EP0143414A2 - Machine à agglomérer - Google Patents

Machine à agglomérer Download PDFInfo

- Publication number

- EP0143414A2 EP0143414A2 EP84113946A EP84113946A EP0143414A2 EP 0143414 A2 EP0143414 A2 EP 0143414A2 EP 84113946 A EP84113946 A EP 84113946A EP 84113946 A EP84113946 A EP 84113946A EP 0143414 A2 EP0143414 A2 EP 0143414A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- die

- teeth

- holes

- press

- pelletizing machine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/22—Extrusion presses; Dies therefor

- B30B11/221—Extrusion presses; Dies therefor extrusion dies

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B11/00—Presses specially adapted for forming shaped articles from material in particulate or plastic state, e.g. briquetting presses, tabletting presses

- B30B11/22—Extrusion presses; Dies therefor

- B30B11/228—Extrusion presses; Dies therefor using pressing means, e.g. rollers moving over a perforated die plate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B30—PRESSES

- B30B—PRESSES IN GENERAL

- B30B15/00—Details of, or accessories for, presses; Auxiliary measures in connection with pressing

- B30B15/34—Heating or cooling presses or parts thereof

Definitions

- the invention relates to a pelletizing machine in which press rolls roll on a flat, perforated die.

- Pelleting machines are used to compress and extrude various types of material under the pressure of rolls, the strands being broken or cut into pellets.

- the material is partially compacted before it is pressed into the through holes and in many cases also involves crushing and mixing the components. Crushing is particularly necessary for waste that e.g. B. contain paper, textiles, plastics, straw and other parts of plants or consist of such.

- the press rollers have already been provided with blind holes or with transverse grooves, it could happen with material with a coarse structure or with great moisture that the material was not drawn into the press nip between the press roller and die or the press rollers, which are usually freely rotatably mounted on the pan head, were compacted Material layer slid away.

- the invention has for its object to form press rolls and die so that the drawing of the material into the press nip and the crushing between press rolls and die and the passage of the material through the die are improved.

- the surfaces of the press rolls and die are provided with teeth.

- the teeth on the press rollers are designed so that they grip the supplied material and preferably between the teeth of the die and in any case in press the through holes between the teeth of the die.

- the teeth also prevent the formation of a densified layer of material on the die above its through holes. Since the die and press rollers engage the teeth at least through the material enclosed between them, the press rollers are inevitably rotated when the pan head is driven with a fixed die or the die is rotated with a fixed pan head.

- the teeth are pins in at least part of the surface, but the teeth of the press rollers press on the upper side of the die in such a way that they get as far as possible through the entry openings of the through holes.

- the through holes start from the essentially horizontal upper side of the die and run perpendicularly through it.

- the entire annular top of the die is provided with through holes between the teeth, the shape and size of which depends on the material to be machined.

- a vertical axis leads through the center of the die to the pan head.

- tapered press rollers are used, which are freely rotatable. They are mounted on inclined axes in the pan head, which is driven by a vertical shaft.

- the die and press rollers are provided with a toothing as in the case of angular drives or bevel gears, the teeth of the press rollers pressing the material between the teeth of the die and into the through holes arranged there, and at the same time tearing and tearing fibrous or flat material when pressed between the teeth rub the tooth flanks and on the base of the matrix.

- the teeth do not need to run the entire length of the line of contact between the press roller and the die. Smooth surfaces of the roll and the die can also lie between them or next to them.

- the die in particular, is subject to high wear, it is provided that the die be made in two parts and that the upper part, which is provided with the teeth and the entry openings of the through holes, be easily connected to the lower part.

- This also makes it possible to provide the lower part with special heating and / or cooling devices in order to influence the temperature of the material and to line the through holes in the lower part with ceramic bushings or bushings made of a special material to prevent the pellet strands from sliding in the Improve holes especially with aggressive media.

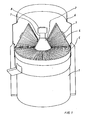

- a drive for a vertical shaft is accommodated in a gear housing 1. These parts are not shown.

- the vertical shaft rotates the pan head 2, on which 3 conical press rollers 4 are arranged on inclined axes, which are pressed by the pan head 2 against the flat die 5, which is firmly supported on the gear housing 1.

- a pressure device 8 for the pan head 2 sits on the vertical shaft 7.

