EP0129162A2 - Procédé pour fermer les extrémités d'un manchon de scellage pour un rouleau de tapis et une machine de fermeture pour la mise en oeuvre du procédé - Google Patents

Procédé pour fermer les extrémités d'un manchon de scellage pour un rouleau de tapis et une machine de fermeture pour la mise en oeuvre du procédé Download PDFInfo

- Publication number

- EP0129162A2 EP0129162A2 EP84106551A EP84106551A EP0129162A2 EP 0129162 A2 EP0129162 A2 EP 0129162A2 EP 84106551 A EP84106551 A EP 84106551A EP 84106551 A EP84106551 A EP 84106551A EP 0129162 A2 EP0129162 A2 EP 0129162A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- carpet roll

- sleeve

- quill

- carpet

- plastic plug

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B25/00—Packaging other articles presenting special problems

- B65B25/14—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form

- B65B25/146—Packaging paper or like sheets, envelopes, or newspapers, in flat, folded, or rolled form packaging rolled-up articles

- B65B25/148—Jumbo paper rolls

Definitions

- the present invention relates to a method for closing the end pieces of a sealing cover for a carpet roll and a sealing machine for carrying out the method.

- the packaging material is placed so that it overlaps, and the longitudinal edge is sealed with an adhesive tape or otherwise, whereby the packaging forms a sealing envelope open at both ends.

- the present invention aims to instruct a method for closing the end pieces of a sealing cover for a carpet roll, the closing process being carried out by machine.

- Another purpose of the invention is to instruct a sealing machine to carry out the method.

- Claim 3 describes a particularly simple way of introducing a carpet roll in a capping machine and the height control of the lifting table.

- the process described in claim 4 ensures that the function of the sealing machine can be coupled to the packaging machine.

- the process described in claim 5 ensures that the sleeve can be positioned in relation to a charger for plastic plugs.

- Claim 6 describes a useful design of the locking bracket.

- Claim 7 describes a useful design of the quill.

- a carpet roll 1 consists of a carpet that has been rolled up on a tube made of plastic or cardboard in a packaging machine.

- a sealing sleeve 3 is placed around the carpet roll, which is created by wrapping the carpet roll in the packaging machine with a packaging material that is normally made of plastic and overlapping, after which the longitudinally running edge is sealed in a suitable manner, for example with adhesive tape.

- the sealing cover is open at both ends and must be closed so that the sealing cover, as shown in Fig. 2, also covers the end pieces of the carpet roll.

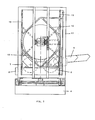

- the carpet roll is brought from a packaging machine, not shown, via a chute 5 to a closing machine.

- a capping machine according to the invention has two support rollers 6 and 7, which run in the longitudinal direction of the machine and are rotatably mounted on a lifting table 8, which is adjustable in height, whereby the center line of Carpet rolls that lie on the support rolls and have different diameters on the Center line can be aligned by two quills 9 each attached to the ends of the machine.

- One support roller 6 is a drive roller which is operated by a geared motor 10.

- the sleeves 9 are each mounted on a carriage 11.

- the sleeves are rotatably suspended on a shaft 12 and can be tilted into an inclined, upward loading position by means of a compressed air cylinder 13.

- the carriages 11 are mounted on wheels that run on rails. They can be moved towards and away from a carpet roll fitted in the machine by means of a motor 14 with a worm drive 15 and a gearwheel which engages with a toothed rack.

- a frame 17 is mounted at the front of each carriage. As can be seen most clearly from FIG. 7, the upper locking clips 16 and the lower locking clips 18 are mounted in each frame.

- the locking brackets can be moved towards and away from each other on vertical guide rods 19.

- the guide rods of the upper and lower locking brackets are staggered so that the locking brackets can get past each other.

- the lower locking bars have the shape of a V; the upper ones have the shape of an inverted V.

- the tips are rounded and are in a vertical symmetrical plane to the machine and a carpet roll.

- the locking brackets can conveniently be operated by chain drive of compressed air cylinders mounted on the frame.

- the open end pieces of a sealing cover 3 are folded over the end pieces of the associated carpet roll 1, and excess material is stuffed into the end of the tube 2 on which the carpet is rolled up.

- a plastic plug 20 is then inserted into each end of the tube.

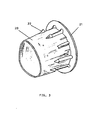

- Fig. 3 shows an embodiment of such a plastic stopper.

- the plug is in the form of a cylindrical ring with a collar 21 and cams or barbs 22 which hold the plug in position in the tube.

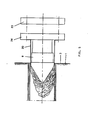

- a quill 9 has a fixed flange 23 and a flange 24 which is slidable on the quill and has an advanced position as shown in Fig. 4 and a retracted position as in Fig. 5 shown, can take.

