WO2021090638A1 - バルブ装置 - Google Patents

バルブ装置 Download PDFInfo

- Publication number

- WO2021090638A1 WO2021090638A1 PCT/JP2020/038309 JP2020038309W WO2021090638A1 WO 2021090638 A1 WO2021090638 A1 WO 2021090638A1 JP 2020038309 W JP2020038309 W JP 2020038309W WO 2021090638 A1 WO2021090638 A1 WO 2021090638A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fluid

- valve

- housing

- spring

- valve body

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K3/00—Gate valves or sliding valves, i.e. cut-off apparatus with closing members having a sliding movement along the seat for opening and closing

- F16K3/22—Gate valves or sliding valves, i.e. cut-off apparatus with closing members having a sliding movement along the seat for opening and closing with sealing faces shaped as surfaces of solids of revolution

- F16K3/24—Gate valves or sliding valves, i.e. cut-off apparatus with closing members having a sliding movement along the seat for opening and closing with sealing faces shaped as surfaces of solids of revolution with cylindrical valve members

- F16K3/26—Gate valves or sliding valves, i.e. cut-off apparatus with closing members having a sliding movement along the seat for opening and closing with sealing faces shaped as surfaces of solids of revolution with cylindrical valve members with fluid passages in the valve member

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/08—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks

- F16K11/085—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks with cylindrical plug

- F16K11/0856—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks with cylindrical plug having all the connecting conduits situated in more than one plane perpendicular to the axis of the plug

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/08—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks

- F16K11/087—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only taps or cocks with spherical plug

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K27/00—Construction of housing; Use of materials therefor

- F16K27/04—Construction of housing; Use of materials therefor of sliding valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K27/00—Construction of housing; Use of materials therefor

- F16K27/06—Construction of housing; Use of materials therefor of taps or cocks

- F16K27/065—Construction of housing; Use of materials therefor of taps or cocks with cylindrical plugs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K27/00—Construction of housing; Use of materials therefor

- F16K27/06—Construction of housing; Use of materials therefor of taps or cocks

- F16K27/067—Construction of housing; Use of materials therefor of taps or cocks with spherical plugs

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K5/00—Plug valves; Taps or cocks comprising only cut-off apparatus having at least one of the sealing faces shaped as a more or less complete surface of a solid of revolution, the opening and closing movement being predominantly rotary

- F16K5/06—Plug valves; Taps or cocks comprising only cut-off apparatus having at least one of the sealing faces shaped as a more or less complete surface of a solid of revolution, the opening and closing movement being predominantly rotary with plugs having spherical surfaces; Packings therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K5/00—Plug valves; Taps or cocks comprising only cut-off apparatus having at least one of the sealing faces shaped as a more or less complete surface of a solid of revolution, the opening and closing movement being predominantly rotary

- F16K5/08—Details

- F16K5/14—Special arrangements for separating the sealing faces or for pressing them together

- F16K5/20—Special arrangements for separating the sealing faces or for pressing them together for plugs with spherical surfaces

Definitions

- the present disclosure relates to a valve device that performs at least one of fluid flow rate adjustment and flow path switching.

- the device comprises a housing provided with an inlet into which the cooling water is introduced and an outlet into which the cooling water is discharged, and a rotatably supported valve having a valve opening through which the cooling water supplied from the inlet flows.

- This device has a valve seat with a seat opening through which the cooling water that has passed through the valve opening flows, a cylindrical sleeve that guides the cooling water that has passed through the seat opening to the outlet, and a valve seat that is mounted around the sleeve to provide the valve seat. It has a spring that presses against the surface.

- the spring is simply arranged so as to surround the circumference of the sleeve, and the spring is liable to be misaligned. For this reason, vibration from the outside or the like causes the spring to hit the outer peripheral surface of the sleeve, and the spring and the sleeve are likely to be worn. As the wear of the spring and the sleeve progresses in this way, there is a concern that the spring force with which the spring presses the valve seat against the surface of the valve decreases and the leakage of cooling water increases. It is an object of the present disclosure to suppress wear between the spring and the sleeve.

- a valve body having a case member having a fluid outlet for flowing out fluid passing through a fluid inflow portion and a valve outlet for flowing fluid flowing in from the fluid inlet portion, and rotatably provided inside the case member.

- a tubular sleeve that is slidably supported by the inner wall of the fluid inflow portion and forms a flow path that guides the fluid flowing out from the valve outlet to the fluid outlet side of the case member, and surrounds the outer peripheral surface of the sleeve.

- the end portion of the case member opposite to the valve body side of the spring is supported by the spring end support portion formed on the end side of the spring opposite to the valve body side. To. Therefore, the misalignment of the spring can be prevented, and the wear of the spring and the sleeve can be suppressed.

- FIG. 1st Embodiment It is an overall block diagram of the cooling system in which the cooling water of the engine mounted on a vehicle circulates. It is an exploded view of the valve device which concerns on 1st Embodiment. It is sectional drawing of the valve device which concerns on 1st Embodiment. It is a partially enlarged view of FIG. It is a V arrow view in FIG. It is a VI arrow view in FIG. It is a figure which showed the state which the housing and the outlet pipe component are fastened by a tapping screw. It is sectional drawing of the 1st pipe connection part of the valve device which concerns on 2nd Embodiment. It is sectional drawing of the valve device which concerns on 3rd Embodiment. It is sectional drawing of the conventional valve device.

- FIG. 1 It is a front view of the outlet pipe component member of the valve device which concerns on 4th Embodiment. It is a figure which showed the housing of the valve device which concerns on 4th Embodiment, and is the figure which corresponds to FIG. It is a figure which showed the state which the housing and the outlet pipe component are fastened by the tapping screw of the valve device which concerns on 4th Embodiment.

- the valve device 1 of the present embodiment is used in a cooling water circuit of an engine mounted on a vehicle. As shown in FIG. 1, the valve device 1 is applied to the vehicle cooling system 9.

- the vehicle is equipped with an engine 2, a cooling system 9, a heater 6, a device 7, and the like as an internal combustion engine.

- the cooling system 9 includes a valve device 1, a water pump 4, a radiator 5, an ECU 8, and the like.

- the water pump 4 pumps the cooling water toward the water jacket 3 of the engine 2.

- the valve device 1 is provided, for example, at the outlet of the water jacket 3 of the engine 2 and adjusts the flow rate of the cooling water sent to the radiator 5, the heater 6, and the device 7.

- the radiator 5 is a heat exchanger that exchanges heat between the cooling water and air to lower the temperature of the cooling water.

- the heater 6 and the device 7 are provided between the valve device 1 and the water pump 4.

- the device 7 includes, for example, an oil cooler, an EGR cooler, and the like.

- the heater 6 heats the air inside the vehicle by exchanging heat between the cooling water and the air inside the vehicle.

- heat exchange is performed between the fluid (for example, oil, EGR gas, etc.) flowing through the device 7 and the cooling water.

- the ECU 8 can control the operation of the valve device 1 and control the flow rate of the cooling water sent to the radiator 5, the heater 6, and the device 7.

- the valve device 1 can adjust the flow rate of the cooling water as the fluid circulating in the cooling water circuit and switch the flow path.

- the cooling water for example, LLC (Long Life Coolant) containing ethylene glycol is used.

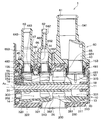

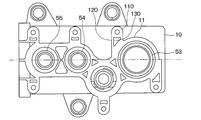

- the valve device 1 of the present embodiment includes a housing 10, an outlet pipe component 60, and a gasket 70 that seals between the valve body 30 and the outlet pipe component 60. ..

- a plurality of protrusions 65 to 67 are formed on the outlet pipe constituent member 60.

- the housing 10 and the outlet pipe component 60 are each made of resin, and the gasket 70 is made of an elastic member.

- the housing 10 and the outlet pipe component 60 form the outer shell of the valve device 1.

- the housing 10, the outlet pipe component 60, and the gasket 70 are fixed and integrated by tapping screws described later.

- the housing 10 has a housing body 11, a first bearing 18 for supporting the shaft 31, a plate 14, and the like, which form a part of the outer shell of the valve device 1.

- a storage space 13 in which the shaft 31, the valve body 30, and the like are housed is formed inside the housing body 11.

- the housing main body 11 includes a fluid inlet portion 24 for allowing the cooling water to flow into the accommodation space 13, and first to third fluid outlet portions 153 and 154 for allowing the cooling water to flow out from the accommodation space 13 to the outlet pipe constituent member 60. 155 is formed.

- the plate 14 is provided with a second bearing 19.

- the shaft 31 is rotatably supported inside the housing body 11 by its first bearing 18 and second bearing 19.

- the shaft 31 rotates about an axis by driving an electric motor (not shown) provided on the outside of the housing body 11.

- the valve body 30 is fixed to the shaft 31. Therefore, as the shaft 31 rotates, the valve body 30 rotates around the axis of the shaft 31 inside the housing body 11.

- the shaft of the shaft 31 and the rotation shaft Ax of the valve body 30 coincide with each other.

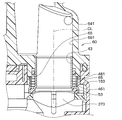

- the valve body 30 has a shaft fixing portion 300, a first cylinder portion 310, a second cylinder portion 320, a plurality of first connecting portions 330, and a plurality of second connecting portions 340.

- the shaft fixing portion 300 is fixed to the outer wall of the shaft 31.

- the first tubular portion 310 and the second tubular portion 320 are provided at positions separated radially outward from the shaft fixing portion 300.

- the first tubular portion 310 is provided on one side of the shaft 31 in the axial direction

- the second tubular portion 320 is provided on the other side of the shaft 31 in the axial direction.

- the first cylinder portion 310 the one on the right side of the paper surface in FIG. 3

- the second cylinder portion 320 is referred to as the second cylinder portion 320.

- a predetermined gap 200 is provided between the first cylinder portion 310 and the second cylinder portion 320.

- the predetermined gap 200 is provided at a position corresponding to the fluid inlet portion 24 of the housing main body 11.

- the predetermined gap 200 between the first cylinder portion 310 and the second cylinder portion 320 and the fluid inlet portion 24 of the housing body 11 are in directions perpendicular to the rotation axis Ax of the valve body 30. It is provided so that at least a part of it overlaps when viewed from the viewpoint.

- a spherical surface 311 is formed on the outer wall of the first tubular portion 310.

- a first valve outlet 373 from which the cooling water flows out is provided on a part of the spherical surface 311.

- the plurality of first connecting portions 330 extend radially between the end of the first tubular portion 310 on the side of the second tubular portion 320 and the shaft fixing portion 300, and the first tubular portion 310 and the shaft fixing portion 300 Are connected.

- a first valve inflow port 381 is formed between the plurality of first connecting portions 330.

- the first valve inflow port 381 is the first cylinder portion of the valve body 30 from the space inside the housing body 11 (specifically, a predetermined gap 200 between the first cylinder portion 310 and the second cylinder portion 320). It is an inflow port where cooling water flows into the space 331 inside the 310.

- two spherical surfaces 321 and 322 having different center points are formed on the outer wall of the second tubular portion 320.

- the second valve outlet 374 is provided on one spherical surface 321 and the third valve outlet 375 is provided on the other spherical surface 322. It is provided.

- the plurality of second connecting portions 340 extend radially between the end portion of the second tubular portion 320 on the side of the first tubular portion 310 and the shaft fixing portion 300, and the second tubular portion 320 and the shaft fixing portion 300 Are connected.

- a second valve inflow port 382 is formed between the plurality of second connecting portions 340.

- the second valve inflow port 382 is the second cylinder portion of the valve body 30 from the space inside the housing body 11 (specifically, a predetermined gap 200 between the first cylinder portion 310 and the second cylinder portion 320). It is an inflow port where cooling water flows into the space 332 inside the 320.

- both the first valve inflow port 381 and the second valve inflow port 382 of the valve body 30 are provided at the portions of the valve body 30 located in the rotation axis Ax direction.

- the outlet pipe component 60 has first to third fluid inflow portions 651, 652, and 653 at positions corresponding to the first to third valve outlets 373, 374, and 375 in the housing main body 11.

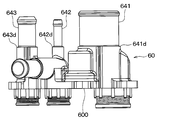

- the outlet pipe component 60 further includes first to third fluid outlets 61, 62, 63 for discharging cooling water from the outlet pipe component 60, and first to third pipe connection portions 641, 642, 643. have.

- the first to third pipe connection portions 641, 642, and 643 each have a tubular shape. Pipes (not shown) through which cooling water flows are connected to the first to third pipe connecting portions 641, 642, and 643, respectively.

- the first fluid outlet 61 is formed in the first pipe connection portion 641.

- the second fluid outlet 62 is formed in the second pipe connecting portion 642, and the third fluid outlet 63 is formed in the third pipe connecting portion 643.

- first to third fluid inflow portions 651, 652, 653 are provided with first to third sleeves 43, 44, 45, first to third seat members 53, 54, 55, etc., respectively. ..

- the first to third sleeves 43, 44, and 45 are slidably supported by the inner walls of the first to third fluid inflow portions 651, 652, and 653 included in the outlet pipe component 60.

- the first to third sleeves 43, 44, and 45 form a flow path through which cooling water flows out from the space inside the valve body 30 via the first to third valve outlets 373, 374, and 375.

- the first to third sleeves 43, 44, and 45 have first to third flange portions 461, 462, and 463 for supporting the seat members 53, 54, and 55 at the ends on the valve body 30 side, respectively. There is.

- the first to third flange portions 461, 462, and 463 extend radially outward from the first to third sleeves 43, 44, and 45 from one end on the housing body 11 side of the first to third sleeves 43, 44, and 45. It is formed like this.

- the first seat member 53 is provided between the flange portion 461 of the first sleeve 43 and the outer wall of the first cylinder portion 310 of the valve body 30.

- the second and third seat members 54 and 55 include the second and third flange portions 462 and 463 of the second and third sleeves 44 and 45, respectively, and the outer wall of the second cylinder portion 320 of the valve body 30. It is provided between.

- the first to third sheet members 53, 54, and 55 are each formed in an annular shape, and cooling water flows on the inner diameter side thereof.

- the first seat member 53 is in sliding contact with the outer wall of the first cylinder portion 310 of the valve body 30. Further, the second and third seat members 54 and 55 are in sliding contact with the outer wall of the second cylinder portion 320 of the valve body 30.

- First to third springs 481, 482, 483 are provided between the first to third flange portions 461, 462, 463 of the first to third sleeves 43, 44, 45 and the outlet pipe component 60, respectively. It is provided.

- the first to third springs 481, 482, 483 are compression coil springs, and the first to third sleeves 43, 44, 45 and the first to third seat members 53, 54, 55 are attached to the valve body 30 side. It is gaining momentum.

- first to third seat members 53, 54, 55 come into close contact with the outer wall of the tubular portion 35 of the valve body 30.

- the first to third seat members 53, 54, 55 are formed in the space formed between the inner wall of the housing body 11 and the outer wall of the valve body 30, and inside the first to third sleeves 43, 44, 45. It prevents the cooling water from leaking between the flow path and the flow path.