- the press rollers 4 When the Köllerköpfs 2 rotate, the press rollers 4, whose teeth also grip material with a coarse structure, roll on the die 5.

- the space in which the press rollers 4 work is surrounded by a funnel 6 in which the material to be processed is poured in from above.

- two press rolls 4 In the pelletizing machine shown, two press rolls 4 are shown. However, three or four press rolls can also be used.

- a pelletizing machine of the type shown with four press rolls can be designed for a large material throughput and can be used for pelletizing straw, for example.

- both the die and the press rollers are provided with toothings which engage in one another, as shown in FIG. 2.

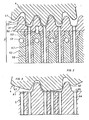

- the die 5 is composed of an upper part 51 and a lower part 52, which are secured against one another by pins 53 or in a similar manner.

- the teeth 41 on the press roller 4 engage between the teeth 54 on the upper part 51.

- the inlet openings of the through holes 56, 57 are arranged between the teeth 54.

- the through holes 57 are surrounded by ceramic bushings 58 in the region of the lower part 52.

- the lower part 52 also contains channels 59 through which a heating or cooling medium can circulate.

- the material falling on the press roller 4 or the die 5 is taken along by the teeth and compressed between teeth 41, 54. It is stretched and broken and rubbed between the tooth flanks, which destroys coarse structures.

- the reduction in the free space between two flanks of the teeth 54 by the penetration of a tooth 41 creates a high pressure in the material, which is thereby pressed into the inlet opening 55 and further into the through hole 56, 57, where the pellet is formed and as a result of the friction is further solidified on the perforated wall.

- the pressure applied during processing and the friction of the material on the surfaces of the die can lead to a strong increase. cause warming. It can therefore be expedient to protect the die 5 from overheating by means of a coolant in the channels 59.

- the introduction of a heating medium into the channels 59 can be expedient in order to remove material that is in the passages 56, 57 when the device is switched off. solidifies or becomes very hard to soften before starting the machine again.

- Ceramic bushings 58 are advantageous if the material to be machined contains aggressive constituents which attack the die, which is usually made of steel, and would produce a very rough surface of the through holes 57 at least after some time.

- the channels 59 and the bushes 58 can be dispensed with, and the teeth and the size of the passages 56, 57 have to be adapted to the respective use.

- the teeth prevent the material from jamming in front of the press rolls and improve the size reduction of the material.

- the teeth 61 of the press roller 4 are widened to approximately twice the pitch.

- a wide surface 63 corresponding to the tip circle of the teeth 61 can roll over a plurality of through holes 56 or over holes with a very large diameter and press the material into them.

- the teeth 62 of the die 5 can have a width or pitch as in FIG. 2.

- a large number of entry openings for the through holes into which the pre-comminuted and, if appropriate, previously ground and mixed material is pressed through the peripheral surface parts 63 can still be accommodated in the flat top side 64 of the die 5.

- the design of the teeth and the holes is to be selected according to the material being treated, although conical press rolls according to FIG. 1 are also preferred for designs according to this example.

- conical pressure rollers with a toothing of rollers and die as in FIG. 2 were used.

- the outside diameter of the die was approx. 760 mm, the height of the teeth approx. 10 mm.

- the die was tempered to prevent the material from melting and overheating.

- dies with diameters of approximately 300 to 1600 mm with correspondingly large press rolls can be used, teeth with a particularly large height being usable.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Manufacture And Refinement Of Metals (AREA)

- Disintegrating Or Milling (AREA)

- Steroid Compounds (AREA)

- Press Drives And Press Lines (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

- Encapsulation Of And Coatings For Semiconductor Or Solid State Devices (AREA)

- Glanulating (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84113946T ATE40076T1 (de) | 1983-11-25 | 1984-11-17 | Pelletiermaschine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3342657A DE3342657C2 (de) | 1983-11-25 | 1983-11-25 | Pelletiermaschine |

| DE3342657 | 1983-11-25 |

Publications (4)

| Publication Number | Publication Date |

|---|---|

| EP0143414A2 true EP0143414A2 (fr) | 1985-06-05 |

| EP0143414A3 EP0143414A3 (en) | 1986-09-10 |

| EP0143414B1 EP0143414B1 (fr) | 1989-01-18 |

| EP0143414B2 EP0143414B2 (fr) | 1992-11-19 |

Family

ID=6215252

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84113946A Expired - Lifetime EP0143414B2 (fr) | 1983-11-25 | 1984-11-17 | Machine à agglomérer |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0143414B2 (fr) |

