WO2015122264A1 - 蒸気発生設備のスケール除去方法及びスケール除去剤 - Google Patents

蒸気発生設備のスケール除去方法及びスケール除去剤 Download PDFInfo

- Publication number

- WO2015122264A1 WO2015122264A1 PCT/JP2015/052012 JP2015052012W WO2015122264A1 WO 2015122264 A1 WO2015122264 A1 WO 2015122264A1 JP 2015052012 W JP2015052012 W JP 2015052012W WO 2015122264 A1 WO2015122264 A1 WO 2015122264A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- salt

- scale

- water

- steam generating

- polyacrylic acid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F5/00—Softening water; Preventing scale; Adding scale preventatives or scale removers to water, e.g. adding sequestering agents

- C02F5/08—Treatment of water with complexing chemicals or other solubilising agents for softening, scale prevention or scale removal, e.g. adding sequestering agents

- C02F5/10—Treatment of water with complexing chemicals or other solubilising agents for softening, scale prevention or scale removal, e.g. adding sequestering agents using organic substances

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

- B08B3/022—Cleaning travelling work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/04—Cleaning involving contact with liquid

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/04—Cleaning involving contact with liquid

- B08B3/041—Cleaning travelling work

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F120/00—Homopolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical or a salt, anhydride, ester, amide, imide or nitrile thereof

- C08F120/02—Monocarboxylic acids having less than ten carbon atoms; Derivatives thereof

- C08F120/04—Acids; Metal salts or ammonium salts thereof

- C08F120/06—Acrylic acid; Methacrylic acid; Metal salts or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L33/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L33/02—Homopolymers or copolymers of acids; Metal or ammonium salts thereof

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/20—Organic compounds containing oxygen

- C11D3/2075—Carboxylic acids-salts thereof

- C11D3/2082—Polycarboxylic acids-salts thereof

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/37—Polymers

- C11D3/3746—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C11D3/3757—(Co)polymerised carboxylic acids, -anhydrides, -esters in solid and liquid compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/37—Polymers

- C11D3/3746—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- C11D3/3757—(Co)polymerised carboxylic acids, -anhydrides, -esters in solid and liquid compositions

- C11D3/3765—(Co)polymerised carboxylic acids, -anhydrides, -esters in solid and liquid compositions in liquid compositions

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D7/00—Compositions of detergents based essentially on non-surface-active compounds

- C11D7/22—Organic compounds

- C11D7/26—Organic compounds containing oxygen

- C11D7/265—Carboxylic acids or salts thereof

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23F—NON-MECHANICAL REMOVAL OF METALLIC MATERIAL FROM SURFACE; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL; MULTI-STEP PROCESSES FOR SURFACE TREATMENT OF METALLIC MATERIAL INVOLVING AT LEAST ONE PROCESS PROVIDED FOR IN CLASS C23 AND AT LEAST ONE PROCESS COVERED BY SUBCLASS C21D OR C22F OR CLASS C25

- C23F14/00—Inhibiting incrustation in apparatus for heating liquids for physical or chemical purposes

- C23F14/02—Inhibiting incrustation in apparatus for heating liquids for physical or chemical purposes by chemical means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F22—STEAM GENERATION

- F22B—METHODS OF STEAM GENERATION; STEAM BOILERS

- F22B37/00—Component parts or details of steam boilers

- F22B37/02—Component parts or details of steam boilers applicable to more than one kind or type of steam boiler

- F22B37/48—Devices or arrangements for removing water, minerals or sludge from boilers ; Arrangement of cleaning apparatus in boilers; Combinations thereof with boilers

- F22B37/52—Washing-out devices

-

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2303/00—Specific treatment goals

- C02F2303/22—Eliminating or preventing deposits, scale removal, scale prevention

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D2111/00—Cleaning compositions characterised by the objects to be cleaned; Cleaning compositions characterised by non-standard cleaning or washing processes

- C11D2111/10—Objects to be cleaned

- C11D2111/14—Hard surfaces

- C11D2111/20—Industrial or commercial equipment, e.g. reactors, tubes or engines

Definitions

- the present invention relates to a scale removal method and a scale remover for efficiently removing scale adhered to a boiler can of a steam generation facility.

- scale components such as calcium, magnesium, silica, and iron brought into the boiler can scale and adhere to the heat transfer surface with a high heat load, causing expansion, bending, and bursting due to overheating of the steel material.

