WO2017010415A1 - 振動発生装置 - Google Patents

振動発生装置 Download PDFInfo

- Publication number

- WO2017010415A1 WO2017010415A1 PCT/JP2016/070234 JP2016070234W WO2017010415A1 WO 2017010415 A1 WO2017010415 A1 WO 2017010415A1 JP 2016070234 W JP2016070234 W JP 2016070234W WO 2017010415 A1 WO2017010415 A1 WO 2017010415A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- vibration

- seat surface

- surface portion

- seat

- exciter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60N—SEATS SPECIALLY ADAPTED FOR VEHICLES; VEHICLE PASSENGER ACCOMMODATION NOT OTHERWISE PROVIDED FOR

- B60N2/00—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles

- B60N2/90—Details or parts not otherwise provided for

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C7/00—Parts, details, or accessories of chairs or stools

- A47C7/62—Accessories for chairs

- A47C7/72—Adaptations for incorporating lamps, radio sets, bars, telephones, ventilation, heating or cooling arrangements or the like

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47C—CHAIRS; SOFAS; BEDS

- A47C7/00—Parts, details, or accessories of chairs or stools

- A47C7/62—Accessories for chairs

- A47C7/72—Adaptations for incorporating lamps, radio sets, bars, telephones, ventilation, heating or cooling arrangements or the like

- A47C7/727—Adaptations for incorporating lamps, radio sets, bars, telephones, ventilation, heating or cooling arrangements or the like with speakers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B06—GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS IN GENERAL

- B06B—METHODS OR APPARATUS FOR GENERATING OR TRANSMITTING MECHANICAL VIBRATIONS OF INFRASONIC, SONIC, OR ULTRASONIC FREQUENCY, e.g. FOR PERFORMING MECHANICAL WORK IN GENERAL

- B06B1/00—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency

- B06B1/02—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of electrical energy

- B06B1/04—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of electrical energy operating with electromagnetism

- B06B1/045—Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency making use of electrical energy operating with electromagnetism using vibrating magnet, armature or coil system

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60N—SEATS SPECIALLY ADAPTED FOR VEHICLES; VEHICLE PASSENGER ACCOMMODATION NOT OTHERWISE PROVIDED FOR

- B60N2/00—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles

- B60N2/90—Details or parts not otherwise provided for

- B60N2002/981—Warning systems, e.g. the seat or seat parts vibrates to warn the passenger when facing a danger

Definitions

- the present invention relates to a vibration generator, and more particularly to a vibration generator that is provided on a seat surface portion of a seat and can transmit vibration to a seated person.

- a vehicle alarm device in which a vibrating body is installed on the seat surface portion of a vehicle seat and a seated person is warned by the vibration of the vibrating body (see, for example, Patent Document 1).

- a vibrating body is installed between the cushion material of the seat surface portion and the seat cover so as to be in contact with the seat cover.

- the vibrating body comes into contact with the seated person via the seat surface. For this reason, it becomes possible to improve the vibration transmission efficiency to a seated person.

- the alarm can be felt by the vibration even when the vehicle is being driven.

- the vibrating body is disposed between the cushion material and the seat skin so as to be easily in contact with the seat skin so that the seated person can easily feel the vibration. For this reason, the sitting comfort may be impaired or the sitting comfort may be uncomfortable. Further, when the elastic performance of the cushion material of the seat is lowered and the cushion material is stagnant, there is a possibility that the strength of vibration experienced by the seated person, the vibration generation position, and the like may be greatly changed.

- a vibration body is provided on the seat surface portion of the seat, such as a vehicle alarm device, and a seated person sitting on the seat surface portion is subjected to vibration in the vertical direction from the seat surface portion, In some cases, the seated person is difficult to feel the vibration of the vibrating body.

- the vibrating body In order to increase the vibration to the seated person, it is conceivable to increase the vibration output in the vibrating body.

- the vibrating body has a tendency to increase in size, and the weight may increase.

- the present invention has been made in view of the above problems, and it is an object of the present invention to provide a vibration generating device in which a seated person can easily experience vibration even when vibration is generated from the inside of a seating surface portion of a seat. .

- the vibration generator includes a vibration transmission member that extends in the horizontal direction of the seat surface portion inside the seat surface portion of the seat and can transmit vibration in the extending direction; And an exciter for transmitting the vibration in the extending direction to the vibration transmitting member.

- the above-described vibration generator is characterized by transmitting the vibration of the exciter in the extending direction of the vibration transmitting member extending in the horizontal direction of the seat surface. For this reason, in the above-described vibration generator, vibration can be transmitted in the horizontal direction, not in the vertical direction in which the weight of the seated person is applied on the seat surface portion. Since the vibration can be transmitted in a direction different from the vertical direction in which the cushion material or the like is easily expanded and contracted by pressure in the seat surface portion, the vibration is difficult to weaken, and the seated person can easily feel the vibration.

- the vibration transmission member is a rod-shaped body, and one end of the rod-shaped body is one of the front end portion and the rear end portion of the seat surface portion, and Located at a position closer to the side in the left-right direction of the seat surface portion, the other end of the rod-shaped body is an end on the side different from the front end or the rear end of the seat surface where one end of the rod-shaped body is located. And is installed inside the seating surface portion so as to be positioned closer to the center in the left-right direction than the position nearing the side portion of the seating surface portion where one end of the rod-shaped body is located. It may be.

- the vibration transmitting member is constituted by a rod-shaped body.

- the rod-shaped body extends from the position at the front end or the rear end of the seat surface portion toward the side in the left-right direction, toward the center at the other end of the seat surface portion in the left-right direction. And installed inside the seat surface.

- the vibration transmission member is installed on the seat surface portion so as to cross the thigh from the inside to the outside of the thigh of the seated person. Therefore, by vibrating the vibration transmitting member installed in this manner, the seated person can feel the vibration in a wide range from the buttocks to the thigh back. In addition, it is possible to make the seated person feel the vibration with certainty.

- the vibration transmission member may be a cylindrical bar-shaped body having a substantially circular cross-sectional shape.

- the cross-sectional shape of the vibration transmitting member By forming the cross-sectional shape of the vibration transmitting member into a substantially circular shape, the cross-sectional shape does not hit the angulated part of the buttocks, thighs, etc. compared to the case where the cross-sectional shape is a triangle or a quadrangle. For this reason, it becomes possible to improve the sitting comfort of the seated person.

- the vibration transmitting member may be installed in an elastic member provided inside the seat surface portion.

- the vibration transmitting member since the vibration transmitting member is installed in the elastic member, the vibration of the vibration transmitting member is transmitted through another member such as a seat frame, and the vibration escapes. It becomes possible to prevent.

- the vibration generator according to an embodiment of the present invention is characterized in that the vibration of the exciter is transmitted in the extending direction of the vibration transmitting member that extends in the horizontal direction of the seat surface portion. For this reason, in the vibration generator according to the present invention, vibration can be transmitted in the horizontal direction, not in the vertical direction in which the weight of the seated person is applied on the seat surface portion. Since the vibration can be transmitted in a direction different from the vertical direction in which the cushion material or the like is easily expanded and contracted by pressure in the seat surface portion, the vibration is difficult to weaken, and the seated person can easily feel the vibration.

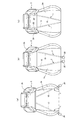

- FIG. 1A shows a plan view of the seat

- FIG. 1B shows a rear perspective view of the seat

- FIG. 2 shows a side sectional view of the seat.

- the vibration generator 1 is roughly configured by a vibration transmission member 10 and an exciter 20, and is provided on the seat surface portion 2 a of the vehicle seat 2.

- the vibration transmission member 10 is a columnar rod-shaped member, and is formed of a rigid body so as to easily transmit vibration.

- a metal such as iron is generally used for the vibration transmitting member 10.

- the material for forming the vibration transmitting member 10 is not limited to metal or the like, and the material or the like is not particularly limited as long as the vibration of the exciter 20 can be easily transmitted.

- the vibration transmitting member 10 is not limited to a cylindrical shape as long as it is a rod-shaped member.

- the cross section is preferably substantially circular, but may be a polygon such as a triangle or a quadrangle.

- the cross-sectional shape is a triangle or a quadrangle, care must be taken not to affect the sitting comfort of the seated person.

- the cross-sectional shape is substantially circular, the angled portion does not hit the buttocks, the thighs, and the like, so that sitting comfort and the like can be improved.

- the vehicle seat 2 has an external skeleton formed of a seat frame (not shown).

- the seat surface part 2a and the backrest part are provided inside the vehicle seat 2.

- 2b is filled with an elastic member made of cushion material 3 or the like.

- the vibration transmitting member 10 is provided so as to be embedded in the cushion material 3 of the seat surface portion 2a. Specifically, a method of embedding the vibration transmission member 10 by insert molding in which the cushion material 3 is molded in a state where the vibration transmission member 10 is disposed inside when the cushion material 3 is molded is used. Further, after the cushion material 3 is molded, an insertion hole for inserting the vibration transmission member 10 is formed by post-processing, and after the vibration transmission member 10 is inserted, the vibration transmission member 10 is attached to the cushion material 3 with an adhesive or the like. A method of fixing is used.

- the vibration transmitting member 10 is embedded in the cushion material 3.

- the vibration transmission member 10 is installed on the vehicle seat 2 so as not to contact a member such as a seat frame, in which the vibration of the vibration transmission member 10 is easily transmitted and the vibration escapes. Further, the vibration transmitting member 10 may be provided with a locking portion that is hooked on the cushion material 3 or a return portion that does not fall off so that the vibration transmitting member 10 is not detached from the seat surface portion 2a due to vibration.

- the vibration transmitting member 10 has a rear end portion side (side on which the exciter 20 is attached) at a position near the center of the rear end portion of the seat surface portion 2a. ) Is located, and is installed on the seat surface portion 2a so that the front end portion side of the vibration transmitting member 10 is located in the vicinity of the left end portion (position near the left side portion) of the front end portion of the seat surface portion 2a.

- an angle adjustment mechanism for adjusting the angle of the backrest 2b is provided at the left and right positions of the connecting portion (the rear portion of the seat 2a) of the seat surface portion 2a and the backrest portion 2b in the vehicle seat 2. Is provided. For this reason, in order to avoid the installation location of the angle adjustment mechanism part in the seat surface part 2a, it is desirable to arrange

- the rear end side of the vibration transmitting member 10 is disposed at a position closer to the center of the rear end of the seat surface 2a, and the vicinity of the left end of the front end of the seat 2a (close to the left side).

- the vibration transmitting member 10 is installed on the seating surface portion 2a so that the front end portion side of the vibration transmitting member 10 is positioned at the position (2).

- the rod-shaped member of the vibration transmitting member 10 is arranged so as to cross the thigh from the inside to the outside of the seated person's thigh.

- the front end portion side of the vibration transmitting portion 10 is disposed as close to the front side as possible and close to the side portion of the seating surface portion 2a while taking care not to make the seated person feel uncomfortable. .

- the front end portion of the vibration transmitting portion 10 is arranged as close to the front side of the seat surface portion 2a as possible and as close to the side portion as possible, vibration can be generated in a wide range. Therefore, it becomes possible to let the seated person feel the vibration in a wider range.

- each vibration transmission member 10 is paired with respect to the seat surface portion 2a. It may be provided.

- the rear end side of each vibration transmitting member 10 is located at a position closer to the center of the rear end of the seat surface 2a, and is near the left end of the front end of the seat surface 2a (near the left side).

- the pair of vibration transmitting members 10 are installed on the seat surface portion 2a so that the front end side of each vibration transmitting member 10 is positioned near the right end portion (position near the right side portion).

- the vibration transmission member 10 can be arranged in a C shape in a plan view of the seat surface portion 2a.

- the exciter 20 is attached to the rear end of the vibration transmitting member 10 as shown in FIGS. More specifically, the exciter 20 is a rear end portion of the vibration transmitting member 10 and is fixed in a state where the frame portion 21 (see FIG. 3) of the exciter 20 is in contact with the rear cross section. Further, the exciter 20 is fixed to the vibration transmission member 10 so as not to contact any members other than the vibration transmission member 10. Thus, by fixing the exciter 20 to the vibration transmission member 10, the vibration of the exciter 20 is easily transmitted to members other than the vibration transmission member 10, such as the seat frame of the vehicle seat 2, and the vibration escapes. There is nothing.

- the exciter 20 is an acoustic output device capable of transmitting the vibration force transmitted from the voice coil to an object in contact with the main body of the exciter and outputting vibrations and sounds via the object. .

- FIG. 3 is a sectional view showing a schematic structure of the exciter 20.

- FIG. 3 shows a state where the exciter 20 is fixed to the rear end portion of the vibration transmitting member 10.

- the exciter 20 is roughly configured by a frame portion 21, a damper portion 22, an outer yoke 23, a permanent magnet 24, an inner yoke 25, a bobbin 26, and a voice coil 27.

- the outer yoke 23 has a bowl shape in which a side wall portion 23a and a bottom portion 23b are continuously formed and a recess is provided.

- the permanent magnet 24 is attached to the inside of the bottom 23b of the outer yoke 23 and is formed in a disk shape.

- the inner yoke 25 is placed on the permanent magnet 24.

- the inner yoke 25 has a disk shape. The diameter of the inner yoke 25 is slightly larger than the diameter of the permanent magnet 24.

- a gap d is provided between the inner surface of the side wall portion 23 a of the outer yoke 23 and the outer peripheral side surface of the inner yoke 25.

- the tip end of the cylindrical bobbin 26 is located in the gap d.

- a voice coil 27 is wound around the tip of the bobbin 26.

- the frame portion 21 has a dish shape having a diameter larger than the outer diameter of the outer yoke 23 so that the recess of the outer yoke 23 can be covered.

- a leg portion 21 a that protrudes toward the outer yoke 23 is formed on the outer edge portion of the frame portion 21.

- the dish-shaped portion on the side opposite to the side from which the leg portion 21 a of the frame portion 21 protrudes is fixed to the cross-sectional portion of the rear end portion of the vibration transmitting member 10.

- a base portion 26a of the bobbin 26 is fixed to the opposite side of the dish-shaped portion of the frame portion 21 fixed to the cross-sectional portion of the vibration transmitting portion 10.

- a plurality of damper portions 22 extending in a substantially spiral shape in the outer peripheral direction of the frame portion 21 are provided on the leg portion 21a of the frame portion 21 at equal intervals.

- tip part (spiral-shaped center side edge part) of the damper part 22 is being fixed to the periphery of the side wall part 23a of the outer side yoke 23.

- the bobbin 26 vibrates in accordance with the frequency of the sound signal. More specifically, the bobbin 26 is vibrated in a direction (vertical direction in FIG. 3) in which the outer yoke 23 approaches and separates from the frame portion 21 via the damper portion 22. The vibration of the bobbin 26 is transmitted to the vibration transmitting member 10 through the frame portion 21. The vibration to the vibration transmitting member 10 is applied to the extending direction (extending direction) of the rod member of the vibration transmitting member 10. Thus, by transmitting vibration in the extending direction of the vibration transmitting member 10 via the exciter 20, vibration can be transmitted in the front-rear direction of the vehicle seat 2.

- the vibration transmitting member 10 is caused to vibrate in the front-rear direction by changing / adjusting the frequency of the acoustic signal input to the exciter 20.

- This vibration in the front-rear direction can cause the vibration transmitting member 10 to resonate.

- the entire vibration transmitting member 10 can be vibrated. Therefore, it is possible to transmit vibration to the entire vehicle seat 2 without being limited to the extending direction of the vibration transmitting member 10.

- the rod-shaped member of the vibration transmitting member 10 is installed on the seat surface portion 2a so as to cross the thigh from the inside to the outside of the seated person's thigh. For this reason, by resonating the vibration transmitting member 10, vibration can be experienced in a wide range from the buttocks to the back of the thigh. Furthermore, it is possible to make the seated person feel the vibration with certainty.

- the vibration transmitting member 10 is composed of a rod-shaped member.

- the vibration can be generated in the entire vibration transmission member 10.

- the vibration transmitting member 10 has a greatly bent shape or the like, the vibration in the stretching direction is weakened at the bent portion. For this reason, the vibration at the tip portion of the vibration transmission member 10 is weakened, and it becomes difficult to generate the vibration of the entire vibration transmission member 10.

- the vibration by the exciter 20 is input with respect to the extending direction of the rod-shaped member. Since the vibration in the stretching direction is largely transmitted in the front-rear direction through the inside of the rod-shaped member, the vibration is hardly inhibited.

- the vibration by the exciter 20 is the extending direction of the vibration transmitting member 10 and is the front-rear direction of the seat surface portion 2a. For this reason, the vibration of the exciter can be transmitted over a wider range than when the exciter is installed in the seat surface portion 2a so as to transmit the vibration in the vertical direction of the seat. Furthermore, in the seat surface portion 2a, vibration can be transmitted in a direction different from the vertical direction in which the cushion material or the like is easily expanded and contracted by pressure. For this reason, it is difficult for the vibration to be weakened by the compression of the cushioning material or the like, and the seated person can easily feel the vibration.

- the vehicle seat 2 is likely to move up and down.

- the damper portion 22 of the exciter 20 can be vibrated up and down in the same direction as the vibration by the exciter 20. Sex occurs.

- the exciter 20 may be damaged by the vertical vibration, or the performance may be deteriorated.

- the damper portion 22 of the exciter 20 is provided in the vibration transmission member 10 so as to vibrate in the front-rear direction of the seat surface portion 2a. For this reason, it becomes possible to reduce the influence by the vertical vibration of the vehicle.

- the exciter 20 is provided at the rear end portion of the vibration transmitting member 10 so as not to contact the seat surface portion 2a of the vehicle seat 2. For this reason, the vibration of the exciter 20 can be directly transmitted to the vibration transmitting member 10. Furthermore, it is possible to minimize the reduction of vibration due to contact with other members such as the vehicle seat 2.

- the vibration transmitting member 10 can be resonated, but also the vehicle seat 2 and the seat surface portion 2a can be resonated.

- the cushion performance of the cushion material deteriorates over time due to the seating of the seated person and the like.

- the resonance frequency of the vehicle seat 2 and the seat surface portion 2a is likely to change over time.

- the vehicle seat 2 and the seat surface portion 2a can be changed by changing / adjusting the frequency of the acoustic signal input to the exciter 20. It can resonate. Therefore, it is possible to generate vibration more effectively according to the state of the vehicle seat 2 and the seat surface portion 2a, and it is possible to improve the sensory performance of vibration for the seated person.

- the vibration for the vibration transmitting unit 10 is output using the exciter 20.

- the vibration generator 1 by setting and adjusting the frequency and the like of the acoustic signal input to the exciter 20, it is possible not only to generate vibration from the exciter 20 to the vibration transmitting unit 10, but also to generate music or the like. Therefore, it is possible to use the vibration generator 1 as an acoustic device for outputting sound as well as simple vibration.

- vibration generator according to the present invention has been described in detail with reference to an example and the drawings.

- the vibration generator according to the present invention is not limited to the example described in the embodiment. It will be apparent to those skilled in the art that various changes and modifications can be made within the scope of the claims. Also in these cases, it is possible to achieve the same effect as the vibration generator 1 shown in the embodiment.

- the rear of the vibration transmitting member 10 is located at a position closer to the center of the rear end portion of the seat surface portion 2 a.

- the vibration transmitting portion 10 is positioned on the seat surface portion so that the end portion side is located, and the front end portion side of the vibration transmitting member 10 is positioned in the vicinity of the left end portion of the front end portion of the seat surface portion 2a (position near the left side portion). The case where it installed in 2a was demonstrated.

- the installation position of the vibration generator 1 is not limited to the installation positions shown in FIGS. 1 (a) and 1 (b) and FIG.

- the rear end side of the vibration transmitting member 10 (the side on which the exciter 20 is attached) near the left end (or near the right end) of the front end of the seat surface 2a. ) And the rear end portion of the seat surface portion 2a, which is installed on the seat surface portion 2a so that the front end portion side of the vibration transmitting member 10 is located near the center position in the left-right direction.

- the exciter 20 fixed to the rear end portion of the vibration transmission member 10 is located on the front side of the vehicle seat 2, and the front end portion of the vibration transmission member 10 is located on the rear end portion of the seat surface portion 2a.

- the seat surface portion 2a is embedded in the cushion material. In this way, even when the vibration transmitting member 10 is provided on the seat surface portion 2a, it is possible to make the seated person feel effective vibration by resonance or the like, similarly to the vibration transmitting member 10 according to the embodiment. Is possible.

- the rear end side (the side on which the exciter 20 is attached) of the vibration transmitting member 10 is located at the front end of the seat surface 2a and closer to the center position in the left-right direction. Even if it is installed on the seat surface portion 2a so that the front end portion side of the vibration transmitting member 10 is located near the left end portion (or near the right end portion) of the rear end portion of the seat surface portion 2a. Good. Also in this case, the exciter 20 fixed to the rear end portion of the vibration transmission member 10 is located on the front side of the vehicle seat 2, and the front end portion of the vibration transmission member 10 is located on the rear side end portion of the seat surface portion 2a.

- the seat surface portion 2a is embedded in the cushion material. In this way, even when the vibration transmitting member 10 is provided on the seat surface portion 2a, it is possible to make the seated person feel effective vibration by resonance or the like, similarly to the vibration transmitting member 10 according to the embodiment. Is possible.

- the front end portion of the vibration transmitting member 10 is located at the front end portion of the seat surface portion 2a and at the center position in the left-right direction, and the rear end portion of the seat surface portion 2a is located. Even if it is installed on the seat surface portion 2a so that the rear end portion side (the side on which the exciter 20 is attached) is located near the left end portion (or near the right end portion). Good. In this case, the exciter 20 fixed to the rear end portion of the vibration transmission member 10 is located on the rear side of the vehicle seat 2, and the front end portion of the vibration transmission member 10 is located on the front end portion of the seat surface portion 2a. In this state, the seat surface portion 2a is embedded in the cushion material. In this way, even when the vibration transmitting member 10 is provided on the seat surface portion 2a, it is possible to make the seated person feel effective vibration by resonance or the like, similarly to the vibration transmitting member 10 according to the embodiment. Is possible.

- the vibration transmitting member 10 may be installed in the left-right direction of the seat surface portion 2a. Moreover, as shown in FIG.5 (b), you may install so that a pair of vibration transmission member 10 extended in the front-back direction may become parallel.

- the exciter 20 is directly fixed to the rear end portion of the vibration transmission member 10.

- the exciter 20 is limited to a structure that is not necessarily fixed directly to the vibration transmission member 10. It is not a thing. It is sufficient that the exciter 20 can be attached to the vibration transmission member 10 so that at least the extending direction of the vibration transmission member 10 and the vibration transmission direction of the exciter 20 are the same direction. By setting it as such an attachment structure, the vibration of the exciter 20 can be effectively transmitted with respect to the extending direction of the vibration transmission member 10.

- crank shape means a shape in which two narrow right-angle curves are alternately connected, and the extending direction line at one end and the extending direction line at the other end are parallel to each other.

- the vibration of the exciter 20 is extended in the extending direction of the vibration transmitting member 10 as in the vibration generating device 1 according to the embodiment. Can be communicated to. Accordingly, the vibration of the exciter 20 can be effectively transmitted in the extending direction of the vibration transmitting member 10.

- a substantially S-shaped connection in which the narrow curve portion of the crank shape is a gentle curve.

- a member may be used.

- the vibration generation direction of the exciter 20 and the extending direction of the vibration transmission member 10 are opposite to each other, a U-shaped connection member or the like in which the vibration direction is the same horizontal direction may be used.

- the vibration generator 1 according to the present invention is not limited to the configuration provided in the seat surface portion 2a.

- the vibration generator 1 can be provided on the backrest 2b.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Aviation & Aerospace Engineering (AREA)

- Transportation (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Chair Legs, Seat Parts, And Backrests (AREA)

- Seats For Vehicles (AREA)

- Details Of Audible-Bandwidth Transducers (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP16824395.4A EP3321127B1 (en) | 2015-07-10 | 2016-07-08 | Vibration generating device |

| US15/736,757 US10293729B2 (en) | 2015-07-10 | 2016-07-08 | Vibration generator |

| EP20194400.6A EP3785987A1 (en) | 2015-07-10 | 2016-07-08 | Vibration generating device |

| CN201680032551.3A CN107614322B (zh) | 2015-07-10 | 2016-07-08 | 振动产生装置 |

| US16/375,920 US10532682B2 (en) | 2015-07-10 | 2019-04-05 | Vibration generator |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015138391A JP6517101B2 (ja) | 2015-07-10 | 2015-07-10 | 振動発生装置 |

| JP2015-138391 | 2015-07-10 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/736,757 A-371-Of-International US10293729B2 (en) | 2015-07-10 | 2016-07-08 | Vibration generator |

| US16/375,920 Continuation US10532682B2 (en) | 2015-07-10 | 2019-04-05 | Vibration generator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017010415A1 true WO2017010415A1 (ja) | 2017-01-19 |

Family

ID=57757398

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/070234 Ceased WO2017010415A1 (ja) | 2015-07-10 | 2016-07-08 | 振動発生装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US10293729B2 (enExample) |

| EP (2) | EP3785987A1 (enExample) |

| JP (1) | JP6517101B2 (enExample) |

| CN (2) | CN107614322B (enExample) |

| WO (1) | WO2017010415A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109693592B (zh) * | 2017-10-20 | 2021-10-26 | 株式会社泰极爱思 | 交通工具用座椅 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6511486B2 (ja) | 2017-05-30 | 2019-05-15 | クラリオン株式会社 | 振動発生装置および振動発生方法 |

| WO2019044824A1 (ja) * | 2017-08-31 | 2019-03-07 | パイオニア株式会社 | 座席 |

| US10513211B2 (en) * | 2017-12-21 | 2019-12-24 | GM Global Technology Operations LLC | Haptic device with waveguide and seat assembly having the same |

| EP3531715B1 (en) * | 2018-02-27 | 2022-02-09 | Flexound Systems OY | A seat arranged for enhanced sound perception via vibration |

| JP6905484B2 (ja) * | 2018-03-02 | 2021-07-21 | フォルシアクラリオン・エレクトロニクス株式会社 | 振動発生装置 |

| JP2019165916A (ja) * | 2018-03-23 | 2019-10-03 | クラリオン株式会社 | 振動発生装置 |

| JP2019214018A (ja) * | 2018-06-12 | 2019-12-19 | クラリオン株式会社 | 振動発生装置 |

| WO2020009112A1 (ja) | 2018-07-05 | 2020-01-09 | クラリオン株式会社 | 振動発生装置 |

| CN111071123A (zh) * | 2018-10-18 | 2020-04-28 | 株式会社泰极爱思 | 车辆座椅 |

| US12185637B2 (en) | 2018-12-28 | 2024-12-31 | Faurecia Clarion Electronics Co., Ltd. | Vibration generation device |

| US12268821B2 (en) * | 2019-12-17 | 2025-04-08 | Panasonic Automotive Systems Co., Ltd. | Awakening inducing device and awakening inducing system |

| KR20230102522A (ko) * | 2021-12-30 | 2023-07-07 | 현대자동차주식회사 | 시트의 진동모터 어셈블리 |

| EP4476095A1 (en) | 2022-02-07 | 2024-12-18 | Leggett & Platt Canada Co. | Interactive adjustable seat with multiple modes of operation |

| KR20250137642A (ko) * | 2023-01-20 | 2025-09-18 | 레겟 앤드 플랫 캐나다 코포레이션 | 익사이터 기반 시트 마사지 시스템에서 코일 압축의 감소 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6185985U (enExample) * | 1984-11-12 | 1986-06-05 | ||

| JPH06113932A (ja) * | 1992-09-30 | 1994-04-26 | Bodeisonitsuku Kk | ラック付き体感音響人体載置物 |

| JP2009255809A (ja) * | 2008-04-18 | 2009-11-05 | Toyota Boshoku Corp | 報知装置付き乗物用シート |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1530688A (en) * | 1975-04-08 | 1978-11-01 | Bodysonic Kk | Sound reproduction system |

| JPS60158386U (ja) * | 1984-03-30 | 1985-10-22 | パイオニア株式会社 | 体感音響装置 |

| US5256920A (en) * | 1990-12-21 | 1993-10-26 | Lockheed Sanders, Inc. | Acoustic transducer |

| JPH0640295A (ja) | 1992-07-10 | 1994-02-15 | Mazda Motor Corp | 自動車シートの音響加振体支持構造 |

| WO1995019247A1 (en) * | 1994-01-18 | 1995-07-20 | Dynatex International (Inc.) | Method and apparatus for scribing and/or breaking semiconductor wafers |

| US5535853A (en) * | 1994-11-14 | 1996-07-16 | Otis Elevator Company | Actuator having a two ended actuator rod movable longitudinally and transversely |

| US5813234A (en) * | 1995-09-27 | 1998-09-29 | Wighard; Herbert F. | Double acting pulse tube electroacoustic system |

| KR980001247A (ko) | 1996-06-11 | 1998-03-30 | 마사히로 후쿠오카 | 좌석진동장치 |

| JP2001353471A (ja) * | 2000-04-14 | 2001-12-25 | Tokin Corp | 多機能振動アクチュエータ |

| JP4422354B2 (ja) * | 2001-02-09 | 2010-02-24 | パイオニア株式会社 | 電気−機械−音響変換器 |

| JP2006341839A (ja) * | 2005-05-10 | 2006-12-21 | Aisin Seiki Co Ltd | 車両用報知装置及び車両用警報装置 |

| JP4981279B2 (ja) | 2005-08-22 | 2012-07-18 | クラリオン株式会社 | 車両用異常報知装置及び制御プログラム |

| US7681949B2 (en) * | 2006-04-12 | 2010-03-23 | Lear Corporation | Haptic vehicle seat |

| JP2009120015A (ja) | 2007-11-14 | 2009-06-04 | Toyota Motor Corp | 車両用シート及び車両用警報装置 |

| US20090227913A1 (en) * | 2008-03-07 | 2009-09-10 | Toyota Boshoku Kabushiki Kaisha | Vehicle seat |

| GB2471913B (en) * | 2009-07-17 | 2012-02-01 | Samsung Electro Mech | Horizontal linear vibrator |

| CN201784492U (zh) | 2010-07-20 | 2011-04-06 | 浙江吉利汽车研究院有限公司 | 一种汽车按摩座椅 |

| US9266451B2 (en) * | 2012-06-22 | 2016-02-23 | GM Global Technology Operations LLC | Alert systems and methods for a vehicle |

| US20150020308A1 (en) * | 2013-06-14 | 2015-01-22 | Sheila Reichle | Infant accessory with vibration system |

| KR101467500B1 (ko) * | 2013-08-21 | 2014-12-01 | 주식회사 예일전자 | 감각신호출력장치 |

| KR101543115B1 (ko) * | 2013-12-18 | 2015-08-07 | 현대자동차주식회사 | 자동차의 시트 햅틱 장치 |

| US20170297463A1 (en) * | 2014-09-24 | 2017-10-19 | Nidec Copal Corporation | Seat sitting part vibration device |

| CN204444960U (zh) | 2015-03-09 | 2015-07-08 | 郑州大学 | 一种用于座椅的定时提醒装置 |

| US10722426B2 (en) * | 2015-09-29 | 2020-07-28 | Bruce Murison | Remote drive and wearable adult devices |

-

2015

- 2015-07-10 JP JP2015138391A patent/JP6517101B2/ja not_active Expired - Fee Related

-

2016

- 2016-07-08 CN CN201680032551.3A patent/CN107614322B/zh not_active Expired - Fee Related

- 2016-07-08 EP EP20194400.6A patent/EP3785987A1/en not_active Withdrawn

- 2016-07-08 EP EP16824395.4A patent/EP3321127B1/en not_active Not-in-force

- 2016-07-08 US US15/736,757 patent/US10293729B2/en not_active Expired - Fee Related

- 2016-07-08 WO PCT/JP2016/070234 patent/WO2017010415A1/ja not_active Ceased

- 2016-07-08 CN CN202010228083.5A patent/CN111376808B/zh not_active Expired - Fee Related

-

2019

- 2019-04-05 US US16/375,920 patent/US10532682B2/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6185985U (enExample) * | 1984-11-12 | 1986-06-05 | ||

| JPH06113932A (ja) * | 1992-09-30 | 1994-04-26 | Bodeisonitsuku Kk | ラック付き体感音響人体載置物 |

| JP2009255809A (ja) * | 2008-04-18 | 2009-11-05 | Toyota Boshoku Corp | 報知装置付き乗物用シート |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109693592B (zh) * | 2017-10-20 | 2021-10-26 | 株式会社泰极爱思 | 交通工具用座椅 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3785987A1 (en) | 2021-03-03 |

| US20190232841A1 (en) | 2019-08-01 |

| JP2017019386A (ja) | 2017-01-26 |

| US10293729B2 (en) | 2019-05-21 |

| EP3321127B1 (en) | 2020-10-14 |

| US10532682B2 (en) | 2020-01-14 |

| CN107614322A (zh) | 2018-01-19 |

| CN111376808B (zh) | 2022-01-21 |

| CN111376808A (zh) | 2020-07-07 |

| CN107614322B (zh) | 2020-04-10 |

| EP3321127A4 (en) | 2019-03-27 |

| US20180170228A1 (en) | 2018-06-21 |

| EP3321127A1 (en) | 2018-05-16 |

| JP6517101B2 (ja) | 2019-05-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017010415A1 (ja) | 振動発生装置 | |

| JP2019048626A (ja) | 車両用シート装置 | |

| US9387784B2 (en) | Headrest and vehicle seat provided therewith | |

| JP2017019386A5 (enExample) | ||

| JP6726333B2 (ja) | 振動発生装置 | |

| JP5987911B2 (ja) | イヤホン | |

| JP6197904B1 (ja) | ホーンの音源装置 | |

| JP6403323B2 (ja) | 椅子用遮蔽部材、及び、椅子 | |

| US11673498B2 (en) | Vehicle seat with vibration device | |

| JP6905484B2 (ja) | 振動発生装置 | |

| EP3797880A1 (en) | Vibration generating device | |

| JP2019165916A (ja) | 振動発生装置 | |

| JPH07323068A (ja) | 電気−機械振動変換器 | |

| US20240165669A1 (en) | Structural body, vibrating device, and sensory acoustic apparatus | |

| JP2006000546A (ja) | 椅子 | |

| WO2025143114A1 (ja) | 座席およびスピーカ | |

| JPH07112305B2 (ja) | 電気・機械振動変換器 | |

| TW202416873A (zh) | 震動器及具有該震動器之電動床 | |

| CN115534784A (zh) | 具有振动装置的车辆座椅 | |

| JP6440301B2 (ja) | 椅子用遮蔽部材、及び、椅子 | |

| JP2019112016A (ja) | 振動装置、及び、それを備えた振動装置付き座席 | |

| JP2011235727A (ja) | 車両用シートの防振構造 | |

| KR20080079036A (ko) | 공명발생부를 갖는 전화기 | |

| JP2019214018A (ja) | 振動発生装置 | |

| JP2005137568A (ja) | 振動装置及び寝具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16824395 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15736757 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2016824395 Country of ref document: EP |