EP0672012B1 - Conteneur pour materiaux en vrac, muni d'un dispositif de vidage - Google Patents

Conteneur pour materiaux en vrac, muni d'un dispositif de vidage Download PDFInfo

- Publication number

- EP0672012B1 EP0672012B1 EP93922878A EP93922878A EP0672012B1 EP 0672012 B1 EP0672012 B1 EP 0672012B1 EP 93922878 A EP93922878 A EP 93922878A EP 93922878 A EP93922878 A EP 93922878A EP 0672012 B1 EP0672012 B1 EP 0672012B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- holder

- webs

- container

- framework

- roof

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000013590 bulk material Substances 0.000 title claims abstract description 5

- 239000000571 coke Substances 0.000 claims abstract description 3

- 239000004576 sand Substances 0.000 claims abstract description 3

- 239000000463 material Substances 0.000 claims abstract 3

- -1 gravel Substances 0.000 claims description 2

- 238000003466 welding Methods 0.000 claims description 2

- 239000002184 metal Substances 0.000 abstract 2

- 238000003860 storage Methods 0.000 description 3

- 239000011521 glass Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 239000002699 waste material Substances 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000004064 recycling Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000002123 temporal effect Effects 0.000 description 1

- 238000012549 training Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D90/00—Component parts, details or accessories for large containers

- B65D90/54—Gates or closures

- B65D90/62—Gates or closures having closure members movable out of the plane of the opening

- B65D90/626—Gates or closures having closure members movable out of the plane of the opening having a linear motion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65F—GATHERING OR REMOVAL OF DOMESTIC OR LIKE REFUSE

- B65F1/00—Refuse receptacles; Accessories therefor

- B65F1/12—Refuse receptacles; Accessories therefor with devices facilitating emptying

- B65F1/125—Features allowing the receptacle to be lifted and emptied by its bottom

Definitions

- two types of containers are known from the patent literature and technical use according to the preamble: On the one hand, those that are preferably known from the management of waste glass (for example, according to WO-A-93/12018), and on the other hand, those that are mostly known as Railway wagon bodies are designed and have a flap-operated emptying opening.

- Waste glass containers generally have individual drop-in openings, preferably for bottles, stand at a recycling point for some time, are removed by special trucks and replaced by empty containers.

- the emptying takes place either in the glassworks or on a train station by lifting the container shell or lowering the pyramid or conical bottom.

- the formation of such containers is in accordance with the loading and unloading speeds, and the amount of the bulk goods.

- both loading and unloading are characterized by a high temporal mass flow.

- Special devices so-called railway gutters, are also required for unloading.

- Special storage devices and silos are required for the storage prior to loading and subsequent storage after unloading.

- the use of such bulk goods containers designed as wagon bodies therefore requires high capital expenditure, for the containers themselves, for silos and for the railway gutters.

- the unit of use is also always at least one whole wagon, even if it is only to be partially filled.

- GB-A-1'071'600 describes a container that has a floor drain. It contains in its lower part a multiplicity of roof-shaped webs and a further component, which also has a multiplicity of roof-shaped webs, which are arranged such that they pass between the roof-shaped webs of the container, in such a way that when the container is in relation to the Part is in a certain position, the webs of the component and the webs of the container come to lie next to each other and the container is closed with it.

- the disadvantage of this device is that the container can only be emptied at specially provided unloading stations and the component contains moving parts that are susceptible to malfunction.

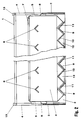

- Fig. 1 the container according to the invention is shown in a perspective view. It consists of a frame 1, for example welded together from square tubes, with four vertical struts 4, which are connected at their upper ends by horizontal struts 20. In the lower part of the frame 1 strong side plates 2 are welded on all four sides. A container 3 is embedded in this frame 1 in such a way that it can move along the vertical struts 4. For this purpose, 3 guides 5 are attached in the corners of the container, which are based on 6 and 7 are described in more detail. In the interior of the container 3, roof-shaped connecting struts 6 are visible which connect and stiffen the longitudinal walls of the container 3.

- the upper edge of the container 3 is connected to a roof-shaped bar 7 for stiffening, for example by welding, which at the same time serves as a deflecting device, so that no bulk material remains on the edge.

- a roof-shaped bar 7 for stiffening, for example by welding, which at the same time serves as a deflecting device, so that no bulk material remains on the edge.

- Around the container 3 also runs - welded to it - another, downwardly and outwardly inclined strip 8, which, in the position of the container according to FIG. 1, the upper edge of the side plates 2 - and thus also the space between side plates 2 and container 3 - covers.