- scale components such as calcium, magnesium, silica, and iron brought into the boiler can scale and adhere to the heat transfer surface with a high heat load, causing expansion, bending, and bursting due to overheating of the steel material.

- An anti-scaling agent prevents the hardness component brought into the aqueous system from being scaled.

- Phosphate salts such as trisodium phosphate and sodium tripolyphosphate, and polymers such as sodium polyacrylate are used as scale inhibitors.

- Patent Document 1 describes a scale removal method by chemical cleaning using a chelating agent such as high-concentration ethylenediaminetetraacetic acid (EDTA) or an organic acid such as sulfamic acid.

- EDTA high-concentration ethylenediaminetetraacetic acid

- organic acid such as sulfamic acid.

- Patent Document 2 proposes a method for removing the scale without stopping the operation of the boiler.

- a specific chelating agent such as EDTA, nitrilotriacetic acid (NTA) or diethylenetriamine and a specific dispersing agent such as polymaleic acid are added to the boiler can, and the scale is removed while the boiler is operating. To do.

- the chelating agent used in the scale removal method of Patent Document 2 acts on iron, which is a base material of a boiler, and corrosion occurs.

- Patent Document 3 proposes a method in which a chelating agent and an anticorrosive agent are used in combination.

- the scale is removed by the chelating agent while the corrosion is suppressed by the chelating agent and aldonic acid or a salt thereof.

- Patent Document 4 proposes a method for removing the hardness scale without using a chelating agent.

- a composition comprising a mixture of a polymeric sequestering agent and another water-soluble anionic vinyl polymer dispersant is used.

- Patent Document 4 describes that adhesion of a hardness scale can be prevented or an effect of removing the adhered scale can be obtained by adding a high concentration of the sequestering agent and dispersant. Has been.

- This invention is made

- the scale adhering to the inside of a boiler can etc. can be efficiently removed by the chemical addition amount which can be economically accepted, without corroding a boiler. It is an object to provide a descaling method and a descaling agent.

- An object of the present invention is to provide a scale removal method and a scale remover that can efficiently remove scale adhered to a boiler can even in equipment operated with water supply containing high concentration of iron. To do.

- the present inventors have efficiently used a scale attached to the system with a small addition concentration by using polyacrylic acid and / or a salt thereof in a specific molecular weight range. It has been found that it can be removed. As a result of further research, even when drain is collected and reused as feed water, or when steel is used in highly corrosive economizers, even when iron is contained in a high concentration in the feed water The present inventors have found that the above-described problems can be solved without reducing the scale removal efficiency by using polymethacrylic acid and / or a salt thereof in a specific molecular weight range together.

- the gist of the present invention is as follows.

- a scale removal method for removing scale adhered to a system of a steam generation facility polyacrylic acid having a weight average molecular weight of more than 20,000 and not more than 170,000 and / or a salt thereof is contained in the steam generation facility.

- a method for removing the scale of a steam generating facility comprising adding water or feed water of the steam generating facility.

- the concentration of the polyacrylic acid and / or salt thereof in the water of the steam generation unit of the steam generation facility is 1 to 1,000 mg / L in [1].

- the method for removing the scale of the steam generating facility is characterized in that it is added as described above.

- the water supply of the steam generation facility contains iron, and further, polymethacrylic acid having a weight average molecular weight of more than 1,000 and not more than 100,000 and / or a salt thereof is added to the steam generation facility.

- a method for removing the scale of the steam generating facility which comprises adding the water to the water in the water or the feed water of the steam generating facility.

- the concentration of the polymethacrylic acid and / or salt thereof in the water of the steam generation unit of the steam generation facility is 1 to 1,000 mg / L in [3].

- the method for removing the scale of the steam generating facility is characterized in that it is added as described above.

- the weight concentration ratio of polyacrylic acid and / or a salt thereof to polymethacrylic acid and / or a salt thereof in the water in the steam generating part of the steam generating facility is from 1: 100 to A method for removing scale from a steam generating facility, comprising adding polyacrylic acid and / or a salt thereof and polymethacrylic acid and / or a salt thereof so as to be 100: 1.

- a scale remover that removes the scale attached to the system of the steam generating facility, polyacrylic acid having a weight average molecular weight of more than 20,000 and not more than 170,000 and / or a salt thereof, and a weight average molecular weight of 1,000.

- a scale remover for steam generating equipment comprising more than 100,000 and not more than 100,000 polymethacrylic acid and / or a salt thereof.

