EP0249765A2 - Elément télescopique à double paroi d'une cloison mobile - Google Patents

Elément télescopique à double paroi d'une cloison mobile Download PDFInfo

- Publication number

- EP0249765A2 EP0249765A2 EP87107437A EP87107437A EP0249765A2 EP 0249765 A2 EP0249765 A2 EP 0249765A2 EP 87107437 A EP87107437 A EP 87107437A EP 87107437 A EP87107437 A EP 87107437A EP 0249765 A2 EP0249765 A2 EP 0249765A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- cover plates

- telescopic

- wall part

- plates

- double

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000005192 partition Methods 0.000 title claims abstract description 12

- 238000007789 sealing Methods 0.000 claims abstract description 68

- 238000009413 insulation Methods 0.000 abstract description 3

- 210000001503 joint Anatomy 0.000 description 5

- 230000033001 locomotion Effects 0.000 description 4

- 238000005253 cladding Methods 0.000 description 2

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 239000000463 material Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B2/00—Walls, e.g. partitions, for buildings; Wall construction with regard to insulation; Connections specially adapted to walls

- E04B2/74—Removable non-load-bearing partitions; Partitions with a free upper edge

- E04B2/82—Removable non-load-bearing partitions; Partitions with a free upper edge characterised by the manner in which edges are connected to the building; Means therefor; Special details of easily-removable partitions as far as related to the connection with other parts of the building

Definitions

- the invention relates to a double-shell telescopic element of a movable partition, with a wall part which contains cover plates on both sides of a supporting frame and is movably suspended with rollers in ceiling-fixed tracks, with a telescopic part which can be extended horizontally from the wall part, with external cover plates, with sealing strips on the top and / or lower edge of the wall part, which can be extended between the cover plates against the ceiling or the floor, and with a sealing strip edge section which projects between the cover plates of the telescopic part and is coupled to the telescopic part.

- Movable, smooth partitions consist of several individual wall elements, which are suspended by rollers in ceiling-fixed rails.

- the individual wall elements are released from a lock and moved along the running rail into a storage area and stowed parallel to one another.

- the wall elements are brought close together in one plane and braced by sealing strips, which are extended between the cladding panels of the wall elements against the ceiling and / or the floor.

- a telescopic element with an edge-side telescopic part which can be extended horizontally against a fixed building wall or the like when the wall is closed to also clamp the wall elements horizontally against each other and to close the available internal width of the building opening in question without a gap with the partition.

- the known telescopic elements have on their telescopic part outer cover plates which overlap the cover plates of the wall part both in the retracted and extended positions in order to achieve a visually clean partition closure. Since the cover plates of the telescopic part overlap the cover plates of the wall part, the telescope part cover plates are spaced apart from the sealing strip edge section which is coupled to the telescopic part by the thickness of the wall part cover plates. If the telescopic part is extended, there is consequently an intermediate space between the cover plates of the telescopic part, which is filled in by the cover plates of the wall part in the retracted position of the telescopic part.

- the space which forms when the telescopic part is extended has the consequence that the acoustic insulation of the partition wall is reduced at this point, because sound waves can then pass undisturbed from this space under the sealing strip edge section from one side to the other of the telescopic element.

- the object of the invention is to develop a two-shell telescopic element of the type mentioned at the outset in such a way that improved sound insulation with an optically appealing appearance is achieved.

- This object is achieved in that relatively thin intermediate plates are provided which engage behind the cover plates of the wall part and the cover plates of the telescopic part in their abutment or overlap area.

- the advantages of the invention lie in particular in the fact that the joints formed when the telescopic part is extended between the cover plates of the wall part and the cover plates of the telescopic part are covered by internal intermediate plates essentially over the entire vertical height of the telescopic element. Since the intermediate plates have a wall thickness that is considerably reduced compared to the cover plates and also consist of an acoustically sufficiently insulating material, when the telescopic part is extended, only a comparatively narrow space is generated between the cover plates and the telescoping sealing strip edge section, which corresponds to the wall thickness of the cover plates . These narrow gaps are covered by outward-spreading rubber lips, which are located on the sealing strips, so that the free passage of sound waves is prevented.

- the cover plates of the wall part and the cover plates of the telescopic part are flush, and the intermediate plates are fastened to the inner surfaces of the cover plates of the wall part or the telescopic part and engage with their free end behind the cover plates of the telescopic part or the wall part and thus form the basis of the when extending of the telescopic part resulting shadow gap, which is equal to or larger than the telescopic stroke.

- This embodiment has the advantage that the cover plates of the telescopic part are aligned with the other cover plates of the partition, so that a visually appealing flat design of the entire partition is created.

- the cover plates of the telescopic part overlap the cover plates of the wall part both in the retracted and in the extended state.

- the intermediate plates are attached to the free vertical edge of the telescopic part and project with their free end behind the cover plates of the wall part.

- the cover plates of the telescopic part are guided by means of a suitable mechanism (according to the simultaneously filed patent application EP ........) such that they overlap the cover plates of the wall part during the telescopic movement and when the come out of the extended position from the cladding panels of the wall section and then - perpendicular to the board levels - move into a position flush with the cover panels of the wall section.

- the intermediate plates internally attached to the cover plates of the wall part and with their free end protrude long enough into the telescopic part to form the basis for the desired or emerging shadow gap.

- the sealing strips of the wall part are flush with the sealing strip edge sections of the telescopic part.

- additional covering elements are then provided on the sealing strips in the area of this joint, the vertical height of which is approximately equal to the height of the sealing strips, so that a direct path for the passage of sound waves is prevented at these joints when the telescopic part is extended.

- the sealing strip edge sections telescopically overlap the sealing strips, which likewise prevents a clear path for the passage of sound.

- the abutting or overlapping areas between sealing strips and sealing strip edge sections can be offset against the abutting or overlapping areas of the cover plates.

- the cover elements between the sealing strips and sealing strip edge sections that are aligned with one another can then advantageously be placed on the outside either on the sealing strip or the sealing strip edge section and are then flush with the intermediate plates.

- Elastic sealing lips are preferably arranged between the sealing strips, the sealing strip edge sections and the cover plates.

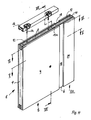

- Fig. L shows a perspective view of the two-shell telescopic element l, which is suspended on rollers la in a thick rail lb longitudinally displaceable.

- the telescopic element 1 has a wall part 8, on the support frame 9 of the rollers la and outer plates 4 on both sides are attached.

- the telescopic part 20 has cover plates 24 which partially overlap the cover plates 4 of the wall part 8 during the telescopic movement and run in corresponding, external, parallel running planes when the telescopic part 20 moves horizontally.

- an upper and a lower horizontal sealing strip 10 are provided, which have a sealing strip edge section 12 coupled to the telescopic part 20 and consequently participating in the movement of the telescopic part.

- An actuating mechanism (not shown) is arranged between the cover plates 4 of the wall part 8 and the cover plates 24 of the telescopic part 20 and moves both the telescopic part 20 and the sealing strips 10 by means of a crank which can be attached from the outside (for example at point 5).

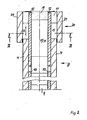

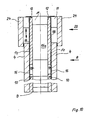

- Fig. 2 shows a horizontal section along the line II-II of Fig. 1

- Fig. 3 shows a vertical section along the line III-III of Fig. 1 or 2.

- Figs. 2 and 3 is produced when extending of the telescopic part 20 in this known telescopic element l between the cover plates 24 and the sealing strip edge section l2 a butt joint l3 on both sides, through which sound waves can pass undisturbed.

- another butt joint l3 is created at the joint between the sealing strips l0 and the sealing strip edge sections l2, which also allows undisturbed passage of sound waves.

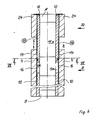

- FIGS. 1, 2 and 3 show different views of a telescopic element 1 according to the invention, namely in a perspective overall view (FIG. 4) in a first horizontal section along the line VV (FIG. 5), a second horizontal section along the line VI-VI (FIG. 6) and a vertical section along the line VII-VII (Fig. 7).

- FIGS. 1, 2 and 3 correspond to FIGS. 1, 2 and 3, so that the differences from the known telescopic element 1 are clearly recognizable.

- a cover plate 4 is screwed onto a support frame 9 of the wall part 8 on both sides. Between the cover plates 4, a sealing strip 10 is arranged at the upper and lower edge of the wall part 8, which can be extended electrically or mechanically against the floor or the ceiling by means of an actuation mechanism (not shown).

- a telescopic part 20 On the right edge of the telescopic element 1, a telescopic part 20 is arranged, which has a vertical edge beam 11, which can be extended horizontally and on both Sides each cover plate 24 holds.

- the sealing strips l0 have a sealing strip edge section l2 projecting between the cover plates 24 of the telescopic part 20, which is coupled to the telescopic part 20 and can be telescoped together with it.

- the cover plates 4 of the wall part 8 are flush with the cover plates 24 of the telescopic part 20.

- Thin intermediate plates 18 are screwed against the inner surface of the cover plates 24, the free end of which protrudes behind the cover plates 4 of the wall part 8 that the cover plates 4 can be engaged even when the telescopic part 20 is fully extended.

- the adjacent vertical edges of the cover plates 4, 24 form a butt joint when the telescopic part 20 is retracted.

- shadow gaps with the width of the telescopic stroke are formed at the abutment of the cover plates 4, 24, which reveal the intermediate plates 18.

- the intermediate plates 18 run over the entire height of the cover plates 4, 24 and consist of thin material, e.g. Sheet. This ensures that the gap l4 behind the cover plates 4, which must be present for receiving the intermediate plates l8, is very narrow.

- the sealing strips l0 and the sealing strip edge sections l2 have sealing lips l5 which bear outward against the cover plates 4, 24, cf. Fig. 7, so that no free sound path is formed from one side of the telescopic element 1 to the other side.

- the upper and lower telescopic sealing strip edge section l2 is slidably mounted on a rail l5a, which is firmly connected to the associated sealing strip l0.

- the sealing strip edge section l2 is e.g. coupled at its front end to the edge beam 11 of the telescopic part 20.

- the cover elements 16 are e.g. screwed onto the outer surface of the sealing strip edge section l2 and overlap the sealing strips l0.

- the wall thickness of the cover elements l6 corresponds to the wall thickness of the intermediate plates l8, so that the cover elements l6 can be accommodated in the gap l4 created by the intermediate plates l8.

- the cover elements l6 have approximately the height of the sealing strip l0 and each have their own sealing lip l7 on their upper and lower horizontal edge in order to implement a mechanical lock against direct sound passage in the area of the joint l3.

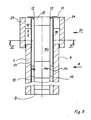

- the cover plates 24 of the telescopic part 20 are arranged such that they cover the cover plates 4 of the wall part 8 at least during a section of the telescopic part motion overlap.

- intermediate plates l8 are fastened, which with their free ends engage the cover plates 4 of the wall part 8 on the inside and extend over the entire height of the cover plates 4, 24, cf. . 9 to ll.

- the sealing strips l0 and the sealing strip edge sections l2 in turn have sealing lips l5, which bear against the intermediate plates l3 and prevent undisturbed passage of sound from one side of the telescopic element to the other side of the telescopic element. Since the joint l3a between the sealing strip l0 and the sealing strip edge section l2 lies in the region of the wall part 8, additional cover elements l6 are also provided in this embodiment, which have the height of the sealing strips l0, are screwed onto the sealing strips l0 or the sealing strip edge sections l2 and overlap the joint l3a that forms during telescoping. As a result, the joint l3a is blocked against direct sound passage.

- the intermediate plates 18 and the cover elements 16 have a small wall thickness in comparison to the cover plates 4, 24.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Building Environments (AREA)

- Specific Sealing Or Ventilating Devices For Doors And Windows (AREA)

- Extensible Doors And Revolving Doors (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19863619392 DE3619392A1 (de) | 1986-06-09 | 1986-06-09 | Zweischaliges teleskopelement einer beweglichen trennwand |

| DE3619392 | 1986-06-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0249765A2 true EP0249765A2 (fr) | 1987-12-23 |

| EP0249765A3 EP0249765A3 (fr) | 1990-05-23 |

Family

ID=6302629

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87107437A Withdrawn EP0249765A3 (fr) | 1986-06-09 | 1987-05-22 | Elément télescopique à double paroi d'une cloison mobile |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4833840A (fr) |

| EP (1) | EP0249765A3 (fr) |

| JP (1) | JPH0781350B2 (fr) |

| AU (1) | AU7404087A (fr) |

| DE (1) | DE3619392A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2205336A (en) * | 1987-06-02 | 1988-12-07 | Michael Sacks | Bullet resistant partitions |

| DE202009014565U1 (de) | 2009-10-28 | 2010-02-04 | Dorma Gmbh + Co. Kg | Mobile Trennwand mit Wandanschlusselement |

Families Citing this family (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6003275A (en) | 1990-02-14 | 1999-12-21 | Steelcase Development Inc. | Furniture system |

| US6170200B1 (en) | 1990-02-14 | 2001-01-09 | Steelcase Development Inc. | Furniture system |

| US6134844A (en) | 1990-02-14 | 2000-10-24 | Steelcase Inc. | Method and apparatus for displaying information |

| US5511348A (en) | 1990-02-14 | 1996-04-30 | Steelcase Inc. | Furniture system |

| US5873205A (en) * | 1990-11-28 | 1999-02-23 | Advantage Office Systems, Llc | Privacy panel for use with open office furniture systems |

| CA2101110A1 (fr) * | 1992-07-23 | 1994-01-24 | Kenneth James Macquarrie | Cloison amovible de hauteur variable |

| US5577348A (en) * | 1993-05-25 | 1996-11-26 | Rosconi Ag | Partition wall with sliding termination panel |

| CH689233A5 (de) * | 1996-05-07 | 1998-12-31 | Dorma Tuerautomatik Ag | Schiebewand |

| US5791094A (en) * | 1997-01-09 | 1998-08-11 | Diverse Industries, Inc. | Movable wall for ball court |

| US5918422A (en) * | 1997-05-14 | 1999-07-06 | Bucher, Jr.; Robert Joseph | Open office panel system |

| US6058665A (en) * | 1998-03-10 | 2000-05-09 | Steelcase Development Inc. | Adjustable door and doorway construction |

| FR2791234B1 (fr) * | 1999-03-24 | 2003-10-17 | Nicaise Gregoire | Dispositif adaptable de delimitation et d'amenagement des espaces et des volumes |

| AUPQ297399A0 (en) * | 1999-09-20 | 1999-10-14 | Rapini Pty Ltd | Storage unit |

| AT4650U1 (de) * | 2000-10-05 | 2001-10-25 | Lenz Gmbh | Rahmenpaneelen-system zur aufhängung von paneelen in räumen |

| US7707790B2 (en) * | 2003-06-12 | 2010-05-04 | Steelcase Inc. | Office system |

| US7516624B2 (en) * | 2005-06-01 | 2009-04-14 | Weeth Frederic R | Cooling room |

| DE102005048157A1 (de) * | 2005-10-06 | 2007-04-19 | Dorma Gmbh + Co. Kg | Mobile Trennwand |

| DE102005048155A1 (de) * | 2005-10-06 | 2007-04-19 | Dorma Gmbh + Co. Kg | Mobile Trennwand |

