EP1330320B1 - Procede et dispositif de fabrication d'une piece a denture interieure, en particulier d'une roue a denture interieure - Google Patents

Procede et dispositif de fabrication d'une piece a denture interieure, en particulier d'une roue a denture interieure Download PDFInfo

- Publication number

- EP1330320B1 EP1330320B1 EP01992620A EP01992620A EP1330320B1 EP 1330320 B1 EP1330320 B1 EP 1330320B1 EP 01992620 A EP01992620 A EP 01992620A EP 01992620 A EP01992620 A EP 01992620A EP 1330320 B1 EP1330320 B1 EP 1330320B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- preform

- ironing

- during

- side wall

- mandrel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 16

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 6

- 238000010409 ironing Methods 0.000 claims description 39

- 125000006850 spacer group Chemical group 0.000 claims description 2

- 238000003825 pressing Methods 0.000 claims 4

- 230000001105 regulatory effect Effects 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J5/00—Methods for forging, hammering, or pressing; Special equipment or accessories therefor

- B21J5/02—Die forging; Trimming by making use of special dies ; Punching during forging

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21J—FORGING; HAMMERING; PRESSING METAL; RIVETING; FORGE FURNACES

- B21J5/00—Methods for forging, hammering, or pressing; Special equipment or accessories therefor

- B21J5/06—Methods for forging, hammering, or pressing; Special equipment or accessories therefor for performing particular operations

- B21J5/12—Forming profiles on internal or external surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K1/00—Making machine elements

- B21K1/28—Making machine elements wheels; discs

- B21K1/30—Making machine elements wheels; discs with gear-teeth

Definitions

- the invention relates to a method and an apparatus for producing a workpiece with internal toothing, in particular a ring gear, according to the preamble of the first claim.

- Such internal gears are generated for example by pressure-rolling.

- a cup-shaped preform is gem. DE 198 30 817 A1 pressed by means of tapered rollers during a feed movement against a tool chuck, which has the outer profile of the internal teeth to be generated, and reduced in diameter, wherein the preform rotates relative to the tapered rollers.

- the material of the cylinder wall region of the preform flows into the profile of the tool chuck, whereby the inner profile of the workpiece is generated.

- the disadvantage is the workpiece material demanding high flexing work in the flow-forming and thus insufficient quality of the internal teeth produced.

- the flexing work is also associated with a high local energy input, which leads to energy losses. Due to the high stress of the tool chuck, it often comes to a breaking out of the outer teeth shown therein.

- the productivity of this method is relatively low with a high device cost, because it can be made only 3 to 4 parts per minute.

- JP 61 038732 A describes the production of a workpiece with internal toothing by means of ironing, wherein an upper die is lowered and thus a further die is pressed against a cup-shaped preform whose bottom has an elongated formation running in the direction of the upper die.

- the face of the preform is seated during the downward movement on a stop of the mandrel, which in turn is held shock-damped by hydraulic cylinders. Due to the very specific design of the preform or the workpiece and, accordingly, the tool, this device has only limited use.

- the object of the invention is to provide a method and apparatus for energy-saving production of a workpiece with internal teeth, in particular a ring gear, which ensure a significant increase in productivity with high quality of the internal teeth in a relatively simple structural design of the device.

- the device for producing a workpiece with internal teeth in particular a ring gear for transmission, has a mandrel with an outer profile corresponding to the internal teeth to be generated, and a forming tool, which reduces the outer diameter of a cup-shaped preform during a feed movement, whereby material of the cylinder wall area in the outer profile the spine flows.

- a drawing ring is used as the forming tool, which ensures ironing of the cylinder wall area during the advancing movement and acts on the preform during the ironing two tool elements generating axial compressive stresses in the cylindrical side wall of the preform, the preform being directed towards the end face of the cylindrical side wall first die element in the form of an axially movable, designed as a cylindrical pressure sleeve plunger is arranged such that it acts during the ironing on the end face with a force.

- an axially movable counter-holder is arranged such that it acts during the ironing on the bottom of the bottom of the preform with a counter-holding force.

- the counter-holder can have a circular pressure surface pointing in the direction of the underside of the base, which acts essentially on the entire bottom region, or an annular pressure surface, which is adapted to the width of the cylinder wall of the preform and aligned substantially flush with it, and onto the edge region of the preform Bottom of the bottom of the preform acts.

