EP0146869B1 - Dispositif d'empilage intermédiaire de matière à découper - Google Patents

Dispositif d'empilage intermédiaire de matière à découper Download PDFInfo

- Publication number

- EP0146869B1 EP0146869B1 EP84115166A EP84115166A EP0146869B1 EP 0146869 B1 EP0146869 B1 EP 0146869B1 EP 84115166 A EP84115166 A EP 84115166A EP 84115166 A EP84115166 A EP 84115166A EP 0146869 B1 EP0146869 B1 EP 0146869B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- board

- stack

- boards

- work

- abutments

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H33/00—Forming counted batches in delivery pile or stream of articles

- B65H33/16—Forming counted batches in delivery pile or stream of articles by depositing articles in batches on moving supports

- B65H33/18—Forming counted batches in delivery pile or stream of articles by depositing articles in batches on moving supports with separators between adjacent batches

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S414/00—Material or article handling

- Y10S414/10—Associated with forming or dispersing groups of intersupporting articles, e.g. stacking patterns

- Y10S414/101—Associated with forming or dispersing groups of intersupporting articles, e.g. stacking patterns with article-supporting fluid cushion

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S414/00—Material or article handling

- Y10S414/10—Associated with forming or dispersing groups of intersupporting articles, e.g. stacking patterns

- Y10S414/112—Group formed or dispensed by reversible apparatus

Definitions

- the invention relates to a device for. Intermediate stacking of material to be cut, in which the material to be cut is fed from the work table to a first work station, in particular a vibrating table, to a stack lift, on which the material to be cut is stored in part stacks with the intermediate storage of boards and from there to the work table of a second work station, in particular a cutting table of a cutting machine , is fed.

- a first work station in particular a vibrating table

- a stack lift on which the material to be cut is stored in part stacks with the intermediate storage of boards and from there to the work table of a second work station, in particular a cutting table of a cutting machine , is fed.

- Such a device is known from DE-PS-1 244 711.

- the material to be cut is shaken on a vibrating table before the cutting process, in order to thereby align the individual sheets precisely with one another.

- the material to be cut is stacked on a stack lift.

- the partial stacks lie one above the other on the stack lift, boards being arranged between the individual partial stacks. Moving the partial stack from the vibrating table to the boards or from the boards to the cutting table is done in a simple manner in that the boards are designed as air boards, d. H. they are provided with an air supply and on the surface facing the partial stacks with air outlet nozzles.

- the object of the invention is to provide a device with which it is possible to stack material to be cut without the partial stacks being shifted during loading or unloading.

- movable stops are arranged below the level of the support surfaces of the work tables, the stops being in the retracted position outside the displacement formed when the boards are raised and lowered, engaging in the extended position in the extended position and when a board is placed on the board the support surface of the board forms a level with the support surfaces of the work tables on the extended stops.

- the stops When loading the stack lift, it is lowered to such an extent that a transport pallet lying thereon and / or partial stacks already deposited are located below the stops. Then the stops are moved to the extended position and the board is placed on them. The stops hold the board in this position, in which the support surface of the board forms a plane with the support surface of the work tables. The partial stack to be put down is pushed onto the board and then the stack lift is raised so that the top board with the now placed partial stack relieves the stops. The stops are moved to their retracted position, i.e. H.

- the stack lift is lowered to such an extent that the surface of the last stacked part lies below the stops and forms an intermediate space to the underside of the board to be placed later. Finally, the stops for receiving the next board and a further partial stack are moved into the extended position.

- the stack lift When processing the partial stack, the stack lift is raised so far that the stops can be moved under the board carrying the uppermost partial stack.

- the stack lift is lowered to such an extent that the top board rests on the stops and there is a gap between the underside of the top board and the surface of the stack of taps below it, or in the final stage of the workflow there is a gap between the underside of the top air board and the surface of the Transport pallet forms.

- the prepared partial stack is then fed to the second work station, the board is removed and the stops are moved into the retracted position.

- the next partial stack is then raised by the stack lift.

- the stops according to the invention thus have the task of ensuring the horizontal position of the board lying on them and the flushness of the contact surface of the board with the contact surfaces of the work tables. While the stack lift usually takes over the carrying function for the partial stack and the boards in between, this carrying function for the top board and the partial stack located on it is performed by the stops. By separating the top board from the remaining stack during loading or unloading, it is prevented that the partial stack under the top board moves.

- the stops can be attached to both the workstations and the stack lift.

- the stops are expediently designed as flaps, one end of which is pivotally attached to the underside of the work tables of the work stations and the free end of which serves to support the board. If the flaps are arranged on the underside of the work tables, the stack lift is particularly space-saving. To pivot the flap, force elements should also be on the underside of the workbenches, in particular whose hydraulic power cylinder can be arranged.

