CN101332580B - 抛光装置和抛光方法 - Google Patents

抛光装置和抛光方法 Download PDFInfo

- Publication number

- CN101332580B CN101332580B CN2008101285883A CN200810128588A CN101332580B CN 101332580 B CN101332580 B CN 101332580B CN 2008101285883 A CN2008101285883 A CN 2008101285883A CN 200810128588 A CN200810128588 A CN 200810128588A CN 101332580 B CN101332580 B CN 101332580B

- Authority

- CN

- China

- Prior art keywords

- rubbing head

- sand belt

- substrate

- wafer

- oscillating motion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims description 15

- 238000005498 polishing Methods 0.000 title abstract description 37

- 230000033001 locomotion Effects 0.000 claims abstract description 76

- 230000007246 mechanism Effects 0.000 claims abstract description 46

- 239000000758 substrate Substances 0.000 claims abstract description 44

- 239000004065 semiconductor Substances 0.000 claims abstract description 10

- 239000004576 sand Substances 0.000 claims description 118

- 230000007306 turnover Effects 0.000 claims description 3

- 238000012546 transfer Methods 0.000 description 19

- 239000002245 particle Substances 0.000 description 10

- 239000000463 material Substances 0.000 description 7

- 238000012360 testing method Methods 0.000 description 6

- 239000012530 fluid Substances 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 4

- 230000004087 circulation Effects 0.000 description 4

- 230000008859 change Effects 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 210000002469 basement membrane Anatomy 0.000 description 2

- 230000002950 deficient Effects 0.000 description 2

- 229910003460 diamond Inorganic materials 0.000 description 2

- 239000010432 diamond Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000007517 polishing process Methods 0.000 description 2

- 238000005096 rolling process Methods 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 239000000498 cooling water Substances 0.000 description 1

- 229910052802 copper Inorganic materials 0.000 description 1

- 239000010949 copper Substances 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920005644 polyethylene terephthalate glycol copolymer Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

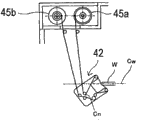

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/002—Machines or devices using grinding or polishing belts; Accessories therefor for grinding edges or bevels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B9/00—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor

- B24B9/02—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground

- B24B9/06—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/16—Machines or devices using grinding or polishing belts; Accessories therefor for grinding other surfaces of particular shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B9/00—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor

- B24B9/02—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground

- B24B9/06—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain

- B24B9/065—Machines or devices designed for grinding edges or bevels on work or for removing burrs; Accessories therefor characterised by a special design with respect to properties of materials specific to articles to be ground of non-metallic inorganic material, e.g. stone, ceramics, porcelain of thin, brittle parts, e.g. semiconductors, wafers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68707—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a robot blade, or gripped by a gripper for conveyance

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68792—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by the construction of the shaft

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Computer Hardware Design (AREA)

- Inorganic Chemistry (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Robotics (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Grinding And Polishing Of Tertiary Curved Surfaces And Surfaces With Complex Shapes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007171959 | 2007-06-29 | ||

| JP171959/2007 | 2007-06-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101332580A CN101332580A (zh) | 2008-12-31 |

| CN101332580B true CN101332580B (zh) | 2012-05-09 |

Family

ID=39816648

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2008101285883A Active CN101332580B (zh) | 2007-06-29 | 2008-06-27 | 抛光装置和抛光方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US7976361B2 (enExample) |

| EP (1) | EP2008769B1 (enExample) |

| JP (2) | JP5188285B2 (enExample) |

| KR (1) | KR101488993B1 (enExample) |

| CN (1) | CN101332580B (enExample) |

| DE (1) | DE602008005211D1 (enExample) |

| TW (1) | TWI436852B (enExample) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20110081839A1 (en) * | 2009-10-06 | 2011-04-07 | Apple Inc. | Method and apparatus for polishing a curved edge |

| US8892238B2 (en) * | 2009-10-06 | 2014-11-18 | Edward T. Sweet | Edge break details and processing |

| CN101934489B (zh) * | 2010-07-30 | 2012-10-03 | 溧阳市四方不锈钢制品有限公司 | 管坯焊缝打磨机 |

| JP5649417B2 (ja) * | 2010-11-26 | 2015-01-07 | 株式会社荏原製作所 | 固定砥粒を有する研磨テープを用いた基板の研磨方法 |

| US8540551B2 (en) * | 2010-12-15 | 2013-09-24 | Corning Incorporated | Glass edge finish system, belt assembly, and method for using same |

| CN102233536A (zh) * | 2011-05-10 | 2011-11-09 | 淄博隆嘉工贸有限公司 | 陶瓷手模自动抛光机 |

| TWI663018B (zh) * | 2012-09-24 | 2019-06-21 | 日商荏原製作所股份有限公司 | 研磨方法及研磨裝置 |

| US9339912B2 (en) | 2013-01-31 | 2016-05-17 | Taiwan Semiconductor Manufacturing Company, Ltd. | Wafer polishing tool using abrasive tape |

| JP6071611B2 (ja) * | 2013-02-13 | 2017-02-01 | Mipox株式会社 | オリエンテーションフラット等切り欠き部を有する、結晶材料から成るウエハの周縁を、研磨テープを使用して研磨することにより円形ウエハを製造する方法 |

| JP2015000451A (ja) * | 2013-06-17 | 2015-01-05 | ワイエイシイ株式会社 | 基板表面加工装置 |

| JP6113624B2 (ja) * | 2013-10-11 | 2017-04-12 | 株式会社荏原製作所 | 基板処理装置および基板処理方法 |

| CN105196140B (zh) * | 2015-10-20 | 2017-05-31 | 慈溪市华表机械有限公司 | 一种外圆超精机 |

| EP3335832B1 (en) * | 2016-12-15 | 2021-02-03 | Ebara Corporation | Polishing apparatus and pressing pad for pressing polishing tool |

| JP6920849B2 (ja) * | 2017-03-27 | 2021-08-18 | 株式会社荏原製作所 | 基板処理方法および装置 |

| JP6974067B2 (ja) * | 2017-08-17 | 2021-12-01 | 株式会社荏原製作所 | 基板を研磨する方法および装置 |

| JP7129166B2 (ja) * | 2018-01-11 | 2022-09-01 | 株式会社荏原製作所 | 基板処理装置及び制御方法 |

| JP7226711B2 (ja) * | 2019-02-28 | 2023-02-21 | 範多機械株式会社 | 斫り装置 |

| CN110405587B (zh) * | 2019-07-29 | 2024-12-24 | 周口市超越科技电子有限公司 | 一种马达电枢自动抛光机 |

| CN111745504B (zh) * | 2020-05-20 | 2022-06-21 | 深圳市裕展精密科技有限公司 | 打磨机构、打磨装置及打磨方法 |

| CN111941201B (zh) * | 2020-08-21 | 2021-12-07 | 许昌学院 | 一种用于法布里-珀罗干涉仪镜板的高精度制造装置 |

| CN114619338B (zh) * | 2022-03-28 | 2024-11-15 | 南通市睿联环保设备有限公司 | 一种扫地车液压杆生产装置 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1977361A (zh) * | 2005-04-19 | 2007-06-06 | 株式会社荏原制作所 | 基底处理设备 |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2837342B2 (ja) * | 1993-12-13 | 1998-12-16 | 日本ミクロコーティング株式会社 | 研磨装置 |

| JP3081140B2 (ja) | 1995-09-21 | 2000-08-28 | 日本ミクロコーティング株式会社 | 研磨テープによる研磨装置 |

| NO306765B1 (no) * | 1998-04-03 | 1999-12-20 | Grobi As | Anordning for kantrunding av hull i et arbeidsstykke |

| US6685539B1 (en) * | 1999-08-24 | 2004-02-03 | Ricoh Company, Ltd. | Processing tool, method of producing tool, processing method and processing apparatus |

| US6629875B2 (en) * | 2000-01-28 | 2003-10-07 | Accretech Usa, Inc. | Machine for grinding-polishing of a water edge |

| JP4156200B2 (ja) * | 2001-01-09 | 2008-09-24 | 株式会社荏原製作所 | 研磨装置及び研磨方法 |

| JP2003220546A (ja) * | 2002-01-24 | 2003-08-05 | Soken Kogyo Kk | ベルト式研磨装置 |

| JP4090247B2 (ja) * | 2002-02-12 | 2008-05-28 | 株式会社荏原製作所 | 基板処理装置 |

| JP4125148B2 (ja) * | 2003-02-03 | 2008-07-30 | 株式会社荏原製作所 | 基板処理装置 |

| WO2005081301A1 (en) * | 2004-02-25 | 2005-09-01 | Ebara Corporation | Polishing apparatus and substrate processing apparatus |

| KR101249430B1 (ko) * | 2004-10-15 | 2013-04-03 | 가부시키가이샤 에바라 세이사꾸쇼 | 폴리싱장치 및 폴리싱방법 |

| JP2006142388A (ja) * | 2004-11-16 | 2006-06-08 | Nihon Micro Coating Co Ltd | 研磨テープ及び方法 |

| JP5196709B2 (ja) * | 2005-04-19 | 2013-05-15 | 株式会社荏原製作所 | 半導体ウエハ周縁研磨装置及び方法 |

| US20090017733A1 (en) * | 2005-04-19 | 2009-01-15 | Ebara Corporation | Substrate processing apparatus |

| EP1976806A4 (en) * | 2005-12-09 | 2011-08-10 | Applied Materials Inc | METHOD AND DEVICE FOR PROCESSING A SUBSTRATE |

| US7993485B2 (en) * | 2005-12-09 | 2011-08-09 | Applied Materials, Inc. | Methods and apparatus for processing a substrate |

| WO2007126815A2 (en) * | 2006-03-30 | 2007-11-08 | Applied Materials, Inc. | Methods and apparatus for polishing an edge of a subtrate |

| JP2008036783A (ja) * | 2006-08-08 | 2008-02-21 | Sony Corp | 研磨方法および研磨装置 |

| JP2008284684A (ja) * | 2007-05-21 | 2008-11-27 | Applied Materials Inc | 研磨アームを使用して基板の縁部を研磨する方法及び装置 |

-

2008

- 2008-06-16 US US12/213,186 patent/US7976361B2/en active Active

- 2008-06-19 TW TW097122820A patent/TWI436852B/zh active

- 2008-06-19 JP JP2008160380A patent/JP5188285B2/ja active Active

- 2008-06-23 DE DE602008005211T patent/DE602008005211D1/de active Active

- 2008-06-23 EP EP08011343A patent/EP2008769B1/en active Active

- 2008-06-27 CN CN2008101285883A patent/CN101332580B/zh active Active

- 2008-06-27 KR KR20080061705A patent/KR101488993B1/ko active Active

-

2012

- 2012-12-14 JP JP2012273699A patent/JP5525590B2/ja active Active

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1977361A (zh) * | 2005-04-19 | 2007-06-06 | 株式会社荏原制作所 | 基底处理设备 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5525590B2 (ja) | 2014-06-18 |

| EP2008769A1 (en) | 2008-12-31 |

| US7976361B2 (en) | 2011-07-12 |

| US20090004952A1 (en) | 2009-01-01 |

| KR101488993B1 (ko) | 2015-02-02 |

| DE602008005211D1 (de) | 2011-04-14 |

| EP2008769B1 (en) | 2011-03-02 |

| CN101332580A (zh) | 2008-12-31 |

| TWI436852B (zh) | 2014-05-11 |

| TW200932423A (en) | 2009-08-01 |

| KR20090004590A (ko) | 2009-01-12 |

| JP2013075358A (ja) | 2013-04-25 |

| JP2009028892A (ja) | 2009-02-12 |

| JP5188285B2 (ja) | 2013-04-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101332580B (zh) | 抛光装置和抛光方法 | |

| US6306016B1 (en) | Wafer notch polishing machine and method of polishing an orientation notch in a wafer | |

| CN102941522B (zh) | 抛光装置 | |

| TW200810881A (en) | Methods and apparatus for polishing an edge of a substrate | |

| US20080293334A1 (en) | Methods and apparatus for using a bevel polishing head with an efficient tape routing arrangement | |

| KR102063157B1 (ko) | 스프링 연마장치 | |

| CN1289281A (zh) | 研磨装置及研磨方法 | |

| US6220940B1 (en) | Micro-finishing apparatus | |

| JP2009016759A (ja) | 半導体ウェーハ端面研磨装置およびこれに用いる研磨ヘッド | |

| JPH11198009A (ja) | 薄板円板状ワークの両面研削装置および断面形状測定装置 | |

| CN216179321U (zh) | 一种砂带打磨机 | |

| JP4078183B2 (ja) | デバイスウェハの周辺部研磨装置 | |

| JPH0724720A (ja) | 両端軸状部研磨装置 | |

| KR200424875Y1 (ko) | 연마필름을 이용한 평면폴리싱장치 | |

| JP3888618B2 (ja) | ロッド端面加工装置 | |

| CN107443213B (zh) | 一种可翻转的xy轴全伺服砂带机 | |

| KR200414569Y1 (ko) | 자동연마장치 | |

| CN108436674B (zh) | 异型工件自调整磨削装置及磨削方法 | |

| CN219853787U (zh) | 一种恒力浮动砂带机 | |

| KR200208032Y1 (ko) | 리니어 모션가이드가 설치된 초정밀 연마기 | |

| JP2929227B2 (ja) | ワーク研摩機 | |

| JP2007007818A (ja) | 研磨加工方法および研磨加工装置 | |

| CN121104843A (zh) | 磨抛设备 | |

| JPH02232159A (ja) | 平面研磨方法及び装置 | |

| JP2002096262A (ja) | 研削装置及び被加工物の保持方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |