EP0777084A2 - Mélangeur pour brûleur - Google Patents

Mélangeur pour brûleur Download PDFInfo

- Publication number

- EP0777084A2 EP0777084A2 EP96118734A EP96118734A EP0777084A2 EP 0777084 A2 EP0777084 A2 EP 0777084A2 EP 96118734 A EP96118734 A EP 96118734A EP 96118734 A EP96118734 A EP 96118734A EP 0777084 A2 EP0777084 A2 EP 0777084A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- annular disc

- mixing device

- adjusting ring

- air passage

- air

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D11/00—Burners using a direct spraying action of liquid droplets or vaporised liquid into the combustion space

- F23D11/36—Details, e.g. burner cooling means, noise reduction means

- F23D11/40—Mixing tubes or chambers; Burner heads

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C7/00—Combustion apparatus characterised by arrangements for air supply

- F23C7/002—Combustion apparatus characterised by arrangements for air supply the air being submitted to a rotary or spinning motion

- F23C7/004—Combustion apparatus characterised by arrangements for air supply the air being submitted to a rotary or spinning motion using vanes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C7/00—Combustion apparatus characterised by arrangements for air supply

- F23C7/008—Flow control devices

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C9/00—Combustion apparatus characterised by arrangements for returning combustion products or flue gases to the combustion chamber

- F23C9/006—Combustion apparatus characterised by arrangements for returning combustion products or flue gases to the combustion chamber the recirculation taking place in the combustion chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2202/00—Fluegas recirculation

- F23C2202/50—Control of recirculation rate

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/11402—Airflow diaphragms at burner nozzle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23D—BURNERS

- F23D2900/00—Special features of, or arrangements for burners using fluid fuels or solid fuels suspended in a carrier gas

- F23D2900/11403—Flame surrounding tubes in front of burner nozzle

Definitions

- the invention relates to a mixing device for a burner according to the preamble of claim 1.

- a mixing device of this type is known for example from DE 39 30 569 C2 and DE 92 12 924 U1.

- the centering hub for the nozzle shaft is held coaxially in the air guide tube, the swirl vanes serving to support and hold the centering hub.

- the air guide tube axially penetrates the annular disc, which closes the annular space between the burner tube and the air guide tube.

- This known mixing device is structurally complex. Adaptation to different burner capacities is only possible through design changes.

- the invention has for its object to provide a mixing device of the type mentioned, which is structurally simpler and can therefore be manufactured more cost-effectively.

- the mixing device should also be able to be adjustably adapted to different burner outputs.

- the air guide tube is located on the downstream side of the annular disk, while the centering hub for the nozzle shaft is arranged on the upstream side of the annular disk.

- the annular disc can serve both as a carrier of the air guide tube and as a carrier of the centering hub and thus of the nozzle shaft.

- the entire mixing device is preferably supported only by the annular disk in the burner tube. This results in the possibility of storing the entire mixing device axially adjustable in the burner tube in a simple manner.

- the washer is mounted on its outer circumference in a guide and sealing ring which is slidable in the burner tube.

- the mixing device can be adapted to support different burner capacities by changing the average cross section of the annular gap between the conical air nozzle of the air guide tube and the fuel nozzle. This allows the air flow through the Air nozzle in combination with a burner-side blower pressure control can be adapted to the fuel throughput of the fuel nozzle.

- the speed at which the combustion air is supplied to the flame via the air nozzle must be within a predetermined range. This type of adaptation is therefore only possible if the power of the fan with which the combustion air is added to the burner tube and thus to the air guide tube can be adjusted. By adjusting the blower power it is achieved that the exit velocity of the combustion air at the air nozzle does not increase inadmissibly when the passage cross section of the air nozzle is reduced.

- the passage cross section of the air passage openings of the annular disc is preferably adjustable. If the burner output is reduced to a certain minimum, the passage cross section of the air passage openings can be reduced, so that a smaller amount of air enters the chamber formed by the air guide tube and the fuel nozzle. As a result, the amount of combustion air supplied to the flame via the air nozzle is also reduced without the exit velocity of the combustion air at the air nozzle changing in an impermissible manner.

- the adjustment of the passage cross section of the air passage openings is preferably effected by an adjusting ring which covers the air passage openings more or less by twisting or by axial displacement with respect to the annular disk.

- the air passage of the annular disc forms a continuous annular gap, on which the swirl vanes are located downstream are arranged.

- the swirl vanes impart a swirl to the combustion air without the passage cross section of the air passage being significantly reduced.

- the annular disc can be carried by radial vanes, which simultaneously hold or form the centering hub for the nozzle shaft.

- the blades advantageously also form an axial guide for the mixing device in the burner tube, which counteracts tilting of the annular disc. Supporting the nozzle shaft via the vanes has the further advantage that the heat transfer from the hot burner tube to the nozzle shaft is reduced, the combustion air flowing past the vanes additionally causing cooling. Since the air passage is an annular gap that is open over the entire circumference, an adjustment of the passage cross section is not provided in this embodiment.

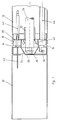

- FIGS. 1 to 3 A first exemplary embodiment of the mixing device is shown in FIGS. 1 to 3.

- the mixing device is inserted into a burner tube 10.

- a recirculation tube 12 is attached to the burner tube 10 downstream by means of a bayonet lock 14.

- the recirculation tube 12 engages axially into the burner tube 10 up to recirculation openings 16 in the wall of the burner tube 10.

- the recirculation openings 16 distributed equally over the circumference of the burner tube 10 allow combustion gases from the combustion chamber to be returned to the flame burning in the recirculation tube 12 .

- the mixing device is inserted into the burner tube 10, the mixing device being mounted axially displaceably in the burner tube 10 by means of an essentially cylindrical guide and sealing ring 18.

- the downstream edge of the guide and sealing ring 18 moves depending on the axial adjustment more or less over the recirculation openings 16, so that the passage cross section of the recirculation openings 16 and thus the recirculation of the combustion gases can be adjusted by axially displacing the mixing device.

- the mixing device has an annular washer 20 which is seated with its outer circumference in the guide and sealing ring 18, so that the washer 20 is sealed on the outer circumference against the inner wall of the burner tube 10.

- the annular disc 20 is pierced in the middle by a nozzle opening.

- a centering hub 22 is attached to the annular disk 20 on the upstream side connects to the nozzle opening.

- the centering hub 22 passes through the nozzle opening of the washer 20 with a collar 24, which is flanged on the downstream side of the washer 20 to fix the centering hub 22 to the washer 20.

- the centering hub 22 serves to receive the nozzle shaft 26 of the burner.

- a screw for fixing the nozzle shaft 26 is screwed into a threaded bore 28 of the centering hub 22.

- the liquid or gaseous fuel is supplied via the nozzle shaft 26 and is dispensed under pressure via the fuel nozzle 30 arranged at the front end of the nozzle shaft 26.

- a short air guide tube 32 is attached, preferably welded, which narrows at its front end to form a conical air nozzle 34.

- the diameter of the air guide tube 32 is larger than the diameter of the centering hub 22.

- the annular disc 20 has air passage openings 36.

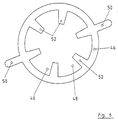

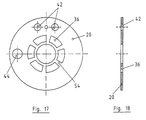

- 6 sector-shaped air passage openings 36 are provided with the same mutual angular distance and with the same angular width, as shown in FIG. 3.

- the combustion air supplied via the burner tube 10 passes through the air passage openings 36 into the chamber 38 formed by the air guide tube 32 and the fuel nozzle 30 and exits to the flame through the annular gap formed by the fuel nozzle 30 and the air nozzle 34.

- the air passage openings 36 are punched out of the sheet of the ring disk 20 so that the punched-out tab remains connected to the sheet of the ring disk 20 at one radial edge.

- the tabs are bent out of the plane of the annular disk 20 so that they form swirl vanes 40 which protrude into the chamber 38.

- the swirl vanes 40 are each bent up in the same circumferential direction and preferably lie with their outer edge against the inner wall of the air guide tube 32.

- the swirl vanes 40 issue the combustion air entering the chamber 38 a rotational speed component around the nozzle shaft 26 so that the combustion air swirls out of the air nozzle 34.

- ignition electrodes 42 for igniting the burner flame and a sight tube 44 for observing the burner flame are inserted into the annular disc 20 closed in this area.

- the mixing device has predetermined passage cross sections for the combustion air, which are determined by the cross section of the air passage openings 36 and the passage cross section of the annular gap formed by the air nozzle 34 and the fuel nozzle 30.

- the annular gap formed by the air nozzle 34 and the fuel nozzle 30 is adapted to the fuel throughput in the cross-section of the passage.

- the cone angle or the opening diameter of the air nozzle 34 is changed.

- a change in the passage cross-section of the annular gap causes a change in the exit speed of the combustion air, unless the air delivery of the fan is also changed.

- the mixing device to the burner output by changing the air nozzle 34 should therefore be accompanied by an adaptation of the fan.

- the passage cross section of the air passage openings 36 is preferably changed to match the burner power.

- a change in the passage cross section of the air passage openings 36 leads to a different dynamic pressure in the burner tube 10 with the delivery volume of the fan unchanged, but the passage cross section of the air passage openings 36 forms a throttle point for the combustion air, so that the pressure in the chamber 38 and thus the exit velocity of the combustion air the annular gap of the air nozzle 34 does not change significantly, when the emerging amount of combustion air is adjusted by adjusting the cross section of the air passage openings 36.

- the structure of the second exemplary embodiment shown in FIGS. 4 to 6 corresponds to that of the first exemplary embodiment of FIGS. 1 to 3. Only an additional adjustment of the passage cross section of the air passage openings 36 is provided.

- an adjusting ring 46 is arranged on the upstream side on the annular disk 20.

- the adjusting ring 46 is a stamped sheet metal part shown in FIG. 6.

- the adjusting ring 46 has the shape of an annular disk and is fixed with its inner circumference between a shoulder screwed into the outer wall of the centering hub 22 and the annular disk 20.

- the radial width of the adjusting ring 46 is so large that the adjusting ring 46 covers the circular ring area of the air passage openings 36 of the annular disk 20.

- the adjusting ring 46 has air passage openings 48 which correspond in size and arrangement to the air passage openings 36 of the ring disk 20.

- the adjusting ring 46 can be rotated relative to the ring disk 20 by means of a grip tab 50 formed on its outer circumference between a first position in which the radial webs 52 between the air passage openings 48 of the adjusting ring 46 and the radial webs 54 between the air passage openings 36 of the ring disk 20 overlap. and a second position, in which these webs 52 of the adjusting ring 46 are offset by the web width relative to the webs 54 of the ring disk 20 and reduce the passage cross section of the air passage openings 36 of the ring disk 20.

- the air passage openings 36 of the annular disc 20 have their maximum free passage cross section.

- this passage cross section is continuously reduced until it reaches its minimum value in the second position.

- the rotation of the adjusting ring 46 takes place in the direction of rotation in which the webs 52 of the adjusting ring 46 extend from the side corresponding to the free end of the swirl vanes 40 via the passage openings 36 of the washer 20 slide.

- the swirl-generating effect of the swirl vanes 40 is therefore not impaired when reducing the passage cross section of the air passage openings 36, but rather is increased, since the free passage area of the air passage openings 36 is increasingly covered.

- the adjusting ring 46 is preferably slightly curved, so that it is clamped between its outer edge resting on the annular disc 20 and its inner edge resting on the shoulder of the centering hub 22.

- the adjusting ring 46 is thus under friction both on the washer 20 and on the shoulder of the centering hub 22, so that it can be adjusted against this friction and is secured in its respective setting by friction.

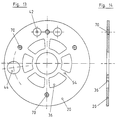

- FIGS. 7 to 10 A third exemplary embodiment is shown in FIGS. 7 to 10. Unless otherwise described below, this third exemplary embodiment corresponds to the preceding second exemplary embodiment. While in the second exemplary embodiment the adjusting ring 46 is rotatably mounted in order to adjust the passage cross section of the air passage openings 36, the adjusting ring 46 in the third exemplary embodiment is axially adjustable.

- the adjusting ring 46 is arranged in its angular position so that its webs 52 coincide with the area of the air passage openings 36 of the annular disc 20, in which the respective swirl vane 40 is bent up, so that a straight, axially parallel air passage through the air passage openings 36 is not possible.

- the adjusting ring 46 is axially adjustable. In one end position of its axial displacement, the adjusting ring 46 bears against the annular disk 20, so that the webs 52 of the adjusting ring 46 partially cover the air passage openings 36. If the adjusting ring 46 is increasingly lifted axially from the ring disk 20, the webs 52 of the adjusting ring 46 continuously less impede the passage of air through the air passage openings 36.

- a mechanism shown in FIG. 9 is used for the axial adjustment of the adjustment ring 46.

- a Z-shaped support tab 56 is attached to the washer 20.

- a screw bolt 58 with an outer collar is supported on the free leg of the support tab 56 parallel to the annular disk 20.

- the end of the screw bolt 58 which passes through the support tab 56 is screwed into a threaded bushing 60 which is fastened to a web 52 of the adjusting ring 46.

- a helical compression spring 62 coaxially surrounding the screw bolt 58 and the threaded bushing 60 is supported on one end on the support tab 56 and on the other end on the adjusting ring 46.

- the adjusting ring 46 can be lifted more or less far from the washer 20 against the force of the helical compression spring 62. Since the bolt 58 runs parallel to the nozzle shaft 26, an adjustment, e.g. using a pin wrench or an extension rod that protrudes outwards on the back of the burner, even with the mixer installed and even during operation.

- FIGS. 11 to 16 A fourth exemplary embodiment is shown in FIGS. 11 to 16.

- the annular disk 20, as the individual illustration in FIGS. 13 and 14 shows, has completely punched-out air passage openings 36 and no swirl vanes 40.

- the adjusting ring 46 is arranged on the downstream side of the ring disk 20.

- the swirl vanes 40 are produced when the air passage openings 48 of the adjusting ring 46 are punched out and bent out of the adjusting ring 46, as is shown in the individual illustration in FIGS. 15 and 16.

- the air guide tube 32 with the conical air nozzle 34 is welded to the downstream side of the adjusting ring 46.

- the adjusting ring 46 has over its outer circumference projecting tabs 64 with elongated holes 66 extending in the circumferential direction. Through these elongated holes 66, screws 68 engage, which are screwed into threaded bores 70 in the annular disk 20. When screws 68 are loosened, the adjusting ring 46 can be rotated against the annular disk 20 in order to adjust the cross section of the air passage openings 36. In the desired setting, the screws 68 are tightened in order to fix the adjusting ring 46.

- the adjusting ring 46 can be exchanged with the air nozzle 34 in a simple manner, so that an air nozzle 34 with a different outlet cross section can be used. Since the swirl vanes 40 are not integrally formed on the annular disk 20 in this embodiment, the annular disk 20 can also be used rotated through 180 °, so that there is mirror-symmetrical installation with respect to FIG. The same ring disk 20 can thus be used in burners in which the ignition electrodes 42 are arranged on the right or left with respect to the sight tube 44.

- the swirl vanes are formed on the annular disc 20 or the adjusting ring 46, depending on which of these parts is arranged downstream.

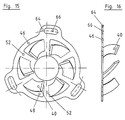

- FIGS. 17 to 19 This is shown in FIGS. 17 to 19 in a fifth exemplary embodiment, which otherwise corresponds to the second exemplary embodiment in FIGS. 4 to 6.

- the annular disk 20, which is shown in FIGS. 17 and 18, has only air passage openings 36.

- the adjusting ring 46 arranged on the upstream side on the annular disk 20 has swirl vanes 40 which reach through the air passage openings 36 of the annular disk 20.

- FIGS. 20 to 24 show a sixth exemplary embodiment which enables a particularly high throughput of combustion air, but does not provide any adjustment of the passage cross section for the combustion air.

- the annular disk 20 is designed as a circular ring, the inner circular surface of which is completely punched out as an air passage.

- the annular disc 20 On the upstream side of the annular disc 20, four vanes 72 offset by 90 ° to one another are welded on.

- the vanes 72 run in axial sectional planes radially to the central axis of the mixing device.

- a pair of the wings 72 are stamped as a coherent sheet metal part.

- the central region 74, at which the two wings 72 are connected to one another, is formed into an arc of a circle extending over 90 °.

- the opposite circular arc-shaped connecting areas 74 form the centering hub 22 for the nozzle shaft 26.

- the two connecting areas of the pairs of wings 72 are connected to one another by a welded-on ring 76.

- the outer edges of the vanes 72 which run in the axial direction lie on a radius which corresponds to the outer radius of the guide ring 18. If the mixing device is pushed into the burner tube 10, it is supported and guided on the one hand by the guide ring 18 and on the other hand by the vanes 72 on the inner circumference of the burner tube 10.

- annular gap that is open over the entire circumference remains free as an air passage for the combustion air.

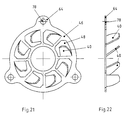

- An adjusting ring 46 is arranged downstream of the annular disc 20, which is shown in FIGS. 21 and 22 in individual representation.

- the adjusting ring 46 essentially corresponds to the adjusting ring shown in FIGS. 11 and 12.

- the adjusting ring 46 in this sixth exemplary embodiment does not have elongated holes in the tab 64, but rather simple bores 78 into which screw 68 are inserted in order to screw the adjusting ring 46 to the annular disk 20.

- the adjusting ring 46 is therefore not adjustable relative to the annular disk 20 and thus has no adjusting function.

- Swirl blades 40 are punched out and bent up from the adjusting ring 46, as shown in FIGS. 21 and 22.

- the air guide tube 32 is welded to the adjusting ring 46, which narrows outward in a convex manner to the air nozzle 34.

- the outer edge of the swirl blades 40 abuts the air guide tube 32.

- the inner edge of the swirl vanes 40 widens in the downstream direction, so that a free passage remains between the inner edge of the swirl vanes 40 and the nozzle shaft inserted into the centering hub 22.

- the adjusting ring 46 leaves relatively large air passage openings 48 in an axial top view, which are covered neither by the swirl vanes 40 nor by the annular disk 20. This results in a large air passage cross section for the combustion air, the swirl vanes 40 imparting a swirl to the combustion air flowing through.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Gas Burners (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29518919U DE29518919U1 (de) | 1995-11-29 | 1995-11-29 | Mischeinrichtung für einen Brenner |

| DE29518919U | 1995-11-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0777084A2 true EP0777084A2 (fr) | 1997-06-04 |

| EP0777084A3 EP0777084A3 (fr) | 1998-08-26 |

| EP0777084B1 EP0777084B1 (fr) | 2002-01-30 |

Family

ID=8016057

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96118734A Expired - Lifetime EP0777084B1 (fr) | 1995-11-29 | 1996-11-22 | Mélangeur pour brûleur |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0777084B1 (fr) |

| AT (1) | ATE212702T1 (fr) |

| DE (2) | DE29518919U1 (fr) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003022423A1 (fr) * | 2001-09-05 | 2003-03-20 | Webasto Thermosysteme International Gmbh | Systeme de conversion de carburant et d'air en reformat, et procede de montage d'un systeme de ce type |

