WO2018079825A1 - 清掃用ドライシート - Google Patents

清掃用ドライシート Download PDFInfo

- Publication number

- WO2018079825A1 WO2018079825A1 PCT/JP2017/039306 JP2017039306W WO2018079825A1 WO 2018079825 A1 WO2018079825 A1 WO 2018079825A1 JP 2017039306 W JP2017039306 W JP 2017039306W WO 2018079825 A1 WO2018079825 A1 WO 2018079825A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- surface layer

- patterning

- fiber

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/16—Cloths; Pads; Sponges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/06—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by a fibrous or filamentary layer mechanically connected, e.g. by needling to another layer, e.g. of fibres, of paper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

- B32B5/265—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary characterised by one fibrous or filamentary layer being a non-woven fabric layer

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4326—Condensation or reaction polymers

- D04H1/435—Polyesters

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4374—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece using different kinds of webs, e.g. by layering webs

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/44—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling

- D04H1/46—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres

- D04H1/48—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres in combination with at least one other method of consolidation

- D04H1/49—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres in combination with at least one other method of consolidation entanglement by fluid jet in combination with another consolidation means

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/44—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling

- D04H1/46—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres

- D04H1/498—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties the fleeces or layers being consolidated by mechanical means, e.g. by rolling by needling or like operations to cause entanglement of fibres entanglement of layered webs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/03—3 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/20—All layers being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/40—Symmetrical or sandwich layers, e.g. ABA, ABCBA, ABCCBA

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0253—Polyolefin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0276—Polyester fibres

- B32B2262/0284—Polyethylene terephthalate [PET] or polybutylene terephthalate [PBT]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/12—Conjugate fibres, e.g. core/sheath or side-by-side

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/73—Hydrophobic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2432/00—Cleaning articles, e.g. mops or wipes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

Definitions

- the present invention relates to a dry sheet for cleaning.

- a cleaning dry sheet in which a fiber sheet is formed by entangling fibers in a resin net is known.

- Such a dry sheet for cleaning includes a sheet having an uneven pattern shape on the front surface or the back surface (for example, Patent Document 1).

- An object of the present invention is to provide a cleaning dry sheet that can exhibit excellent collection performance regardless of the weight and shape of the object to be collected.

- the invention according to claim 1 is a cleaning dry sheet comprising a plurality of layers, and is sandwiched between the fiber layers respectively provided on the front surface layer and the back surface layer.

- a non-woven fabric layer provided in an intermediate layer, and an entangled portion in which the fiber layer and the non-woven fabric layer are entangled, and the entangled portion includes a low entangled portion in the surface layer and the back layer

- a highly entangled portion having a fiber density higher than the entangled portion and entangled and formed in a concave shape is provided, and the highly entangled portion is provided at substantially the same location corresponding to the front surface layer and the back surface layer

- the fibers of the layer and the back layer have a blending ratio of polyethylene terephthalate fibers of 80% or more, the fiber diameter of the polyethylene terephthalate fibers is 3.3 dtex or more, and the highly entangled portion includes the surface layer and the back surface.

- the front layer and the back layer are provided with a high entangled portion entangled with a higher fiber density than the low entangled portion in the entangled portion, Since the fibers of the surface layer and the back surface layer are configured as described above, the surface layer and the back surface layer of the cleaning dry sheet have different fiber densities. For this reason, the collection performance and the collection characteristics are different in each of the low entangled portion and the high entangled portion having different fiber densities, and the collection objects of various weights and sizes are suitably collected at each location. can do. For this reason, the dry sheet for cleaning can be made bulky, and the collection performance can be further improved.

- the highly entangled portion is provided at substantially the same location corresponding to the front surface layer and the back surface layer, for example, when the highly entangled portion is provided at different locations, only one side is hydroentangled.

- the opposite surface side is entangled in the case, and there is no fear that the expected bulkiness cannot be obtained. That is, since the part to which the water flow is applied is a high entangled part on both sides, there is no possibility that the low entangled part is excessively entangled.

- the fiber diameter of the polyethylene terephthalate fiber which comprises a hydrophobic fiber layer is 3.3 dtex or more, the rigidity (cushion property) of a fiber improves and it can operate even with a light force.

- gap between fibers is ensured with the polyethylene terephthalate fiber of the thick fiber diameter of 3.3 dtex or more, and a to-be-collected object can be collected suitably.

- the highly entangled portion is formed with an area ratio of 20 to 90% with respect to the surface area in plan view of the front and back surfaces, the distribution and ratio of portions having different fiber densities can be made suitable.

- the fibers of the cleaning dry sheet Dust and dust can be collected alternately at high density and low density, and different high dust and dust can be collected at high and low entanglement parts. It is possible to collect different garbage and dust alternately at the low entanglement portion and to exhibit good collection performance.

- the cleaning dry sheet can exhibit excellent collection performance regardless of the weight and shape of the object to be collected.

- a cleaning dry sheet according to an embodiment of the present invention will be described with reference to FIGS.

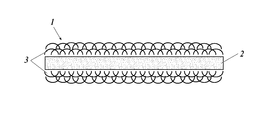

- the cleaning dry sheet 1 includes an inner layer 2 as a nonwoven fabric layer and an outer layer 3 as a fiber layer.

- the inner layer 2 is an intermediate layer sandwiched between outer layers 3 described later, and is formed of a nonwoven fabric.

- the inner layer 2 is preferably a spunbonded nonwoven fabric from the viewpoint of maintaining strength.

- the inner layer 2 is 15 (N / 5 cm) or more in the wiping direction (CD direction) on the cleaning surface of the cleaning dry sheet 1 and is in the CD direction. It is preferable that it is 35 (N / 5 cm) or more in a direction perpendicular to the direction (MD direction).

- the basis weight of the inner layer 2 is preferably set in the range of 13-20 g / m 2 .

- the wiping direction on the cleaning surface of the cleaning dry sheet is a direction orthogonal to the longitudinal direction of the jig body when the cleaning dry sheet is mounted on a predetermined jig, and is in the moving direction during cleaning. It is the direction along.

- the outer layer 3 is a layer that forms the front surface layer and the back surface layer of the cleaning dry sheet 1, and is mainly formed of hydrophobic fibers. Specifically, the hydrophobic fibers are contained in a weight ratio of 50 to 99% with respect to the total weight of the outer layer 3.

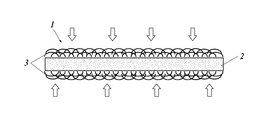

- the outer layer 3 is pre-entangled by applying water to the entire surface with a weak water pressure of less than 20 kPa and integrated with the inner layer 2, and then subjected to a first hydroentanglement with a water pressure of 20-30 kPa, and will be described later.

- a second hydroentanglement to the patterning portion 31 at a water pressure of 60-80 kPa, a shape having uneven patterning is formed.

- the water entanglement is performed by applying water from both sides to the same portion of the front surface layer and the back surface layer of the cleaning wet sheet 1.

- the patterning portion 31 is formed so as to correspond to the same location in the surface layer and the back surface layer.

- the outer layer 3 a chemical fiber mainly composed of polyethylene terephthalate, polypropylene, polyethylene or the like is applied.

- the blending ratio of the polyethylene terephthalate fiber is preferably 80% or more, and the fiber diameter is preferably 3.3 dtex or more.

- the rigidity (cushioning property) of the fiber is improved, and it can be operated even with a light force.

- interval between fibers is ensured by the polyethylene terephthalate fiber of a thick fiber diameter of 3.3 dtex or more, and to-be-collected objects, such as garbage and dust, can be collected suitably.

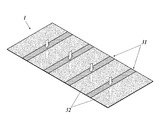

- the outer layer 3 includes a patterning portion 31 as a high entanglement portion and a non-patterning portion 32 as a low entanglement portion.

- the patterning unit 31 performs the second hydroentanglement on the outer layer 3 integrated by the first hydroentanglement, so that the fibers are entangled more than the first hydroentanglement stage. That is, the patterning portion 31 has a fiber density higher than that of the non-patterning portion 32. For this reason, the patterning portion 31 has a shape recessed more concavely than the non-patterning portion 32. That is, the patterning unit 31 includes a bottom 311 that is the bottom of the recess, and an inclined part 312 that is an inclined surface that connects the non-patterning part 32 and the bottom 311 described later.

- the outer layer 3 of the front surface layer and the back surface layer is hydroentangled from both sides at the same corresponding location. That is, the patterning portion 31 is formed at the same location corresponding to the front surface layer and the back surface layer of the outer layer 3.

- pressure is applied to the opposite side, and the fibers are crushed by pressure even though they are not entangled, and are bulky. There is no risk of decrease. For this reason, the bulkiness of the cleaning dry sheet 1 can be secured in a high state.

- the patterning unit 31 extends along a direction (MD direction) perpendicular to the direction of the wiping direction (CD direction). Further, the patterning portions 31 are formed in a plurality of rows with a predetermined interval. Further, these patterning portions 31 are formed so as to have an area ratio of 20 to 90% with respect to the surface area in plan view of the front surface or the back surface of the cleaning dry sheet 1. Specifically, in the CD direction, the area ratio is calculated using the width dimension of one patterning portion 31 and the width dimension of one non-patterning portion 32 as unit lengths. For example, when the width dimension of the patterning part 31 is 3 mm and the width dimension of the non-patterning part 32 is 12 mm, the area ratio is 20%.

- the outer layer 3 preferably has a weight per side of 20-25 g / m 2 from the viewpoint of patterning, and preferably combines two or more kinds of chemical fibers (synthetic fibers).

- the non-patterning portion 32 is a portion that is not subjected to the second hydroentanglement and is not subjected to compression other than the fiber compression due to the pre-entanglement and the first hydroentanglement, and the fiber density is lower than that of the patterning portion 31. In other words, the degree of freedom of fiber is high.

- the non-patterning portion 32 mainly slides on the surface to be cleaned during the wiping operation of the cleaning dry sheet 1. That is, it is a part that is greatly involved in the collection property of the cleaning dry sheet 1.

- the cleaning dry sheet 1 includes the collection surface in which the outer layer 3 has the patterning portions 31 with high fiber density and the non-patterning portions 32 with low fiber density arranged alternately. Moreover, the location with high fiber density has high collection performance with respect to heavy garbage, and the location with low fiber density has high collection performance with respect to lightweight waste. For this reason, it is possible to cope with the collection of both heavy and lightweight garbage with one cleaning dry sheet 1. Furthermore, in the present invention, by setting the ratio of the patterning portion 31 to the non-patterning portion 32 in the range of 20 to 80%, the balance between the collection performance of heavy waste and the collection performance of light waste is made suitable. Yes.

- the pattern layer 31 having a higher fiber density than other portions is provided in the front surface layer and the back surface layer.

- the back layer will have locations with different fiber densities. For this reason, in each location where fiber density differs, collection performance and collection characteristics differ, and it is possible to collect the collection thing of various weights and sizes suitably in each location.

- the patterning part 31 is provided in the location corresponding to a surface layer and a back surface layer, for example, when providing the patterning part 31 in a different location, it will hydroentangle only one side, but actually The opposite surface side is also entangled, and there is no fear that the expected bulkiness cannot be obtained.

- the cleaning dry sheet 1 can be made bulky, and the collection performance can be further improved.

- the patterning portion 31 is formed with an area ratio of 20-90% in plan view with respect to the front and back surfaces, the distribution and ratio of portions with different fiber densities are made suitable. Therefore, it is possible to exhibit good collection performance with respect to various kinds of garbage.

- the patterning part 31 is extended in the direction perpendicular

- the patterning unit 31 and the non-patterning 32 can collect different dust and dust, and can exhibit good collection performance.

- the spunbond nonwoven fabric is used for the inner layer 2, there is no possibility that the surface made of the resin will be damaged during cleaning as in the case of using a conventional resin net.

- the non-patterning part 32 and the patterning part 31 are formed by pre-entanglement and patterning entanglement, respectively, both can be formed by hydroentanglement, and the cleaning dry sheet 1 is manufactured by a simple method. can do. Further, for example, when the patterning portion 31 is formed by a heat roll or the like, the non-patterning portion 32 also receives pressure from the roll, so that the fibers are crushed up to the non-patterning portion 32 and the difference in fiber density is small. As a result, the diversity of collection performance cannot be secured. However, in this embodiment, since only the patterning unit 31 receives a high water pressure due to patterning entanglement, there is no such fear.

- this invention is not limited to the said embodiment and modification, Of course, it can change suitably about a specific structure.

- Example 1 In the cleaning dry sheet 1 of Example 1, a fiber web mainly composed of polyethylene terephthalate was used for the outer layer 3, and a spunbond nonwoven fabric was used for the inner layer 2.

- the hydrophobic fiber a chemical fiber mainly composed of polyethylene terephthalate, polypropylene, polyethylene, or the like is used.

- the outer layer 3 is composed of 100% hydrophobic fibers, contains 90% polyethylene terephthalate as hydrophobic fibers, and contains 10% polypropylene and polyethylene core-sheath fibers as binder fibers. .

- polyethylene terephthalate fibers having a fineness of 3.3 dtex and binder fibers having a fineness of 1.7 dtex were used.

- the width dimension of the patterning portion 31 formed in the outer layer 3 is 3 mm in the CD direction, and the width dimension of the non-patterning portion 32 is 12 mm in the CD direction. That is, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 20%.

- the width dimension of the patterning part 31 of the patterning part 31 formed in the outer layer 3 is 6 mm in the CD direction, and the width dimension of the non-patterning part 32 in the CD direction. It is formed to 6 mm. That is, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 50%.

- Example 3 In the cleaning dry sheet 1 of Example 3, the width dimension of the patterning section 31 of the patterning section 31 formed on the outer layer 3 is 12 mm in the CD direction, and the width dimension of the non-patterning section 32 is in the CD direction. It is formed to 3 mm. That is, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 80%.

- Example 4 In the cleaning dry sheet 1 of Example 4, the width dimension of the patterning section 31 of the patterning section 31 formed in the outer layer 3 is 13 mm in the CD direction, and the width dimension of the non-patterning section 32 in the CD direction. It is formed to 2 mm. That is, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 87%.

- the width dimension of the patterning part 31 of the patterning part 31 formed on the outer layer 3 is 15 mm in the CD direction, and the width dimension of the non-patterning part 32 in the CD direction. It is formed to 0 mm. That is, the area ratio of the patterning portion 31 (strictly, in this case, not the patterning portion 31 but the patterning entangled portion) in the surface area of the outer layer 3 in a plan view is 100%.

- the width dimension of the patterning portion 31 formed in the outer layer 3 is formed to be 0 mm in the CD direction, and the width dimension of the non-patterning portion 32 is formed to be 15 mm in the CD direction. ing. That is, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 0%.

- the width dimension of the patterning portion 31 formed in the outer layer 3 is 2 mm in the CD direction, and the width dimension of the non-patterning portion 32 is 14 mm in the CD direction. ing. In other words, the area ratio of the patterning portion 31 to the surface area of the outer layer 3 in plan view is 13%.

- Comparative Example 4 The cleaning dry sheet 1 of Comparative Example 4 was evaluated by changing the blending ratio of the outer layer 3 using the same fibers as in the Examples. That is, the outer layer 3 having a PET of 3.3 dtex of 70% and a binder fiber of 1.7 dtex of 30% has a width dimension of 6 mm for the patterning part and a width dimension of 6 mm for the non-patterning part (patterning rate of 50%), as in Example 2. did.

- a floor wiping test using the cleaning dry sheet 1 of Example 1-4 and Comparative Example 1-4 was performed.

- the cleaning dry sheet 1 was attached to a mounting jig for the cleaning dry sheet 1 (not shown), and the floor formed with an acrylic plate was slid and wiped.

- the mounting jig has a flat plate member attached to the tip of a rod-shaped member serving as a handle so as to be rotatable in almost all directions, and the cleaning dry sheet 1 is attached to the flat plate member.

- a weight of 450 g was attached to the flat plate member so that the pressing force between the cleaning dry sheet 1 and the floor surface became constant.

- the floor surface formed of an acrylic plate was used as a wiping surface, and it was examined how much various collected materials arranged here could be collected.

- the cleaning dry sheet 1 was moved 25 cm from the center to the right, 50 cm to the left, and 25 cm to the right again from the wiping surface having a width of 50 cm, and the wiping surface was reciprocated once.

- tests were carried out on three types of dust, sesame as heavy garbage, and hair as lightweight garbage.

- Examples 1-4 can collect 4 to 5 of 10 sesame S of heavy garbage, and 4 to 5 of hair H of lightweight trash (except Example 4). I was able to collect it. Moreover, it was confirmed that any dust can be collected well. In other words, it was found that Example 1-4 can exhibit good collecting properties, and in particular, Example 1-3 exhibits even better collecting properties. Further, in Comparative Example 1 with a patterning rate of 100%, 5 or 6 sesame S were collected in 10 grains, which was equal to or higher than Example 1-3. It was found that the collection performance with the book could hardly be demonstrated.

- the present invention can be used for cleaning dry sheets.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

- Nonwoven Fabrics (AREA)

- Laminated Bodies (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/344,794 US20200046195A1 (en) | 2016-10-31 | 2017-10-31 | Dry sheet for cleaning |

| CN201780065243.5A CN109862818A (zh) | 2016-10-31 | 2017-10-31 | 清扫用干式片材 |

| EP17865468.7A EP3533370B1 (en) | 2016-10-31 | 2017-10-31 | Dry sheet for cleaning |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016213895A JP6456898B2 (ja) | 2016-10-31 | 2016-10-31 | 清掃用ドライシートの製造方法 |

| JP2016-213895 | 2016-10-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018079825A1 true WO2018079825A1 (ja) | 2018-05-03 |

Family

ID=62023640

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/039306 Ceased WO2018079825A1 (ja) | 2016-10-31 | 2017-10-31 | 清掃用ドライシート |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20200046195A1 (enExample) |

| EP (1) | EP3533370B1 (enExample) |

| JP (1) | JP6456898B2 (enExample) |

| CN (1) | CN109862818A (enExample) |

| WO (1) | WO2018079825A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021025193A (ja) * | 2019-08-07 | 2021-02-22 | ダイワボウホールディングス株式会社 | 不織布及びその製造方法、ならびにワイパー |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6470236B2 (ja) * | 2016-08-26 | 2019-02-13 | 大王製紙株式会社 | 水解性シート及び当該水解性シートの製造方法 |

| JP6211160B1 (ja) * | 2016-09-30 | 2017-10-11 | 大王製紙株式会社 | 水解性シート |

| JP7706220B2 (ja) * | 2019-09-25 | 2025-07-11 | 大王製紙株式会社 | 清掃用シートの製造方法 |

| USD946847S1 (en) * | 2020-07-02 | 2022-03-22 | Gizmospring.com Dongguan Limited | Scrubber |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS537775B2 (enExample) | 1975-08-15 | 1978-03-22 | ||

| JP2007154359A (ja) * | 2005-12-05 | 2007-06-21 | Kao Corp | 嵩高シート |

| JP2008188853A (ja) * | 2007-02-05 | 2008-08-21 | Etsumi Kobayashi | 積層シート |

| JP2009285316A (ja) * | 2008-05-30 | 2009-12-10 | Asahi Kasei Home Products Kk | クリーナー |

| JP2014129632A (ja) * | 2012-12-29 | 2014-07-10 | Uni Charm Corp | 清掃部材を製造する方法及び装置 |

| US20140366294A1 (en) * | 2013-06-18 | 2014-12-18 | The Procter & Gamble Company | Bonded laminate cleaning implement |

| JP2015092954A (ja) * | 2013-11-11 | 2015-05-18 | 花王株式会社 | 清掃シート |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3409988B2 (ja) * | 1997-03-21 | 2003-05-26 | ユニ・チャーム株式会社 | 拭き取りシート |

| JP4824882B2 (ja) * | 2001-05-24 | 2011-11-30 | ユニ・チャーム株式会社 | 積層シート |

| US7176150B2 (en) * | 2001-10-09 | 2007-02-13 | Kimberly-Clark Worldwide, Inc. | Internally tufted laminates |

| JP2003230519A (ja) * | 2002-02-07 | 2003-08-19 | Crecia Corp | 床用清掃シート |

| JP2005074133A (ja) * | 2003-09-03 | 2005-03-24 | Daio Paper Corp | 清掃用シート |

| JP2005245715A (ja) * | 2004-03-03 | 2005-09-15 | Unitika Ltd | 主として台所用に適した拭き布 |

| JP5427926B2 (ja) * | 2008-02-01 | 2014-02-26 | 花王株式会社 | 清掃具 |

| JP2011117095A (ja) * | 2009-12-02 | 2011-06-16 | Daiwabo Holdings Co Ltd | 不織布及びそれを用いた拭き取り材 |

| US9327473B2 (en) * | 2012-10-31 | 2016-05-03 | Kimberly-Clark Worldwide, Inc. | Fluid-entangled laminate webs having hollow projections and a process and apparatus for making the same |