- the width of the board i. H. perpendicular to the direction of displacement of the partial stack on the board, several flaps with force elements can be provided.

- stops are also advisable to arrange the stops not on the underside of the work tables, but rather on a swivel.

- thorn-like projections could extend under the board in the extended position or engage in corresponding recesses in the board and thus hold the board in a flush position with the work tables.

- the displacement of the extensions from the retracted to the extended position and back would also be effected by force elements.

- the boards advantageously have supports on their underside, the length of the individual supports being the same but greater than the height of the partial stack lying under the board.

- the use of such boards with supports is indicated when the individual partial stacks consist of lightweight, high-quality single sheets. In this case, the load of all partial stacks does not rest on the lower partial stack, but the boards are supported on the other boards.

- the boards In order to ensure that the partial stacks are easily pushed over, the boards should be designed as air boards with air inlet and outlet openings.

- the stacking lift advantageously has wheels for moving. While the partial stack lying on the board is being moved to the next work station when the stops are extended, or while partial stacks are being transported from one work station over the board to the other work station, the stack lift can leave the work area and bring in new material.

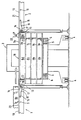

- a stacking lift 3 is located between a shaking table 1, which is only partially shown, and a cutting table 2, which is also only partially shown, of a paper cutting machine.

- the partially raised lifting fork 5 of the stack lift 4 passes through a pallet 6 on which the material to be cut is stored with the interposition of air boards 7a to 7e to partial stacks 8a to 8d.

- a plurality of flaps 13 are arranged pivotably about the joints 14 perpendicular to the plane of the drawing.

- hydraulic power cylinders 15 also arranged on the undersides 9 and 11 engage with their piston rods 16 on angle pieces 17 arranged on the flaps 13.

- the arrangement of the flaps on the undersides 9 and 11 and the dimension of the flaps with the supports 18 arranged at the free end of the flap is such that, when the flaps 13 are pivoted out, as shown in the figure, the air board 7e can be placed on the supports 18 , wherein the support surface 19 forms a plane with the support surfaces 20 and 21 of the worktops 10 and 12.

- the air inlet opening of the air board 7e which is not shown in any more detail, is connected to an air bell 22, which is shown schematically. An air flow is blown through this into the board 7e and then through air outlet openings arranged on the top of the board.

- the air film forming above the air board 7e makes it easier to push the partial stack 8e over from the support surface 20 to the air board 7e.

- the lifting fork 5 of the stack lift 3 is moved so far down that a gap remains between the underside of the air board 7e and the surface of the partial stack 8d. This ensures that the upper individual sheets of the partial stack 8d cannot be moved during the displacement of the partial stack 8e onto the air board 7e.

- the lifting fork 5 of the stack lift 3 is raised slightly in order to relieve the flaps 13.

- the air board 7e comes to a standstill with its four supports 23 on the air board 7d, whereby it does not touch the partial stack 8d located on the air board 7d.

- the other air boards 7a to 7d do not have such supports 23, the board 7b lies directly on the partial stack 8a, the board 7c directly on the partial stack 8b and the board 7d directly on the partial stack 8c.

Landscapes

- Pile Receivers (AREA)

- Stacking Of Articles And Auxiliary Devices (AREA)

- Details Of Cutting Devices (AREA)

- Sheets, Magazines, And Separation Thereof (AREA)

- Collation Of Sheets And Webs (AREA)

- Warehouses Or Storage Devices (AREA)

- Forming Counted Batches (AREA)

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84115166T ATE27439T1 (de) | 1983-12-14 | 1984-12-11 | Vorrichtung zum zwischenstapeln von schneidegut. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE8335816U | 1983-12-14 | ||

| DE19838335816U DE8335816U1 (de) | 1983-12-14 | 1983-12-14 | Vorrichtung zum zwischenstapeln von schneidgut |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0146869A2 EP0146869A2 (fr) | 1985-07-03 |

| EP0146869A3 EP0146869A3 (en) | 1985-07-31 |

| EP0146869B1 true EP0146869B1 (fr) | 1987-05-27 |

Family

ID=6759824

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84115166A Expired EP0146869B1 (fr) | 1983-12-14 | 1984-12-11 | Dispositif d'empilage intermédiaire de matière à découper |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4613267A (fr) |

| EP (1) | EP0146869B1 (fr) |

| JP (2) | JPS60144276A (fr) |

| AT (1) | ATE27439T1 (fr) |

| DE (2) | DE8335816U1 (fr) |

| ES (1) | ES8603785A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3613462A1 (de) * | 1986-04-22 | 1987-10-29 | Wolfgang Mohr | Vorrichtung zum be- und entladen eines stapellifts |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2587311A1 (fr) * | 1985-09-18 | 1987-03-20 | Schauman | Procede et installation de manutention automatique et stockage temporaire de paquets empiles de produits semi-finis en feuilles. |

| US5256028A (en) * | 1986-07-23 | 1993-10-26 | Winski Ernest P | Process for handling material |

| DE3914598C2 (de) * | 1989-05-03 | 1994-05-19 | Focke & Co | Verfahren und Vorrichtung zum Abräumen von Gegenständen von einer Unterlage mit hohem Reibungswiderstand |

| DE3940190A1 (de) * | 1989-12-05 | 1991-06-06 | Kolbus Gmbh & Co Kg | Verfahren zum be- und entladen von paletten mit stapeln von flaechigen produkten und einrichtung zur durchfuehrung des verfahrens |

| US5562403A (en) * | 1991-02-11 | 1996-10-08 | Winski; Ernest P. | Load forming apparatus and methods |

| DE59404575D1 (de) * | 1993-10-05 | 1997-12-18 | Seemi | Verfahren und Einrichtung zum Palettieren von Schlauchabschnitten aus Papier oder dgl. |

| US6305500B1 (en) * | 1999-08-25 | 2001-10-23 | Maxtor Corporation | Material delivery system for clean room-like environments |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US30742A (en) * | 1860-11-27 | Improvement in ordnance | ||

| US674262A (en) * | 1900-02-21 | 1901-05-14 | Garland H Duncan | Lumber-stacker. |

| US1225523A (en) * | 1915-02-27 | 1917-05-08 | Robert E Surles | Lumber-stacker. |

| US3146897A (en) * | 1962-01-11 | 1964-09-01 | Kalamazoo Paper Company | Paper pile separating and stacking transfer apparatus |

| DE1584410A1 (de) * | 1963-06-14 | 1970-01-22 | S I I Fornaci Magnetti S P A | Mechanische Einrichtung zur Automatisierung des Produktionsvorganges von Ziegeln |

| DE1244711B (de) * | 1965-06-12 | 1967-07-20 | Rudolf Mohr | Vorrichtung zum Stapeln von Schneidegut und selbsttaetigem Zufuehren an den Arbeitstisch, insbesondere von Papierschneidemaschinen |

| US3398841A (en) * | 1967-02-07 | 1968-08-27 | Mohr Rudolf | Apparatus for stacking material and automatically feeding the material to a worktable of a paper-cutting machine |

| US3548995A (en) * | 1968-06-13 | 1970-12-22 | Sta Hi Corp | Controlled variable speed stacking device for publication conveyor |

| US3960374A (en) * | 1972-06-15 | 1976-06-01 | Harris-Intertype Corporation | Sheet delivery system |

| US3897877A (en) * | 1973-08-22 | 1975-08-05 | Goldco Industries | Apparatus for positioning and orienting palletized articles |

| CA975813A (en) * | 1974-09-06 | 1975-10-07 | Theodore E. O'brien | Apparatus for automatically stacking and compressing batts of compressible material |

| JPS5655166U (fr) * | 1979-10-06 | 1981-05-14 | ||

| JPS6011676B2 (ja) * | 1980-04-10 | 1985-03-27 | 小森印刷機械株式会社 | 印刷機排紙部の紙流れ防止装置 |

| JPS5930620B2 (ja) * | 1981-05-21 | 1984-07-27 | 東洋ガラス機械株式会社 | 多重積層容器体からの容器取出移送装置 |

| JPS5811787U (ja) * | 1981-07-15 | 1983-01-25 | 株式会社日立製作所 | 行先表示装置 |

-

1983

- 1983-12-14 DE DE19838335816U patent/DE8335816U1/de not_active Expired

-

1984

- 1984-12-07 JP JP59257741A patent/JPS60144276A/ja active Pending

- 1984-12-10 US US06/679,745 patent/US4613267A/en not_active Expired - Fee Related

- 1984-12-11 DE DE8484115166T patent/DE3463921D1/de not_active Expired

- 1984-12-11 EP EP84115166A patent/EP0146869B1/fr not_active Expired

- 1984-12-11 AT AT84115166T patent/ATE27439T1/de not_active IP Right Cessation

- 1984-12-14 ES ES538622A patent/ES8603785A1/es not_active Expired

-

1991

- 1991-09-27 JP JP1991099454U patent/JP2525234Y2/ja not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3613462A1 (de) * | 1986-04-22 | 1987-10-29 | Wolfgang Mohr | Vorrichtung zum be- und entladen eines stapellifts |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE27439T1 (de) | 1987-06-15 |