| WO2003072234A1 (fr) * | 2002-02-28 | 2003-09-04 | Webasto Thermosysteme Gmbh | Systeme pour transformer un combustible et de l'air en un reformat |

| EP1533566A2 (fr) * | 2003-11-18 | 2005-05-25 | MEKU Metallverarbeitungs GmbH & Co. KG | Dispositif de mélange pour brûleur |

| DE10144408B4 (de) * | 2001-09-10 | 2007-05-10 | Webasto Ag | Düse zum Zerstäuben von flüssigem Brennstoff |

| DE10144407B4 (de) * | 2001-09-10 | 2007-05-10 | Webasto Ag | Düse zum Zerstäuben von flüssigem Brennstoff |

| ITMO20100087A1 (it) * | 2010-03-29 | 2011-09-30 | Ancora Spa | Bruciatore ad elevata stabilita' di fiamma, particolarmente per il trattamento termico di manufatti ceramici. |

| WO2013087919A1 (fr) * | 2011-12-16 | 2013-06-20 | Shell Internationale Research Maatschappij B.V. | Dispositif de séparation comprenant une coupelle rotative |

| ITMO20120292A1 (it) * | 2012-11-27 | 2014-05-28 | Alberto Benfenati | Bruciatore |

| EP2287530A3 (fr) * | 2009-08-07 | 2014-07-02 | Dome Holding GmbH | Unité de mélange pour un brûleur |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19604347A1 (de) * | 1996-02-07 | 1997-08-14 | Koerting Ag | Brenner für flüssigen oder gasförmigen Brennstoff, insbesondere für Öl |

| DE202006013853U1 (de) * | 2006-09-07 | 2006-12-21 | Meku Metallverarbeitungs Gmbh & Co. Kg | Mischeinrichtung für einen Brenner |

| DE102006049294A1 (de) * | 2006-10-19 | 2008-04-24 | Robert Bosch Gmbh | Mischeinrichtung für einen Öl- oder Gasbrenner |

| DE202009002700U1 (de) | 2009-03-05 | 2009-04-30 | Meku Metallverarbeitungs Gmbh & Co. Kg | Mischeinrichtung für einen Brenner |

| DE202009010691U1 (de) | 2009-08-07 | 2009-10-08 | Meku Metallverarbeitungs Gmbh & Co. Kg | Mischkopf mit axial verstellbarem Düsenstock |

| DE102011011281A1 (de) | 2011-02-15 | 2012-08-16 | Scheer Heizsysteme & Produktionstechnik Gmbh | Mischvorrichtung |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9212924U1 (de) | 1992-09-25 | 1992-11-26 | MEKU Metallverarbeitungs-GmbH, 7735 Dauchingen | Mischeinrichtung für einen Brenner |

| DE3930569C2 (de) | 1989-09-13 | 1995-06-01 | Siegfried W Schilling | Brennerkopf |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2339125A1 (de) * | 1973-08-02 | 1975-02-13 | Volkswagenwerk Ag | Drallscheibe fuer einen brenner |

| DE7919481U1 (de) * | 1979-07-07 | 1979-10-04 | Maschinenfabrik Augsburg-Nuernberg Ag, 8000 Muenchen | Anordnung von zuendelektroden bei heizoelbrennern |

| DE3124113A1 (de) * | 1981-06-19 | 1982-12-30 | Thermostar Heisler + Leins oHG Heizungs-und Klimatechnik, 7250 Leonberg | Flammrohr eines oelvergasungsbrenners ii |

| JPS58205011A (ja) * | 1982-05-26 | 1983-11-29 | Sanyo Electric Co Ltd | 燃料油バ−ナ |

| AT395057B (de) * | 1988-06-14 | 1992-09-10 | Vaillant Gmbh | Geblaesebrenner, insbesondere gas-geblaesebrenner |

| DE4010360A1 (de) * | 1990-03-31 | 1991-10-02 | Peter Erat | Diffusor mit integrierter zuendeinrichtung und drallscheibe |

| DE4430888A1 (de) * | 1993-12-18 | 1995-07-06 | Deutsche Forsch Luft Raumfahrt | Einstellbarer Blaubrenner |

| DE9404776U1 (de) * | 1994-03-22 | 1994-07-21 | Köhne, Heinrich, Prof. Dr.-Ing., 52074 Aachen | Brenner für Flüssigbrennstoffe |

| DE29518918U1 (de) * | 1995-11-29 | 1996-01-25 | MEKU Metallverarbeitungs-GmbH, 78083 Dauchingen | Mischeinrichtung für einen Brenner |

-

1995

- 1995-11-29 DE DE29518919U patent/DE29518919U1/de not_active Expired - Lifetime

-

1996

- 1996-11-22 DE DE59608673T patent/DE59608673D1/de not_active Expired - Lifetime

- 1996-11-22 EP EP96118734A patent/EP0777084B1/fr not_active Expired - Lifetime

- 1996-11-22 AT AT96118734T patent/ATE212702T1/de active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3930569C2 (de) | 1989-09-13 | 1995-06-01 | Siegfried W Schilling | Brennerkopf |

| DE9212924U1 (de) | 1992-09-25 | 1992-11-26 | MEKU Metallverarbeitungs-GmbH, 7735 Dauchingen | Mischeinrichtung für einen Brenner |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2003022422A1 (fr) * | 2001-09-05 | 2003-03-20 | Webasto Thermosysteme International Gmbh | Systeme de conversion d'air et de carburant en reformat et son procede de montage |

| US7357820B2 (en) | 2001-09-05 | 2008-04-15 | Webasto Ag | System for converting fuel and air into reformate |

| WO2003022423A1 (fr) * | 2001-09-05 | 2003-03-20 | Webasto Thermosysteme International Gmbh | Systeme de conversion de carburant et d'air en reformat, et procede de montage d'un systeme de ce type |

| DE10144408B4 (de) * | 2001-09-10 | 2007-05-10 | Webasto Ag | Düse zum Zerstäuben von flüssigem Brennstoff |

| DE10144407B4 (de) * | 2001-09-10 | 2007-05-10 | Webasto Ag | Düse zum Zerstäuben von flüssigem Brennstoff |

| WO2003072234A1 (fr) * | 2002-02-28 | 2003-09-04 | Webasto Thermosysteme Gmbh | Systeme pour transformer un combustible et de l'air en un reformat |

| EP1533566A2 (fr) * | 2003-11-18 | 2005-05-25 | MEKU Metallverarbeitungs GmbH & Co. KG | Dispositif de mélange pour brûleur |

| EP1533566A3 (fr) * | 2003-11-18 | 2007-07-25 | MEKU Metallverarbeitungs GmbH & Co. KG | Dispositif de mélange pour brûleur |

| EP2287530A3 (fr) * | 2009-08-07 | 2014-07-02 | Dome Holding GmbH | Unité de mélange pour un brûleur |

| ITMO20100087A1 (it) * | 2010-03-29 | 2011-09-30 | Ancora Spa | Bruciatore ad elevata stabilita' di fiamma, particolarmente per il trattamento termico di manufatti ceramici. |

| WO2011120597A1 (fr) * | 2010-03-29 | 2011-10-06 | Ancora S.P.A. | Brûleur à haute stabilité de la flamme, en particulier pour le traitement thermique d'articles céramiques |

| WO2013087919A1 (fr) * | 2011-12-16 | 2013-06-20 | Shell Internationale Research Maatschappij B.V. | Dispositif de séparation comprenant une coupelle rotative |

| AU2012351536B2 (en) * | 2011-12-16 | 2015-10-08 | Shell Internationale Research Maatschappij B.V. | Separation device comprising a swirler |

| US10427172B2 (en) | 2011-12-16 | 2019-10-01 | Shell Oil Company | Separation device comprising a swirler |

| ITMO20120292A1 (it) * | 2012-11-27 | 2014-05-28 | Alberto Benfenati | Bruciatore |

