kk | Classification device for folded book |

| US4772003A (en) * | 1987-02-24 | 1988-09-20 | Dainihon Insatsu Kabushiki Kaisha | Apparatus for stacking signatures or the like |

| JPH0432459A (ja) * | 1990-05-25 | 1992-02-04 | Toppan Printing Co Ltd | 刷本類の自動区分け装置における区分けフォーク駆動制御方法 |

| US5393196A (en) * | 1991-05-28 | 1995-02-28 | Winkler & Duennebier Maschinenfabrik Und Eisengiesserei Kg | Method and apparatus for stacking of envelopes or the like |

| JPH06219622A (ja) * | 1993-01-20 | 1994-08-09 | Dainippon Printing Co Ltd | 刷本集積装置 |

| EP0741101A2 (fr) * | 1995-05-05 | 1996-11-06 | CIVIEMME S.r.l. | Méthode pour séparer une pile de cahiers dans un empileur et empileur pour la mise en oeuvre de cette méthode |

| FR2777876A1 (fr) * | 1998-04-24 | 1999-10-29 | Realisations Etudes Et Commerc | Dispositif d'empilage et de transfert de cahiers imprimes sous forme de cartouches |

Non-Patent Citations (3)

| Title |

|---|

| PATENT ABSTRACTS OF JAPAN vol. 006, no. 207 (M - 165) 19 October 1982 (1982-10-19) * |

| PATENT ABSTRACTS OF JAPAN vol. 016, no. 206 (M - 1248) 15 May 1992 (1992-05-15) * |

| PATENT ABSTRACTS OF JAPAN vol. 018, no. 592 (M - 1702) 11 November 1994 (1994-11-11) * |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2159177A1 (fr) | 2008-08-29 | 2010-03-03 | Müller Martini Holding AG | Procédé et dispositif de fabrication de piles de feuilles imprimées |

| US8376346B2 (en) | 2008-08-29 | 2013-02-19 | Mueller Martini Holding Ag | Device and method for producing stacks composed of printed sheets |

| EP2316767A1 (fr) | 2009-11-03 | 2011-05-04 | Müller Martini Holding AG | Dispositif et procédé de fabrication de piles de produits d'impression |

| US8413792B2 (en) | 2009-11-03 | 2013-04-09 | Mueller Martini Holding Ag | Method and device for producing stacks composed of printed products |

| DE102011084469A1 (de) * | 2011-10-13 | 2013-04-18 | Robert Bosch Gmbh | Separiervorrichtung |

| DE102011088625A1 (de) | 2011-12-14 | 2013-06-20 | Müller Martini Holding AG | Einrichtung zum Herstellen von Stapelpaketen |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1405809B1 (fr) | 2009-07-01 |

| JP4860103B2 (ja) | 2012-01-25 |

| US7021035B2 (en) | 2006-04-04 |

| US20040065214A1 (en) | 2004-04-08 |

| DE50213650D1 (de) | 2009-08-13 |

| JP2004123387A (ja) | 2004-04-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0623542B1 (fr) | Dispositif pour empiler un chant de feuilles imprimées | |

| EP2072430B1 (fr) | Dispositif de saisie de paquet pour un dispositif de palettisation et procédé de palettisation de paquets | |

| DE3735486C2 (fr) | ||

| EP0583562B1 (fr) | Dispositif pour amener d'une manière continue des corps d'ouvrage | |

| DE3203506A1 (de) | Vorrichtung zum einfuehren von blattpaketen in eine bearbeitungsmaschine | |

| EP0366038B1 (fr) | Dispositif pour plier en zigzag et empiler une bande de matériau | |

| CH667056A5 (de) | Verfahren und vorrichtung zur handhabung eines stapels von blaettern. | |

| EP1405809B1 (fr) | Dispositif pour former des colis de produits empilés | |

| DE3038058A1 (de) | Einrichtung zum aufstapeln von flachen gegenstaenden,insbesondere von faltschachtel-zuschnitten | |

| DE3126807A1 (de) | Stangenstapler fuer gefalzte druckbogen | |

| EP1816098B1 (fr) | Procédé et dispositif pour former des piles | |

| DE2508745C2 (de) | Vorrichtung zum Aufstauen vereinzelt mittels einer Transportvorrichtung zugeförderter Papierbögen zu Stapeln und zum Weitertransportieren dieser Stapel | |

| EP1378472A1 (fr) | Dispositif pour transporter une pile de feuilles imprimées, juxtaposées sur chant, reposant sur un support | |

| EP0309745B1 (fr) | Dispositif pour empiler des articles imprimés arrivant de façon continue en formation imbriquée | |

| EP0773179B1 (fr) | Dispositif pour faire des piles auxiliaires pendant l'échange en continue de piles dans un empileur d'une machine à imprimer | |

| EP1350750B1 (fr) | Méthode et dispositif pour former des piles d'objets plats arrivant en continu | |

| DE3911969A1 (de) | Vorrichtung zum riesweisen ablegen von boegen, insbesondere papierboegen, auf einen stapel | |

| EP0540505B1 (fr) | Installation pour empiler des pièces à usiner partagées en forme de plaques individuelles ou en paquets | |

| DE3931710C2 (de) | Non-Stop-Bogenanleger für Bogenrotationsmaschinen | |

| EP0741101B1 (fr) | Méthode pour séparer une pile de cahiers dans un empileur et empileur pour la mise en oeuvre de cette méthode | |

| EP1199275B1 (fr) | Dispositif pour la formation d'une pile de feuilles imprimées arrangées l' une à côté de l'autre | |

| EP0019036B1 (fr) | Dispositif pour empiler des produits de forme parallélépipédique, en particulier des imprimés, des journaux ou analogues de cette forme | |

| DE2753048C2 (de) | Verfahren und Vorrichtung zur Herstellung einer gebündelten Stange aus Druckbogen | |

| DE2547298A1 (de) | Verfahren zum aufbau eines stapels vorgegebener laenge von aus einer druckmaschine herausgefuehrten produkten und vorrichtung zur durchfuehrung des verfahrens | |

| EP0810174A2 (fr) | Dispositif pour l'empilage vertical de produits imprimés |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17P | Request for examination filed |

Effective date: 20040720 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE FR GB IT LI |

|

| 17Q | First examination report despatched |

Effective date: 20070129 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50213650 Country of ref document: DE Date of ref document: 20090813 Kind code of ref document: P |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20100406 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20101020 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20101025 Year of fee payment: 9 Ref country code: IT Payment date: 20101023 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20111026 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20120123 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20121002 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130501 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121002 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50213650 Country of ref document: DE Effective date: 20130501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121002 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121031 |