| JP5712195B2 (ja) * | 2012-12-04 | 2015-05-07 | 花王株式会社 | 拭き取りシート用不織布基材 |

| JP6037555B2 (ja) * | 2012-12-12 | 2016-12-07 | 株式会社ソフト99コーポレーション | ウェットシート |

| JP3189024U (ja) * | 2013-12-06 | 2014-02-20 | 株式会社メイテック | 清拭布 |

-

2016

- 2016-10-31 JP JP2016213895A patent/JP6456898B2/ja active Active

-

2017

- 2017-10-31 WO PCT/JP2017/039306 patent/WO2018079825A1/ja not_active Ceased

- 2017-10-31 CN CN201780065243.5A patent/CN109862818A/zh active Pending

- 2017-10-31 US US16/344,794 patent/US20200046195A1/en not_active Abandoned

- 2017-10-31 EP EP17865468.7A patent/EP3533370B1/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS537775B2 (enExample) | 1975-08-15 | 1978-03-22 | ||

| JP2007154359A (ja) * | 2005-12-05 | 2007-06-21 | Kao Corp | 嵩高シート |

| JP2008188853A (ja) * | 2007-02-05 | 2008-08-21 | Etsumi Kobayashi | 積層シート |

| JP2009285316A (ja) * | 2008-05-30 | 2009-12-10 | Asahi Kasei Home Products Kk | クリーナー |

| JP2014129632A (ja) * | 2012-12-29 | 2014-07-10 | Uni Charm Corp | 清掃部材を製造する方法及び装置 |

| US20140366294A1 (en) * | 2013-06-18 | 2014-12-18 | The Procter & Gamble Company | Bonded laminate cleaning implement |

| JP2015092954A (ja) * | 2013-11-11 | 2015-05-18 | 花王株式会社 | 清掃シート |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3533370A4 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021025193A (ja) * | 2019-08-07 | 2021-02-22 | ダイワボウホールディングス株式会社 | 不織布及びその製造方法、ならびにワイパー |

| JP7733437B2 (ja) | 2019-08-07 | 2025-09-03 | 大和紡績株式会社 | 不織布及びその製造方法、ならびにワイパー |

Also Published As

| Publication number | Publication date |

|---|---|

| CN109862818A (zh) | 2019-06-07 |

| US20200046195A1 (en) | 2020-02-13 |

| JP6456898B2 (ja) | 2019-01-23 |

| JP2018068780A (ja) | 2018-05-10 |

| EP3533370B1 (en) | 2024-09-11 |

| EP3533370A4 (en) | 2020-04-01 |

| EP3533370A1 (en) | 2019-09-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2018079825A1 (ja) | 清掃用ドライシート | |

| CN104159489B (zh) | 具有片材和丝束纤维之间的差微重叠的清洁制品 | |

| US7553783B2 (en) | Cleaning sheet | |

| TWI473591B (zh) | Nonwoven and its manufacturing method, and wiping material | |

| CN110719747B (zh) | 清扫用片材 | |

| US20090151100A1 (en) | Swab | |

| JP6412675B2 (ja) | 清掃用ウェットシート | |

| JP6670103B2 (ja) | 清掃用具 | |

| JP2018068780A5 (enExample) | ||

| JP4908428B2 (ja) | 可変嵩高作業表面を有するクリーニングワイプ | |

| JP2004033237A (ja) | 清掃用シート | |

| JP4226918B2 (ja) | 清掃シート | |

| JP4061254B2 (ja) | 清掃用シート | |

| TWI839394B (zh) | 擦拭片材 | |

| JP2003011068A (ja) | 研磨不織布及びその製造方法 | |

| JP6462955B2 (ja) | 清掃用ウェットシートおよび清掃用ウェットシートの製造方法 | |

| US11382482B2 (en) | Cleaning sheet | |

| JP6546528B2 (ja) | 清掃用具 | |

| JP6677676B2 (ja) | 清掃用シート | |

| JP4445368B2 (ja) | 清掃用シート | |

| JP2005074133A (ja) | 清掃用シート | |

| WO2018230287A1 (ja) | 清掃用シート及び清掃用シートの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17865468 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 2017865468 Country of ref document: EP Effective date: 20190531 |