- the pressure stamp is axially movable in the direction of the advancing movement of the drawing ring by a movement corresponding to the ironing length of the preform.

- the axial lifting movement of the plunger taking place during ironing can be regulated as a function of its pressure force.

- the plunger is mounted axially movable via a hydraulic piston.

- the device may advantageously be integrated in a hydraulic press, consisting of a press table and a press ram.

- the mandrel is arranged axially fixed on the press table and mounted on the mandrel, axially displaceable via a hydraulic piston, the plunger.

- the plunger At the press ram of the pull ring are preferably fixed to the frame and the counter-holder preferably arranged axially movable via a hydraulic piston.

- the plunger is preferably formed as a cylindrical pressure sleeve.

- The, the length of the Preform adapted, distance of the pressure surface of the plunger to the end face of the mandrel is adjustable for example via spacers.

- the mandrel is rotatably mounted when producing a helical toothing.

- the production of the workpiece with internal teeth characterized in that a cup-shaped preform, having a bottom and a substantially cylindrical side wall, over a mandrel, which has the outer profile corresponding to the internal teeth to be generated, is reduced in its outer diameter, so that material of Cylinder wall portion flows into the outer profile of the mandrel, according to the invention reducing the outer diameter by ironing by means of a draw ring and during the ironing additional axial compressive stresses are applied to the cylindrical side wall of the preform, which are produced by two acting on both sides of the cylindrical side wall of the tool elements , wherein in the direction of the end face of the cylindrical side wall of the preform, a first tool element in the form of an axially movable, designed as a cylindrical pressure sleeve, plunger during the ironing on the end face with a force acts.

- a counter-holder simultaneously acts on the underside of the bottom in order to avoid deformations in the bottom region and to apply a counter-holding force.

- the counter-holding force of the counter-holder and the force of the plunger should be mutually adjustable so that during the entire Abstreckvorganges a flow of material is ensured in the radial direction to completely fill the contour of the mandrel.

- the plunger performs an axial stroke movement corresponding to the ironing length of the preform in the direction of the advancing movement of the drawing ring, which is regulated as a function of its pressure force.

- the productivity can be increased by 4 to 6 times in comparison to the spin forming.

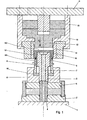

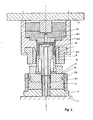

- Fig. 1 and 2 the basic structure of the device integrated in a press is shown.

- the lower tool part 2 On the press table 1, the lower tool part 2 is arranged, which has a first hydraulic piston 3.

- On the lower tool part 2 is axially fixed on a punch 4 of the mandrel 5 is fixed, which has an outer profile 6.

- the hydraulic piston 3 is mounted on an adapter 8 of the printing sleeve designed as a pressure piston 9 axially movable.

- the axial position of the plunger 9 can be changed over distances 10, the between Adapter 8 and plunger 9 are attachable.

- the tool upper part 11 is arranged on the press ram P and has a counter-holder 12, which is axially adjustable via a second hydraulic piston 13.

- the drawing ring 14 is further fixed to the frame via an adapter 15.

- Gem. Fig. 1 the cup-shaped preform N was inserted with the cylindrical side wall N1 down over the mandrel 5, so that the end face N2 in the direction of the plunger 9 and the bottom of the bottom N3 in the direction of the anvil 12 has.

- the hydraulic piston 13 moves the counter-holder 12 in the direction of the tool lower part until the counter-holder 12 rests against the underside of the base N3.

- the frame-mounted on the press ram P frame 14 moves in the forward stroke with the press ram P in the direction of the press table 1, simultaneously the first hydraulic piston 3 is pressurized and presses the plunger 9 with the force F1 against the end face N2 of the preform N (Fig. 2).

- the counter-holder 12 exerts a counterhold force F2 on the bottom of the cup.

- the pressure piston 9 performs a movement in the direction of the preliminary stroke of the drawing ring 14 in accordance with the ironing of the preform N, the pressure acting on the side wall N1 being produced by the forces F1 and F2 is maintained.

- the material flow is favored so that material flows reliably into the profile 6 of the mandrel 5. This ensures excellent quality of the internal teeth.

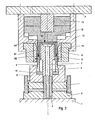

- Fig. 3 and 4 in the counter-holder 12 provide a material overflow 12.2.