- the cooling water flows into the accommodation space 13 of the housing body 11 from the fluid inlet portion 24 of the housing body 11.

- the accommodation space 13 The cooling water of the water flows as follows. That is, the cooling water in the accommodation space 13 flows through the first valve inlet 381 and the second valve inlet 382 of the valve body 30 to the first to third valve outlets 373, 374, 375 of the valve body 30. ..

- the cooling water further passes through the first to third seat members 53, 54, 55 and the first to third sleeves 43, 44, 45, and then the first to third fluid outlets of the outlet pipe component 60. It flows out from 61, 62, 63.

- the cooling water is a valve. It stays in the accommodation space 13 without flowing into the first valve inflow port 381 and the second valve inflow port 382 of the body 30.

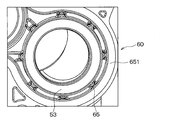

- valve devices 1 are provided at the ends of the outlet pipe constituent members 60 on the opposite sides of the first to third springs 481, 482, and 483 from the valve body 30 side, respectively. It has a first protrusion 65, eight second protrusions 66, and eight third protrusions 67.

- the first to third protrusions 65, 66, and 67 correspond to the spring end support portion.

- the valve device 1 supports the spring end portion of the outlet pipe component 60 at a portion radially outer of the end portion of the first to third springs 481, 482, 483 opposite to the valve body 30 side.

- the first to third protrusions 65, 66, and 67 are provided as an example of the portion.

- the eight first protrusions 65 support the end of the first spring 481 on the side opposite to the valve body 30 side from the radial outside of the first spring 481. Further, the eight second protrusions 66 support the end portion of the second spring 482 opposite to the valve body 30 side from the radial outside of the spring 482. Further, the eight third protrusions 67 support the end portion of the third spring 483 on the side opposite to the valve body 30 side from the radial outside of the third spring 483.

- the first to third protrusions 65, 66, and 67 are opposite to the valve body 30 side of the first to third springs 481, 482, and 483 in the outlet pipe component 60, respectively.

- the first to third springs 481, 482, and 483 project radially outward from the end of the spring.

- the first protrusion 65 projects outward in the radial direction of the first spring 481 from the end of the outlet pipe component 60 on the side opposite to the valve body 30 side of the first spring 481. ..

- the first protrusion 65 is parallel to the axis CL of the first fluid inflow portion 651 from a portion of the outlet pipe component 60 that is radially outer from the end portion of the first spring 481 opposite to the valve body 30 side. It extends to. Then, the first protrusion 65 supports the end portion of the first spring 481 on the side opposite to the valve body 30 side from the radial outside of the first spring 481.

- the axis CL of the first fluid inflow portion 651 coincides with the axis CL of the first sleeve 43.

- the configurations of the second and third protrusions 66 and 67 are substantially the same as the configurations of the first protrusion 65.

- first to third protrusions 65, 66, and 67 are inserted into the first to third fluid outlets 153, 154, and 155 formed in the housing body 11, respectively.

- the first to third protrusions 65, 66, and 67 are formed at positions where they come into contact with the inner peripheral surfaces of the first to third fluid outlets 153, 154, and 155 formed in the housing body 11.

- the first to third protrusions 65, 66, and 67 also function as guides when assembling the housing body 11 and the outlet pipe component 60.

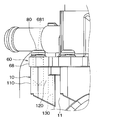

- the housing 10 and the outlet pipe component 60 are fixed by a tapping screw 80 as an example of a screw.

- the outlet pipe component 60 is formed with a screw fixing portion 68 in which a through hole 681 for inserting the tapping screw 80 is formed.

- the housing 10 includes a housing main body 11 having a flow path through which a fluid flows, a screw fastening portion 110 to which the tapping screw 80 is fastened, and a connecting portion 120 connecting the housing main body 11 and the screw fastening portion 110. have.

- the operator inserts the tapping screw 80 into the through hole 681 formed in the screw fixing portion 68, and then tightens and fixes the tapping screw 80 to the screw fastening portion 110 of the housing 10.

- the operator tightens and fixes the tapping screw 80 by cutting into the screw fastening portion 110 of the housing 10.

- the housing 10 and the outlet pipe component 60 are integrated.

- a hole 130 is formed in a connecting portion 120 that connects the housing body 11 and the screw fastening portion 110.

- the hole 130 is formed between the screw fastening portion 110 and the housing body 11.

- the hole 130 is formed so as to penetrate the connecting portion 120 in the vertical direction.

- the hole 130 is formed in the connecting portion 120 that connects the housing body 11 and the screw fastening portion 110. Therefore, when the tapping screw 80 is tightened and fixed to the screw fastening portion 110 of the housing 10, even if the screw fastening portion 110 is cracked and cracked, the crack grows along the connecting portion 120, and the hole 130 It does not stop and spread to the housing body 11 side. Therefore, leakage of the cooling water inside the housing 10 is prevented.

- the valve device 1 of the present embodiment includes a case member composed of the housing 10 and the outlet pipe component 60.

- the case members include a fluid inlet portion 24 into which a fluid flows, first to third fluid inflow portions 651, 652, 653 in which a fluid flowing in from the fluid inlet portion 24 flows, and first to third fluid inflow portions 651, 652.

- the first to third fluid outlets 61, 62, 63 which allow the fluid to flow out through 653.

- the valve device 1 has first to third valve outlets 373, 374, 375 through which the fluid flowing in from the fluid inlet portion flows, and includes a valve body 30 rotatably provided inside the case member. There is.

- valve device 1 is slidably supported by the inner wall of the fluid inflow portion, and guides the fluid flowing out from the first to third valve outlets 373, 374, and 375 to the fluid outlet side of the case member.

- the tubular first to third sleeves 43, 44, and 45 to be formed are provided.

- the valve device 1 is arranged so as to surround the outer peripheral surfaces of the first to third sleeves 43, 44, 45, and the first to third sleeves 43, 44, 45 are urged toward the valve body 30 side.

- the third springs 481, 482, 483 are provided.

- the valve device 1 is provided with a spring end support portion at an end portion of the case member on the side opposite to the valve body 30 side of the first to third springs 481, 482, 483.

- the spring end support portion has the end portion of the first to third springs 481, 482, 483 opposite to the valve body 30 side in the axial direction, which is radially outside of the first to third springs 481, 482, 483. Support from.

- the first to third springs 481, 482, 483 are formed on the end opposite to the valve body 30 side of the first to third springs 481, 482, 483 in the case member.

- the ends of the springs 481, 482, and 483 on the side opposite to the valve body 30 side in the axial direction are supported. Therefore, the first to third springs 481, 482, 483 and the first to third sleeves 43, 44, 45 do not come into contact with each other, and the misalignment of the first to third springs 481, 482, 483 is prevented. Therefore, wear of the first to third springs 481, 482, 483 and the first to third sleeves 43, 44, 45 can be suppressed.

- the spring end support portions are a plurality of spring end support portions that project toward the valve body 30 side from the end portions of the case member that are opposite to the valve body 30 side in the axial direction of the first to third springs 481, 482, 483. It has first to third protrusions 65, 66, 67. In this way, the spring end support portion can be formed by the plurality of first to third protrusions 65, 66, 67.

- the case member includes a housing 10 having a fluid inlet portion 24, and an outlet pipe component 60 having first to third fluid inflow portions 651, 652, 653 and first to third fluid outlets 61, 62, 63. And have.

- the housing 10 has first to third fluid outlets 153, 154, and 155 that introduce the fluid flowing in from the fluid inlet 24 into the first to third fluid inflows 651, 652, and 653.

- the plurality of first to third protrusions 65, 66, 67 also function as guides when assembling the housing body 11 and the outlet pipe constituent member 60 when assembling the housing 10 and the outlet pipe constituent member 60.

- the outlet pipe component 60 has a screw fixing portion 68 in which a through hole 681 for inserting the tapping screw 80 is formed.

- the housing 10 includes a housing main body 11 having a flow path through which cooling water flows, a screw fastening portion 110 to which the tapping screw 80 is fastened, and a connecting portion 120 connecting the housing main body 11 and the screw fastening portion 110. ,have.

- the housing main body 11 and the outlet pipe constituent member 60 are attached to each other. Can be assembled. A hole 130 is formed between the screw fastening portion 110 and the housing body 11.

- the tapping screw 80 is cracked on the housing main body 11 side when the tapping screw 80 is tightened and fixed to the screw fastening portion 110. Can be prevented from progressing.

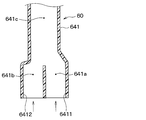

- the valve device 1 of the present embodiment includes an outlet pipe component 60 having a first pipe connecting portion 641. Further, the first pipe connecting portion 641 has a first inflow port 6411 into which the cooling water flows in, and a first flow path 641a in which the cooling water flowing in from the first inflow port 6411 flows. Further, it has a second inflow port 6412 into which the cooling water flows in, and a second flow path 641b in which the cooling water flowing in from the second inflow port 6412 flows. Further, the first pipe connecting portion 641 has a third flow path 641c through which the cooling water flowing through the first flow path 641a and the cooling water flowing through the second flow path 641b are combined to flow.

- the first flow path 641a and the second flow path 641b are formed so as to run side by side next to each other.

- first flow path 641a, the second flow path 641b, and the third flow path 641c of the first pipe connection portion 641 are not provided with right-angled portions that are perpendicular to the flow direction of the cooling water. That is, at the confluence portion where the cooling water flowing through the first flow path 641a and the cooling water flowing through the second flow path 641b merge, the first to third flow paths 641a, 641b, 641c of the first pipe connecting portion 641 are formed.

- the inner wall is formed so as to have an angle of 90 degrees or more with respect to the flow direction of the cooling water.

- the valve device 1 of the present embodiment includes an outlet pipe component 60 having a first pipe connecting portion 641 through which cooling water as a fluid flows.

- the first pipe connecting portion 641 has a first inflow port 6411 into which the cooling water flows in, and a first flow path 641a in which the cooling water flowing in from the first inflow port 6411 flows. Further, it has a second inflow port 6412 into which the cooling water flows in, and a second flow path 641b in which the cooling water flowing in from the second inflow port 6412 flows. Further, the first pipe connecting portion 641 has a third flow path 641c through which the cooling water flowing through the first flow path 641a and the cooling water flowing through the second flow path 641b are combined to flow.

- the first to third flow paths 641a, 641b, 641c of the first pipe connecting portion 641 are formed.

- the inner wall is formed so as to have an angle of 90 degrees or more with respect to the flow direction of the cooling water.

- the inner wall forming the first to third flow paths 641a, 641b, 641c of the first pipe connecting portion 641 is formed so as to be 90 degrees with respect to the flow direction of the cooling water.

- the water flow resistance can be reduced in comparison.

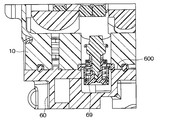

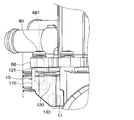

- FIGS. 9 to 10 A cross-sectional view of the valve device 1 of the present embodiment is shown in FIG. In FIG. 9, the valve device 1 is shown upside down. That is, the housing 10 is shown to be on the upper side in the vertical direction with respect to the outlet pipe constituent member 60.

- the outlet pipe component 60 of the present embodiment is provided with a relief valve 69 for suppressing the engine 2 from overheating when the electric motor that drives the shaft 31 fails.

- This relief valve 69 is arranged in the second flow path 641b of the first pipe connecting portion 641 shown in FIG. When the water temperature rises, the relief valve 69 mechanically opens to allow cooling water to flow from the third flow path 641c of the first pipe connecting portion 641 to the water jacket 3 of the engine 2.

- the outlet pipe component 60 of the present embodiment is formed with a joint surface 600 to be joined to the housing 10 and a recess 602 formed at a position recessed from the joint surface 600.

- the relief valve 69 has a flange portion 691 fixed to the outlet pipe component 60.

- the relief valve 69 is press-fitted and fixed in the recess 602 formed in the outlet pipe component 60.

- the outlet pipe component 60 is installed so that the joint surface 600 to be joined to the housing 10 of the outlet pipe component 60 faces upward in the vertical direction.

- the flange portion 691 of the relief valve 69 is press-fitted and fixed to the recess 602 formed in the outlet pipe component 60.

- the relief valve 69 is arranged so as to enter a recessed position from the joint surface 600 to be joined to the housing 10 of the outlet pipe component 60.

- the housing 10 is prepared, the housing 10 is arranged so as to cover the outlet pipe constituent member 60 from above, and the outlet pipe constituent member 60 is screwed to the housing 10.

- FIG. 1 A cross-sectional view of a conventional valve device is shown in FIG.

- the relief valve 69 is fixed to the joint surface 600 to be joined to the housing 10 of the outlet pipe component 60. Therefore, the stability of the relief valve 69 when the outlet pipe component 60 is assembled to the housing 10 is not good.

- the valve device 1 of the present embodiment includes a housing 10 and an outlet pipe component 60 having a first pipe connecting portion 641 through which cooling water as a fluid flows. Further, a relief valve 69 is provided which is arranged in the second flow path 641b of the first pipe connection portion 641 and mechanically opens and closes the second flow path 641b. Further, the outlet pipe component 60 is formed with a joint surface 600 to be joined to the housing 10 and a recess 602 formed at a position recessed from the joint surface 600. Further, the relief valve 69 has a flange portion 691 fixed to the outlet pipe constituent member 60. The relief valve 69 has a flange portion 691 fixed to a recess 602 formed in the outlet pipe constituent member 60.

- the relief valve 69 since the flange portion 691 is fixed to the recess 602 formed in the outlet pipe constituent member 60, the relief valve 69 when assembling the outlet pipe constituent member 60 to the housing 10 The stability of the can be improved.

- FIG. 11 shows a front view of the outlet pipe component 60 of the valve device according to the fourth embodiment.

- the positions of the first to third stoppers 641d, 642d, 643d formed in the first to third pipe connecting portions 641, 642, 643 are the same. That is, the lengths from the joint surface 600 of the outlet pipe component 60 to the housing 10 to the first to third stoppers 641d, 642d, and 643d are the same.

- a hose (not shown) is connected to the first to third pipe connection portions 641, 642, 643.

- the first to third stoppers 641d, 642d, 643d come into contact with the hoses attached to the first to third pipe connecting portions 641, 642, 643.

- the valve device 1 of the present embodiment includes a housing 10 and an outlet pipe component 60 in which the first to third pipe connecting portions 641, 642, 643 are formed. Further, the outlet pipe constituent member 60 is formed with first to third stoppers 641d, 642d, 643d that come into contact with the tip of the hose attached to the outlet pipe constituent member 60. The lengths of the outlet pipe component 60 from the joint surface 600 with the housing 10 to the first to third stoppers 641d, 642d, and 643d are the same.

- the valve device according to the fifth embodiment will be described with reference to FIGS. 12 to 13.

- the valve device 1 of the present embodiment is different from the valve device 1 of the first embodiment in that it further has ribs 121.

- the rib 121 is formed so as to expand in a direction orthogonal to the axial direction of the screw hole of the screw fastening portion 110.

- a hole 130 can be formed in the connecting portion 120 that connects the housing body 11 and the screw fastening portion 110.

- the spring end support portion is formed by eight protrusions 65, but the number of protrusions 65 is not limited to eight.

- a ring-shaped spring end support portion may be formed at an end portion of the outlet pipe component 60 on the side opposite to the valve body 30 side of the first to third springs 481, 482, 483. Then, by the ring-shaped spring end support portion, the end portions of the first to third springs 481, 482, 483 opposite to the valve body 30 side are arranged in the radial direction of the first to third springs 481, 482, 483. It may be supported from the outside.

- the outlet pipe component 60 of the first embodiment has a plurality of first to third protrusions 65, 66, 67 as spring end support portions.

- a plurality of first to third protrusions 65, 66, 67 as spring end support portions may be provided separately from the outlet pipe constituent member 60.

- the present disclosure is not limited to the above-described embodiment, and can be changed as appropriate. Further, the above-described embodiments are not unrelated to each other, and can be appropriately combined unless the combination is clearly impossible. Further, in each of the above embodiments, it goes without saying that the elements constituting the embodiment are not necessarily essential except when it is clearly stated that they are essential and when they are clearly considered to be essential in principle. No. Further, in each of the above embodiments, when numerical values such as the number, numerical values, amounts, and ranges of the constituent elements of the embodiment are mentioned, when it is clearly stated that they are particularly essential, and in principle, the number is clearly limited to a specific number. It is not limited to the specific number except when it is done.

- the housing 10 and the outlet pipe component 60 correspond to the case member, and the protrusions 65 to 67 correspond to the spring end support portion.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Valve Housings (AREA)

- Multiple-Way Valves (AREA)

- Sliding Valves (AREA)

- Taps Or Cocks (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202080075016.2A CN114616415B (zh) | 2019-11-07 | 2020-10-09 | 阀装置 |

| DE112020005471.3T DE112020005471T5 (de) | 2019-11-07 | 2020-10-09 | Ventilvorrichtung |

| US17/735,441 US11873909B2 (en) | 2019-11-07 | 2022-05-03 | Valve device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019202524A JP7167900B2 (ja) | 2019-11-07 | 2019-11-07 | バルブ装置 |

| JP2019-202524 | 2019-11-07 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US17/735,441 Continuation US11873909B2 (en) | 2019-11-07 | 2022-05-03 | Valve device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021090638A1 true WO2021090638A1 (ja) | 2021-05-14 |

Family

ID=75849917

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/038309 Ceased WO2021090638A1 (ja) | 2019-11-07 | 2020-10-09 | バルブ装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11873909B2 (enExample) |

| JP (1) | JP7167900B2 (enExample) |

| CN (1) | CN114616415B (enExample) |

| DE (1) | DE112020005471T5 (enExample) |

| WO (1) | WO2021090638A1 (enExample) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7172958B2 (ja) | 2019-11-07 | 2022-11-16 | 株式会社デンソー | バルブ装置 |

| US20240044418A1 (en) * | 2022-08-08 | 2024-02-08 | Hanon Systems | Electronic fluid valve system |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018169067A1 (ja) * | 2017-03-17 | 2018-09-20 | 株式会社山田製作所 | 制御バルブ |

| JP2019007614A (ja) * | 2017-06-28 | 2019-01-17 | 株式会社山田製作所 | 制御バルブ |

| US20190249786A1 (en) * | 2018-02-14 | 2019-08-15 | Fisher Controls International Llc | Ball Valve Having an Adjustable Trim Arrangement |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59191438U (ja) * | 1983-06-07 | 1984-12-19 | 中央発條株式会社 | 座板付圧縮コイルばね |

| DE3321819C1 (de) * | 1983-06-16 | 1984-07-26 | Werner Dipl.-Ing. 3167 Burgdorf Hartmann | Hahn mit kugelfoermigem Kueken |

| JPS6029939U (ja) * | 1983-08-05 | 1985-02-28 | 中央発條株式会社 | 振動減衰用座板付圧縮コイルばね |

| FR2576080B1 (fr) * | 1985-01-11 | 1987-03-20 | Europ Propulsion | Vanne a obturateur spherique |

| DE102011108430A1 (de) * | 2011-07-26 | 2012-02-09 | Horst Thiele Maschinenbau-Hydraulische Geräte GmbH | Rohrbruchventileinrichtung |

| WO2014148126A1 (ja) * | 2013-03-21 | 2014-09-25 | 日立オートモティブシステムズ株式会社 | 流量制御弁 |

| DE112014002468T5 (de) * | 2013-05-17 | 2016-02-25 | Magna Powertrain Inc. | Leichtgängiges Dichtungsverfahren für ein Temperaturregelventil |

| US9500299B2 (en) * | 2013-07-25 | 2016-11-22 | Schaeffler Technologies AG & Co. KG | Thermal management valve module with isolated flow chambers |

| JP6119875B2 (ja) * | 2013-11-25 | 2017-04-26 | 株式会社島津製作所 | 流量制御弁 |

| KR101550628B1 (ko) * | 2014-06-16 | 2015-09-07 | 현대자동차 주식회사 | 멀티 유량 제어밸브를 갖는 엔진시스템 |

| JP6432433B2 (ja) | 2014-07-07 | 2018-12-05 | 株式会社デンソー | バルブ装置 |

| EP3073161B1 (en) | 2015-03-25 | 2018-08-01 | Magna Powertrain Inc. | Multiport valve with modular rotor |

| WO2016194502A1 (ja) | 2015-06-05 | 2016-12-08 | 日立オートモティブシステムズ株式会社 | 流量制御弁 |

| DE102016203070B3 (de) * | 2016-02-26 | 2017-06-01 | Schaeffler Technologies AG & Co. KG | Anschlussstutzen und Wärmemanagementmodul mit einem solchen |

| US9835259B2 (en) * | 2016-04-16 | 2017-12-05 | Amit Shah | Top entry trunnion ball valve for safe in-line maintenance and method to facilitate such maintenance |

| JP6772991B2 (ja) * | 2016-09-27 | 2020-10-21 | 株式会社デンソー | 弁装置および冷却システム |

| JP6991708B2 (ja) * | 2016-12-13 | 2022-01-12 | キヤノン株式会社 | ばね支持装置、動力伝達装置及び画像形成装置 |

| JP7114890B2 (ja) * | 2017-12-12 | 2022-08-09 | 株式会社デンソー | 冷却水制御弁装置 |

| JP7141586B2 (ja) | 2018-05-21 | 2022-09-26 | ケイディケイ株式会社 | ラベル片付き郵便はがき及びその製造方法 |

| JP7172749B2 (ja) * | 2019-03-06 | 2022-11-16 | 株式会社デンソー | バルブ装置 |

| CN111720591B (zh) * | 2019-03-18 | 2024-06-28 | 罗伯特·博世有限公司 | 分配阀和制冷系统 |

| JP7287245B2 (ja) * | 2019-11-12 | 2023-06-06 | 株式会社デンソー | 制御弁 |

-

2019

- 2019-11-07 JP JP2019202524A patent/JP7167900B2/ja active Active

-

2020

- 2020-10-09 WO PCT/JP2020/038309 patent/WO2021090638A1/ja not_active Ceased

- 2020-10-09 CN CN202080075016.2A patent/CN114616415B/zh active Active

- 2020-10-09 DE DE112020005471.3T patent/DE112020005471T5/de active Pending

-

2022

- 2022-05-03 US US17/735,441 patent/US11873909B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018169067A1 (ja) * | 2017-03-17 | 2018-09-20 | 株式会社山田製作所 | 制御バルブ |

| JP2019007614A (ja) * | 2017-06-28 | 2019-01-17 | 株式会社山田製作所 | 制御バルブ |

| US20190249786A1 (en) * | 2018-02-14 | 2019-08-15 | Fisher Controls International Llc | Ball Valve Having an Adjustable Trim Arrangement |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114616415B (zh) | 2023-12-05 |

| US11873909B2 (en) | 2024-01-16 |

| DE112020005471T5 (de) | 2022-08-18 |

| US20220260163A1 (en) | 2022-08-18 |

| JP2021076159A (ja) | 2021-05-20 |

| JP7167900B2 (ja) | 2022-11-09 |

| CN114616415A (zh) | 2022-06-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10808856B2 (en) | Flow control valve | |

| JP2020101291A (ja) | 弁装置 | |

| JP6846076B2 (ja) | 流量制御弁および冷却システム | |

| CN108005773B (zh) | 控制阀 | |

| JP7176482B2 (ja) | バルブ装置 | |

| US11149627B2 (en) | Cooling-water control valve device | |

| CN112664679B (zh) | 阀装置 | |

| US11105430B2 (en) | Control valve | |

| CN111750137B (zh) | 控制阀 | |

| JP6995833B2 (ja) | 制御バルブ | |

| JP7785099B2 (ja) | 制御バルブ | |

| WO2021090638A1 (ja) | バルブ装置 | |

| JP7434814B2 (ja) | バルブ装置 | |

| JP7331646B2 (ja) | バルブ装置 | |

| JP2022087263A (ja) | 弁装置および冷却システム | |

| JP7185765B2 (ja) | 制御弁 | |

| JP7240185B2 (ja) | 制御弁 | |

| WO2012140879A1 (ja) | ハイブリッド建設機械 | |

| JP7756557B2 (ja) | 制御バルブ | |

| JP7142150B2 (ja) | 制御バルブ | |

| JP2012137040A (ja) | 熱交換ユニットおよびその製造方法 | |

| JP4728179B2 (ja) | 接続管を備えた内燃機関 | |

| US20250219498A1 (en) | Motor assembly, pump, and boiler including the same | |

| JP7137498B2 (ja) | 制御弁 | |

| JP2019211064A (ja) | バルブ装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20885358 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20885358 Country of ref document: EP Kind code of ref document: A1 |