| WO2014083516A1 (fr) * | 2012-11-27 | 2014-06-05 | Alberto Benfenati | Brûleur |

| CN104854404A (zh) * | 2012-11-27 | 2015-08-19 | 本费纳蒂·阿尔贝托 | 燃烧器 |

| CN104854404B (zh) * | 2012-11-27 | 2017-05-10 | 安科拉股份公司 | 燃烧器 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59608673D1 (de) | 2002-03-14 |

| ATE212702T1 (de) | 2002-02-15 |

| EP0777084A3 (fr) | 1998-08-26 |

| DE29518919U1 (de) | 1996-01-25 |

| EP0777084B1 (fr) | 2002-01-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0777084B1 (fr) | Mélangeur pour brûleur | |

| EP0826426B1 (fr) | Arroseur | |

| DE4110507C2 (de) | Brenner für Gasturbinentriebwerke mit mindestens einer für die Zufuhr von Verbrennungsluft lastabhängig regulierbaren Dralleinrichtung | |

| EP0048438A2 (fr) | Brûleur à mazout et à gaz pour installation dans les chaudières de chauffage et les chaudières de générateurs de vapeur | |

| DE3122163C2 (de) | Brenner für Brennstoff in Fluidform | |

| DE2659089C3 (de) | Brenner, insbesondere für flüssige Brennstoffe | |

| EP0233330A1 (fr) | Ensemble de brûleur-chaudière | |

| DE3930569A1 (de) | Mischeinrichtung fuer brenner | |

| EP0683883B1 (fr) | Bruleur a flamme bleue optimisant la combustion | |

| DE4228817A1 (de) | Brenner für Gasturbinentriebwerke | |

| EP2287530B1 (fr) | Unité de mélange pour un brûleur | |

| DE2410141C3 (de) | Brenner for fluide Brennstoffe | |

| DE4430888A1 (de) | Einstellbarer Blaubrenner | |

| DE19708218C2 (de) | Gasbrenner | |

| EP2295857B1 (fr) | Brûleur ayant un tête de mélange dotée d'une buse réglable axialement | |

| DE8909202U1 (de) | Mischeinrichtung für Gebläsebrenner | |

| EP1000665A2 (fr) | Buse rotative | |

| EP0501209B1 (fr) | Dispositif de combustion pour mazout ou analogue | |

| EP0683884B1 (fr) | Bruleur a flamme bleue ajustable | |

| DE2150112C3 (de) | Brenner mit Brennkammer und koaxial in der Oxidationsmittelzufuhrleitung gehaltertem Brennstoffverteilerrohr | |

| DE19503781A1 (de) | Öl- oder Gasgebläsebrenner | |

| DE19519696A1 (de) | Mischeinrichtung für Brenner von Kleinfeuerungsanlagen | |

| DE9212924U1 (de) | Mischeinrichtung für einen Brenner | |

| DE1812405C3 (de) | Wirbelbrenner mit einer zentralen öl- und/oder Gaszuführung | |

| DE8604089U1 (de) | Mischeinrichtung für einen Gas- und Ölbrenner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT CH DE FR IT LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT CH DE FR IT LI |

|

| 17P | Request for examination filed |

Effective date: 19980730 |

|

| 17Q | First examination report despatched |

Effective date: 19991112 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: MEKU VERWALTUNGSGESELLSCHAFT MBH |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR IT LI |

|

| REF | Corresponds to: |

Ref document number: 212702 Country of ref document: AT Date of ref document: 20020215 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59608673 Country of ref document: DE Date of ref document: 20020314 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: R. A. EGLI & CO. PATENTANWAELTE |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20151124 Year of fee payment: 20 Ref country code: CH Payment date: 20151123 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20151120 Year of fee payment: 20 Ref country code: FR Payment date: 20151124 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20151229 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59608673 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 212702 Country of ref document: AT Kind code of ref document: T Effective date: 20161122 |