WO2021201164A1 - 拡散部材、面光源装置および表示装置 - Google Patents

拡散部材、面光源装置および表示装置 Download PDFInfo

- Publication number

- WO2021201164A1 WO2021201164A1 PCT/JP2021/014012 JP2021014012W WO2021201164A1 WO 2021201164 A1 WO2021201164 A1 WO 2021201164A1 JP 2021014012 W JP2021014012 W JP 2021014012W WO 2021201164 A1 WO2021201164 A1 WO 2021201164A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- light

- light source

- optical element

- unit

- diffusing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133602—Direct backlight

- G02F1/133606—Direct backlight including a specially adapted diffusing, scattering or light controlling members

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

- B32B15/09—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B33/00—Layered products characterised by particular properties or particular surface features, e.g. particular surface coatings; Layered products designed for particular purposes not covered by another single class

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/02—Physical, chemical or physicochemical properties

- B32B7/023—Optical properties

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21S—NON-PORTABLE LIGHTING DEVICES; SYSTEMS THEREOF; VEHICLE LIGHTING DEVICES SPECIALLY ADAPTED FOR VEHICLE EXTERIORS

- F21S2/00—Systems of lighting devices, not provided for in main groups F21S4/00 - F21S10/00 or F21S19/00, e.g. of modular construction

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V3/00—Globes; Bowls; Cover glasses

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V5/00—Refractors for light sources

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V5/00—Refractors for light sources

- F21V5/02—Refractors for light sources of prismatic shape

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V5/00—Refractors for light sources

- F21V5/04—Refractors for light sources of lens shape

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V7/00—Reflectors for light sources

- F21V7/22—Reflectors for light sources characterised by materials, surface treatments or coatings, e.g. dichroic reflectors

- F21V7/28—Reflectors for light sources characterised by materials, surface treatments or coatings, e.g. dichroic reflectors characterised by coatings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V9/00—Elements for modifying spectral properties, polarisation or intensity of the light emitted, e.g. filters

- F21V9/14—Elements for modifying spectral properties, polarisation or intensity of the light emitted, e.g. filters for producing polarised light

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21V—FUNCTIONAL FEATURES OR DETAILS OF LIGHTING DEVICES OR SYSTEMS THEREOF; STRUCTURAL COMBINATIONS OF LIGHTING DEVICES WITH OTHER ARTICLES, NOT OTHERWISE PROVIDED FOR

- F21V9/00—Elements for modifying spectral properties, polarisation or intensity of the light emitted, e.g. filters

- F21V9/20—Dichroic filters, i.e. devices operating on the principle of wave interference to pass specific ranges of wavelengths while cancelling others

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B3/00—Simple or compound lenses

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/02—Diffusing elements; Afocal elements

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/133504—Diffusing, scattering, diffracting elements

- G02F1/133507—Films for enhancing the luminance

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/133526—Lenses, e.g. microlenses or Fresnel lenses

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133602—Direct backlight

- G02F1/133603—Direct backlight with LEDs

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133602—Direct backlight

- G02F1/133605—Direct backlight including specially adapted reflectors

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133602—Direct backlight

- G02F1/133606—Direct backlight including a specially adapted diffusing, scattering or light controlling members

- G02F1/133607—Direct backlight including a specially adapted diffusing, scattering or light controlling members the light controlling member including light directing or refracting elements, e.g. prisms or lenses

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133602—Direct backlight

- G02F1/133611—Direct backlight including means for improving the brightness uniformity

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1335—Structural association of cells with optical devices, e.g. polarisers or reflectors

- G02F1/1336—Illuminating devices

- G02F1/133614—Illuminating devices using photoluminescence, e.g. phosphors illuminated by UV or blue light

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/416—Reflective

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES F21K, F21L, F21S and F21V, RELATING TO THE FORM OR THE KIND OF THE LIGHT SOURCES OR OF THE COLOUR OF THE LIGHT EMITTED

- F21Y2105/00—Planar light sources

- F21Y2105/10—Planar light sources comprising a two-dimensional array of point-like light-generating elements

- F21Y2105/14—Planar light sources comprising a two-dimensional array of point-like light-generating elements characterised by the overall shape of the two-dimensional array

- F21Y2105/16—Planar light sources comprising a two-dimensional array of point-like light-generating elements characterised by the overall shape of the two-dimensional array square or rectangular, e.g. for light panels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES F21K, F21L, F21S and F21V, RELATING TO THE FORM OR THE KIND OF THE LIGHT SOURCES OR OF THE COLOUR OF THE LIGHT EMITTED

- F21Y2113/00—Combination of light sources

- F21Y2113/10—Combination of light sources of different colours

- F21Y2113/13—Combination of light sources of different colours comprising an assembly of point-like light sources

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F21—LIGHTING

- F21Y—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES F21K, F21L, F21S and F21V, RELATING TO THE FORM OR THE KIND OF THE LIGHT SOURCES OR OF THE COLOUR OF THE LIGHT EMITTED

- F21Y2115/00—Light-generating elements of semiconductor light sources

- F21Y2115/10—Light-emitting diodes [LED]

Definitions

- the present disclosure relates to a diffusing member, a method for manufacturing a diffusing member, a surface light source device, a display device, and a dielectric multilayer film.

- Patent Document 1 JP6299811B discloses a surface light source device that emits light in a planar manner.

- the surface light source device may be used as a backlight of a liquid crystal display device.

- the surface light source device of Patent Document 1 is a direct type, and the light source faces the diffusion member.

- uneven brightness occurs due to the arrangement of the light sources.

- the non-uniformity of brightness becomes remarkable.

- An object of the present disclosure is to make the in-plane distribution of brightness sufficiently uniform while reducing the thickness of the surface light source device.

- the first diffusion member according to the present disclosure is A light diffusing part with light transmission and light diffusivity,

- the reflectance of light of a specific wavelength incident at an incident angle of 0 ° is 80% or more, and the reflectance of at least a part of the light of the specific wavelength incident at an incident angle larger than 45 ° in absolute value is A light reflecting portion smaller than 50% is provided in this order.

- the second diffusion member according to the present disclosure is A light diffusing part with light transmission and light diffusivity, A light reflecting portion having a transmittance of light of a specific wavelength incident at an incident angle of 0 ° lower than the transmittance of light of a specific wavelength incident at an incident angle larger than 0 ° is provided in this order.

- the light diffusing portion may be formed as an uneven surface forming the surface of the light reflecting portion.

- the light diffusing portion may have an uneven surface facing the side opposite to the light reflecting portion side and may be joined to the light reflecting portion.

- the light diffusing portion has an uneven surface having light diffusing property on the light diffusing portion side in the stacking direction in which the light diffusing portion and the light reflecting portion are laminated.

- the optical sheet to be included may be included.

- the light diffusing portion has light diffusing property on the side opposite to the light reflecting portion side in the stacking direction in which the light diffusing portion and the light reflecting portion are laminated.

- An optical sheet having a rough surface may be included.

- the light diffusing portion is an optical sheet having uneven surfaces having light diffusing properties on both sides in the stacking direction in which the light diffusing portion and the light reflecting portion are laminated. It may be included.

- the light diffusing portion may include a plurality of optical sheets having light diffusing properties.

- the light diffusing portion may include a microlens having a plurality of unit optical elements.

- the unit optical element may include an element surface having a normal direction inclined at an angle larger than 45 ° with respect to the stacking direction in which the light diffusing portion and the light reflecting portion are laminated.

- the unit optical element may include an element surface having a normal direction inclined at an angle of less than 45 ° with respect to the stacking direction in which the light diffusing portion and the light reflecting portion are laminated.

- a display indicating the direction in which the light diffusing portion should be arranged may be provided.

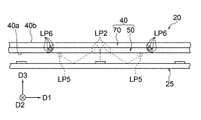

- the first and second diffusing members according to the present disclosure further include an optical element portion provided on the side of the light reflecting portion opposite to the light diffusing portion and having an uneven surface on the opposite side of the light reflecting portion. You may.

- the third diffusion member according to the present disclosure is A light diffusing part with light transmission and light diffusivity, A light reflecting part whose transmittance of light of a specific wavelength incident at an incident angle of 0 ° is lower than that of light of a specific wavelength incident at an incident angle larger than 0 °.

- An optical element portion having an uneven surface on the side opposite to the light reflecting portion is provided in this order.

- the uneven surface is an element having a normal direction inclined at an angle of 25 ° or less with respect to the stacking direction in which the light reflecting portion and the optical element portion are laminated. It may include a surface.

- the optical element portion may be joined to the light reflecting portion.

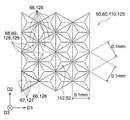

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the unit optical element may be a convex portion protruding on the opposite side of the light reflecting portion.

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the unit optical element may include an element surface having a normal direction inclined at an angle of 25 ° or less with respect to the stacking direction in which the light reflecting portion and the optical element portion are laminated.

- the element surface may form the uneven surface.

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the unit optical element may include a curved element surface, and the element surface may form the uneven surface.

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the unit optical element When observed from the stacking direction in which the optical element portion and the light reflecting portion are laminated, the unit optical element may have dimensions smaller than a 1.5 mm square.

- the optical element portion may include a microlens having a plurality of unit optical elements.

- the unit optical element may include an element surface formed as a matte surface, and the element surface may form the uneven surface.

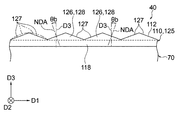

- the optical element portion may have a plurality of unit optical elements arranged in one direction. Each unit optical element may extend linearly in the other direction, which is not parallel to the one direction.

- the optical element portion may have a plurality of unit optical elements arranged in one direction. Each unit optical element may extend linearly in the other direction, which is non-parallel to the one direction.

- the unit optical element may be a convex portion protruding to the opposite side of the light reflecting portion.

- the optical element portion may have a plurality of unit optical elements arranged in one direction. Each unit optical element may extend linearly in the other direction, which is non-parallel to the one direction.

- the unit optical element may include an element surface having a normal direction inclined at an angle of 25 ° or less with respect to the stacking direction in which the light reflecting portion and the optical element portion are laminated.

- the optical element portion may have a plurality of unit optical elements arranged in one direction. Each unit optical element may extend linearly in the other direction, which is non-parallel to the one direction.

- the unit optical element may include a curved element surface, and the element surface may form the uneven surface.

- the optical element portion may have a plurality of unit optical elements arranged in one direction. Each unit optical element may extend linearly in the other direction, which is non-parallel to the one direction.

- the unit optical element may include an element surface formed as a matte surface, and the element surface may form the uneven surface.

- the surface light source device is with any of the first and third diffusion members according to the present disclosure described above, It includes a light source that emits light incident on the diffusion member.

- the light emitted from the light source may be P-polarized.

- the light source includes a plurality of light sources arranged regularly. At least one of the light diffusing portion and the optical element portion may include a microlens having a plurality of unit optical elements arranged in a direction non-parallel to the arrangement direction of the plurality of light sources.

- the light source includes a plurality of light sources arranged regularly. At least one of the light diffusing portion and the optical element portion includes a microlens having a plurality of unit optical elements.

- the unit optical element may include an element surface having a normal direction that is non-parallel to the arrangement direction of the plurality of light sources when observed from the stacking direction in which the light diffusing portion and the light reflecting portion are laminated. ..

- the surface light source device is A support substrate that supports the light source from the side opposite to the diffusion member is further provided.

- the diffusion member may further have a thermoplastic resin layer provided on the support substrate side of the light diffusion portion.

- the surface light source device is A support substrate that supports the light source from the side opposite to the diffusion member is further provided.

- the diffusion member may further have a thermoplastic resin layer provided on the support substrate side of the light diffusion portion.

- the display device according to the present disclosure includes any of the surface light source devices according to the present disclosure described above.

- the first dielectric multilayer film according to the present disclosure is A dielectric multilayer film used in combination with at least one of a diffractive optical element and a microlens.

- the reflectance of light of a specific wavelength incident at an incident angle of 0 ° is 80% or more, and the reflectance of at least a part of the light of the specific wavelength incident at an incident angle larger than 45 ° in absolute value is Less than 50%.

- the second dielectric multilayer film according to the present disclosure is A dielectric multilayer film used in combination with at least one of a diffractive optical element and a microlens.

- the transmittance of light of a specific wavelength incident at an incident angle of 0 ° is lower than the transmittance of light of the specific wavelength incident at an incident angle larger than 0 °.

- the method for manufacturing the first diffusion member according to the present disclosure is as follows.

- the present invention comprises a step of peeling the mold from a light diffusing portion composed of a cured product of the resin composition and laminated with the light reflecting portion.

- the method for manufacturing the second diffusion member according to the present disclosure is as follows.

- the present invention comprises a step of peeling the mold from a microlens or a diffractive optical element composed of a cured product of the resin composition and laminated with the dielectric multilayer film.

- the method for manufacturing the third diffusion member according to the present disclosure is as follows.

- the present invention comprises a step of curing a resin composition applied on the other surface of the dielectric multilayer film to form an optical element portion having an uneven surface on the dielectric multilayer film.

- the in-plane distribution of brightness can be sufficiently made uniform while reducing the thickness of the surface light source device.

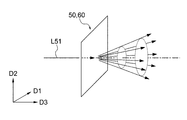

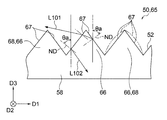

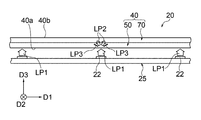

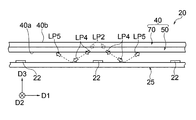

- FIG. 1 is a diagram for explaining a first specific example of the embodiment, and is a perspective view showing a display device and a surface light source device.

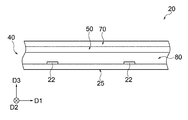

- FIG. 2 is a vertical cross-sectional view of the surface light source device of FIG.

- FIG. 3 is a plan view showing a plurality of light sources of the surface light source device of FIG.

- FIG. 4 is a graph for explaining the diffusion characteristics due to the light diffusion portion of the diffusion member that can be included in the surface light source device of FIG. 2, and shows the angular distribution of the radiation intensity.

- FIG. 5 is a perspective view showing a light diffusing portion of the diffusing member that can be included in the surface light source device of FIG. 2, and is a diagram for explaining the light diffusing characteristics of the diffractive optical element forming the light diffusing portion.

- FIG. 6 is a graph for explaining the light diffusion characteristics of the diffractive optical element of FIG. 5, and shows an angular distribution of radiant intensity.

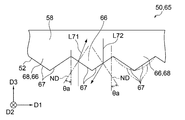

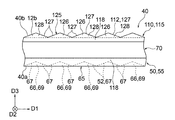

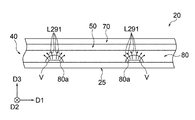

- FIG. 7 is a vertical cross-sectional view showing an example of a microlens that can be included in the surface light source device of FIG.

- FIG. 8 is a vertical cross-sectional view showing another example of the microlens that may be included in the surface light source device of FIG.

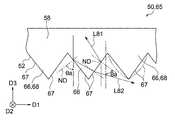

- FIG. 9 is a vertical cross-sectional view showing still another example of the microlens that may be included in the surface light source device of FIG.

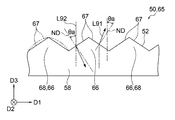

- FIG. 10 is a vertical cross-sectional view showing still another example of the microlens that may be included in the surface light source device of FIG.

- FIG. 10 is a vertical cross-sectional view showing still another example of the microlens that may be included in the surface light source device of FIG. FIG.

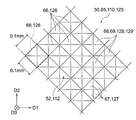

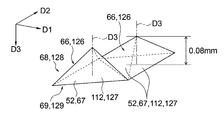

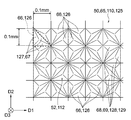

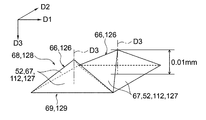

- FIG. 11A is a plan view showing an example of a specific configuration of a microlens that can be included in the surface light source device of FIG. 11B is a perspective view showing a unit optical element of the microlens of FIG. 11A.

- FIG. 12A is a plan view showing another example of a specific configuration of the microlens that may be included in the surface light source device of FIG. 12B is a perspective view showing a unit optical element of the microlens of FIG. 12A.

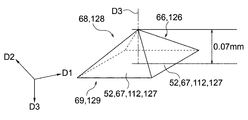

- FIG. 13A is a plan view showing an example of a specific configuration of a microlens that can be included in the surface light source device of FIG.

- FIG. 13B is a perspective view showing a unit optical element of the microlens of FIG. 13A.

- FIG. 13A is a plan view showing an example of a specific configuration of a microlens that can be included in the surface light source device of FIG.

- FIG. 13B is a perspective view showing a unit optical element of the microlen

- FIG. 14A is a plan view showing an example of a specific configuration of a microlens that can be included in the surface light source device of FIG. 14B is a perspective view showing a unit optical element of the microlens of FIG. 14A.