| AT (1) | ATE40076T1 (fr) |

| DE (2) | DE3342657C2 (fr) |

| DK (1) | DK158070C (fr) |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4824352A (en) * | 1987-10-16 | 1989-04-25 | Hadley Richard S | Apparatus for pelletizing materials |

| WO1995025623A1 (fr) * | 1994-03-23 | 1995-09-28 | Bresch Entsorgung Gmbh | Dispositif permettant de liberer le gaz propulseur contenu dans des materiaux cellulaires expanses et procede faisant appel audit dispositif |

| EP1049533A1 (fr) * | 1998-01-23 | 2000-11-08 | Crop Care Australasia Pty. Ltd. | Jeu de combinaison mathematique |

| EP1541328A1 (fr) * | 2002-07-19 | 2005-06-15 | Zhanbin Che | Procede et dispositif permettant de mettre en forme une matiere en vrac provenant d'une matiere premiere vegetale |

| CN1327944C (zh) * | 2003-11-20 | 2007-07-25 | 登封电厂集团铝合金有限公司 | 对辊制团机 |

| WO2012080574A1 (fr) * | 2010-12-17 | 2012-06-21 | Teknologian Tutkimuskeskus Vtt | Presse à disque |

| EP2548724A1 (fr) * | 2011-07-18 | 2013-01-23 | Zaklady Urzadzen Kotlowych Staporkow Spolka Akcyjna | Dispositif pour la fabrication d'un combustible solide sous la forme d'un profil et procédé pour la fabrication d'un combustible solide |

| EP2594393A1 (fr) * | 2011-11-21 | 2013-05-22 | ZUK-MR System Sp. z o.o. | Outil de formage d'un dispositif de fabrication de granulés combustibles ou de granulés alimentaires pour animaux |

| EP2543503A3 (fr) * | 2011-07-04 | 2013-06-05 | NCT GmbH | Procédé et dispositif destinés à la production simultanée de plusieurs brins à partir d'un matériau moulable |

| ITPI20130008A1 (it) * | 2013-02-14 | 2014-08-14 | Giuseppe Calderani | Gruppo di compressione con ruote coniche per pellettatrice |

| EP2774751A1 (fr) * | 2013-03-04 | 2014-09-10 | Amandus Kahl GmbH & Co. KG | Matrice plate et procédé de détachement d'un composant de la plaque de pressage d'un corps de matrice |

| KR20150119887A (ko) * | 2013-02-22 | 2015-10-26 | 마그 아우토매틱 게엠베하 | 파쇄롤러 조립기 및 그 사용 |

| KR20170080667A (ko) * | 2014-11-05 | 2017-07-10 | 마그 아우토매틱 게엠베하 | 스퀴징-롤러 조립기, 스퀴징-롤러를 포함하는 조립 시스템 및 스퀴징-롤러 조립기의 용도 |

| CN115025718A (zh) * | 2022-07-25 | 2022-09-09 | 安徽环态生物能源科技开发有限公司 | 一种颗粒成型机用可柔性调节的压辊机构 |

| CN116943529A (zh) * | 2023-09-12 | 2023-10-27 | 广州宝韩科技有限公司 | 一种生物质颗粒加工装置及加工工艺 |

| CN118268085A (zh) * | 2024-06-04 | 2024-07-02 | 济南金曰公路工程有限公司 | 一种用于复合改性沥青的橡胶粉生产设备 |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3711379A1 (de) * | 1987-04-04 | 1988-10-20 | Hoelter Heinz | Pelletisierpresse |

| DE3806945C2 (de) * | 1988-03-03 | 1995-01-26 | Kahl Amandus Maschf | Kollerpresse |

| DE4013760A1 (de) * | 1990-04-28 | 1991-10-31 | Sevar Entsorgung | Einrichtung zum formen wuerstchenfoermiger formlinge aus pastoesem schlammaterial |

| DE102007028399B4 (de) * | 2007-06-15 | 2009-09-10 | Guido Pusch | Vorrichtung zum Herstellen von brennbaren Pellets aus nachwachsenden Rohstoffen |

| CN101884894B (zh) * | 2010-06-29 | 2012-12-26 | 卢秉威 | 秸杆颗粒机 |

| EP3835048B1 (fr) | 2019-12-12 | 2024-05-08 | Johannes Wissing | Machine à granuler pourvue de matrice à déplacement en hauteur |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE317814C (fr) * | ||||

| DE613028C (de) * | 1934-01-24 | 1935-05-10 | Albert William Sizer | Formmaschine fuer Futtermittel u. dgl. |

| US3063361A (en) * | 1959-12-02 | 1962-11-13 | Emil J W Gehrke | Mobile pelletizing apparatus |

| DE1208936B (de) * | 1960-01-12 | 1966-01-13 | Harry J Immohr | Pelletisier-Pressform |

| DE1777199A1 (de) * | 1968-09-23 | 1971-03-18 | Muehlenbau Dresden Veb | Ringmatrize zum Formen von Presslingen in Futtermittelpressen |

| DE2002638A1 (de) * | 1970-01-22 | 1971-07-29 | Amandus Kahl Nachf | Verfahren und Presse zum Verpressen von Tierfutter |

| DE2151865A1 (de) * | 1970-11-11 | 1972-05-18 | Leuna Werke Veb | Vorrichtung zum Granulieren von thermoplastischen Kunststoffen und Polyolefinwachsen |

| DE2714614A1 (de) * | 1977-04-01 | 1978-10-12 | Projektierung Chem Verfahrenst | Verfahren und vorrichtung zur herstellung von produkten aus wenigstens teilweise koernigem oder pulverartigem einsatzgut |

| NL8204241A (nl) * | 1982-11-02 | 1984-06-01 | Commanditaire Vennootschap Bur | Pelleteerinrichting. |

| DE3342658A1 (de) * | 1983-11-25 | 1985-06-05 | Howaldtswerke-Deutsche Werft Ag Hamburg Und Kiel, 2300 Kiel | Matrize fuer eine pelletisiermaschine |

| DE3342659A1 (de) * | 1983-11-25 | 1985-06-05 | Howaldtswerke-Deutsche Werft Ag Hamburg Und Kiel, 2300 Kiel | Pelletisiermatrize |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE7315926U (de) * | 1973-04-26 | 1974-11-28 | Papenmeier G Kg | Granulier vorrichtung |

-

1983

- 1983-11-25 DE DE3342657A patent/DE3342657C2/de not_active Expired

-

1984

- 1984-11-17 AT AT84113946T patent/ATE40076T1/de not_active IP Right Cessation

- 1984-11-17 EP EP84113946A patent/EP0143414B2/fr not_active Expired - Lifetime

- 1984-11-17 DE DE8484113946T patent/DE3476177D1/de not_active Expired

- 1984-11-23 DK DK559284A patent/DK158070C/da not_active IP Right Cessation

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE317814C (fr) * | ||||

| DE613028C (de) * | 1934-01-24 | 1935-05-10 | Albert William Sizer | Formmaschine fuer Futtermittel u. dgl. |

| US3063361A (en) * | 1959-12-02 | 1962-11-13 | Emil J W Gehrke | Mobile pelletizing apparatus |

| DE1208936B (de) * | 1960-01-12 | 1966-01-13 | Harry J Immohr | Pelletisier-Pressform |

| DE1777199A1 (de) * | 1968-09-23 | 1971-03-18 | Muehlenbau Dresden Veb | Ringmatrize zum Formen von Presslingen in Futtermittelpressen |

| DE2002638A1 (de) * | 1970-01-22 | 1971-07-29 | Amandus Kahl Nachf | Verfahren und Presse zum Verpressen von Tierfutter |

| DE2151865A1 (de) * | 1970-11-11 | 1972-05-18 | Leuna Werke Veb | Vorrichtung zum Granulieren von thermoplastischen Kunststoffen und Polyolefinwachsen |

| DE2714614A1 (de) * | 1977-04-01 | 1978-10-12 | Projektierung Chem Verfahrenst | Verfahren und vorrichtung zur herstellung von produkten aus wenigstens teilweise koernigem oder pulverartigem einsatzgut |

| NL8204241A (nl) * | 1982-11-02 | 1984-06-01 | Commanditaire Vennootschap Bur | Pelleteerinrichting. |

| DE3342658A1 (de) * | 1983-11-25 | 1985-06-05 | Howaldtswerke-Deutsche Werft Ag Hamburg Und Kiel, 2300 Kiel | Matrize fuer eine pelletisiermaschine |

| DE3342659A1 (de) * | 1983-11-25 | 1985-06-05 | Howaldtswerke-Deutsche Werft Ag Hamburg Und Kiel, 2300 Kiel | Pelletisiermatrize |