- the flange is normally in the advanced position against a stop device, not shown, by means of a spring 25.

- the sleeves are provided at the end with a tapered part 26, followed by a short cylindrical part 27 with a diameter that corresponds to the inside diameter of a plastic plug 20, and then a cylindrical part 28 with a smaller diameter. This ensures that a plastic plug slides easily over the sleeve and away from it.

- a plastic plug which has been applied to the quill in its oblique, upward-facing position, therefore lies with its flange 21 against the flange 24.

- the locking bracket grips the open end pieces of a sealing sleeve over the End pieces of a carpet roll have put together the excess material so that it forms an approximate cylinder 29 which protrudes a short distance beyond the closing bracket.

- the sleeves 9 are each moved towards the ends of the carpet roll by a compressed air cylinder 30.

- the end piece 26 of the sleeve 9 enters the end of the cylindrical material 29, whereby the material is caught between the part 26 of the sleeve on one side and the plastic plug 20 on the other side.

- the cylinder 29 retains its cylindrical shape even after the striker has moved apart.

- the sleeve 9 therefore presses the material of the cylinder 29 into the end piece of the tube 2.

- the sleeve 9 centers and smoothes the packaging material in the pipe end, after which the plastic plug 20 is moved into the sleeve by the continued movement of the sleeve Tube is pushed into it.

- the quill is then withdrawn.

- the quills 9 can also be positioned so that the end 26 of the quill has been inserted into the end of the cylinder 29 before the carpet roll is rotated.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Containers And Plastic Fillers For Packaging (AREA)

- Package Closures (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DK2771/83 | 1983-06-16 | ||

| DK277183A DK277183D0 (da) | 1983-06-16 | 1983-06-16 | Fremgangsmade til lukning af enderne af en forseglingspose til en taepperulle og en lukkemaskine til gennemfoerelse af fremgangsmaden |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0129162A2 true EP0129162A2 (fr) | 1984-12-27 |

| EP0129162A3 EP0129162A3 (fr) | 1986-02-05 |

Family

ID=8115604

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84106551A Withdrawn EP0129162A3 (fr) | 1983-06-16 | 1984-06-07 | Procédé pour fermer les extrémités d'un manchon de scellage pour un rouleau de tapis et une machine de fermeture pour la mise en oeuvre du procédé |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0129162A3 (fr) |

| DK (1) | DK277183D0 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19547833A1 (de) * | 1995-12-21 | 1997-07-03 | Voith Sulzer Finishing Gmbh | Vorrichtung und Verfahren zur Herstellung eines Transportverbundes für Schmalrollen |

| EP0962389A1 (fr) * | 1998-06-01 | 1999-12-08 | Fuji Photo Film Co., Ltd. | Procédé et dispositif d'emballage pour articles cylindriques |

| IT201600131568A1 (it) * | 2016-12-28 | 2018-06-28 | A T F Automazioni Tessili Frigerio S R L | Metodo e dispositivo di imballaggio per rotoli di materiale in foglio |

| CN108792088A (zh) * | 2018-08-01 | 2018-11-13 | 珠海市中亚包装设备有限公司 | 端封装置和薄膜包装机 |

| CN112455918A (zh) * | 2020-12-18 | 2021-03-09 | 江苏中烟工业有限责任公司 | 一种加热卷烟再造烟叶存储结构及在线收卷系统和方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1460498A (en) * | 1974-05-02 | 1977-01-06 | Nippon Kokan Kk | Method and apparatus for packaging cylindrical objects |

| NL7906771A (nl) * | 1978-05-16 | 1980-03-18 | Darwen Equipment Makers Ltd | Inrichting voor het afdichten van de uiteinden van papieren of kunsstof wikkels. |

| JPS58125422A (ja) * | 1981-12-14 | 1983-07-26 | 友和産業株式会社 | 金属コイル端面包装装置 |

-

1983

- 1983-06-16 DK DK277183A patent/DK277183D0/da not_active Application Discontinuation

-

1984

- 1984-06-07 EP EP84106551A patent/EP0129162A3/fr not_active Withdrawn

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19547833A1 (de) * | 1995-12-21 | 1997-07-03 | Voith Sulzer Finishing Gmbh | Vorrichtung und Verfahren zur Herstellung eines Transportverbundes für Schmalrollen |

| DE19547833C2 (de) * | 1995-12-21 | 1998-10-08 | Voith Sulzer Finishing Gmbh | Transportverbund für Schmalrollen, Verfahren zu dessen Herstellung und Vorrichtung zur Durchführung des Verfahrens |

| EP0962389A1 (fr) * | 1998-06-01 | 1999-12-08 | Fuji Photo Film Co., Ltd. | Procédé et dispositif d'emballage pour articles cylindriques |

| US6192656B1 (en) | 1998-06-01 | 2001-02-27 | Fuji Photo Film Co., Ltd. | Method of and apparatus for packaging cylindrical article |

| IT201600131568A1 (it) * | 2016-12-28 | 2018-06-28 | A T F Automazioni Tessili Frigerio S R L | Metodo e dispositivo di imballaggio per rotoli di materiale in foglio |

| CN108792088A (zh) * | 2018-08-01 | 2018-11-13 | 珠海市中亚包装设备有限公司 | 端封装置和薄膜包装机 |

| CN108792088B (zh) * | 2018-08-01 | 2024-04-09 | 珠海市中亚科技有限公司 | 端封装置和薄膜包装机 |

| CN112455918A (zh) * | 2020-12-18 | 2021-03-09 | 江苏中烟工业有限责任公司 | 一种加热卷烟再造烟叶存储结构及在线收卷系统和方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DK277183D0 (da) | 1983-06-16 |

| EP0129162A3 (fr) | 1986-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1278327B (de) | Vorrichtung zum Stapeln und Einwickeln von Muenzen, Spielmarken od. dgl. in eine Folie | |

| EP0025923A1 (fr) | Procédé et dispositif pour la production automatique de saucisses en chapelets en utilisant des enveloppes synthétiques comme boyaux | |

| CH644814A5 (de) | Verfahren und vorrichtung zum oeffnen von gefalteten, gebundenen oder gehefteten mehrblaettrigen erzeugnissen, insbesondere druckprodukten. | |

| EP0386409A2 (fr) | Procédé d'emballage de manchons tubulaires plissés dans un filet tubulaire pour le traitement ultérieur en boyaux pour une machine de bourrage automatique de saucisses | |

| DE2632853C2 (de) | Vorrichtung zum Herstellen von Beuteln aus einer zweilagigen Bahn aus thermoplastischem Material | |

| DE2250667C3 (de) | Vorrichtung zum Aufrichten von flachgefalteten Verpackungskartons in eine viereckige Füllstellung | |

| DE3115956A1 (de) | Vorrichtung zum verpacken von gefluegel in plastikbeutel | |

| DE3040398C2 (de) | Verfahren zum Auswechseln eines fertigen Wickels gegen einen leeren Wickelkern in einer Doppeltragwalzenwickelmaschine sowie Vorrichtung zur Durchführung des Verfahrens | |

| DE4421661B4 (de) | Vorrichtung zum Längsumreifen eines Gut-Stapels von Zeitschriften, Magazinen, Kartonagen o. dgl. | |

| EP0129162A2 (fr) | Procédé pour fermer les extrémités d'un manchon de scellage pour un rouleau de tapis et une machine de fermeture pour la mise en oeuvre du procédé | |

| DE3707877C2 (fr) | ||

| DE2422000C2 (de) | Verfahren und Vorrichtung zum Verpacken eines auf einer Palette angeordneten, großvolumigen Verpackungsguts | |

| DE2806343C2 (de) | Verfahren zum Überziehen einer Schrumpffolienhaube über Stückgut und Vorrichtung zur Durchführung des Verfahrens | |

| DE2207043A1 (de) | Verfahren und Vorrichtung zum kontinu lerhchen Herstellen von Beuteln aus dünn wandigem thermoplastischem Folienschlauch | |

| EP1294634B1 (fr) | Procede et dispositif pour faire tourner et detendre des ressorts | |

| DE766078C (de) | Verfahren zum Einhuellen von Pralinen oder aehnlichen Gegenstaenden | |

| DE684840C (de) | Vorrichtung zum Herstellen von Papiersaecken | |

| DE2334577A1 (de) | Tragebeutel und vorrichtung zu dessen aufrichtung | |

| DE1936892B2 (de) | Maschine zum einschlagen von palettenlasten in schrumpffolie | |

| DE1535986C3 (de) | Vorrichtung zum selbsttätigen Umhüllen eines Kunstseidenwickels | |

| DE10361551B4 (de) | Vorrichtung zur Verkleidung von Produkten mit dehnbaren Manschetten | |

| DE2529157C3 (de) | Vorrichtung zum Verschließen von Verpackungsbehältern | |

| DE69707987T2 (de) | Verfahren und Vorrichtung zum Aufrichten flach gefalteter schlauchförmiger Zuschnitte | |

| DE558108C (de) | Vorrichtung zum Hochrichten und Wiederumlegen von Schachtelscheiden fuer Schiebeschachteln | |

| DE1274432B (de) | Maschine zum Herstellen von gezwickelten Schlauchstuecken mit einer Klappe und Manschette |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE DE GB NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): BE DE GB NL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19861006 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: NIELSEN, HENNING SCHODT Inventor name: HANSEN, HENRIK VANG |