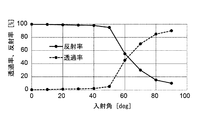

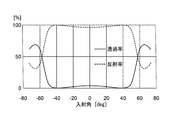

- FIG. 15 is a graph showing an example of the optical characteristics of the light reflecting portion of the diffusing member that can be included in the surface light source device of FIG. 2, and is a graph for explaining the reflection angle dependence of the reflectance and the transmittance. ..

- FIG. 16 is a graph showing another example of the optical characteristics of the light reflecting portion of the diffusing member that may be included in the surface light source device of FIG.

- FIG. 17 is a graph showing still another example of the optical characteristics of the light reflecting portion that may be included in the surface light source device of FIG.

- FIG. 18 is an enlarged graph of a part of the graph of FIG.

- FIG. 19 is a vertical cross-sectional view showing a surface light source device, and is a diagram for explaining the operation of the diffusion member and the surface light source device.

- FIG. 20 is a vertical cross-sectional view of the surface light source device corresponding to FIG. 2, and is a diagram for explaining the operation of the diffusion member and the surface light source device.

- FIG. 21 is a vertical cross-sectional view of the surface light source device corresponding to FIG. 2, and is a diagram for explaining the operation of the diffusion member and the surface light source device.

- FIG. 22 is a vertical cross-sectional view of the surface light source device corresponding to FIG. 2, and is a diagram for explaining the operation of the diffusion member and the surface light source device.

- FIG. 20 is a vertical cross-sectional view of the surface light source device corresponding to FIG. 2, and is a diagram for explaining the operation of the diffusion member and the surface light source device.

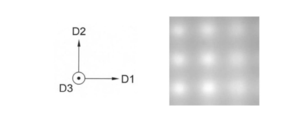

- FIG. 23A is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 1.

- FIG. 23B is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 2.

- FIG. 23C is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 3.

- FIG. 23D is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 4.

- FIG. 23E is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 5.

- FIG. 23B is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 2.

- FIG. 23C is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to

- FIG. 23F is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 6.

- FIG. 23G is a simulation result of calculating the in-plane distribution of the illuminance of the surface light source device according to the sample 7.

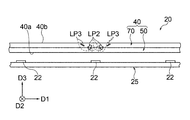

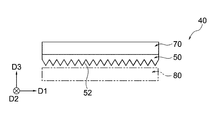

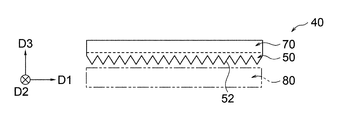

- FIG. 24 is a diagram for explaining a second specific example of the embodiment, and is a vertical cross-sectional view showing an example of a diffusion member that can be included in the surface light source device of FIG.

- FIG. 25A is a vertical cross-sectional view showing an example of a microlens that can be included in the optical element portion of the diffusion member of FIG. 24.

- FIG. 25B is a vertical cross-sectional view showing another example of a microlens that may be included in the optical element portion of the diffusion member of FIG. 24.

- FIG. 26 is a perspective view showing another example of the optical element portion of the diffusion member of FIG. 24.

- FIG. 27 is a vertical cross-sectional view of the optical element portion corresponding to FIG. 25A, and is a diagram for explaining the operation of the optical element portion.

- FIG. 28 is a vertical cross-sectional view of the surface light source device corresponding to FIG. 2, and is a diagram illustrating an example in which the diffusion member includes a thermoplastic resin layer.

- FIG. 29 is a vertical cross-sectional view of the surface light source device corresponding to FIG.

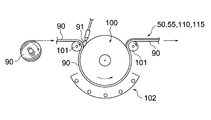

- FIG. 30 is a side view illustrating an example of a method of manufacturing a light diffusing portion and an optical element portion that can be included in the diffusing member of FIG. 2 or FIG. 24.

- FIG. 31 is a diagram illustrating an example of a layer structure of a light diffusing portion that can be included in the diffusing member of FIG. 2 or FIG. 24.

- FIG. 32 is a diagram illustrating another example of a method of manufacturing a light diffusing portion and an optical element portion that may be included in the diffusing member of FIG. 2 or FIG. 24.

- FIG. 30 is a side view illustrating an example of a method of manufacturing a light diffusing portion and an optical element portion that can be included in the diffusing member of FIG. 2 or FIG. 24.

- FIG. 33 is a diagram illustrating an example of a layer structure of a light diffusing portion that can be included in the diffusing member of FIG. 2 or FIG. 24.

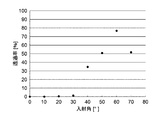

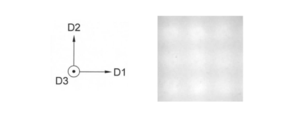

- FIG. 34 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the first embodiment.

- FIG. 35 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the second embodiment.

- FIG. 36 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the third embodiment.

- FIG. 37 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the fourth embodiment.

- FIG. 34 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the first embodiment.

- FIG. 35 is a diagram showing the in-plane distribution of the radiation intensity on the light

- FIG. 38 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the fifth embodiment.

- FIG. 39 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to the sixth embodiment.

- FIG. 40 is a diagram showing the in-plane distribution of the radiation intensity on the light emitting surface of the surface light source device according to Comparative Example 1.

- sheet is not distinguished from each other based only on the difference in designation.

- sheet is a concept that includes members that can be called “film” or “board”, and is not distinguished only by the difference in name.

- the normal direction of the sheet-shaped (sheet-shaped, plate-shaped) member refers to the normal direction of the target sheet-shaped (film-shaped, plate-shaped) member to the sheet surface.

- the "sheet surface (film surface, plate surface)” is a target sheet-like member (film-like) when the target sheet-like (film-like, plate-like) member is observed as a whole and from a broad perspective. Refers to a surface that coincides with the plane direction of the member (member, plate-shaped member).