| JP2525234Y2 (ja) | 1997-02-05 |

| JPH081281U (ja) | 1996-08-13 |

| DE8335816U1 (de) | 1984-04-26 |

| JPS60144276A (ja) | 1985-07-30 |

| ES8603785A1 (es) | 1986-01-16 |

| EP0146869A3 (en) | 1985-07-31 |

| US4613267A (en) | 1986-09-23 |

| EP0146869A2 (fr) | 1985-07-03 |

| DE3463921D1 (en) | 1987-07-02 |

| ES538622A0 (es) | 1986-01-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0077508B1 (fr) | Procédé et dispositif d'emballage de piles d'objets palettisés | |

| DE2440278C2 (de) | Vorrichtung zum Palettieren von Gegenständen | |

| EP0510428A1 (fr) | Appareil pour envelopper une charge palettisée au moyen d'une feuille étirable | |

| DE10123326C1 (de) | Auslagevorrichtung für eine Bogen verarbeitende Maschine und Verfahren zum Auslegen von Bogen in einer Bogen verarbeitenden Maschine | |

| DE2911457A1 (de) | Stapelvorrichtung | |

| EP0765827A1 (fr) | Dispositif d'alimentation et de stockage d'objets en forme de plaques | |

| EP0860253A2 (fr) | Procédé et appareil pour la fabrication de portes multi-couches | |

| EP0316568B1 (fr) | Dispositif pour enlever des piles de feuilles | |

| EP0146869B1 (fr) | Dispositif d'empilage intermédiaire de matière à découper | |

| EP0437246B1 (fr) | Presse pour la fabrication d'assemblages par dents collées | |

| DE2614558A1 (de) | Verfahren und vorrichtung zur herstellung palettenloser kollis | |

| DE19708125A1 (de) | Stapler | |

| DE2545444C3 (de) | Vorrichtung zum Zusammenbauen von Möbelkorpussen | |

| EP0195992A2 (fr) | Organe de préhension dans une installation de stratification | |

| DE4227726C2 (de) | Anlage zum Pressen von Laminaten | |

| DE3105237A1 (de) | Anlage zum vergueten von spanplatten, faserplatten u. dgl. | |

| DE102006050648B3 (de) | Vorrichtung zum Umsetzen von Blechteilen zwischen zwei Pressen und zum Wechseln der Greifwerkzeuge | |

| EP0298435B1 (fr) | Dispositif pour transporter des flans de carton | |

| DE2626630C2 (de) | Verfahren und Gerät zur Trennung und Stapelung von gestanzten Bögen | |

| DE19914357C2 (de) | Folien-Legeanlage zum wenigstens oberseitigen Belegen von Trägerplatten mit Folien | |

| DE2255103A1 (de) | Verfahren und vorrichtung zum beschicken von pressen | |

| DE2630094A1 (de) | Verfahren und geraet zur trennung und stapelung von gestanzten boegen | |

| DE3336937A1 (de) | Vorrichtung zum abnehmen einzelner scheibenfoermiger gegenstaende, insbesondere glasscheiben, von einem scheibenvorrat | |

| DE2736832A1 (de) | Verfahren zum kontinuierlichen auslegen von flaechigen formaten aus papier-, karton- und folienmaterial auf paletten | |

| DE2807368C3 (de) | Formmaschine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| 17P | Request for examination filed |

Effective date: 19841224 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| ITCL | It: translation for ep claims filed |

Representative=s name: MODIANO & ASSOCIATI S.R.L. |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| EL | Fr: translation of claims filed | ||

| TCNL | Nl: translation of patent claims filed | ||

| 17Q | First examination report despatched |

Effective date: 19860221 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 27439 Country of ref document: AT Date of ref document: 19870615 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3463921 Country of ref document: DE Date of ref document: 19870702 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed |

Owner name: MODIANO & ASSOCIATI S.R.L. |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: ROLF MOHR |

|

| NLS | Nl: assignments of ep-patents |

Owner name: ROLF MOHR EN WOLFGANG MOHR BEIDEN TE HOFHEIM A.D. |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| ITPR | It: changes in ownership of a european patent |

Owner name: CESSIONE;ROLF MOHR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732 |

|

| ITTA | It: last paid annual fee | ||

| EPTA | Lu: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 84115166.5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19961101 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19961125 Year of fee payment: 13 Ref country code: CH Payment date: 19961125 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19961126 Year of fee payment: 13 Ref country code: BE Payment date: 19961126 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19961127 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19961128 Year of fee payment: 13 Ref country code: AT Payment date: 19961128 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19961227 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971211 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971211 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971211 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971231 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971231 |

|

| BERE | Be: lapsed |

Owner name: MOHR ROLF Effective date: 19971231 Owner name: MOHR WOLFGANG Effective date: 19971231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980701 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19971211 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980901 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84115166.5 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |