EP1075601B1 - Vacuumpumpe - Google Patents

Vacuumpumpe Download PDFInfo

- Publication number

- EP1075601B1 EP1075601B1 EP99923485A EP99923485A EP1075601B1 EP 1075601 B1 EP1075601 B1 EP 1075601B1 EP 99923485 A EP99923485 A EP 99923485A EP 99923485 A EP99923485 A EP 99923485A EP 1075601 B1 EP1075601 B1 EP 1075601B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rotors

- pump

- pump chamber

- pump according

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01C—ROTARY-PISTON OR OSCILLATING-PISTON MACHINES OR ENGINES

- F01C1/00—Rotary-piston machines or engines

- F01C1/08—Rotary-piston machines or engines of intermeshing engagement type, i.e. with engagement of co- operating members similar to that of toothed gearing

- F01C1/12—Rotary-piston machines or engines of intermeshing engagement type, i.e. with engagement of co- operating members similar to that of toothed gearing of other than internal-axis type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/12—Arrangements for admission or discharge of the working fluid, e.g. constructional features of the inlet or outlet

- F04C29/122—Arrangements for supercharging the working space

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/08—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing

- F04C18/12—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of other than internal-axis type

- F04C18/123—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of other than internal-axis type with radially or approximately radially from the rotor body extending tooth-like elements, co-operating with recesses in the other rotor, e.g. one tooth

Definitions

- the invention relates to a pump for the simultaneous generation of Pressure and vacuum.

- Such pumps are advantageous when an industrial process Requires compressed air and negative pressure at the same time, since the pump only needs a drive.

- a separate charging port that communicates with the atmosphere is connected to ensure the volume flow for the compressed air. Accordingly, several must be separated from each other in the pump chamber Cells are formed. In the prior art, this is only with rotary slide systems successful which are known for example from GB-A-818 691. But rotary valves are subject to wear and can only be lubricated if special materials are used operate.

- a pump for simultaneous Generation of compressed air and negative pressure provided that is almost wear-free and without the use of special materials can be manufactured.

- rotate in the pump chamber has two at least three-bladed rotors around parallel, axes offset against each other and combing without contact, to separate from each other with the peripheral wall of the pump chamber To form cells.

- the rotors can be in the pump chamber those for the simultaneous generation of compressed air and vacuum differentiate required cells. Because the rotors contactless with each other and also with the peripheral wall of the Pump chamber interact, occurs in the area of the pump chamber no wear and tear.

- the sealing gap between the rotors can be kept very small by optimizing their geometry; he is only a fraction of a millimeter in practical versions, so that good pressure and vacuum values are guaranteed. These values become even better with increasing operating time, since the Time-forming deposits to reduce the size of the sealing gap to lead.

- a pump with two three-bladed rotors that run in opposite directions around parallel axes rotate, is already known from DE-A-2 422 857. This However, the pump has no charging connection and is therefore not suitable for simultaneous generation of compressed air and negative pressure.

- the pump according to the invention is particularly suitable for use in suitable for paper processing industries, mainly for applications, which do not provide or adjust compressed air separately and Require vacuum.

- Compressed air is e.g. to blow on one side Stacks of paper needed to support sheet separation.

- the pulsating compressed air generation by the pump according to the invention proves to be useful here, since the paper edges by intermittent occurring compressed air can be separated more easily. Is negative pressure in such applications for sucking the top sheet of paper required.

- the rotors form with the pump chamber connected to the suction port through which Rotation of the rotors and their volume increasing suction cell Pressure cell that reduces its volume when the rotors rotate and is connected to the pressure connection.

- This pressure cell is out two initially separated from each other in the course of the rotation of the rotors Charging cells formed, each with an associated charging port have and with the further rotation of the rotors with each other Pressure cell are combined.

- the charging cells are before their union essentially isobar and isochoric in the pump chamber, i.e. the air in the charging cells experiences at the displacement of the charging cells essentially no pressure and no volume change.

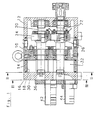

- the single-stage pump for the simultaneous generation of Pressure and vacuum has a housing that consists of a load-bearing Middle part 10, one on one side of the middle part 10 attached housing cover 12, one on the other side of the Middle part 10 attached housing ring 14 and one on the housing ring 14 adjoining cover plate 16 there. Between the middle part 10, the housing ring 14 and the cover plate 16 is a pump chamber 18 educated.