- the first direction D1, the second direction D2, and the stacking direction D3 are indicated by arrows as common directions between the drawings.

- the tip side of the arrow is one side of each direction D1, D2, D3.

- an arrow directed toward the back of the paper along the direction perpendicular to the paper of the drawing is indicated by a symbol with an X in the circle.

- an arrow pointing from the paper surface to the front along the direction perpendicular to the paper surface of the drawing is indicated by a symbol having dots in the circle.

- FIG. 1 is a perspective view schematically showing a display device 10 as an application example of the surface light source device 20 and the diffusion member 40.

- the display device 10 displays, for example, a moving image, a still image, character information, or an image composed of a combination thereof.

- the display device 10 can be used, for example, as an in-vehicle liquid crystal display device.

- the display device 10 can be used indoors or outdoors for various purposes such as advertising, presentations, television images, and display of various information.

- the display device 10 shown in FIG. 1 has a surface light source device 20 having a light emitting surface 20a and a display panel 15 arranged so as to face the light emitting surface 20a.

- FIG. 2 is a vertical cross-sectional view showing a surface light source device 20 as a first specific example.

- the surface light source device 20 has a light source 22 and a diffusion member 40 that adjusts the optical path of the light emitted from the light source 22 as main components.

- the diffusion member 40 is arranged so as to face the light source 22. That is, the diffusion member 40 is a sheet-like member and faces the light source 22 in the normal direction thereof.

- the diffusing member 40 can effectively eliminate the unevenness of brightness caused by the presence of the light source 22 by diffusing the light emitted from the light source 22.

- the illuminance at each position on the light emitting side surface 40b of the diffusion member 40 or the illuminance at each position on the virtual light receiving surface parallel to the light emitting side surface 40b located near the light emitting side surface 40b can be made uniform.

- the diffusion member 40 described in the present embodiment is devised to sufficiently make the in-plane distribution of brightness uniform while reducing the thickness of the surface light source device 20.

- the “illuminance on the light emitting side surface 40b” used in the following description means “illuminance on the light emitting side surface 40b” or “illuminance on the light receiving surface” described above.

- the display device 10 the surface light source device 20, and the diffusion member 40 in one embodiment will be described with reference to the illustrated first specific example.

- the display panel 15 of the display device 10 will be described. As shown in FIG. 1, the display panel 15 is laminated with the surface light source device 20 in the stacking direction D3. The display panel 15 is arranged so as to face the light emitting surface 20a of the surface light source device 20. The display panel 15 has a display surface 15a on which an image is displayed as a surface facing the side opposite to the surface light source device 20 in the stacking direction D3. In the illustrated example, the display panel 15 is formed in a rectangular shape when observed from the stacking direction D3, that is, in a plan view from the front direction.

- the display panel 15 is configured as, for example, a transmissive liquid crystal display panel. A part of the light incident from the surface light source device 20 is transmitted through the display panel 15 as a liquid crystal display panel, so that an image is displayed on the display surface 15a.

- the display panel 15 includes a liquid crystal layer having a liquid crystal material. The light transmittance of the display panel 15 changes according to the strength of the electric field applied to the liquid crystal layer.

- a liquid crystal display panel having a pair of polarizing plates and a liquid crystal cell (liquid crystal layer) arranged between the pair of polarizing plates can be used.

- the polarizing plate has a polarizer.

- the polarizer decomposes the incident light into two vertical polarization components.

- the polarization component in one direction passes through the polarizer.

- the polarization component in the other direction which is perpendicular to one direction, is absorbed by the polarizer.

- the liquid crystal cell has a pair of support plates and a liquid crystal display arranged between the pair of support plates. The liquid crystal cell is configured so that an electric field can be applied to each region forming one pixel.

- the orientation of the liquid crystal in the liquid crystal cell to which an electric field is applied changes.

- the polarized light component in a specific direction emitted from the surface light source device 20 and transmitted through the polarizing plate arranged on the surface light source device 20 side of the liquid crystal cell is polarized when passing through the liquid crystal cell to which no electric field is applied. Rotate the direction 90 °.

- the polarization component in a specific direction maintains its polarization direction when passing through a liquid crystal cell to which an electric field is applied.

- Whether the polarization component in a specific direction that has passed through one polarizing plate is further transmitted through the other polarizing plate or is absorbed by the other polarizing plate and blocked is controlled by the presence or absence of an electric field applied to the liquid crystal cell. can.

- the surface light source device 20 has a light emitting surface 20a that emits planar light.

- the surface light source device 20 is configured as a direct type backlight.

- the light source 22 is provided in the region overlapping the light emitting surface 20a.

- the normal direction of the display panel 15, the normal direction of the display surface 15a, the normal direction of the light emitting surface 20a, the normal direction of the diffusion member 40, and the light diffusion portion 50 included in the diffusion member 40 which will be described later.

- the normal directions of the light reflecting portion 70 and the optical element portion 110, and the normal directions of the support substrate 25 described later that supports the light source 22 are parallel to each other. In the illustrated example, these normal directions coincide with the stacking direction D3 and are also referred to as the front direction.

- the light source 22 has a light emitting element that emits light.

- a light emitting diode is exemplified as a light emitting element.

- the light emitting diode is also referred to as an LED.

- the dimensions of the light emitting diode used as the light source 22 are not particularly limited. From the viewpoint of making the image of the light source 22 inconspicuous, a small light emitting diode, for example, a mini LED or a micro LED may be used.

- the lengths WL1 and WL2 on one side of the light source 22 having a quadrangular shape in the observation from the stacking direction D3 shown in FIG. 3 may be preferably 0.5 mm or less, more preferably 0.2 mm or less. But it may be.