| DE102008027821A1 (de) * | 2008-06-11 | 2009-12-17 | Dorma Gmbh + Co. Kg | Trennwand aus transparenten Wandelementen |

| US20090313935A1 (en) * | 2008-06-24 | 2009-12-24 | Environmental Interiors, Inc. | High Impact, Moisture Resistant Wall Panel System |

| EP2224076B1 (fr) * | 2009-02-27 | 2013-06-05 | M-T Patents GmbH | Tribune |

| US8402699B2 (en) | 2010-07-14 | 2013-03-26 | Kimball International, Inc. | Sliding privacy door for partition systems |

| DE102015108663A1 (de) * | 2015-06-01 | 2016-12-01 | Dorma Deutschland Gmbh | Trennwandelement |

| US10041249B1 (en) * | 2015-07-31 | 2018-08-07 | Timothy Hebert | Adjustable barrier for partitioning a building space |

| US12054942B2 (en) | 2020-12-08 | 2024-08-06 | STARC Systems, Inc. | Temporary wall system with fire block protection |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2836126A1 (de) * | 1978-08-18 | 1980-02-28 | Vki Rheinhold & Mahla Ag | Anschlussbausatz fuer trennwaende und zweischalige demontierbare trennwand mit anschlusselement. |

| DE3239485A1 (de) * | 1982-10-25 | 1984-05-03 | Rüterbau GmbH, 3012 Langenhagen | U-foermiges anschlussstueck fuer wandelemente |

| DE3425484A1 (de) * | 1984-07-11 | 1986-01-23 | aboplan Viol und Partner GmbH, 2903 Bad Zwischenahn | Versetzbare trennwand aus wandelementen und verfahren zur herstellung und demontage der wandelemente |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3341992A (en) * | 1964-10-07 | 1967-09-19 | Robert Haws Co | Portable room dividing panel |

| US3327439A (en) * | 1964-10-21 | 1967-06-27 | Ralph W Eatough | Wall panel locking actuator |

| US3638376A (en) * | 1970-01-05 | 1972-02-01 | Hough Mfg Corp | Portable partition |

| DE2438982C2 (de) * | 1974-08-14 | 1976-09-09 | Hueppe Justin Fa | Versetzbare trennwand aus mindestens einem raumhohen, zweischaligen wandelement |

| US4014137A (en) * | 1976-03-08 | 1977-03-29 | Hough Manufacturing Corporation | Drop action panel arrangement for operable partitions |

| JPS5428411A (en) * | 1977-08-04 | 1979-03-03 | Kouji Unayama | Device for fixing room partition wall |

| SU842162A1 (ru) * | 1979-08-23 | 1981-06-30 | Ордена Трудового Красного Знамени Централь-Ный Научно-Исследовательский И Проектныйинститут Строительных Металлоконструкций"Цниипроектстальконструкция" | Составной стержень |

| CH658090A5 (de) * | 1982-11-16 | 1986-10-15 | Karl Haab | Wandelement mit einer abdichtungsvorrichtung und aus diesen bestehende trennwand. |

| US4462192A (en) * | 1982-06-01 | 1984-07-31 | American Standard, Inc. | Seal assembly |

-

1986

- 1986-06-09 DE DE19863619392 patent/DE3619392A1/de active Granted

-

1987

- 1987-05-22 EP EP87107437A patent/EP0249765A3/fr not_active Withdrawn

- 1987-06-08 US US07/059,105 patent/US4833840A/en not_active Expired - Fee Related

- 1987-06-08 JP JP62141635A patent/JPH0781350B2/ja not_active Expired - Lifetime

- 1987-06-09 AU AU74040/87A patent/AU7404087A/en not_active Abandoned

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2836126A1 (de) * | 1978-08-18 | 1980-02-28 | Vki Rheinhold & Mahla Ag | Anschlussbausatz fuer trennwaende und zweischalige demontierbare trennwand mit anschlusselement. |

| DE3239485A1 (de) * | 1982-10-25 | 1984-05-03 | Rüterbau GmbH, 3012 Langenhagen | U-foermiges anschlussstueck fuer wandelemente |

| DE3425484A1 (de) * | 1984-07-11 | 1986-01-23 | aboplan Viol und Partner GmbH, 2903 Bad Zwischenahn | Versetzbare trennwand aus wandelementen und verfahren zur herstellung und demontage der wandelemente |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2205336A (en) * | 1987-06-02 | 1988-12-07 | Michael Sacks | Bullet resistant partitions |

| DE202009014565U1 (de) | 2009-10-28 | 2010-02-04 | Dorma Gmbh + Co. Kg | Mobile Trennwand mit Wandanschlusselement |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3619392A1 (de) | 1987-12-10 |

| EP0249765A3 (fr) | 1990-05-23 |

| DE3619392C2 (fr) | 1988-07-28 |

| JPH0781350B2 (ja) | 1995-08-30 |

| JPS6375239A (ja) | 1988-04-05 |

| AU7404087A (en) | 1987-12-10 |

| US4833840A (en) | 1989-05-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0249765A2 (fr) | Elément télescopique à double paroi d'une cloison mobile | |

| EP0249066B1 (fr) | Elément télescopique à double paroi | |

| DE1555995A1 (de) | Schalenaufbau | |

| DE202017103784U1 (de) | Abdeckungsvorrichtung | |

| DE1683009B2 (de) | Falttür mit mindestens zwei Tafeln | |

| DE2851549C2 (de) | Vorrichtung zum Verbinden von Schaltafeln insbesondere im Bereich von Abstufungen eines Bauwerkes | |

| DE2350343A1 (de) | Moebeleinheit zum aufstellen in einer rechtwinkligen ecke eines raumes | |

| DE2427997C2 (de) | Versetzbare Trennwand | |

| DE3913383C2 (fr) | ||

| DE7901833U1 (de) | Schiebetuer mit vertikaldichtungseinrichtung | |

| DE2533856C3 (de) | Sturz | |

| DE2924444C2 (de) | Zarge für Fenster oder Türen, insbesondere für Kellerfenster | |

| DE2811676C2 (de) | Schiebetüranschluß, insbesondere für vorfertigbare Trennwände | |

| DE2805973A1 (de) | Tuer insbesondere zweifluegelige tuer | |

| DE3719829A1 (de) | Trennwandeinheit mit einzelnen rand an rand aneinandergefuegten plattenelementen | |

| DE1709319A1 (de) | Raumteiler | |

| DE3903756C1 (en) | Apparatus for securing the transportation path between a building and a vehicle by movable shielding walls | |

| DE2523851A1 (de) | Trennwandsystem, insbesondere wandfeldkonstruktion o.dgl. | |

| DE2628923C3 (de) | Vorrichtung zum Be- und Entlüften eines mit großformatigen Dacheindeckungsplatten eingedeckten Kaltdachs | |

| DE2857046C2 (de) | Umsetzbares Wandelement | |

| EP0413125A2 (fr) | Volet roulant pour meubles | |

| DE2502537C2 (de) | Kletterschalung für turmartige Stahlbetonbauten | |

| DE2142606C3 (de) | Zweischalige schalldämmende Innentrennwand und Verfahren zur Herstellung derselben | |

| DE3914744A1 (de) | Teleskopelement fuer eine trennwand | |

| DE3446036A1 (de) | Kabine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HUEPPE FORM SONNENSCHUTZ- UND RAUMTRENNSYSTEME GMB |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900711 |

|

| 17Q | First examination report despatched |

Effective date: 19910726 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19920306 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: SCHUESSLER, KARL Inventor name: PETERSEN, GERD, DIPL.-ING. Inventor name: KALISCHEWSKI,ROLF |