- a pump chamber 18 educated in the opposite wall parts of the Housing cover 12 and the middle part 10 are two shafts 20, 22 Flying parallel to and offset from each other in ball bearings stored.

- the pinion 24, 26 are in meshing engagement with one another so that the shafts 20, 22 rotate synchronously with each other in opposite directions.

- For the rotary drive is the lower shaft 22 led out of the housing cover 12.

- each rotor has 30, 32 three wings 30a and 32a.

- the pump chamber 18 has the side view Form of two intersecting circles, joined together in the form of an "8" are.

- the blades 30a of the rotor 30 have a shape that the shape of the blades 32a of the rotor 32 is different.

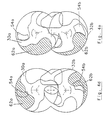

- the geometry the wing 30a, 32a and the pump chamber 18 is determined so that at the rotation of the rotors 30, 32 a plurality of separate cells are formed, as with reference to Figures 4a to 4h further explained in more detail below by the wings 30a, 32a without contact a sealing gap of a fraction of 1 mm above and along slide the outer circumference of the pump chamber 18.

- the cover plate 16 is provided with a series of cutouts, which is closed to the outside by an attached closure plate 36 become.

- the closure plate 36 are two pipe sockets 42, 44th screwed.

- the upper pipe socket 42 forms the suction connection and is connected to a recess 50 of the cover plate 16.

- the lower Pipe socket 44 forms the pressure connection and is with a recess 52 connected in the cover plate 16.

- Two further cutouts 54a, 54b in the cover plate 16 are open to the atmosphere and form charging connections.

- Figure 4a shows the rotors 30, 32 in a rotational position in which their wings 30a, 32a with the wall of the pump chamber 18 a closed, only common to the recess 50 Form cell 60.

- This cell 60 enlarges in the further Rotation of the rotors 30, 32 their volume, as can be seen in Figure 4b.

- This cell 60 is therefore a suction cell.

- FIG. 4c shows two cells 62a, 62b which are separate from one another arise immediately after the state shown in FIG cell 60 was separated into two sub-cells.

- the rotor 30 assigned cell 62a already borders the recess 54a, and the Cell 62b associated with rotor 32 approaches recess 54b.

- Figure 4d are the cells 62a, 62b with those leading to the atmosphere Recesses 54a and 54b in connection and are filled with air and charged to ambient pressure so that the air mass flow increases becomes.

- the cells 62a, 62b are thus charging cells.

- the pump chamber 18 is free of any lubricant because the Work rotors 30, 32 without contact. To the drive side is the Pump chamber 18 sealed by seals on the shafts 20, 22.

- the housing can be equipped with cooling fins for cooling be arranged, and by one on the side of the GcHouseldeckels 12 Cooling fan is cooling air from the cover plate 16 over the Housing ring 14, the middle part 10 and the housing cover 12 out.

- a resonance damper is used to dampen the operating noise is matched to the operating frequency of the pump. This frequency is due to the three-bladed design of the rotors triple speed of the shafts 20, 22. The increased operating frequency facilitates the accommodation of the resonance damper because of its length is reduced accordingly.

- the described flying bearing arrangement of the rotors is advantageous up to a volume flow of approximately 300 m 3 / h.

- Pumps with a larger volume flow are preferably designed with rotors mounted on both sides. In this case, connections are left in both side plates.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Applications Or Details Of Rotary Compressors (AREA)

- Rotary Pumps (AREA)

Description

- Figur 1

- einen Längsschnitt der erfindungsgemäßen Pumpe;

- Figur 2

- eine Ansicht entlang Linie II-II in Figur 1;

- Figur 3

- eine Ansicht entlang Linie III-III in Figur 1; und

- Figuren 4a bis 4h

- schematische Ansichten verschiedener Rotorstellungen zur Erläuterung der Wirkungsweise.

Claims (10)

- Pumpe zur gleichzeitigen Erzeugung von Druck und Unterdruck, mit einer in einem Gehäuse gebildeten Pumpenkammer (18), die einen Sauganschluß, einen Druckanschluß und einen Aufladeanschluß aufweist, dadurch gekennzeichnet, daß in der Pumpenkammer (18) zwei mindestens dreiflügelige Rotoren (30, 32) um parallele, gegeneinander versetzte Achsen gegenläufig rotieren und berührungslos kämmen sowie mit der Umfangswandung der Pumpenkammer (18) voneinander getrennte Zellen (60, 62a, 62b, 64) bilden.