- the emission wavelength of the light source 22 can be appropriately selected according to the application of the surface light source device 20.

- the surface light source device 20 may have a light emitting element that emits blue light and a light emitting element that emits yellow light, and may generate white light.

- the surface light source device 20 may include a light emitting element that emits blue light, a light emitting element that emits green light, and a light emitting element that emits red light, and may generate white light.

- one light source 22 may include a plurality of types of light emitting elements arranged close to each other, or may include only a single light emitting element. That is, a plurality of types of light sources 22 having different emission wavelengths may be used.

- the light source 22 may include a light emitting diode that emits blue light having a wavelength of 450 nm as a light emitting element.

- a light emitting diode having a large output can be used as the light source 22.

- the light source 22 may be composed of only a light emitting element.

- the light source 22 may include an optical element such as a cover or a lens that adjusts the light distribution from the light emitting element in addition to the light emitting element, or absorbs the light from the light emitting element to emit light having a different wavelength. It may contain an emitting phosphor.

- the light distribution characteristics of the light source 22 are not particularly limited.

- the light distribution characteristic of the light source 22 may be a Lambertian light distribution. With the Lambertian light distribution, the highest peak intensity is obtained in the stacking direction D3, which is the optical axis, in the emission intensity distribution from the light source 22 directed to the stacking direction D3, and the peak is obtained in a direction inclined by 60 ° from the optical axis. Half the strength is obtained.

- the peak intensity may be obtained in a direction other than the stacking direction D3.

- the bad wing light distribution disclosed in Patent Document 1 JP6299811B

- Patent Document 1 JP6299811B

- the surface light source device 20 may have a plurality of light sources 22 or may have only a single light source 22.

- the quantity of the light source 22 is appropriately selected according to the application of the surface light source device 20, the area of the light emitting surface 20a, and the like. From the viewpoint of eliminating the unevenness of brightness caused by the arrangement of the light sources 22, it is preferable that the plurality of light sources 22 included in the surface light source device 20 are regularly arranged on the surface perpendicular to the stacking direction D3.

- a plurality of light sources 22 are arranged in a honeycomb array arranged at a constant pitch in each of three directions inclined by 60 ° with each other, or in a square array arranged at a constant pitch in each of two directions perpendicular to each other. May be arranged.

- the plurality of light sources 22 are arranged at a constant pitch in each of the first direction D1 and the second direction D2 perpendicular to each other.

- the array pitch PL1 in the first direction D1 and the light distribution pitch PL2 of the light source 22 in the second direction D2 are the same.

- the example is not limited to the illustrated example, and the array pitch PL1 and the array pitch PL2 may be different.

- the first direction D1 and the second direction D2 are parallel to the side edges of the rectangular surface light source device 20 and the diffusion member 40, respectively.

- the array pitch PL1 and the array pitch PL2 of the light source 22 may be 0.2 mm or more and 10 mm or less, respectively.

- the light source 22 may emit only P-polarized light when it enters the diffusion member 40.

- the P-polarized light is light that vibrates on a surface including the traveling direction of the light when it is incident on the diffusing member 40 and the normal direction of the diffusing member 40 to the incoming light side surface 40a.

- the illustrated surface light source device 20 further has a support substrate 25 that supports the light source 22 in addition to the light source 22 and the diffusion member 40.

- the support substrate 25 supports a plurality of light sources 22 from the side opposite to the diffusion member 40 in the stacking direction D3.

- the support substrate 25 includes a circuit that supplies electric power to the light source 22.

- the support substrate 25 is a sheet-like member.

- the support substrate 25 has a light reflectivity that reflects light and directs it toward the diffusion member 40.

- the light reflectivity of the support substrate 25 is not particularly limited as long as it is exhibited with respect to the light emitted from the light source 22 or the light used for light emission by the surface light source device 20.

- the light used for light emission in the surface light source device 20 may include light emitted from the light source 22 and wavelength-converted.

- the sheet-shaped substrate main body 26, the reflective layer 27 laminated on the substrate main body 26 from the diffusion member 40 side in the stacking direction D3, and the light source 22 are electrically connected. It has a wiring 28 and.

- the substrate body 26 extends in a direction perpendicular to the stacking direction D3, and the substrate body 26 has an insulating property.

- the reflective layer 27 is reflective to the light emitted from the light source 22 or to the light used for light emission by the surface light source device 20.

- the reflectivity of the reflective layer 27 may be regular reflection, which is also called specular reflection, diffuse reflection, or anisotropic diffuse reflection.

- the substrate body 26 may be a resin film containing diffusion particles, for example, a film made of white polyethylene terephthalate.

- the reflective layer 27 may be a metal layer laminated on the substrate main body 26, or may be a reflective diffractive optical element.

- the wiring 28 is electrically connected to a terminal (not shown) of the light source 22 via solder or the like. When the substrate body 26 and the reflective layer 27 have an insulating property, the wiring 28 is preferably located between the substrate body 26 and the reflective layer 27.

- the light source 22 may be covered with the sealing material 23.

- the sealing material 23 is provided corresponding to each light source 22.

- the encapsulant 23 is two-dimensionally arranged in the same manner as the light source 22.

- the light source 22 has a surface and a side surface facing the diffusion member 40 covered with a sealing material 23.

- the sealing material 23 is fixed to the support substrate 25.

- the portion where the light source 22 and the wiring 28 are electrically connected may also be covered with the sealing material 23.

- a thermosetting resin such as a silicone resin or an epoxy resin

- a thermoplastic resin such as an olefin resin

- the diffusion member 40 is arranged on the sealing material 23. That is, the diffusion member 40 is supported by the sealing material 23 and is separated from the light source 22 and the support substrate 25 in the stacking direction D3.

- the sealing material 23 may be bonded to the diffusion member 40 by adhesion, adhesion, welding or the like.

- the distance DX shown in FIG. 2 is the distance between the light source 22 and the diffusion member 40 along the stacking direction D3. In other words, the distance DX refers to the distance along the stacking direction D3 between the surface of the light source 22 facing the diffusion member 40 side and the light incoming side surface 40a of the diffusion member 40.

- the diffusion member 40 has a light diffusion unit 50 and a light reflection unit 70 in this order.

- the light diffusing unit 50 is located on the light input side of the light to be diffused by the diffusing member 40 with the light reflecting unit 70 as a reference.

- the light reflecting unit 70 is located on the light emitting side of the light to be diffused by the diffusing member 40 with the light diffusing unit 50 as a reference.

- the diffusion member 40 has a sheet shape.

- the diffusion member 40 extends in the first direction D1 and the second direction D2 perpendicular to the stacking direction D3.

- the light diffusing portion 50 forms the light entering side surface 40a of the diffusing member 40.

- the light reflecting portion 70 forms the light emitting side surface 40b of the diffusion member 40.

- the light diffusing portion 50 and the light reflecting portion 70 may be joined to each other, may be merely in contact with each other and may not be joined to each other, and may be separated from each other. ..

- the light diffusing unit 50 has light transmissivity and light diffusing property with respect to the light emitted from the light source 22 or the light used for light emission by the surface light source device 20.

- the light diffusing unit 50 has light transmissivity and light diffusing property with respect to visible light.

- the light diffusing portion 50 may include an optical sheet 55 that is simply overlapped with another member or bonded to another member by adhesion or adhesion, may be an optical sheet 55, or may be an optical sheet 55, a member, a structure, or the like. It may be a part, or may be a surface of an optical sheet, a member, a structure, or the like.

- the total light transmittance of the light diffusing unit 50 is preferably 50% or more, more preferably 70% or more, and further preferably 90% or more.

- the utilization efficiency of the light from the light source 22 is improved.

- the light diffusing unit 50 is applied to the surface light source device 20, the in-plane distribution of the illuminance on the light emitting side surface 40b of the diffusing member 40 can be effectively made uniform. Therefore, the light diffusing unit 50 is made of a material having high transparency to the light emitted from the light source 22 or to the light used for light emission by the surface light source device 20.

- the total light transmittance is a value measured by a method based on JIS K7361-1: 1997, with the incident angle set to 0 degree.

- the total light transmittance is a value measured using an ultraviolet-visible near-infrared spectrophotometer V-7200 manufactured by JASCO Corporation.

- the light diffusivity of the light diffusing unit 50 may be isotropic diffusion or anisotropic diffusion.

- the light diffusing unit 50 may diffuse light in a direction within a specific angle range.

- the specific angle range may be one, or may be plural apart from each other.

- the diffusion by the light diffusing unit 50 is not limited to diffusing the transmitted light, and the reflected light may be diffused.

- the diffusion angle ⁇ of the light incident on the light diffusing unit 50 is preferably 10 ° or more, more preferably 15 ° or more, and further preferably 20 ° or more.

- the diffusion angle of the light incident on the light diffusion unit 50 is preferably 85 ° or less, more preferably 60 ° or less, and even more preferably 50 ° or less.

- the diffusion angle ⁇ is the half-value full width (FWHM) in the angular distribution of the radiant intensity (watt / steradian) obtained when light is incident on the light entry side surface of the light diffusion unit 50 at an incident angle of 0 °. ..

- FIG. 4 is a graph showing an angular distribution of radiation intensity on the light emitting side surface of the light diffusing portion 50 when a parallel light flux is incident on the incident side surface of the light diffusing portion 50 at an incident angle of 0 °.

- the vertical axis is the value of radiant intensity

- the horizontal axis is the emission angle.

- the half-value full width in the angular distribution of radiant intensity corresponding to each diffusion ⁇ is the width (°) of the range of the emission angle at which half of the maximum transmitted light intensity I max in the angular distribution of radiant intensity can be obtained.

- the angular distribution of radiant intensity can be measured using a variable angle photometer or a variable angle spectrophotometer.

- a variable angle photometer (goniophotometer) GP-200 manufactured by Murakami Color Technology Research Institute can be used.

- the incident angle means the angle (°) formed by the traveling direction of the incident light with respect to the normal direction of the sheet-like member to which the light is incident.

- the emission angle means an angle (°) formed by the traveling direction of the emitted light with respect to the normal direction of a member such as a sheet from which the light is emitted.

- FIG. 5 is a perspective view for explaining another preferable light diffusing characteristic of the light diffusing portion 50, which has a light diffusing property different from that of FIG.

- the light ray L51 is incident on the light diffusing portion 50 at an incident angle of 0 °. That is, the light ray L51 is vertically incident on the light diffusing portion 50.

- the light ray L51 is diffused by optical actions such as refraction, reflection, and diffraction in the light diffusing portion 50. According to the light diffusing portion 50 shown in FIG.

- the light ray L51 is mainly a circle from the apex to the bottom surface of a cone whose apex is located on the light diffusing portion 50 and whose bottom surface is arranged parallel to the light diffusing portion 50. It is traveling along the optical path toward each position on the circumference.

- the radiant intensity on the side of the light diffusing portion 50 facing the light reflecting portion 70 has a peak at an emission angle other than 0 °. ..

- the radiation intensity on the side of the light diffusing portion 50 facing the light reflecting portion 70 is the emission direction in which the emission angle is 0 °. It has a peak at an emission angle other than 0 ° in the angle distribution in any plane including.

- the absolute value of the emission angle having a peak of radiant intensity may be preferably 30 ° or more and 60 ° or less, more preferably 30 ° or more and 50 ° or less, and further preferably 30 ° or more and 45 ° or less.

- the absolute value of the emission angle of 90% or more of the light incident on the light diffusing unit 50 at an incident angle of 0 ° may be 30 ° or more and 60 ° or less.

- the absolute value of the emission angle of 95% or more of the light incident on the light diffusing unit 50 at an incident angle of 0 ° may be 30 ° or more and 60 ° or less.

- the absolute value of the emission angle of 98% or more of the light may be 30 ° or more and 60 ° or less.

- the diffusing member 40 suppresses the illuminance in the region directly above the light source 22 from becoming too high, and is perpendicular to the stacking direction D3.

- the illuminance in the region separated from the light source 22 in the above direction can be increased.

- the in-plane distribution of illuminance can be effectively made uniform.

- the reflectance of the light incident on the light reflecting unit 70 which will be described later, at an incident angle of 0 ° or more and a peak angle or less in absolute value is preferable. It is 80% or more. It is more preferably 85% or more, and further preferably 90% or more.

- the peak angle means an absolute value of an emission angle having a peak of radiant intensity.

- the solid line in FIG. 6 is a graph showing the angular distribution of the radiation intensity on the light emitting side surface of the light diffusing portion 50 shown in FIG. 5 when the incident angle of the incident light is 0 °.

- the light diffusing unit 50 is not particularly limited, and various configurations having light transmissivity and light diffusing property can be adopted.

- the light diffusing unit 50 may include at least one of a transmissive diffractive optical element 60 and a microlens 65.

- the diffractive optical element 60 is an element that exerts a diffractive action on incident light.

- the diffractive optical element 60 may be a hologram element.

- a diffractive optical element having diffractive properties for achieving the desired light diffusivity can be designed relatively easily.

- the diffractive optical element 60 may have the diffusion characteristics shown in FIG.

- the microlens 65 has a plurality of unit optical elements 66.

- the unit optical element 66 is an element that changes the traveling direction of light by refraction, reflection, or the like.

- the unit optical element 66 is a concept including an element called a unit shape element, a unit prism, and a unit lens.

- the unit optical element 66 is configured as a convex portion 68 or a concave portion 69.

- the light diffusing portion 50 has a main body portion 58, and a unit optical element 66 as a convex portion 68 is formed in the main body portion 58.

- the light diffusing portion 50 may have a main body portion 58 and a unit optical element 66 as a recess 69 provided on the main body portion 58.

- the main body 58 has a sheet shape.

- the main body 58 extends in the first direction D1 and the second direction D2 perpendicular to the stacking direction D3. In the example shown in FIG. 2, the main body portion 58 is joined to the light reflecting portion 70.

- the unit optical element 66 has an element surface 67 inclined with respect to the stacking direction D3.

- the unit optical element 66 is defined by the element surface 67.

- the microlens 65 has an uneven surface 52 formed by the element surface 67 of the unit optical element 66.

- the microlens 65 can bend the traveling direction of the incident light by the uneven surface 52.

- the uneven surface 52 may face either direction in the stacking direction D3.

- the uneven surface 52 faces the light source 22 in the stacking direction D3.

- the uneven surface 52 faces the light reflecting portion 70 in the stacking direction D3.

- the uneven surface 52 can bend the traveling direction of the light L71, L81, L91, L101 incident from the light source 22 side, and can change the traveling direction of the light L72, L82, L92, L102 incident from the light reflecting portion 70 side. Can be bent. In particular, as shown in FIGS.

- the microlens 65 bends the traveling direction of the incident light from a direction having a small inclination angle with respect to the stacking direction D3, and makes the inclination angle with respect to the stacking direction D3 larger than that at the time of incident. Can be done. That is, the inclination angle formed by the traveling direction of the light emitted from the light diffusing portion 50 with respect to the stacking direction D3 is made larger than the inclination angle formed by the traveling direction of the incident light to the light diffusing portion 50 with respect to the stacking direction D3. be able to.

- the traveling direction of the light is changed by refracting the lights L71, L72, L91, and L92 at the element surface 67.

- the traveling direction of the light is changed by reflecting the lights L82 and L101 on the element surface 67, preferably by total internal reflection.

- the change in the traveling direction due to the reflection shown in FIGS. 8 and 10 tends to be larger than the change in the traveling direction due to the refraction shown in FIGS. 7 and 9.

- the more the normal direction ND of the element surface 67 is inclined with respect to the stacking direction D3, in other words, the more the element surface 67 rises in the stacking direction D3, the more easily the light is reflected by the element surface 67.

- the normal direction ND of the element surface 67 forms an inclination angle ⁇ a larger than 45 ° with respect to the stacking direction D3

- the light not significantly inclined with respect to the stacking direction D3 is the element surface 67.

- the traveling direction of the light is greatly inclined with respect to the stacking direction D3 due to the reflection at.

- the unit optical element 66 may include an element surface 67 having a normal direction ND inclined at an inclination angle ⁇ a larger than 45 ° with respect to the stacking direction D3. .. Since the element surface 67 rises in the stacking direction D3, reflection, preferably total reflection, is likely to occur. That is, according to the unit optical element 66 including the element surface 67, the optical path of the light transmitted through the microlens 65 can be greatly bent by reflection, preferably by total reflection. By greatly adjusting the traveling direction of light, the in-plane distribution of illuminance can be more effectively homogenized.

- the diffusion characteristic of the microlens 65 is affected by the tilt angle ⁇ a of the element surface 67 of the unit optical element 66. Therefore, the cross-sectional shape of the microlens 65 can be appropriately adjusted based on the optical characteristics required for the surface light source device 20 and the diffusion member 40.

- the inclination angles ⁇ a of the plurality of element surfaces 67 included in one unit optical element 66 may be different from each other or may be the same.