- the counter-holder 12 has in the direction of the preform N a pressure piece 12.1, which is also reduced in diameter in the direction of the preform N, so that between the pressure piece 12.1 and adapter 15, a gap is formed, in which the excess material can flow and thus as Material overflow 12.2 is used.

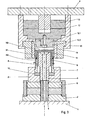

- FIG. 5 it is also possible, in addition to the material overflow 12.2 provided in FIGS. 3 and 4, to arrange a further material overflow 12.3 at the end of the cylindrical side wall N1.

- This can be the gap between serve the outer diameter of the plunger 9 and the inner diameter of the pull ring 14.

- an increased axial pressure is exerted for calibrating in order to achieve a better filling and a higher accuracy of the internal toothing.

- the possibly excess material can flow off as described above.

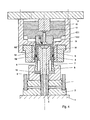

- the increased pressure can now be applied, for example, by the pressure piston 9 being connected to a threaded ring G1 via an intermediate piece Z which has threads G at its outer diameter and which in turn is connected to the cylinder 3.1 and thus via the lower tool part 2 the press table 1 is supported.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

- Forging (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Turning (AREA)

- Gears, Cams (AREA)

Claims (21)

- Dispositif pour la fabrication d'une pièce à denture interne, en particulier d'une roue creuse, utilisant une ébauche (N) en forme de cuvette avec une paroi latérale (N1) sensiblement cylindrique, lequel dispositif comprend un mandrin (5) avec un profil extérieur (6) correspondant à la denture intérieure à produire, ainsi qu'un outil de formage qui est adapté pour réduire, pendant un mouvement d'avancement, le diamètre extérieur de la paroi latérale cylindrique (N1), de sorte que le matériau de la paroi latérale (N1) coule vers le profil extérieur (6) du mandrin (5), l'outil de formage étant conformé comme une bague d'étirage (14) garantissant, lors d'un mouvement d'avancement, l'étirage de la paroi latérale cylindrique (N1), caractérisé en ce que le dispositif comprend deux éléments d'outil supplémentaires, qui sont adaptés pour se mettre en prise sur l'ébauche (N) pendant l'étirage et produire dans la paroi latérale (N1) de l'ébauche des contraintes de compression axiales, un premier des deux éléments d'outil supplémentaires prenant la forme d'un poinçon de chasse (9) mobile dans le sens axial et conformé comme une douille de compression cylindrique et étant disposé en direction de la face frontale (N2) de la paroi latérale (N1) de l'ébauche (N) de manière à exercer une force (F1) sur la face frontale (N2) pendant l'étirage.

- Dispositif selon la revendication 1, caractérisé en ce qu'en direction de la face intérieure du fond (N3) de l'ébauche (N), un deuxième élément d'outil prenant la forme d'un contre-appui (12) est disposé de manière mobile dans le sens axial, de telle manière que pendant l'étirage, il agisse avec la bague d'étirage (14) sur la face inférieure du fond (N3) de l'ébauche (N) en exerçant une force de contre-appui (F2).

- Dispositif selon la revendication 2, caractérisé en ce que le contre-appui (12) présente une surface d'appui circulaire orientée vers la face inférieure du fond (N3), afin d'agir pour l'essentiel sur l'ensemble de la zone de fond.

- Dispositif selon la revendication 2 ou 3, caractérisé en ce que le contre-appui (12) possède une surface d'appui annulaire orientée vers la face inférieure du fond (N3), qui est adaptée à la largeur de la paroi latérale cylindrique (N1) de l'ébauche et sensiblement alignée avec celle-ci, pour agir sur la zone de bord de la face inférieure du fond (N3) de l'ébauche (N).

- Dispositif selon l'une quelconque des revendications 1 à 4, caractérisé en ce que le poinçon de chasse (9) est mobile dans le sens axial pendant l'étirage selon un mouvement axial correspondant à la longueur d'étirage de l'ébauche (N), dans la direction du mouvement d'avancement de la bague d'étirage (14).

- Dispositif selon l'une quelconque des revendications 1 à 5, caractérisé en ce que le mouvement axial du poinçon de chasse (9) qui a lieu pendant l'étirage peut être régulé en fonction de sa force (F1).

- Dispositif selon l'une quelconque des revendications 1 à 6, caractérisé en ce que le poinçon de chasse (9) est supporté de manière mobile dans le sens axial par un piston hydraulique (3).

- Dispositif selon l'une quelconque des revendications 1 à 7, caractérisé en ce qu'il est intégré dans une presse, composée d'une table de presse (1) et d'un coulisseau de presse (P), de telle manière qu'un poinçon (4) soit disposé de manière stationnaire dans le sens axial sur la table de presse (1) et que le poinçon de chasse (9) soit supporté sur le poinçon (4) de manière mobile dans le sens axial à l'aide du piston hydraulique (3), et que le contre-appui (12) est disposé sur le coulisseau de presse (P) de manière mobile dans le sens axial sous l'action d'une pression et la bague d'étirage (14) est disposée de manière solidaire du bâti.

- Dispositif selon l'une quelconque des revendications 1 à 8, caractérisé en ce que la distance entre la surface d'appui du poinçon de chasse (9) et la face frontale du mandrin (5), adaptée à la longueur de l'ébauche (N), peut être ajustée au moyen de bagues d'écartement (10).

- Dispositif selon l'une quelconque des revendications 1 à 9, caractérisé en ce que le mandrin (5) est supporté avec possibilité de rotation en vue de l'éjection de l'ébauche/de la pièce (N).

- Dispositif selon l'une quelconque des revendications 1 à 10, caractérisé en ce qu'un éjecteur (7) orienté dans le mandrin (5) le long de son axe est supporté avec possibilité de rotation.

- Dispositif selon l'une quelconque des revendications 1 à 11, caractérisé en ce qu'il est prévu sur un côté ou les deux à l'extrémité de l'ébauche/de la pièce (N) un trop-plein pour le matériau.

- Dispositif selon la revendication 12, caractérisé en ce qu'un trop-plein pour le matériau (12.2) est prévu dans le contre-appui (12).

- Dispositif selon la revendication 12, caractérisé en ce qu'un trop-plein pour le matériau est formé dans l'adaptateur (8) dans lequel le poinçon de chasse (9) est supporté.

- Procédé pour la fabrication d'une pièce à denture interne, en particulier d'une roue creuse, utilisant une ébauche (N) en forme de cuvette avec un fond (N3) et une paroi latérale (N1) sensiblement cylindrique, dont le diamètre extérieur est réduit à l'aide d'un mandrin (5) présentant un profil extérieur correspondant à la denture interne à produire, de telle manière que le matériau de la paroi latérale cylindrique (N1) s'écoule dans le profil extérieur du mandrin (5), et dans lequel la réduction du diamètre extérieur est obtenue par étirage au moyen d'une bague d'étirage (14), caractérisé en ce que pendant l'étirage, des contraintes de compression axiale supplémentaires sont exercées sur la paroi latérale cylindrique (N1) de l'ébauche (N) et les contraintes de compression axiale sont produites par deux éléments d'outil supplémentaires agissant de part et d'autre sur la zone de la paroi latérale cylindrique (N1), un premier des deux éléments d'outil supplémentaires, prenant la forme d'un poinçon de chasse (9) conformé commune une douille de compression cylindrique et mobile dans le sens axial agissant dans la direction de la face frontale (N2) de la paroi latérale (N1) cylindrique de l'ébauche (N) pendant l'étirage pour exercer une force (F1) sur la face frontale (N2).

- Procédé selon la revendication 15, caractérisé en ce que pendant l'étirage, un deuxième élément d'outil prenant la forme d'un contre-appui (12) agit en exerçant une force de contre-appui (F2) sur la face inférieure du fond (N3).

- Procédé selon la revendication 15 ou 16, caractérisé en ce que pendant l'étirage, le poinçon de chasse (9) effectue un mouvement de course axiale correspondant à la longueur d'étirage de l'ébauche (N) dans le sens du mouvement d'avancement de la bague d'étirage (14).

- Procédé selon l'une quelconque des revendications 15 à 17, caractérisé en ce que le mouvement axial du poinçon de chasse (9) effectué pendant l'étirage est régulé en fonction de sa force (F1).

- Procédé selon l'une quelconque des revendications 15 à 18, caractérisé en ce que la force de contre-appui (2) du contre-appui (12) et la force (F1) du poinçon de chasse (9) peuvent être régulées l'une par rapport à l'autre de telle sorte que pendant toute l'opération d'étirage, un écoulement de matériau soit garanti dans le sens radial pour remplir complètement le contour du mandrin (5).

- Procédé selon l'une quelconque des revendications 15 à 19, caractérisé en ce que lorsque l'étirage est terminé, une pression axiale augmentée est exercée sur l'ébauche/la pièce (N) pour calibrer celle-ci.

- Procédé selon l'une quelconque des revendications 15 à 20, caractérisé en ce que pendant l'étirage et/ou l'application de la pression de calibrage, le matériau excédentaire s'écoule dans des trop-pleins pour le matériau.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06007394A EP1700651A1 (fr) | 2000-11-02 | 2001-11-01 | Procédé et dispositif de fabrication d'une pièce à denture intérieure, en particulier d'une roue à denture intérieure |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10054399 | 2000-11-02 | ||

| DE10054399A DE10054399A1 (de) | 2000-11-02 | 2000-11-02 | Verfahren und Vorrichtung zur Herstellung eines Werkstückes mit Innenverzahnung, insbesondere eines Hohlrades |

| PCT/DE2001/004192 WO2002036287A1 (fr) | 2000-11-02 | 2001-11-01 | Procede et dispositif de fabrication d'une piece a denture interieure, en particulier d'une roue a denture interieure |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06007394A Division EP1700651A1 (fr) | 2000-11-02 | 2001-11-01 | Procédé et dispositif de fabrication d'une pièce à denture intérieure, en particulier d'une roue à denture intérieure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1330320A1 EP1330320A1 (fr) | 2003-07-30 |

| EP1330320B1 true EP1330320B1 (fr) | 2006-04-12 |

Family

ID=7661964

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01992620A Expired - Lifetime EP1330320B1 (fr) | 2000-11-02 | 2001-11-01 | Procede et dispositif de fabrication d'une piece a denture interieure, en particulier d'une roue a denture interieure |

| EP06007394A Pending EP1700651A1 (fr) | 2000-11-02 | 2001-11-01 | Procédé et dispositif de fabrication d'une pièce à denture intérieure, en particulier d'une roue à denture intérieure |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06007394A Pending EP1700651A1 (fr) | 2000-11-02 | 2001-11-01 | Procédé et dispositif de fabrication d'une pièce à denture intérieure, en particulier d'une roue à denture intérieure |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7231799B2 (fr) |

| EP (2) | EP1330320B1 (fr) |

| JP (1) | JP2004512956A (fr) |

| KR (1) | KR100833771B1 (fr) |

| AT (1) | ATE322948T1 (fr) |

| AU (1) | AU2002215846A1 (fr) |

| DE (2) | DE10054399A1 (fr) |

| WO (1) | WO2002036287A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102389913A (zh) * | 2011-10-25 | 2012-03-28 | 南通皋液液压机有限公司 | 一种高铁车厢尾钩框架整形液压机 |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1622733A2 (fr) * | 2003-04-22 | 2006-02-08 | Neumayer Tekfor GmbH | Procede de production d'une piece annulaire en forme de cuvette presentant une denture interieure, preforme en forme de cuvette et piece annulaire en forme de cuvette |

| US20070125147A1 (en) * | 2005-12-06 | 2007-06-07 | Yahya Hodjat | Method of forming a part |

| CN100381221C (zh) * | 2006-06-16 | 2008-04-16 | 重庆工学院 | 基于粘性介质传力的板料无模多点成形装置及方法 |

| CN101947621B (zh) * | 2010-07-05 | 2012-07-25 | 南京中盛铁路车辆配件有限公司 | 锻造钩尾框整形模 |

| KR20140037795A (ko) * | 2011-12-21 | 2014-03-27 | 유틸 (광저우) 오토 파츠 씨오.,엘티디. | 철재 지지대의 양방향 동시적 드로우룸 및 그 사용 방법 |

| DE102011122144B4 (de) | 2011-12-22 | 2022-11-24 | Volkswagen Aktiengesellschaft | Vorrichtung und Verfahren zur spanlosen, axial umformenden Ausbildung einer Innenverzahnung an einem Werkstück |

| JP5969234B2 (ja) * | 2012-03-23 | 2016-08-17 | アイシン・エィ・ダブリュ株式会社 | 自動変速機のシリンダ部材製造方法 |

| US9302318B2 (en) * | 2014-12-14 | 2016-04-05 | Griffin Tactical Incorporated | Device and method for construction of baffles from engine block freeze plugs |

| KR101764857B1 (ko) * | 2017-02-14 | 2017-08-03 | 김금자 | 자동차용 매니폴드 제작공정 및 그 제작금형 |

| CN115229017A (zh) * | 2022-06-24 | 2022-10-25 | 中国石油大学(华东) | 一种异形对轮旋压机 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE759661A (fr) * | 1969-12-01 | 1971-04-30 | Hitachi Powdered Metals Cy Ltd | Dispositif de compression de poudre pour former un engrenage helicoidalcomprime |

| GB1373547A (en) * | 1970-11-24 | 1974-11-13 | Renault | Methods of manufacturing helical gear blanks by cold extrusion process |

| FR2191957B1 (fr) * | 1972-07-10 | 1975-03-07 | Glaenzer Spicer Sa | |

| DE2308420A1 (de) * | 1973-02-21 | 1974-10-10 | Schmalbach Lubeca | Einendig offener behaelter aus metall |

| DE2308428A1 (de) | 1973-02-21 | 1974-08-29 | Diehl Fa | Hartkerngeschoss |

| DE2542823C3 (de) * | 1975-09-25 | 1978-11-09 | Fritz Werner Industrie-Ausruestungen Gmbh, 6222 Geisenheim | Rundknetmaschine in Ringläuferbauart mit einem abgesetzten, einteiligen Dorn |

| JPS5816727A (ja) * | 1981-07-24 | 1983-01-31 | Mitsubishi Heavy Ind Ltd | ネジ状部品の成形方法およびその装置 |

| JPS6138732A (ja) | 1984-07-31 | 1986-02-24 | Toyota Motor Corp | 自在継手外輪のクロス溝形成方法及びその装置 |

| DE3639739C2 (de) * | 1986-11-21 | 1993-11-18 | Honda Motor Co Ltd | Verfahren, Ausgangsmaterial und Vorrichtung zum Herstellen eines eine Innenverzahnung aufweisenden topfförmigen Erzeugnisses |

| JPH01317653A (ja) * | 1988-06-15 | 1989-12-22 | Honda Motor Co Ltd | 内歯付きカップ状製品の成形方法 |

| JP2832326B2 (ja) * | 1992-07-14 | 1998-12-09 | 大岡技研株式会社 | 歯形の成形装置及びその装置を使用する歯形成形方法 |

| DE4412224A1 (de) * | 1994-04-09 | 1995-10-12 | Graebener Pressensysteme Gmbh | Presse für eine Kaltverformung von Metallwerkstücken |

| DE19830817B4 (de) | 1998-07-09 | 2011-06-09 | Leifeld Metal Spinning Gmbh | Verfahren zum Umformen eines Werkstücks durch Drückwalzen |

-

2000

- 2000-11-02 DE DE10054399A patent/DE10054399A1/de not_active Withdrawn

-

2001

- 2001-11-01 AU AU2002215846A patent/AU2002215846A1/en not_active Abandoned

- 2001-11-01 KR KR1020037005827A patent/KR100833771B1/ko not_active IP Right Cessation

- 2001-11-01 US US10/415,637 patent/US7231799B2/en not_active Expired - Fee Related

- 2001-11-01 JP JP2002539085A patent/JP2004512956A/ja active Pending

- 2001-11-01 DE DE50109512T patent/DE50109512D1/de not_active Expired - Fee Related

- 2001-11-01 AT AT01992620T patent/ATE322948T1/de not_active IP Right Cessation

- 2001-11-01 EP EP01992620A patent/EP1330320B1/fr not_active Expired - Lifetime

- 2001-11-01 WO PCT/DE2001/004192 patent/WO2002036287A1/fr active IP Right Grant

- 2001-11-01 EP EP06007394A patent/EP1700651A1/fr active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102389913A (zh) * | 2011-10-25 | 2012-03-28 | 南通皋液液压机有限公司 | 一种高铁车厢尾钩框架整形液压机 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR100833771B1 (ko) | 2008-05-29 |

