EP0785054B1 - Wandsäge und Sägeblatt - Google Patents

Wandsäge und Sägeblatt Download PDFInfo

- Publication number

- EP0785054B1 EP0785054B1 EP97810016A EP97810016A EP0785054B1 EP 0785054 B1 EP0785054 B1 EP 0785054B1 EP 97810016 A EP97810016 A EP 97810016A EP 97810016 A EP97810016 A EP 97810016A EP 0785054 B1 EP0785054 B1 EP 0785054B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- saw blade

- flange

- saw

- flange half

- halves

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

- B28D1/02—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by sawing

- B28D1/04—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by sawing with circular or cylindrical saw-blades or saw-discs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27B—SAWS FOR WOOD OR SIMILAR MATERIAL; COMPONENTS OR ACCESSORIES THEREFOR

- B27B5/00—Sawing machines working with circular or cylindrical saw blades; Components or equipment therefor

- B27B5/29—Details; Component parts; Accessories

- B27B5/30—Details; Component parts; Accessories for mounting or securing saw blades or saw spindles

- B27B5/32—Devices for securing circular saw blades to the saw spindle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B27—WORKING OR PRESERVING WOOD OR SIMILAR MATERIAL; NAILING OR STAPLING MACHINES IN GENERAL

- B27B—SAWS FOR WOOD OR SIMILAR MATERIAL; COMPONENTS OR ACCESSORIES THEREFOR

- B27B5/00—Sawing machines working with circular or cylindrical saw blades; Components or equipment therefor

- B27B5/02—Sawing machines working with circular or cylindrical saw blades; Components or equipment therefor characterised by a special purpose only

- B27B5/08—Sawing machines working with circular or cylindrical saw blades; Components or equipment therefor characterised by a special purpose only for sawing with the saw blade abutting parallel against a surface of the workpiece

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

- B28D1/02—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by sawing

- B28D1/04—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by sawing with circular or cylindrical saw-blades or saw-discs

- B28D1/045—Sawing grooves in walls; sawing stones from rocks; sawing machines movable on the stones to be cut

Definitions

- the invention relates to a wall saw, in particular a wall saw for the creation of Flush cuts in concrete and the like, according to the generic term of Claim 1.

- the invention also relates to a saw blade for use in connection with such a wall saw according to the preamble of claim 8.

- Wall saw systems are devices for cutting armored or not reinforced concrete walls with the help of rotating, equipped with cutting segments Saw blades and are, for example, in the company brochures of the applicant No. W 1881 594 10-d, 1994 and W 1838 993 10-d, 1993.

- the saw blade for example in Gradations from 200 mm to 300 mm, one or more times against a saw blade swapped larger diameter to cut to the required depth create.

- the saw blades with larger diameters are each in the previous created cut performed on both sides and can no longer deform axially.

- the saw blade can be used again the fastening screws on the flush flange. After that must the saw head with the saw blade attached to it is placed back on the running rail become.

- the object of the present invention is therefore to provide a wall saw improve that the saw blade change can be made easier and faster. It should be possible, even in confined spaces, such as in particular Flush cut applications occur when changing the saw blade without changing the saw head have to lift off the track and have to tilt.

- the saw blade change should largely possible without lifting the saw blade by the operating personnel his.

- the saw blade should also be prepared so that a case by case required lifting of the saw blade, for example by a replaced one Removing the saw blade from the work area is done in a simpler way than before can.

- the solution to these tasks is a wall saw and a saw blade like this each in the characterizing sections of claim 1 and Claim 8 are defined.

- the wall saw according to claim 1 comprises a saw head that can be moved longitudinally on a running rail with a swiveling one Saw arm and a saw blade with cutting elements detachably attached to the saw arm, the via a drive unit attached to the saw arm standing, drive unit is rotatable.

- the saw blade has a Coupling attached to the saw arm, the two radially telescoping and releasable together connectable flange halves, of which one flange half on the saw arm facing flat side of the saw blade is attached and the second flange half on Saw arm is arranged.

- the inventive design of the coupling with two flange halves Changing the saw blade is much easier.

- the saw blade no longer has to be removed from the Half of the flange. It only has to connect the two flange halves be loosened in order to be able to remove the saw blade. After that, only the saw arm be reset with one half of the flange sliding out of the other. The first Half of the flange remains connected to the replaced saw blade.

- the solved Saw blade can be rolled out of the cut, for example. After that, a Saw blade with a larger diameter rolled into the previously created cut, whereby the the first flange half already connected to it faces the second flange half.

- the first half of the flange only needs to be aligned so that the two Flange halves can slide into each other by automatically adjusting the saw arm.

- the two nested flange halves then only have to be together get connected.

- a very important advantage of the training according to the invention The coupling between the saw head or saw arm and saw blade is that all Manipulations can be done from that side of the saw head, which also is freely accessible for flush cut applications.

- the necessary Lifting manipulations of the saw blade are with vertical cuts and with flush cuts in the bottom area essentially on the alignment of the first flange half on the second flange half limited.

- the flange halves are also aligned with a saw blade change only after the new saw blade in the already in the previous created cut has been rolled. Alignment is therefore relatively unproblematic because the saw blade is supported in the previously created cut and secured against falling over.

- a drive spindle on the drive unit for torque transmission provided on which the second flange half is rotatably mounted. That way transfer the torque directly to the saw blade via the flange halves.

- Fixing the flange half to the drive spindle becomes a central counterpart a central hole in the flange half is inserted and onto the drive spindle screwed.

- the flange half is centered and fixed and can, if necessary can be removed or replaced very quickly.

- the one with the saw blade connected first flange half formed as a mother flange and has one for Circumference of the first flange half opening, approximately V-shaped recess on.

- the approximately V-shaped recess serves to accommodate and center one correspondingly shaped, approximately V-shaped projection, which of the Saw blade facing side of the second flange half designed as a father part protrudes.

- the appropriate design of the flange halves facilitates the automatic Push the two flange halves into each other by adjusting the saw arm.

- the clear width of the recess extends beyond its depth increases and the width of the projection over its height towards the front of the second flange half correspondingly decreases such that the two flange halves are precisely fitted when pushed together.

- the recess in the the first flange half is thus undercut in depth, while the projection with correspondingly bevelled side walls is provided. That way it glides the projection fits perfectly into the undercut recess. This makes them both The flange halves are automatically axially secured and pointing when assembled also no axial play.

- a responsible user will ensure that the Wall saw the flange halves are radially secured.

- the flange halves with an anti-rotation device equipped which in the absence of radial securing of the assembled The halves of the flange prevent rotation of the saw blade. In this way, the Wall saw can only be put into operation if the flange halves are radial are secured.

- the Anti-rotation lock a ring arranged on the circumference of the second flange half with locking screws flush with the surface, over the first flange half is slidable and is releasably fixable there.

- the ring has the saw blade on it opposite side at least one protruding cam, which in the radial unsecured condition of the two flange halves with rigid on the saw head or the Means arranged in a saw arm, for example a saw blade guard, cooperate, to prevent the saw blade from rotating. Is the ring over the first half of the flange pushed, it forms an additional radial securing of the two flanged halves pushed together. Even if the radial locking screws should fail, the two flange halves are still by the ring on radial sliding apart prevented.

- the invention also includes a Saw blade created for use with a wall saw, which at its the Saw head facing side with a flange half designed as a nut part is connected, the one opening to the circumference of the flange half, approximately V-shaped has trained recess, the width increases over its depth.

- the flange half can be made integrally with the saw blade, it turns out as advantageous if the nut flange half is detachably connected to the saw blade.

- a number of screws are provided, which differ from that of the Mother flange half facing away from the flat side of the saw blade, preferably in the same distance from each other, holes can be inserted in the saw blade and flush with the saw blade in holes in the nut flange half are screwable.

- existing saw blades can also be used prepared bores with a mother flange half designed according to the invention be retrofitted to use them with a wall saw on their Saw head or saw arm a father bottle half is arranged.

- a support element releasably with the Saw blade is connectable, which comprises at least one handle that with a. Flange half is connected, the outer contour corresponding to the recess the first flange half is formed.

- the flange half has an approximately V-shaped Shape and has a width that is above the height of the flange half corresponding to the width of the recess on the first flange half decreases that the two flange halves axially fixed in the assembled state are. That created in accordance with the general idea of the invention

- the saw blade and the support element are equipped with a coupling, the two Flange halves according to the invention comprises.

- the support element can be very easily coupled to the saw blade in order to lift the saw blade facilitate.

- the flange halves are weighted when the saw blade is carried of the saw blade held together. After setting down the saw blade, this can Support element can be easily removed again by removing the flange half from the Recess of the flange half connected to the saw blade is pulled out.

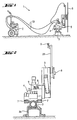

- Fig. 1 is a wall saw system of the generic type with the whole Reference number 1 provided. It includes a, usually hydraulic, Drive unit 2, which via hydraulic lines 10 with a saw head 4 one Wall saw is connected.

- the saw head 4 is longitudinally displaceable on a running rail 3 and has a vertically pivotable saw arm 5, on which a Cutting elements equipped saw blade 6 is rotatably attached.

- Fig. 2 shows a saw head 4 with pivotable saw arm 5.

- the saw head 4 load-bearing track 3 is designed as a profile rail and is by rail feet 3a supported above the floor.

- the saw head 4 has rollers on its support side 7, which facilitate its longitudinal displaceability on the running rail 3.

- the one with the Saw head 4 connected, vertically pivotable saw arm 5 carries a drive unit 8, with the help of which the saw blade, not shown, is rotatable.

- Drive unit 8 a drive spindle, which with coupling elements for the Saw blade is connected.

- Hydraulic connections 9 are on the saw head 4 and on the saw arm 5 provided, via which the drive unit 8 is connected to the drive unit in order to be able to set the drive spindle in rotation or to To allow pivoting of the saw arm. Also shown in Fig. 2 is a Saw blade protection holder 28, which has a connection, not shown, for the Rinse water supply. As far as the device corresponds to that of the prior art Technology well-known wall saws, which are also sold by the applicant become.

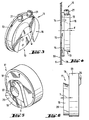

- 3 to 7 are the coupling elements of the modified according to the invention Wall saw shown.

- the coupling elements comprise two flange halves 11 and 17, which can be pushed together and releasably connected to one another.

- first flange half 11 is formed as a mother flange half connected to the saw blade 6.

- the mother flange half 11 has a preferably arranged at the same distance from each other, provided bores Screw plate 12 which in the assembled state on one flat side 29 of the saw blade 6 is applied.

- the second flat side 30 of the saw blade 6 is used Fastening screws 14 inserted through holes in the saw blade 6 and in the an internally threaded holes in the screw plate 12 of the Nut flange half 11 screwed in.

- the mother flange half has a depth d which is approximately 5 mm to approximately 20 mm.

- d is approximately 5 mm to approximately 20 mm.

- an approximately V-shaped recess 13 is provided which extends to the circumference of the Flange half 11 opens.

- the clear width w of the recess decreases in depth d Recess 13 towards the screw plate 12. In this way, the recess has 13 an undercut.

- the circumference of the mother flange half 11 is radial arranged locking screws 21 are provided which protrude into the recess 13. Their function will be explained later.

- the second flange half 17 forms the counterpart the mother flange half connected to the saw blade and is designed as a father part.

- the second flange half 17 is approximately can-shaped and has one Projection 19, which protrudes from that side 18 which faces the mother flange half is.

- the projection 19 corresponds to the recess on the mother flange half shaped and therefore has an approximately V-shaped shape.

- the width b of the protrusion 19 starts from its greatest width on its contact surface 20 over its Height h to the extent that the clear width of the recess at the Half of the mother flange increases over the depth.

- the depth of the recess in the Mother flange half and the height of the projection on the second flange half correspond to each other. In this way, the two flange halves in the collapsed state axially secured and also have no axial play.

- the second flange half 17 is fixed to the drive unit on the saw head or on Saw arm connected.

- it has a central bore 22 for receiving the Drive spindle of the drive unit. It is fixed to the drive spindle for example, by a counterpart, which from the side of the contact surface 20 the drive spindle is screwed on and fixes the second flange half.

- a flange can be provided on the drive spindle, to which the second Half of the flange is screwed on. 5 are not closer to this in the contact surface designated bores indicated, which for receiving the Fixing screws serve.

- Fig. 7 shows the mother flange half 11 and the second flange half 17 in collapsed condition.

- the illustration shows the rear side of the second flange half 17, which is connected to the drive spindle.

- the radial Locking screws 21 on the circumference of the mother flange half 11 are not yet in the corresponding holes with internal thread in the projection of the second Flange half 17 screwed in.

- An axial already indicated in FIGS. 5 and 6 Slidable ring 23 which surrounds the second flange half 17 is on the above

- On its side facing away from the mother flange half 11 or the saw blade has the Ring 23 a protruding cam 24.

- the spring-loaded, pin-shaped latch To release the coupling, the spring-loaded, pin-shaped latch must first be released Engagement with the bore 31 in the ring 23 are brought. This is done, for example by pressing in the bolt, at the same time the ring 23 of the circumference of the Mother flange half 11 is withdrawn. This will make the two flange halves 11, 17 released again and after loosening the screws 21 slide apart.

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Mechanical Engineering (AREA)

- Wood Science & Technology (AREA)

- Forests & Forestry (AREA)

- Mining & Mineral Resources (AREA)

- Processing Of Stones Or Stones Resemblance Materials (AREA)

- Road Repair (AREA)

- Sawing (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19601522 | 1996-01-17 | ||

| DE19601522A DE19601522A1 (de) | 1996-01-17 | 1996-01-17 | Wandsäge und Sägeblatt |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0785054A1 EP0785054A1 (de) | 1997-07-23 |

| EP0785054B1 true EP0785054B1 (de) | 2002-10-30 |

Family

ID=7782978

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97810016A Expired - Lifetime EP0785054B1 (de) | 1996-01-17 | 1997-01-14 | Wandsäge und Sägeblatt |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5887579A (ja) |

| EP (1) | EP0785054B1 (ja) |

| JP (1) | JP3868046B2 (ja) |

| KR (1) | KR100424125B1 (ja) |

| AT (1) | ATE226876T1 (ja) |

| DE (2) | DE19601522A1 (ja) |

| NO (1) | NO315936B1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3501766A1 (de) | 2017-12-22 | 2019-06-26 | HILTI Aktiengesellschaft | Wandsäge mit einer verriegelungseinrichtung |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE511905C2 (sv) * | 1997-07-08 | 1999-12-13 | Anders Johnsen | Anordning för fastsättning av två för samfälld rotation kring en axel anordnade enheter |

| SE521638C2 (sv) | 2001-04-23 | 2003-11-18 | Globe Invent Ab | Metod för bearbetning av ett objekt, maskin och verktygsenhet för utförande av metoden |

| US7055650B2 (en) * | 2001-05-17 | 2006-06-06 | Jlg Industries, Inc. | Saw accessory for aerial work platform |

| US20060201492A1 (en) * | 2002-03-18 | 2006-09-14 | Anthony Baratta | Methods and apparatus for movable machining tools including for wall saws |

| DE102005000013A1 (de) * | 2005-02-22 | 2006-08-31 | Hilti Ag | Steuerbare Wandsäge und Steuerverfahren |

| EP1866121B1 (en) * | 2005-03-23 | 2019-01-23 | Husqvarna AB | Improvements relating to a cutting or sawing machine |

| US20070163412A1 (en) * | 2006-01-15 | 2007-07-19 | Anthony Baratta | Methods and apparatus for movable machining tools, including for wall saws |

| JP2007196322A (ja) * | 2006-01-26 | 2007-08-09 | Shiyuuzo Hiwaki | 切断機 |

| WO2009108094A1 (en) * | 2008-02-29 | 2009-09-03 | Husqvarna Ab | A saw for construction work |

| JP5457375B2 (ja) | 2008-02-29 | 2014-04-02 | フスクバルナ アクティエボラーグ | 電動鋸用通信方法 |

| CA2793263C (en) | 2009-03-17 | 2015-12-15 | Woodway Usa, Inc. | Power generating manually operated treadmill |

| WO2010128903A1 (en) | 2009-05-04 | 2010-11-11 | Husqvarna Ab | A wire saw and a method of rebuilding a wall saw to a wire saw |

| DE102009026638A1 (de) * | 2009-06-02 | 2010-12-16 | Hilti Aktiengesellschaft | Vorrichtung zum Verstellen eines Blattschutzhalters einer Wandsäge |

| EP2473305B1 (en) | 2009-09-02 | 2018-12-26 | Husqvarna AB | A saw for construction cutting work |

| US8343016B1 (en) * | 2009-11-02 | 2013-01-01 | Astilean Aurel A | Leg-powered treadmill |

| ES2903536T3 (es) * | 2014-08-29 | 2022-04-04 | Perini Fabio Spa | Procedimiento y máquina para cortar bobinas de material en banda bobinado |

| EP2993010A1 (de) * | 2014-09-08 | 2016-03-09 | HILTI Aktiengesellschaft | Verfahren zur Steuerung eines Wandsägesystems beim Erstellen eines Trennschnittes |

| WO2017062504A1 (en) | 2015-10-06 | 2017-04-13 | Woodway Usa, Inc. | Manual treadmill and methods of operating the same |

| US10238911B2 (en) | 2016-07-01 | 2019-03-26 | Woodway Usa, Inc. | Motorized treadmill with motor braking mechanism and methods of operating same |

| USD930089S1 (en) | 2019-03-12 | 2021-09-07 | Woodway Usa, Inc. | Treadmill |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3623281A (en) * | 1969-06-16 | 1971-11-30 | Robert H Moffat | Mounting fixture |

| US3683567A (en) * | 1969-12-24 | 1972-08-15 | Frank F Ali | Finishing tool |

| FR2123856A5 (ja) * | 1971-02-03 | 1972-09-15 | Faraut Jacques | |

| JPS5912563U (ja) * | 1982-07-13 | 1984-01-26 | 旭ダイヤモンド工業株式会社 | ダイヤモンド切断砥石のチツプ取付構造 |

| US5015518A (en) * | 1985-05-14 | 1991-05-14 | Toyo Carbon Co., Ltd. | Graphite body |

| US4683683A (en) * | 1985-08-19 | 1987-08-04 | Aleck Block | Abrasive material mounting structure |

| EP0238648B1 (de) * | 1985-10-18 | 1990-05-16 | Longyear Deutschland Gmbh | Verfahren und vorrichtung zur herstellung von tiefen schnitten in beton oder dergl. |

| DE9204693U1 (de) * | 1992-04-04 | 1992-06-25 | Maschinenbau Meißner GmbH, 5250 Engelskirchen | Werkzeugständer, insbesondere für Steinbohrer und Steinsägen |

| DE19504563A1 (de) * | 1995-02-11 | 1996-08-14 | Stihl Maschf Andreas | Spanneinrichtung zum axialen Festspannen eines scheibenförmigen Werkzeugs |

| US5702275A (en) * | 1995-09-01 | 1997-12-30 | Hundertmark; James M. | Steering mechanism |

-

1996

- 1996-01-17 DE DE19601522A patent/DE19601522A1/de not_active Withdrawn

-

1997

- 1997-01-14 EP EP97810016A patent/EP0785054B1/de not_active Expired - Lifetime

- 1997-01-14 DE DE59708586T patent/DE59708586D1/de not_active Expired - Lifetime

- 1997-01-14 AT AT97810016T patent/ATE226876T1/de active

- 1997-01-15 US US08/783,772 patent/US5887579A/en not_active Expired - Lifetime

- 1997-01-16 NO NO19970191A patent/NO315936B1/no not_active IP Right Cessation

- 1997-01-17 KR KR1019970001281A patent/KR100424125B1/ko not_active IP Right Cessation

- 1997-01-17 JP JP00700597A patent/JP3868046B2/ja not_active Expired - Lifetime

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP3501766A1 (de) | 2017-12-22 | 2019-06-26 | HILTI Aktiengesellschaft | Wandsäge mit einer verriegelungseinrichtung |

| WO2019120925A1 (de) | 2017-12-22 | 2019-06-27 | Hilti Aktiengesellschaft | Wandsäge mit einer verriegelungseinrichtung |

| US11597117B2 (en) | 2017-12-22 | 2023-03-07 | Hilti Aktiengesellschaft | Wall saw having a locking device |

Also Published As

| Publication number | Publication date |

|---|---|

| NO970191L (no) | 1997-07-18 |

| KR100424125B1 (ko) | 2004-06-24 |

| NO970191D0 (no) | 1997-01-16 |

| US5887579A (en) | 1999-03-30 |

| EP0785054A1 (de) | 1997-07-23 |

| KR970058867A (ko) | 1997-08-12 |

| ATE226876T1 (de) | 2002-11-15 |

| JPH09193135A (ja) | 1997-07-29 |

| NO315936B1 (no) | 2003-11-17 |

| DE19601522A1 (de) | 1997-07-24 |

| JP3868046B2 (ja) | 2007-01-17 |

| DE59708586D1 (de) | 2002-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0785054B1 (de) | Wandsäge und Sägeblatt | |

| DE1925208C3 (de) | Beton- und Gesteinsbohrmaschine | |

| EP0512210A1 (de) | Schutzeinrichtung für die Türmontage bei Aufzügen | |

| EP0130373A2 (de) | Verfahren und Vorrichtung zum Reparieren von Schieberspindeln | |

| EP0930408A1 (de) | Schalung zum Betonieren von auskragenden Betonbauteilen | |

| EP0245704B1 (de) | Höhenverstellbare Stahlstütze für Deckenschalungen und dergl. | |

| DE2420567A1 (de) | Wickelmaschine fuer bandmaterial | |

| DE3507932A1 (de) | Rundlaufmesser | |

| EP4263411A1 (de) | Schienenbefestigungsvorrichtung für führungsschienenabschnitte einer fahrtreppe oder eines fahrsteiges | |

| DE2823417C3 (de) | Schachtauskleidung zur Verwendung beim Aufwärtsbohren eines Schachtes und Schachtring für eine derartige Schachtauskleidung | |

| EP3848532A1 (de) | Abschalplattenträger-anordnung und verfahren zum positionieren eines abschalplattenträgers auf einer konsole | |

| EP0241422B1 (de) | Mobile Kettensäge für die Bearbeitung von Beton, Gesteinen und Mauerwerk | |

| DE2836747A1 (de) | Bohrstabilisator | |

| EP2321087B1 (de) | Vorrichtung zur lösbaren verbindung von wenigstens zwei anlagemodulen und modulare anlage | |

| DE69207966T2 (de) | Raumschalung | |

| DE2704891A1 (de) | Stichlochbohrmaschine | |

| EP4056785B1 (de) | Stützeinrichtung, deckenstützen, deckenschalungssystem und verfahren zum ausschalen eines deckenschalungspaneels | |

| EP3369646B1 (de) | Adapter zur befestigung eines zweirades an einer aufständervorrichtung und eine vorrichtung zum aufständern eines zweirades | |

| DE2924664C2 (de) | Verriegelungseinrichtung für Formkästen, insbesondere zur Gasbetonherstellung | |

| EP0383225A1 (de) | Einrichtung zum lösbaren Verbinden eines Drehtisches mit einem Bohrrohr | |

| EP4012105B1 (de) | Verfahren zur montage eines fräsrads einer schlitzwandfräse | |

| DE3842376C2 (de) | Bohrwerkzeug zum Aufbohren von Schornsteinschächten | |

| EP1388628A2 (de) | Scharnierband mit einer winkel- und höheneinstellbaren Hebe-Senkvorrichtung für Türen oder Fenster | |

| EP4079673A1 (de) | Abheber für gewindetransportankersystem | |

| DE1500855C3 (de) | Vorrichtung zum Verbinden von Bohrgestängen oder Rohren mit einem Drehantrieb |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| 17P | Request for examination filed |

Effective date: 19980123 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 20020426 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB IT LI SE |

|

| REF | Corresponds to: |

Ref document number: 226876 Country of ref document: AT Date of ref document: 20021115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59708586 Country of ref document: DE Date of ref document: 20021205 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20030226 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20030731 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20151208 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20160127 Year of fee payment: 20 Ref country code: CH Payment date: 20160111 Year of fee payment: 20 Ref country code: DE Payment date: 20160105 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20160112 Year of fee payment: 20 Ref country code: GB Payment date: 20160113 Year of fee payment: 20 Ref country code: AT Payment date: 20151223 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59708586 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20170113 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 226876 Country of ref document: AT Kind code of ref document: T Effective date: 20170114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20170113 |