- Pumpe nach Anspruch 1, dadurch gekennzeichnet, daß die Rotoren (30, 32) mit der Pumpenkammer (18) eine mit dem Sauganschluß (50) verbundene, durch die Drehung der Rotoren (30, 32) ihr Volumen vergrößernde Saugzelle (60) bilden.

- Pumpe nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß die Rotoren (30, 32) mit der Pumpenkammer (18) eine mit dem Druckanschluß (52) verbundene, durch die Drehung der Rotoren (30, 32) ihr Volumen verkleinernde Druckzelle (64) bilden.

- Pumpe nach Anspruch 3, dadurch gekennzeichnet, daß die Rotoren (30, 32) mit der Pumpenkammer zwei im Verlauf der Drehung der Rotoren zunächst voneinander getrennte Aufladezellen (62a, 62b) bilden, die bei der weiteren Drehung der Rotoren miteinander zur Druckzelle (64) vereinigt werden.

- Pumpe nach Anspruch 4, dadurch gekennzeichnet, daß mindestens eine Aufladezelle (62a, 62b) einen zugeordneten Aufladeanschluß (54a, 54b) aufweist.

- Pumpe nach Anspruch 4 oder 5, dadurch gekennzeichnet, daß die Aufladezellen (62a, 62b) vor ihrer Vereinigung im wesentlichen isobar und isochor in der Pumpenkammer (18) verschoben werden.

- Pumpe nach einem der vorstehenden Ansprüche, dadurch gekennzeichnet, daß die Pumpenkammer (18) schmiermittelfrei ist.

- Pumpe nach einem der vorstehenden Ansprüche, dadurch gekennzeichnet, daß die Pumpenkammer (18) zwischen zwei parallelen Seitenplatten (10, 16) begrenzt ist und in wenigstens einer der Seitenplatten (16) die Anschlüsse (50, 52, 54a, 54b) ausgespart sind.

- Pumpe nach einem der vorstehenden Ansprüche, dadurch gekennzeichnet, daß die Wellen (20, 22) fliegend gelagert und die Rotoren (30, 32) auf freien Enden der Wellen (20, 22) angeordnet sind.

- Pumpe nach einem der vorstehenden Ansprüche, dadurch gekennzeichnet, daß die Wellen (20, 22) durch zwei miteinander in Kämmeingriff stehende Ritzel (24, 26) synchronisiert sind und wenigstens einer der Rotoren (30, 32) justierbar auf der zugeordneten Welle (20, 22) befestigt ist.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19819538A DE19819538C2 (de) | 1998-04-30 | 1998-04-30 | Druck-Saug-Pumpe |

| DE19819538 | 1998-04-30 | ||

| PCT/EP1999/002882 WO1999057439A1 (de) | 1998-04-30 | 1999-04-28 | Vacuumpumpe |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1075601A1 EP1075601A1 (de) | 2001-02-14 |

| EP1075601B1 true EP1075601B1 (de) | 2002-09-18 |

Family

ID=7866414

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99923485A Expired - Lifetime EP1075601B1 (de) | 1998-04-30 | 1999-04-28 | Vacuumpumpe |

| EP99948559A Expired - Lifetime EP1076760B1 (de) | 1998-04-30 | 1999-04-28 | Drehkolbenmaschine mit dreiflügeligen rotoren |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99948559A Expired - Lifetime EP1076760B1 (de) | 1998-04-30 | 1999-04-28 | Drehkolbenmaschine mit dreiflügeligen rotoren |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US6364642B1 (de) |

| EP (2) | EP1075601B1 (de) |

| JP (2) | JP2002513880A (de) |

| KR (2) | KR100556077B1 (de) |

| CN (2) | CN1105820C (de) |

| DE (3) | DE19819538C2 (de) |

| WO (2) | WO1999057439A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004009639A1 (de) * | 2004-02-27 | 2005-09-15 | Rietschle Thomas Gmbh + Co. Kg | Drehzahnverdichter |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE20216504U1 (de) * | 2002-10-25 | 2003-03-06 | Werner Rietschle GmbH + Co. KG, 79650 Schopfheim | Verdrängermaschine mit gegensinnig laufenden Rotoren |

| FR2859000B1 (fr) * | 2003-08-20 | 2005-09-30 | Renault Sa | Dent d'engrenage et pompe a engrenages exterieurs |

| GB0410491D0 (en) * | 2004-05-11 | 2004-06-16 | Epicam Ltd | Rotary device |

| EP1640613B1 (de) * | 2004-09-17 | 2006-11-29 | Aerzener Maschinenfabrik GmbH | Drehkolbenverdichter und Verfahren zum Betreiben eines Drehkolbenverdichters |

| TW200848617A (en) * | 2007-06-08 | 2008-12-16 | Jaguar Prec Industry Co Ltd | Motor direct drive air pump, related applications and manufacturing methods thereof |

| JP5725660B2 (ja) * | 2011-09-30 | 2015-05-27 | アネスト岩田株式会社 | クローポンプ |

| EP2674570A1 (de) * | 2012-06-14 | 2013-12-18 | Bobby Boucher | Turbine mit gleich- und gegenläufigen Rotoren auf derselben Ebene |

| CN103775341B (zh) * | 2012-10-15 | 2016-05-18 | 良峰塑胶机械股份有限公司 | 两外形相同的爪式转子对装置 |

| WO2014123539A1 (en) | 2013-02-08 | 2014-08-14 | Halliburton Energy Services, Inc. | Electronic control multi-position icd |

| DE102013112704B4 (de) | 2013-11-18 | 2022-01-13 | Pfeiffer Vacuum Gmbh | Gehäuse für eine Wälzkolbenpumpe |

| US9605739B2 (en) * | 2014-04-11 | 2017-03-28 | Gpouer Co., Ltd. | Power transmission system |

| JP6340556B2 (ja) * | 2015-02-12 | 2018-06-13 | オリオン機械株式会社 | 二軸回転ポンプ |

| JP6221140B2 (ja) * | 2015-02-12 | 2017-11-01 | オリオン機械株式会社 | 二軸回転ポンプ |

| JP6340557B2 (ja) * | 2015-02-12 | 2018-06-13 | オリオン機械株式会社 | 二軸回転ポンプ |

| RU2611117C2 (ru) * | 2015-04-01 | 2017-02-21 | Евгений Михайлович Пузырёв | Роторная машина |

| DE102018203992A1 (de) | 2018-03-15 | 2019-09-19 | Gardner Denver Schopfheim Gmbh | Drehkolbenmaschine |

| CN109630411B (zh) * | 2018-12-06 | 2021-06-11 | 莱州市增峰石业有限公司 | 一种可变压缩比的增压器及应用和发动机调控技术 |

| JP6749714B1 (ja) * | 2019-10-28 | 2020-09-02 | オリオン機械株式会社 | クローポンプ |

| JP7109788B2 (ja) * | 2019-10-28 | 2022-08-01 | オリオン機械株式会社 | 回転ポンプ |

| JP6845596B1 (ja) * | 2020-06-24 | 2021-03-17 | オリオン機械株式会社 | クローポンプ |

| CN116517826B (zh) * | 2023-04-25 | 2024-03-22 | 北京通嘉宏瑞科技有限公司 | 一种转子组件及泵体结构 |

Family Cites Families (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE142587C (de) | ||||

| DE564152C (de) * | 1931-11-22 | 1932-11-14 | Otto Becker Jr | Drehkolbengeblaese, insbesondere fuer Papierverarbeitungsmaschinen |

| GB622873A (en) * | 1947-04-10 | 1949-05-09 | Thomas Desmond Hudson Andrews | Improvements in or relating to rotary blowers |

| US2764407A (en) | 1951-10-03 | 1956-09-25 | Roland Offsetmaschf | Device for controlling the air in machines working with suction |

| FR1147777A (fr) | 1956-04-19 | 1957-11-29 | Turbine volumétrique à deux rotors | |

| GB818691A (en) * | 1957-05-20 | 1959-08-19 | Lacy Hulbert & Company | Improvements in rotary air pumps |

| US2967054A (en) | 1958-05-22 | 1961-01-03 | Mergenthaler Linotype Gmbh | Vacuum and pressure control valve for printing presses |

| DE1133500B (de) | 1959-06-10 | 1962-07-19 | Polysius Gmbh | Roots-Geblaese |

| DE1287729B (de) * | 1961-10-19 | 1969-01-23 | ||

| US3182900A (en) * | 1962-11-23 | 1965-05-11 | Davey Compressor Co | Twin rotor compressor with mating external teeth |

| DE1628347A1 (de) | 1967-01-19 | 1971-06-16 | Hubrich Christoph Dipl Ing | Innere Kuehlung eines im Unterdruckgebiet arbeitenden Rootsgeblaeses |

| DE1915269A1 (de) | 1969-03-26 | 1970-10-08 | Siemens Ag | Roots-Geblaese |

| US3628893A (en) * | 1970-05-04 | 1971-12-21 | Poerio Carpigiani | Liquid and air mixing gear pump |

| DE2027272C2 (de) | 1970-06-03 | 1983-11-03 | Aerzener Maschinenfabrik Gmbh, 3251 Aerzen | Rotationskolbenverdichter |

| AT317935B (de) * | 1971-02-03 | 1974-09-25 | Apaw Sa | Zahnradpumpe zur Herstellung von Luft-Flüssigkeitsgemischen, insbesondere in Softeis- und Schlagobersmaschinen od.dgl. |

| DE2422857A1 (de) * | 1974-05-10 | 1975-11-27 | Petr Terk | Maschine mit zentrisch gelagerten rotoren |

| NO137655C (no) * | 1974-06-14 | 1978-03-29 | Myrens Verksted As | Roterende fortrengningspumpe. |

| US4480970A (en) * | 1981-05-30 | 1984-11-06 | Rolls-Royce Limited | Self priming gear pump |

| DD209880A1 (de) | 1982-08-27 | 1984-05-23 | Halle Maschf Veb | Anordnung und gestaltung der aufladeeinlassoeffnungen an einem schraubenverdichter |

| JPS62157289A (ja) * | 1985-12-29 | 1987-07-13 | Anretsuto:Kk | 高真空用ル−ツブロワ− |

| EP0409287B1 (de) | 1987-05-15 | 1994-04-06 | Leybold Aktiengesellschaft | Vakuumpumpe mit Schöpfraum |

| US4859158A (en) | 1987-11-16 | 1989-08-22 | Weinbrecht John F | High ratio recirculating gas compressor |

| EP0370117B1 (de) | 1988-10-24 | 1994-01-12 | Leybold Aktiengesellschaft | Zweiwellenvakuumpumpe und Verfahren zu ihrem Betrieb |

| GB2233042A (en) * | 1989-06-17 | 1991-01-02 | Fleming Thermodynamics Ltd | Screw expander/compressor |

| FR2653831A1 (fr) * | 1989-11-02 | 1991-05-03 | Cit Alcatel | Pompe volumetrique. |

| GB2243651A (en) * | 1990-05-05 | 1991-11-06 | Drum Eng Co Ltd | Rotary, positive displacement machine |

| US5078583A (en) * | 1990-05-25 | 1992-01-07 | Eaton Corporation | Inlet port opening for a roots-type blower |

| US5071328A (en) * | 1990-05-29 | 1991-12-10 | Schlictig Ralph C | Double rotor compressor with two stage inlets |

| NL9002027A (nl) | 1990-09-14 | 1992-04-01 | Westera Beheer Bv | Inrichting voor het transport van papier, zoals in de vorm van vellen, in drukpersen, boekbindmachines en dergelijke. |

| DE4118843A1 (de) | 1991-06-07 | 1993-02-11 | Sihi Gmbh & Co Kg | Fluessigkeitsringgaspumpe mit fliegend gelagertem fluegelrad |

| DE59207259D1 (de) * | 1992-07-15 | 1996-10-31 | Mario Antonio Morselli | Umlaufmaschine mit conjugierten Profilen in kontinuierlicher Berührung |

| DE4301907A1 (de) | 1993-01-25 | 1994-07-28 | Siemens Ag | Flüssigkeitsringmaschine |

-

1998

- 1998-04-30 DE DE19819538A patent/DE19819538C2/de not_active Revoked

-

1999

- 1999-04-28 CN CN99805637A patent/CN1105820C/zh not_active Expired - Fee Related

- 1999-04-28 JP JP2000547347A patent/JP2002513880A/ja active Pending

- 1999-04-28 US US09/673,640 patent/US6364642B1/en not_active Expired - Fee Related

- 1999-04-28 KR KR1020007011978A patent/KR100556077B1/ko not_active IP Right Cessation

- 1999-04-28 DE DE59906193T patent/DE59906193D1/de not_active Expired - Lifetime

- 1999-04-28 WO PCT/EP1999/002882 patent/WO1999057439A1/de active IP Right Grant

- 1999-04-28 EP EP99923485A patent/EP1075601B1/de not_active Expired - Lifetime

- 1999-04-28 CN CN99805636A patent/CN1128935C/zh not_active Expired - Fee Related

- 1999-04-28 DE DE59902761T patent/DE59902761D1/de not_active Expired - Lifetime

- 1999-04-28 WO PCT/EP1999/002881 patent/WO1999057419A1/de active IP Right Grant

- 1999-04-28 KR KR1020007011977A patent/KR100608527B1/ko not_active IP Right Cessation

- 1999-04-28 US US09/673,641 patent/US6439865B1/en not_active Expired - Fee Related

- 1999-04-28 EP EP99948559A patent/EP1076760B1/de not_active Expired - Lifetime

- 1999-04-28 JP JP2000547364A patent/JP2002513887A/ja not_active Ceased

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102004009639A1 (de) * | 2004-02-27 | 2005-09-15 | Rietschle Thomas Gmbh + Co. Kg | Drehzahnverdichter |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20010043094A (ko) | 2001-05-25 |

| DE19819538A1 (de) | 1999-11-11 |

| CN1299434A (zh) | 2001-06-13 |

| JP2002513880A (ja) | 2002-05-14 |

| US6439865B1 (en) | 2002-08-27 |

| JP2002513887A (ja) | 2002-05-14 |

| EP1076760B1 (de) | 2003-07-02 |

| WO1999057419A1 (de) | 1999-11-11 |

| KR100556077B1 (ko) | 2006-03-07 |

| CN1128935C (zh) | 2003-11-26 |

| CN1299444A (zh) | 2001-06-13 |

| WO1999057439A1 (de) | 1999-11-11 |

| EP1076760A1 (de) | 2001-02-21 |

| DE59906193D1 (de) | 2003-08-07 |

| US6364642B1 (en) | 2002-04-02 |

| KR100608527B1 (ko) | 2006-08-09 |

| CN1105820C (zh) | 2003-04-16 |

| DE19819538C2 (de) | 2000-02-17 |

| EP1075601A1 (de) | 2001-02-14 |

| DE59902761D1 (de) | 2002-10-24 |

| KR20010043093A (ko) | 2001-05-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1075601B1 (de) | Vacuumpumpe | |

| DE3740726C2 (de) | ||

| DE3705863A1 (de) | Kompressor in spiralbauweise | |

| DE4136541C2 (de) | Spiralverdichter mit optimierter Kupplung | |

| DE4210527C2 (de) | Spiralverdichter | |

| DE19530662A1 (de) | Schraubenvakuumpumpe | |

| EP1070848A1 (de) | Verdrängermaschine für kompressible Medien | |

| CH495509A (de) | Schneckenmaschine | |

| DE3312117A1 (de) | Zweiwellen-vakuumpumpe mit innerer verdichtung | |

| EP0365695B1 (de) | Zweiwellenvakuumpumpe mit Schöpfraum | |

| DE112017001321T5 (de) | Spiralverdichter | |

| DE69928172T2 (de) | Vacuumpumpe | |

| DE1503544A1 (de) | Rotierende Vakuumpumpe | |

| EP1073845B1 (de) | Verdrängermaschine | |

| DE102007038966B4 (de) | Mehrstufige Drehkolbenvakuumpumpe bzw. - verdichter | |

| EP0370117B1 (de) | Zweiwellenvakuumpumpe und Verfahren zu ihrem Betrieb | |

| DE19623242C1 (de) | Sperrflügelpumpe | |

| DE202016005209U1 (de) | Schraubenvakuumpumpe | |

| DE4134965A1 (de) | Spiralverdichter mit modifizierter kopfnut | |

| DE2737659A1 (de) | Fluegelzellenpumpe zur erzeugung eines unterdruckes | |

| DE19503716C1 (de) | Zweiwellige Drehkolbenpumpe zur gleichzeitigen Erzeugung von Unterdruck und von Überdruck | |

| DE1428270B2 (de) | Schraubenverdichter mit im Kämmeingriff rotierenden Schraubenrotoren | |

| DE4038704C2 (de) | Drehkolbenpumpe | |

| DE2951591A1 (de) | Mehrstufige waelzkolbenpumpe | |

| DE2254185B2 (de) | Flügelzellenverdichter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20001130 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR GB IT LI SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20011105 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR GB IT LI SE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: TROESCH SCHEIDEGGER WERNER AG |

|

| REF | Corresponds to: |

Ref document number: 59902761 Country of ref document: DE Date of ref document: 20021024 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20021031 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030619 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20100506 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20100427 Year of fee payment: 12 Ref country code: DE Payment date: 20100428 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20100426 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20100428 Year of fee payment: 12 Ref country code: GB Payment date: 20100426 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59902761 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59902761 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20110428 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20111230 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110502 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110430 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110428 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110428 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20111031 |