- flat side plates 2 - as shown - in the sense of the invention, flat hollow profiles or rib plates can also be used, the ribs of which run in the horizontal direction.

- Fig. 2 shows the container of Fig. 1 in longitudinal section. This shows that the container 3 is drawn in the shape of a truncated pyramid in its lower part.

- the bottom opening of the container 3 is closed by a plurality of roof-shaped webs 9, 10.

- the webs 9 hatched vertically in FIG. 2 are welded to the longitudinal side plates 2 of the frame 1, the webs 10 hatched horizontally in FIG. 2 to the container 3.

- Short pieces of webs welded to the container 3 are identified by the number 11. They stiffen the bottom of the container 3; their dimensioning and position is shown in more detail in FIGS. 4 and 5.

- the two outermost roof-shaped webs 10 are welded to a pair of vertically extending plates 12, one of which is shown in plan view in FIG. 2. Their task is explained in more detail in connection with FIG. 3. in the position of the container shown in Figure 2, the container 3 is closed; it can be loaded with the bulk material to be transported.

- four - only schematically drawn - load introduction devices 13 are present in the four upper corners of the frame 1.

- Another possibility is to drive under the side plates 2 of the frame with the forks of a forklift.

- Fig. 3 the container is drawn in the open or emptying position.

- the filled container is, for example, two transverse Beams turned off, which only support the vertical plates 12.

- the frame 1 lowers on it, guided by the guides 5, and thus releases the openings closed by the webs 9.

- this relative movement can also be generated in such a way that the frame 1 is placed on a foundation and the beams - or a lifting device replacing them - are raised.

- the unloading process can take place in a proportionate manner.

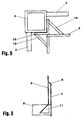

- Fig. 6 shows an embodiment of the guide 5.

- a steel bracket 15 is welded, which rests on two sides of the vertical strut 4, but only has legs so long that they can slide past the side plates with enough play.

- the angle 15 is stiffened by means of a support plate 18 which extends, for example, over the entire length of the angle 15.

- Each corner of the container 3 is provided with a guide 5 in the manner described.

- a first variant contains 15 plastic sliding plates inserted between vertical strut 4 and angle 15.

- a second variant can be seen in FIG. 7.

- the container according to the invention shown in FIGS. 1 to 7, can in principle be produced in any desired size. Modifications only relate to static elements that are not essential to the invention. Of course, it is intended to be designed as an ISO standard container for rail and ship transport.

- the load introduction devices 13, which are only shown schematically, are then to be designed as devices corresponding to the ISO standards; the corresponding devices at the lower four corners must also be provided accordingly.

- the container is simple and robust and inexpensive to manufacture. Instead of storing different grain sizes of bulk goods in expensive and often underutilized silos, these can be stored in the containers according to the invention, which often also saves unnecessary reloading processes. Furthermore, capital-consuming railway gutters can be saved: the containers are unloaded from universally usable container railway wagons and lifted and emptied onto a relatively easy-to-design emptying device. If the containers are not to be emptied at first, they can be stacked, for example as an ISO standard container. The transport train is immediately free again and silo capacity is not required.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Auxiliary Methods And Devices For Loading And Unloading (AREA)

- Filling Or Emptying Of Bunkers, Hoppers, And Tanks (AREA)

- Control And Other Processes For Unpacking Of Materials (AREA)

- Portable Outdoor Equipment (AREA)

Claims (10)

- Conteneur pour matériaux en vrac à déchargement par le fond, en particulier pour les matériaux comme le sable, le gravier, le coke, composé d'un bac (3) qui est rétréci en forme de pyramide tronquée, dans sa partie inférieure, et qui comporte plusieurs nervures en forme de toits (10) s'étendant d'un côté longitudinal du bac (3) à l'autre et reliées à celui-ci dans la zone du rétrécissement, et d'un élément qui comporte lui aussi plusieurs nervures en forme de toits (9) disposées de manière à s'étendre entre les nervures en forme de toits (10) du bac, de sorte que lorsque le bac (3) est dans sa position la plus basse par rapport à l'élément, les nervures (9) de celui-ci et les nervures (10) du bac (3) viennent s'appliquer les unes auprès des autres, fermant ainsi le bac (3), caractérisé- en ce qu'il est prévu un châssis (1) globalement parallélipipédique auquel l'élément est relié solidement, dans sa partie inférieure,- en ce que le bac (3) est mobile verticalement à l'intérieur du châssis (1),- en ce que le châssis (1) se compose de montants (4, 16) formés de tubes carrés, qui sont reliés par soudage par des entretoises (20), à leurs extrémités supérieures, et par des tôles latérales (2), dans leur zone inférieure,- en ce que le bac (3) a lui aussi globalement la forme d'un parallélipipède et comporte au moins dans chacun de ses quatre bords latéraux verticaux un guidage (5) qui est mobile dans le sens vertical au niveau de l'un des montants (4),- en ce que le bac (3) comporte par ailleurs dans sa zone supérieure plusieurs barres de liaison en forme de toits (6) qui s'étendent à l'horizontale d'un côté longitudinal du bac à l'autre et qui sont reliées à celui-ci, et- en ce qu'il est prévu, soudées à deux nervures (10) extérieures du bac (3), deux plaques respectives (12) qui s'étendent à la verticale vers le bas et dans le sens longitudinal du bac (3) et dont la longueur correspond au maximum à l'intervalle défini par les nervures (9) du châssis (1), moyennant quoi, lorsque le conteneur est posé sur deux poutres transversales dont la longueur correspond au minimum à l'écartement entre deux plaques verticales (12) mais au maximum à la largeur intérieure du châssis (1), le châssis (1) s'abaisse sur le bac (3) et les intervalles entre les nervures (9) du châssis (1) et les nervures (10) du bac (3) s'ouvrent pour les matériaux en vrac.

- Conteneur selon la revendication 1, caractérisé- en ce que le bord supérieur du bac (3) est soudé à un rebord en forme de toit (7) qui fait le tour du côté intérieur,- en ce qu'il est prévu, fixé à l'extérieur du bac (3), un rebord (8) incliné vers l'extérieur et vers le bas qui fait également le tour et qui, dans la position fermée du conteneur, couvre précisément l'intervalle défini entre la paroi du bac (3) et les tôles latérales (2) du châssis (1), et- en ce que le bord inférieur du bac (3), à l'endroit où il est posé sur les nervures (9) du châssis (1) en position fermée, est renforcé par un morceau court d'une nervure également en forme de toit (11) qui s'étend vers les tôles latérales (2) à partir du bord rétréci du bac (3).

- Conteneur selon la revendication 1, caractérisé en ce que le châssis (1) comporte quatre montants (4) et le bac (3) est équipé de quatre guidages (5) qui sont appliqués chacun contre deux côtés des tubes carrés formant les montants (4) du châssis (1), les guidages (5) étant contrefichés à l'aide de deux tôles d'appui (18) contre le bac (3).

- Conteneur selon la revendication 1, caractérisé- en ce que le châssis (1) comporte au moins six montants (4, 16) formés de tubes carrés, quatre montants (4) formant les coins du châssis (1) tandis que les montants supplémentaires (16) sont disposés sur les côtés longitudinaux du châssis (1), et- en ce que les guidages (5) sont contrefichés à l'aide de deux tôles d'appui (18) contre le bac (3).

- Conteneur selon la revendication 3 ou 4, caractérisé- en ce que les guidages (5) sont conçus dans les quatre coins du bac comme des équerres (15) qui sont appliquées, aptes à glisser, contre les deux surfaces latérales tournées vers le bac des tubes carrés formant les montants (4) et qui s'étendent à l'horizontale de telle sorte que les guidages (5) peuvent passer devant les tôles latérales (2), et- en ce que les guidages (15) qui sont appliqués, aptes à glisser, contre les tubes carrés formant les montants (16) - lesquels montants (16) sont disposés entre les montants (4) formant les coins du châssis (1) - se composent de profilés en U (17) qui sont appliqués, aptes à glisser, contre la surface latérale des tubes carrés tournée vers le bac (3) et qui s'étendent à l'horizontale de telle sorte que les guidages (5) peuvent passer devant les tôles latérales (2).

- Conteneur selon la revendication 5, caractérisé en ce que les guidages (5) glissent directement le long des montants (4, 16).

- Conteneur selon la revendication 5, caractérisé en ce que les guidages (5) sont pourvus de plaques de glissement.

- Conteneur selon la revendication 3 ou 4, caractérisé- en ce que les guidages (5) prévus dans les quatre coins du bac (3) portent des galets qui peuvent rouler le long des deux surfaces latérales tournées vers le bac des tubes carrés formant les montants (4), et- en ce que les guidages (5) qui agissent au niveau des montants (16) disposés entre les coins du châssis (1) portent des galets qui peuvent rouler le long de la surface latérale des tubes carrés formant les montants (16) qui est tournée vers le bac (3) et le long des surfaces latérales contiguës.

- Conteneur selon la revendication 1, caractérisé en ce que le châssis (1) comporte à chacun de ses huit coins un dispositif d'introduction de charge (13).

- Conteneur selon la revendication 9, caractérisé en ce que les dispositifs d'introduction de charge (13) sont conformes aux exigences des normes du trafic international ferroviaire et par voie d'eau.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH303393 | 1993-10-08 | ||

| CH3033/93 | 1993-10-08 | ||

| PCT/CH1993/000250 WO1995010466A1 (fr) | 1993-10-08 | 1993-10-25 | Conteneur pour materiaux en vrac, muni d'un dispositif de vidage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0672012A1 EP0672012A1 (fr) | 1995-09-20 |

| EP0672012B1 true EP0672012B1 (fr) | 1997-03-05 |

Family

ID=4247123

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93922878A Expired - Lifetime EP0672012B1 (fr) | 1993-10-08 | 1993-10-25 | Conteneur pour materiaux en vrac, muni d'un dispositif de vidage |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US5626253A (fr) |

| EP (1) | EP0672012B1 (fr) |

| AT (1) | ATE149462T1 (fr) |

| CA (1) | CA2151278A1 (fr) |

| DE (1) | DE59305666D1 (fr) |

| ES (1) | ES2102065T3 (fr) |

| WO (1) | WO1995010466A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6010022A (en) * | 1994-05-18 | 2000-01-04 | Buckhorn, Inc. | Dispensing box for flowable material |

| AU2003213129A1 (en) * | 2002-04-15 | 2003-11-03 | Boasso America Corporation (A Louisiana Corporation) | Method and apparatus for supplying bulk product to an end user |

| AT510892A1 (de) * | 2010-12-30 | 2012-07-15 | Schwer Johann | Verfahren zum entfernen von öl oder ölförmigen stoffen von wasseroberflächen |

| BR102018074121A2 (pt) * | 2018-11-23 | 2020-06-02 | Tmsa - Tecnologia Em Movimentação S.A. | Módulo de alívio e dispositivo de descarga de material a granel |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR467082A (fr) * | 1914-01-07 | 1914-06-03 | Dansk Svovlsyre | Dispositif de fond mobile ou fond auxiliaire utilisable pour le vidage de réservoirs, de silos, de chambres de réaction pour le superphosphate, etc. |

| US2782011A (en) * | 1953-06-19 | 1957-02-19 | Sho Me Inc | Hoppers |

| NL250628A (fr) * | 1959-06-22 | |||

| CH411684A (it) * | 1963-10-08 | 1966-04-15 | Pirelli | Contenitore per il trasporto di liquidi e di materiali incoerenti, come polveri e granuli |

| DE1949730B2 (de) * | 1969-10-02 | 1977-05-12 | Verschluss fuer schuettgut-behaelter | |

| US3863799A (en) * | 1973-06-20 | 1975-02-04 | Ppg Industries Inc | Adjustable bin for transporting articles |

| US4295431A (en) * | 1979-11-23 | 1981-10-20 | Aga Ab | Pallet for pressurized gas cylinders |

| US4410111A (en) * | 1980-10-24 | 1983-10-18 | Barger Lloyd D | Storage container for particulate material |

| US4662532A (en) * | 1985-11-04 | 1987-05-05 | Steel King Industries, Inc. | Foldable container |

| US5186351A (en) * | 1988-08-05 | 1993-02-16 | San Joaquin Valley Express | Slurry tank |

| JP2737000B2 (ja) * | 1989-06-19 | 1998-04-08 | キヤノン株式会社 | トナーキット |

| BR8903115A (pt) * | 1989-06-26 | 1991-01-02 | Cpm Do Brasil Ind E Comercio L | Dispositivo para controlar a descarga de material a partir de um reservatorio de armazenagem |

| JPH0734827Y2 (ja) * | 1990-07-09 | 1995-08-09 | セントラル硝子株式会社 | ガラス板用パレット |

| NL9102109A (nl) * | 1991-12-17 | 1993-07-16 | Zuidema Milieu Bv | Inrichting voor het inzamelen van afval, in het bijzonder afval-verpakkingsglas. |