Cited By (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4824352A (en) * | 1987-10-16 | 1989-04-25 | Hadley Richard S | Apparatus for pelletizing materials |

| WO1995025623A1 (fr) * | 1994-03-23 | 1995-09-28 | Bresch Entsorgung Gmbh | Dispositif permettant de liberer le gaz propulseur contenu dans des materiaux cellulaires expanses et procede faisant appel audit dispositif |

| JPH09503545A (ja) * | 1994-03-23 | 1997-04-08 | ブレシュ・エントゾルグング・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツング | 発泡体から発泡ガスを放出する装置および該装置を用いる方法 |

| EP1049533A1 (fr) * | 1998-01-23 | 2000-11-08 | Crop Care Australasia Pty. Ltd. | Jeu de combinaison mathematique |

| EP1049533A4 (fr) * | 1998-01-23 | 2002-11-13 | Crop Care Australasia Pty Ltd | Jeu de combinaison mathematique |

| EP1541328A1 (fr) * | 2002-07-19 | 2005-06-15 | Zhanbin Che | Procede et dispositif permettant de mettre en forme une matiere en vrac provenant d'une matiere premiere vegetale |

| EP1541328A4 (fr) * | 2002-07-19 | 2008-12-17 | Nat Huiyuan Bio Energy Dev Co | Procede et dispositif permettant de mettre en forme une matiere en vrac provenant d'une matiere premiere vegetale |

| CN1327944C (zh) * | 2003-11-20 | 2007-07-25 | 登封电厂集团铝合金有限公司 | 对辊制团机 |

| CN103402750A (zh) * | 2010-12-17 | 2013-11-20 | Vtt科技研究中心 | 盘式压机 |

| WO2012080574A1 (fr) * | 2010-12-17 | 2012-06-21 | Teknologian Tutkimuskeskus Vtt | Presse à disque |

| EP2543503A3 (fr) * | 2011-07-04 | 2013-06-05 | NCT GmbH | Procédé et dispositif destinés à la production simultanée de plusieurs brins à partir d'un matériau moulable |

| EP2548724A1 (fr) * | 2011-07-18 | 2013-01-23 | Zaklady Urzadzen Kotlowych Staporkow Spolka Akcyjna | Dispositif pour la fabrication d'un combustible solide sous la forme d'un profil et procédé pour la fabrication d'un combustible solide |

| EP2594393A1 (fr) * | 2011-11-21 | 2013-05-22 | ZUK-MR System Sp. z o.o. | Outil de formage d'un dispositif de fabrication de granulés combustibles ou de granulés alimentaires pour animaux |

| ITPI20130008A1 (it) * | 2013-02-14 | 2014-08-14 | Giuseppe Calderani | Gruppo di compressione con ruote coniche per pellettatrice |

| KR20150119887A (ko) * | 2013-02-22 | 2015-10-26 | 마그 아우토매틱 게엠베하 | 파쇄롤러 조립기 및 그 사용 |

| US20160046040A1 (en) * | 2013-02-22 | 2016-02-18 | Stefan Dahlheimer | Squeezing-roll granulator and use thereof |

| EP2958723B1 (fr) * | 2013-02-22 | 2018-10-24 | Maag Automatik GmbH | Granulateur à cylindres broyeurs et son utilisation |

| EP2774751A1 (fr) * | 2013-03-04 | 2014-09-10 | Amandus Kahl GmbH & Co. KG | Matrice plate et procédé de détachement d'un composant de la plaque de pressage d'un corps de matrice |

| KR20170080667A (ko) * | 2014-11-05 | 2017-07-10 | 마그 아우토매틱 게엠베하 | 스퀴징-롤러 조립기, 스퀴징-롤러를 포함하는 조립 시스템 및 스퀴징-롤러 조립기의 용도 |

| US11925915B2 (en) | 2014-11-05 | 2024-03-12 | Maag Automatik Gmbh | Squeezing-roll granulator, granulating system comprising same, and use of the squeezing-roll granulator |

| CN115025718A (zh) * | 2022-07-25 | 2022-09-09 | 安徽环态生物能源科技开发有限公司 | 一种颗粒成型机用可柔性调节的压辊机构 |

| CN116943529A (zh) * | 2023-09-12 | 2023-10-27 | 广州宝韩科技有限公司 | 一种生物质颗粒加工装置及加工工艺 |

| CN118268085A (zh) * | 2024-06-04 | 2024-07-02 | 济南金曰公路工程有限公司 | 一种用于复合改性沥青的橡胶粉生产设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| DK559284D0 (da) | 1984-11-23 |

| EP0143414B2 (fr) | 1992-11-19 |

| DK559284A (da) | 1985-05-26 |

| DE3476177D1 (en) | 1989-02-23 |

| ATE40076T1 (de) | 1989-02-15 |

| DE3342657C2 (de) | 1986-11-06 |

| DE3342657A1 (de) | 1985-06-05 |

| EP0143414B1 (fr) | 1989-01-18 |

| EP0143414A3 (en) | 1986-09-10 |

| DK158070C (da) | 1990-08-20 |

| DK158070B (da) | 1990-03-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0143414B1 (fr) | Machine à agglomérer | |

| DE19523704C2 (de) | Vorrichtung zur mechanischen Behandlung von hochkonsistentem Faserstoff | |

| DE3816842C2 (fr) | ||

| AT380829B (de) | Schneckenpresse nach dem baukastenprinzip | |

| DE2633041A1 (de) | Verfahren und vorrichtung zum behandeln eines lignozellulose enthaltenden grundmaterials | |

| DE2837463A1 (de) | Vorrichtung zum selbsttaetigen, regelmaessigen einziehen von elastomerem material in schneckenpressen | |

| EP0143415B1 (fr) | Dispositif d'agglomération à deux étapes | |

| DE1502243A1 (de) | Schneckenpresse | |

| WO2015044050A1 (fr) | Dispositif granulateur | |

| DE69714474T2 (de) | Verfahren und vorrichtung zur herstellung von einem bürstenring | |

| DE4345567B4 (de) | Streumaschine zum Streuen von beleimtem Streugut zu Streugutmatten in einer Anlage zur Herstellung von Holzwerkstoffplatten | |

| DE4302850B9 (de) | Streumaschine zum Streuen von beleimtem Streugut zu Streugutmatten in einer Anlage zur Herstellung von Holzwerkstoffplatten | |

| EP0565823B1 (fr) | Presse pour la déshydratation de matières par compression | |

| DE2940956A1 (de) | Verdichtungs-walzwerk | |

| DE19610576A1 (de) | Kollerverdichtervorrichtung | |

| DE1937547A1 (de) | Verfahren und Vorrichtung zum Granulieren von duroplastischen Pressmassen | |

| DE4034610C2 (de) | Brikettierpresse für Stroh, Holzspäne und dgl. | |

| DE9101212U1 (de) | Vorrichtung zur zubereitung von futtermitteln, insbesondere fuer zootiere | |

| DE3418850A1 (de) | Vorrichtung zur druckbehandlung von fleisch | |

| DE1461012C3 (de) | Vonchtung zum Zerfasern von Papierstoff | |

| DE8333893U1 (de) | Pelletisiermaschine | |

| DE19846935C1 (de) | Vorrichtung zur Erzeugung von Granalien oder Pastillen aus fließfähigem Material | |

| DE2344231C2 (de) | Mischwerkzeuge bei Vorrichtungen zum Beleimen von Fasern und Verfahren hierzu | |

| DE3014802C2 (de) | Schleifer zum Herstellen von Holzschliff | |

| DE315772C (fr) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19861001 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: BLOHM + VOSS AG |

|

| 17Q | First examination report despatched |

Effective date: 19871204 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19890118 Ref country code: BE Effective date: 19890118 |

|

| REF | Corresponds to: |

Ref document number: 40076 Country of ref document: AT Date of ref document: 19890215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3476177 Country of ref document: DE Date of ref document: 19890223 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19891117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19891130 Ref country code: CH Effective date: 19891130 |

|

| 26 | Opposition filed |

Opponent name: HOELTER GMBH Effective date: 19891006 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: HOELTER GMBH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19921119 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) |

Effective date: 19921216 |

|

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930817 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19930927 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19931116 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19931119 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19931130 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19941117 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941118 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 84113946.2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19950601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19941117 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19950731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19950801 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84113946.2 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |