EP1153662B1 - Hitze- und verschleissbeanspruchtes Einbauelement, insbesondere Segment eines Zyklontauchrohres - Google Patents

Hitze- und verschleissbeanspruchtes Einbauelement, insbesondere Segment eines Zyklontauchrohres Download PDFInfo

- Publication number

- EP1153662B1 EP1153662B1 EP01111010A EP01111010A EP1153662B1 EP 1153662 B1 EP1153662 B1 EP 1153662B1 EP 01111010 A EP01111010 A EP 01111010A EP 01111010 A EP01111010 A EP 01111010A EP 1153662 B1 EP1153662 B1 EP 1153662B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heat

- metallic

- ceramic material

- grating

- base body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 102100025840 Coiled-coil domain-containing protein 86 Human genes 0.000 title 1

- 101000932708 Homo sapiens Coiled-coil domain-containing protein 86 Proteins 0.000 title 1

- LELOWRISYMNNSU-UHFFFAOYSA-N hydrogen cyanide Chemical compound N#C LELOWRISYMNNSU-UHFFFAOYSA-N 0.000 title 1

- 239000002131 composite material Substances 0.000 claims description 14

- 239000004568 cement Substances 0.000 claims description 11

- 238000004519 manufacturing process Methods 0.000 claims description 10

- 229910010293 ceramic material Inorganic materials 0.000 claims description 9

- 239000000463 material Substances 0.000 claims description 6

- 229910001208 Crucible steel Inorganic materials 0.000 claims description 3

- 229910000831 Steel Inorganic materials 0.000 claims description 2

- 239000011230 binding agent Substances 0.000 claims description 2

- 238000005266 casting Methods 0.000 claims description 2

- 239000011819 refractory material Substances 0.000 claims description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 claims description 2

- 239000010959 steel Substances 0.000 claims description 2

- 239000000919 ceramic Substances 0.000 description 12

- 238000009434 installation Methods 0.000 description 5

- 238000007654 immersion Methods 0.000 description 4

- 235000012054 meals Nutrition 0.000 description 3

- 230000002787 reinforcement Effects 0.000 description 3

- 238000001354 calcination Methods 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 238000005339 levitation Methods 0.000 description 2

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical class C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- 238000004873 anchoring Methods 0.000 description 1

- 239000010953 base metal Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 210000003298 dental enamel Anatomy 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 235000013312 flour Nutrition 0.000 description 1

- 230000009969 flowable effect Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000005245 sintering Methods 0.000 description 1

- 230000035882 stress Effects 0.000 description 1

- 238000005496 tempering Methods 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/12—Construction of the overflow ducting, e.g. diffusing or spiral exits

- B04C5/13—Construction of the overflow ducting, e.g. diffusing or spiral exits formed as a vortex finder and extending into the vortex chamber; Discharge from vortex finder otherwise than at the top of the cyclone; Devices for controlling the overflow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B04—CENTRIFUGAL APPARATUS OR MACHINES FOR CARRYING-OUT PHYSICAL OR CHEMICAL PROCESSES

- B04C—APPARATUS USING FREE VORTEX FLOW, e.g. CYCLONES

- B04C5/00—Apparatus in which the axial direction of the vortex is reversed

- B04C5/08—Vortex chamber constructions

- B04C5/085—Vortex chamber constructions with wear-resisting arrangements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27B—FURNACES, KILNS, OVENS OR RETORTS IN GENERAL; OPEN SINTERING OR LIKE APPARATUS

- F27B7/00—Rotary-drum furnaces, i.e. horizontal or slightly inclined

- F27B7/20—Details, accessories or equipment specially adapted for rotary-drum furnaces

- F27B7/2016—Arrangements of preheating devices for the charge

- F27B7/2025—Arrangements of preheating devices for the charge consisting of a single string of cyclones

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D1/00—Casings; Linings; Walls; Roofs

- F27D1/0003—Linings or walls

- F27D1/0006—Linings or walls formed from bricks or layers with a particular composition or specific characteristics

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F27—FURNACES; KILNS; OVENS; RETORTS

- F27D—DETAILS OR ACCESSORIES OF FURNACES, KILNS, OVENS OR RETORTS, IN SO FAR AS THEY ARE OF KINDS OCCURRING IN MORE THAN ONE KIND OF FURNACE

- F27D1/00—Casings; Linings; Walls; Roofs

- F27D1/04—Casings; Linings; Walls; Roofs characterised by the form, e.g. shape of the bricks or blocks used

- F27D1/06—Composite bricks or blocks, e.g. panels, modules

- F27D1/08—Bricks or blocks with internal reinforcement or metal backing

Definitions

- the invention relates to a heat and wear-stressed installation element, to assemble a dip tube, the central one from above in a lined with fireproof material Cyclone separator of a cement clinker production line protrudes and can be hung on the cyclone ceiling.

- EP-A-0 447 802 discloses a cyclone immersion tube with the use of a metallic grating known, the z. B. hexagonal honeycomb can be filled with a ceramic material.

- the Known cyclone dip tube will first be the empty one Grating parts connected to each other and hung in the cyclone, after which the open honeycomb grate with ceramic mass fill out.

- Such a production of a cyclone dip tube is particularly difficult if that Ceramic material poured into the honeycomb openings, injected, should be shaken or pressed.

- the invention has for its object a built-in element to assemble a heat and wear segmented dip tube for one with refractory Lined cyclone material of a cement clinker production line to create, the individual built-in element with a Length can be manufactured and assembled even greater than 120 cm should be characterized by a long service life.

- Characteristic of the heat-resistant and wear-resistant according to the invention is that it's a composite body consisting of a comparatively thin-walled and lightweight metallic body, on the webs of a metallic grid-like grating are arranged, the grid openings with a heat resistant and against mechanical and chemical Influences of wear-resistant ceramic mass are filled. there the heat-resistant ceramic mass in the lattice openings of the Rust, which can be elastic, e.g. B. expanded metal grid, poured and / or injected and / or shaken / vibrated and / or pressed.

- the heat-resistant ceramic mass is in any case with the Production of the composite body according to the invention is flowable and it can also be done by additional heat treatment such as Sintering, tempering, etc. are hardened.

- the ceramic mass has z. B. silicon carbide (SiC) and it can also be a hydraulic binder such. B. contain cement according to its Hardening of the ceramic mass gives a special strength.

- the integrated body acts in the composite body according to the invention Grating as reinforcement for the heat-resistant ceramic mass, that on the wear-stressed side of the from the invention

- Composite body segments composed Component should lie, so on the segmented cyclone immersion tube Dip tube outside that of the inflowing into the cyclone Hot gas solid suspension is highly stressed.

- the surface has the lowest possible porosity the invention proposed the surface the ceramic mass with a final coating, in particular Glazing, glaze, enamel etc. to be provided.

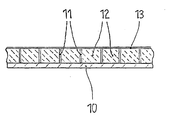

- the drawing shows a section of the cross section through an inventive Composite body installation element or segment, consisting from a heat-resistant metallic base body 10, namely from a thin-walled z. B. 5 to 15 mm thick rolled steel material, on which the webs 11 with a metallic grate grid-shaped openings are tacked or welded. It would be also possible in the manufacture of the composite body, the grate 11 place loosely on the base body 10.

- the openings of the grate 11, viewed in plan, square, hexagonal or otherwise, like polygonal or even round, are with a highly heat-resistant Ceramic mass 12 filled in the lattice openings poured in, shaken and then hardened. To the surface of the ceramic mass 12 has one more protection Coating 13 has the lowest possible porosity, especially one Glaze, glazing, enamelling etc.

- the thickness of the ceramic mass 12 can e.g. B. 25 mm.

- the metallic base body 10 no longer needs a heat resistant cast, the thickness of which is large long segments are approximately more than 15 mm would. Rather, with the construction according to the invention heat-resistant and wear-resistant composite segments manufacture with a length of more than 120 cm without the Thickness of the metallic base body 10 must exceed 15 mm. If the composite body segments become thermally and mechanically highly stressed dip tube of a cyclone of the cyclone suspended gas heat exchanger system / precalcination system a cement clinker burning plant put together, so the heat-resistant Ceramic mass 12 on the outside of the metallic base body 10 arranged, that is the side on which the inflowing abrasive hot gas / solid suspension flows in. It exists but also the possibility of the layer structure of the invention Composite body on both sides of the base metal sheet 10 to arrange. In any case, the service life of the invention Composite installation elements or segments high.

- the metallic base body 10 consists of cast steel, can the metallic grid-shaped grate with its webs 11 completely or partially as a one-piece cast body together with the Base body 10 be made.

- the composite bodies according to the invention are not for production segmented cyclone immersion pipes in cement clinker burning plants too to protect others a high thermochemical and abrasive Components subject to wear can be used, in particular for Protection of those built into the hot gas pipes and hot meal pipes Guiding and / or regulating elements such as swiveling diverter flaps, Impact slider or the like.

Landscapes

- Cyclones (AREA)

- Furnace Details (AREA)

- Heat-Exchange Devices With Radiators And Conduit Assemblies (AREA)

- Earth Drilling (AREA)

Description

Claims (7)

- Hitze und verschleißbeanspruchtes Einbauelement zum Zusammensetzen eines Zyklon-Tauchrohres, welches Tauchrohr bei der Verwendung zentral von oben in einen mit feuerfestem Material ausgekleideten Zyktonabscheider einer Zementklinkerproduktionslinie hineinragt und an der Zyklondecke aufgehängt wird, wobei das Einbauelement als Verbundkörper ausgebildet ist mit einem metallischen gitterförmigen Rost (11) dessen Gitteröffnungen mit einer Keramikmasse (12) ausgefüllt sind,

dadurch gekennzeichnet, dass das Einbauelement ein vorgefertigtes Tauchrohrsegment-Fertigteil ist, bestehend aus einem flachen metallischen dünnwandigen Grundkörper (10), auf dessen an der Tauchrohr-Außenseite zu liegen kommenden Seite die Stege (11) des metallischen gitterförmigen Rostes angeordnet und die Gitteröffnungen mit der Keramikmasse (12) ausgefüllt sind, und dass die außenliegende Oberfläche der Keramikmasse (12) mit einer abschließenden Glasur (13) geringer Porosität beschichtet ist. - Einbauelement nach Anspruch 1,

dadurch gekennzeichnet, dass die Stege (11) des metallischen Rostes auf den Grundkörper (10) geheftet und/oder geschweißt sind. - Einbauelement nach Anspruch 1,

dadurch gekennzeichnet, dass der metallische Grundkörper (10) aus einem dünnwandigen Stahlwalzmaterial besteht. - Einbauelement nach Anspruch 1,

dadurch gekennzeichnet, dass der metallische Grundkörper (10) aus Stahlguss besteht, und dass der metallische gitterförmige Rost mit seinen Stegen (11) ggf. als einteiliger Gusskörper zusammen mit dem Grundkörper (10) hergestellt ist. - Einbauelement nach Anspruch 1,

dadurch gekennzeichnet, dass die hitzebeständige Keramikmasse (12) in die Gitteröffnungen des Rostes (11) eingegossen und/oder eingespritzt und/oder eingerüttelt/rüttelverdichtet und/oder eingepresst ist. - Einbauelement nach den Ansprüchen 1 oder 5,

dadurch gekennzeichnet, dass die hitzebeständige Keramikmasse (12) Siliciumcarbid (SiC) enthält. - Einbauelement nach den Ansprüchen 1, 5 oder 6,

dadurch gekennzeichnet, dass die hitzebeständige Keramikmasse (12) als hydraulisches Bindemittel Zement enthält.

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10023387 | 2000-05-12 | ||

| DE10023387 | 2000-05-12 | ||

| DE10033293 | 2000-07-07 | ||

| DE10033293A DE10033293A1 (de) | 2000-05-12 | 2000-07-07 | Hitze- und verschleißbeanspruchtes Einbauelement, insbesondere Segment zum Zusammensetzen eines segmentierten Zyklontauchrohres |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1153662A1 EP1153662A1 (de) | 2001-11-14 |

| EP1153662B1 true EP1153662B1 (de) | 2004-07-14 |

Family

ID=26005657

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01111010A Expired - Lifetime EP1153662B1 (de) | 2000-05-12 | 2001-05-08 | Hitze- und verschleissbeanspruchtes Einbauelement, insbesondere Segment eines Zyklontauchrohres |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6517597B2 (de) |

| EP (1) | EP1153662B1 (de) |

| CZ (1) | CZ303127B6 (de) |

| DK (1) | DK1153662T3 (de) |

| ES (1) | ES2220618T3 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105040925A (zh) * | 2015-07-01 | 2015-11-11 | 内蒙古筑友建材有限公司 | 一种抗冲击耐磨陶瓷涂层结构及其施工方法 |

| DE102014019472A1 (de) | 2014-12-23 | 2016-06-23 | Khd Humboldt Wedag Gmbh | Tauchrohr für einen Zyklonabscheider |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10214863A1 (de) * | 2002-04-04 | 2003-10-16 | Kloeckner Humboldt Wedag | Zyklonabscheider |

| US7472565B1 (en) * | 2003-04-09 | 2009-01-06 | Fred Lawrence Heldoorn | Plastic takeout holder and ceramic insert for use in bottle manufacturing |

| US20050252244A1 (en) * | 2003-04-09 | 2005-11-17 | Fred Heldoorn | Method, system and apparatus for a takeout holder and insert |

| DK176211B1 (da) * | 2006-03-24 | 2007-02-05 | Smidth As F L | Cyklonseparator |

| AT511613B1 (de) * | 2012-01-24 | 2013-01-15 | Inteco Special Melting Technologies Gmbh | Verfahren und anlage zur abgasreinigung bei vakuum-stahlbehandlungsprozessen |

| AP2016009028A0 (en) | 2013-08-09 | 2016-02-29 | Weir Minerals Australia Ltd | Cyclone separator apparatus and methods of production |

| DE102014100568A1 (de) * | 2014-01-20 | 2015-07-23 | Tenedora Nemak, S.A. De C.V. | Gussteil und Einsatz für ein solches Gussteil |

| US10328439B2 (en) | 2016-07-13 | 2019-06-25 | Wahl Refractory Solutions, Llc | Thimble for cyclone separator |

| US10940492B2 (en) | 2016-07-13 | 2021-03-09 | Fosbel Wahl Holdings, Llc | Thimble for cyclone separator |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1581329A (en) * | 1924-10-15 | 1926-04-20 | Schutz Wilhelm | Masonry coat holder for mortar and the like |

| US3470678A (en) * | 1967-06-20 | 1969-10-07 | Exxon Research Engineering Co | Cyclone separator for high temperature operations |

| DE2405298A1 (de) * | 1974-02-04 | 1975-08-07 | Kloeckner Humboldt Deutz Ag | Verfahren und vorrichtung zur standzeiterhoehung von schleissteilen in sichtern, zyklonen und rohrleitungen |

| DE2405413C3 (de) * | 1974-02-05 | 1981-07-30 | Keramische Industrie-Bedarfs-Kg, Paul Gatzke, 1000 Berlin | Verfahren und Anlage zum Brennen, Sintern oder Fritten von keramischen oder feuerfesten Massen, Zementklinkern o. dgl. |

| FR2433164A1 (fr) * | 1978-08-08 | 1980-03-07 | Produits Refractaires | Blocs a base d'oxydes refractaires electrofondus armes d'un element en un materiau d'une conductivite thermique elevee |

| AU554140B2 (en) * | 1980-07-02 | 1986-08-07 | Dana Corporation | Thermally insulating coating on piston head |

| DE3228902A1 (de) * | 1982-08-03 | 1984-02-09 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Zyklonabscheider |

| JPS6162785A (ja) * | 1984-09-04 | 1986-03-31 | 日本プライブリコ株式会社 | 耐摩耗・耐火材ライニング用アンカ− |

| DE4009004A1 (de) * | 1990-03-21 | 1991-09-26 | Didier Werke Ag | Tauchrohr und verfahren zu dessen herstellung |

| US5417932A (en) * | 1993-06-21 | 1995-05-23 | Texaco Inc. | Vent orifice in fluid catalytic cracking direct-connected cyclone apparatus |

| DE4338484C1 (de) * | 1993-11-11 | 1994-12-01 | Veitsch Radex Ag | Verwendung eines feuerfesten, keramischen Steins auf Basis von MgO zur Auskleidung von Zement-Drehrohröfen |

-

2001

- 2001-05-08 EP EP01111010A patent/EP1153662B1/de not_active Expired - Lifetime

- 2001-05-08 ES ES01111010T patent/ES2220618T3/es not_active Expired - Lifetime

- 2001-05-08 DK DK01111010T patent/DK1153662T3/da active

- 2001-05-11 CZ CZ20011678A patent/CZ303127B6/cs not_active IP Right Cessation

- 2001-05-11 US US09/853,264 patent/US6517597B2/en not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102014019472A1 (de) | 2014-12-23 | 2016-06-23 | Khd Humboldt Wedag Gmbh | Tauchrohr für einen Zyklonabscheider |

| DE102014019472B4 (de) * | 2014-12-23 | 2018-01-04 | Khd Humboldt Wedag Gmbh | Tauchrohr für einen Zyklonabscheider |

| CN105040925A (zh) * | 2015-07-01 | 2015-11-11 | 内蒙古筑友建材有限公司 | 一种抗冲击耐磨陶瓷涂层结构及其施工方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20010052223A1 (en) | 2001-12-20 |

| CZ303127B6 (cs) | 2012-04-18 |

| US6517597B2 (en) | 2003-02-11 |

| EP1153662A1 (de) | 2001-11-14 |

| ES2220618T3 (es) | 2004-12-16 |

| CZ20011678A3 (cs) | 2002-01-16 |

| DK1153662T3 (da) | 2004-09-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1350571A1 (de) | Zyklonabscheider mit segmentiertem Tauchrohr | |

| EP1153662B1 (de) | Hitze- und verschleissbeanspruchtes Einbauelement, insbesondere Segment eines Zyklontauchrohres | |

| DE2925395C2 (de) | Ofendecke für einen elektrothermischen Reduktionsofen | |

| EP2722626A1 (de) | Massenverarbeitungs-widerstandsofen aus phosphatbeton | |

| EP0411336B1 (de) | Flüssigkeitsdurchströmtes Kühlelement für Schachtöfen | |

| EP2175219A1 (de) | Feuerfestes Auskleidungselement | |

| DE1922679C3 (de) | Feuerfeste Decken- oder Wandkonstruktion zum Auskleiden von Industrieöfen o.dgl. und Verfahren zum Einbau | |

| EP2189743B1 (de) | Wärmedämmende Auskleidung von Industrieöfen | |

| DE10033293A1 (de) | Hitze- und verschleißbeanspruchtes Einbauelement, insbesondere Segment zum Zusammensetzen eines segmentierten Zyklontauchrohres | |

| DE202010011142U1 (de) | Korrosionsschutzkörper und Schutzsystem für eine Ofeninnenwand | |

| DE4335707C2 (de) | Verkleidung einer Brennkammerwand | |

| DE102009045808A1 (de) | Fertigbauteil für einen Ofen | |

| DE4009004A1 (de) | Tauchrohr und verfahren zu dessen herstellung | |

| DE102010036587A1 (de) | Hängezylinder für Doppelschachtöfen | |

| WO2014154364A1 (de) | Wölbstein zylinderförmige innere auskleidung eines drehrohrofens und drehrohrofen | |

| EP0209815A2 (de) | Mantelstein für mehrschalige Schornsteine | |

| DE2417141A1 (de) | Keramischer armierter ankerformstein und verfahren zu seiner herstellung | |

| DE3231736C2 (de) | Ummantelung zur Isolierung eines gekühlten Gleit-, Trag- oder Querrohres in einer Feuerungsanlage | |

| DE4133711C1 (en) | Wall for lining glass melting furnace - has ceramic bricks facing furnace interior and outer bricks supporting structure | |

| DE462609C (de) | Freihaengende flache Feuerraumdecke | |

| WO2007085038A1 (de) | Speicherofen und rauchzug sowie bausatz zum aufbau derselben | |

| AT259120B (de) | Ausmauerung, die von heißen Gasen beaufschlagt ist | |

| DE19747320C2 (de) | Auskleidungsblöcke und dessen Verwendung | |

| DD207252A1 (de) | Scheitrechtes verbundoberofenelement | |

| DE1922200U (de) | Schornstein- und lueftungsrohrelement. |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE DK ES Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20020510 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY LI |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): BE DE DK SE |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): BE DE DK ES |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| 17Q | First examination report despatched |

Effective date: 20030515 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE DE DK ES |

|

| REF | Corresponds to: |

Ref document number: 50102830 Country of ref document: DE Date of ref document: 20040819 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2220618 Country of ref document: ES Kind code of ref document: T3 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| 26 | Opposition filed |

Opponent name: POLYSIUS AG Effective date: 20050324 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| R26 | Opposition filed (corrected) |

Opponent name: POLYSIUS AG Effective date: 20050324 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: KHD HUMBOLDT WEDAG GMBH |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 20060921 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20140521 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20140523 Year of fee payment: 14 Ref country code: DK Payment date: 20140521 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150602 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20150531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150531 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20160630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150509 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50102830 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150531 |