-

1993

- 1993-10-25 AT AT93922878T patent/ATE149462T1/de not_active IP Right Cessation

- 1993-10-25 WO PCT/CH1993/000250 patent/WO1995010466A1/fr active IP Right Grant

- 1993-10-25 CA CA002151278A patent/CA2151278A1/fr not_active Abandoned

- 1993-10-25 ES ES93922878T patent/ES2102065T3/es not_active Expired - Lifetime

- 1993-10-25 EP EP93922878A patent/EP0672012B1/fr not_active Expired - Lifetime

- 1993-10-25 DE DE59305666T patent/DE59305666D1/de not_active Expired - Fee Related

- 1993-10-25 US US08/464,843 patent/US5626253A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ES2102065T3 (es) | 1997-07-16 |

| WO1995010466A1 (fr) | 1995-04-20 |

| EP0672012A1 (fr) | 1995-09-20 |

| DE59305666D1 (de) | 1997-04-10 |

| ATE149462T1 (de) | 1997-03-15 |

| CA2151278A1 (fr) | 1995-04-20 |

| US5626253A (en) | 1997-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AT506371B1 (de) | Entladefahrzeug und kombination eines entladefahrzeuges mit einer behälterabdeckung | |

| EP1135287B1 (fr) | Wagon a plate-forme surbaissee | |

| EP0672012B1 (fr) | Conteneur pour materiaux en vrac, muni d'un dispositif de vidage | |

| DE4005534C1 (fr) | ||

| EP0008392A1 (fr) | Véhicule servant à transporter soit des objets ayant une forme définie, soit des chargements pouvant s'écouler | |

| EP2830924B1 (fr) | Conteneur de transport, véhicule, assemblage de traction, procédé pour charger un conteneur de transport et procédé pour transporter de la marchandise en vrac | |

| DE69100115T2 (de) | Dichtes Silo mit hängend angebauter Wandung und Verfahren zu dessen Herstellung. | |

| DE102008031981A1 (de) | Transportfahrzeug zum Anheben und Transportieren von ULDs und Cargopaletten | |

| DE4110847C2 (de) | Stapelbarer Transportbehälter für flüssige und/oder feste Stoffe | |

| DE3816243A1 (de) | Doppelwandige bodenplatte fuer grosscontainer | |

| DE202009017605U1 (de) | Vorrichtung zur Entleerung von fließfähigen Schüttgütern | |

| DE1605012A1 (de) | Fahrzeug,insbes.Eisenbahnwaggon,mit aufklappbarem Dach | |

| DE102006014213A1 (de) | Kippeinrichtung | |

| EP1839988A2 (fr) | Dispositif pour basculer un containeur monté sur un wagon | |

| EP0624499B1 (fr) | Dispositif sur un chassis d'un wagon roulant sur rails pour le chargement horizontal des conteneurs | |

| DE2439172A1 (de) | Verfahren zum beschicken einer siloanlage, und einrichtung zur durchfuehrung dieses verfahrens | |

| EP0677424B1 (fr) | Véhicule de transport de matériaux en plaque | |

| EP0646532B1 (fr) | Récipient de stockage et de transport | |

| EP3694792B1 (fr) | Dispositif souterrain de collecte pour déchets | |

| EP0513436A1 (fr) | Conteneur pour la collecte de déchets | |

| DE3790890C2 (fr) | ||

| DE102007001747A1 (de) | Kippeinrichtung | |

| DE202007003582U1 (de) | Kippeinrichtung | |

| DE29905790U1 (de) | Fahrzeugeigene Vorrichtung zum Be- und Entladen eines Transportfahrzeugs für mehrere im wesentlichen gleiche Behälter | |

| AT338107B (de) | Kombination eines fahrzeuges und mindestens eines behalters zum transport landwirtschaftlicher guter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19950608 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE ES FR GB IT LI NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 19960219 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE ES FR GB IT LI NL PT SE |

|

| REF | Corresponds to: |

Ref document number: 149462 Country of ref document: AT Date of ref document: 19970315 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59305666 Country of ref document: DE Date of ref document: 19970410 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19970501 |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: DR. REINHOLD C. SALGO PATENTANWALT |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2102065 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20000912 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20000922 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20001017 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20001019 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20001027 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20001031 Year of fee payment: 8 Ref country code: AT Payment date: 20001031 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20001102 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20001219 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011025 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011025 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011026 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011031 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020501 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 93922878.9 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20011025 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020628 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20020501 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020702 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20020430 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20021113 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20051025 |