| AU2002215846A1 (en) | 2002-05-15 |

| EP1700651A1 (fr) | 2006-09-13 |

| WO2002036287A1 (fr) | 2002-05-10 |

| KR20030059216A (ko) | 2003-07-07 |

| US7231799B2 (en) | 2007-06-19 |

| EP1330320A1 (fr) | 2003-07-30 |

| JP2004512956A (ja) | 2004-04-30 |

| ATE322948T1 (de) | 2006-04-15 |

| DE10054399A1 (de) | 2002-06-27 |

| US20040016281A1 (en) | 2004-01-29 |

| DE50109512D1 (de) | 2006-05-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19626160C2 (de) | Zahnradherstellungsverfahren | |

| EP1986801B1 (fr) | PROCEDE ET DISPOSITIF DE Formation D'UNE DECOUPE OU D'UNE PERFORATION DANS LA PAROI D'UN COMPOSANT FORME PAR UN PROCEDE DE FACONNAGE SOUS HAUTE PRESSION INTERIEURE | |

| EP2024111B1 (fr) | Dispositif et procédé pour produire des corps profilés | |

| DE1777315A1 (de) | Verfahren zum Durchtrennen eines Rohlings | |

| DE19530056A1 (de) | Verfahren und Vorrichtung zum Herstellen T-förmiger bzw. mindestens eine domartige Abzweigung aufweisender Hohlkörper | |

| DE3433515A1 (de) | Verfahren und werkzeug zum plastischen verformen metallischer werkstuecke durch kaltfliesspressen | |

| EP1330320B1 (fr) | Procede et dispositif de fabrication d'une piece a denture interieure, en particulier d'une roue a denture interieure | |

| EP2127777A1 (fr) | Dispositif et procédé de fabrication ou de traitement de pièces à usiner à partir d'une ébauche, en particulier pour former des profils internes ou des dentures intérieures | |

| DE2557764C3 (de) | Verfahren und Vorrichtung zur Formung eines Tiefbettfelgenrohlings | |

| DE1946178C3 (de) | Verfahren zur Herstellung von Innenprofilen in rohrförmigen Werkstücken | |

| DE3738465A1 (de) | Verfahren und vorrichtung zur ausbildung eines behaelters | |

| DE3716176A1 (de) | Verfahren und vorrichtung zum umformen von hohlkoerpern sowie verwendung des verfahrens bzw. der vorrichtung und dosenkoerper | |

| DE2325837B2 (de) | Vorrichtung zum Herstellen von Innenverzahnungen durch Kaltpressen | |

| DE2144006C3 (de) | Verfahren zur Herstellung von Kegelzahnrädern | |

| DD245827A1 (de) | Verfahren zur umformenden herstellung von hohlkoerpern aus massivem halbzeug | |

| EP0955110A2 (fr) | Procédé et dispositif pour le fluotournage | |

| DE10039706B4 (de) | Verfahren zum Einbringen einer Sicke und Drückwalzmaschine | |

| DE102007002228A1 (de) | Verfahren und Vorrichtung zur Herstellung von innenprofilierten Rohren | |

| DE4032424C2 (de) | Verfahren und Vorrichtung zur Herstellung von gefalzten Rohren | |

| DE19732146B4 (de) | Verfahren und Vorrichtung zum Herstellen ringförmiger Bauteile mit einem keilförmigen Innenprofil | |

| DE19925029A1 (de) | Verfahren zum Umformen und Vorrichtung zur Durchführung des Verfahrens | |

| EP1731246B1 (fr) | Appareil pour la fabrication d'une diversité des objets moulés de poudre. | |

| DE1299855B (de) | Ziehverfahren fuer plattenartige Rohlinge aus einem druckplastifizierbaren Feststoff | |

| DE3614619C1 (de) | Verfahren und Vorrichtung zur Herstellung von Zahnraedern | |

| DE19801491A1 (de) | Verfahren und Vorrichtung zur Herstellung von Hohlkörpern durch Querwalzen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20030425 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| 17Q | First examination report despatched |

Effective date: 20041111 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060412 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 50109512 Country of ref document: DE Date of ref document: 20060524 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060723 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060912 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20060412 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| ET | Fr: translation filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061130 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070115 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: FORSCHUNGSGESELLSCHAFT UMFORMTECHNIK M.B.H. Effective date: 20061130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20071009 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060713 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20071129 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061101 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060412 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20090731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090603 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20081130 |