- scale attached to the system during operation of the steam generation facility can be efficiently removed with a relatively small amount of chemicals used without using a chelating agent and without corroding the system. Moreover, even if high concentration iron exists in the water supply, a high scale removal effect can be obtained.

- the polyacrylic acid having a weight average molecular weight of more than 20,000 and not more than 170,000 is attached to the scale attached to the boiler can, that is, the steam generation unit.

- / or a salt thereof hereinafter referred to as “polyacrylic acid (salt)”

- polyacrylic acid (salt) is added to the water in the steam generation facility or the feed water of the steam generation facility.

- polymethacrylic acid having a weight average molecular weight of more than 1,000 and not more than 100,000 and / or a salt thereof (hereinafter referred to as “polymethacrylic acid (salt)”. ) In combination.

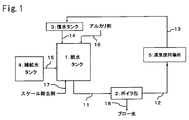

- FIG. 1 is a system diagram showing an embodiment of a steam generation facility for carrying out the present invention.

- 1 is a water supply tank

- 2 is a boiler can (steam generation unit)

- 3 is a condensate tank

- 4 is makeup water.

- Tank 5 is a place where steam is used.

- the water supply in the water supply tank 1 is fed from the water supply line 11 to the boiler can 2.

- the steam generated in the boiler can 2 is fed from the steam line 12 to the steam use place 5, and the condensate is circulated to the feed water tank 1 through the circulation line 13, the condensate tank 3 and the condensate line 14.

- the water supply tank 1 is supplied with supply water in the supply water tank 4 from the supply water line 15, added with an alkali agent from the alkali agent addition line 16, and added with a scale remover from the scale remover line 17. Is done. Blow water is discharged from the boiler can 2 through the blow line 18.

- a polyacrylic acid (salt) or a scale remover containing polyacrylic acid (salt) and polymethacrylic acid (salt) is added to the water supply in the water supply tank 1.

- the scale removing agent may be added to the makeup water tank 4, may be added to the condensate tank 3, the transfer line of each water system, or may be added to these two or more locations.

- polyacrylic acid (salt) and polymethacrylic acid (salt) these may be added to a separate location and may be added to the same location.

- polyacrylic acid (salt) and polymethacrylic acid (salt) may be mixed and added in advance, or may be added separately. The same applies to other optional components described later.

- FIG. 1 shows a circulation type steam generation facility, but the present invention is not limited to the circulation type and can be applied to a once-through type and other steam generation facilities.

- raw water treated with a reverse osmosis membrane raw water softened, raw water ion exchange treated, or the like can be used.

- the operating conditions of the steam generating facility are not particularly limited, but the operating pressure is preferably 0.2 to 4 MPa, more preferably 0.2 to 3 MPa. If it is lower than 0.2 MPa, a sufficient scale removal effect cannot be obtained. When the pressure is higher than 4 PMa, polymers such as polyacrylic acid (salt) and polymethacrylic acid (salt) are affected by thermal decomposition, and the scale removal effect is reduced.

- polyacrylic acid (salt) used as a scale removing component polyacrylic acid (salt) used as a scale removing component

- polymethacrylic acid (salt) used in combination with polyacrylic acid (salt) polymethacrylic acid (salt)

- Other optional additive components that can be used in combination will be described.

- the polyacrylic acid is not particularly limited, and a polyacrylic acid that satisfies the condition of the weight average molecular weight described later can be used.

- examples of the polyacrylate include sodium salt and potassium salt of the polyacrylic acid.

- Polyacrylic acid salt can be produced by adding together with polyacrylic acid, alkali metal hydroxides such as sodium hydroxide and potassium hydroxide, alkali metal carbonates such as sodium carbonate and potassium carbonate, and the like.

- the weight average molecular weight of the polyacrylic acid used in the present invention is more than 20,000 and not more than 170,000, preferably more than 50,000 and not more than 120,000.

- weight average molecular weight of polyacrylic acid is less than 20,000, a sufficient scale removal effect cannot be obtained. Even if the weight average molecular weight of polyacrylic acid exceeds 170,000, the descaling effect decreases.

- the weight average molecular weight of the polyacrylic acid serving as the base of the polyacrylate satisfies the above conditions.

- the amount of polyacrylic acid (salt) added should be such that the concentration in the water of the steam generating part of the steam generating equipment, that is, the concentration in the boiler water is 1 to 1,000 mg / L, particularly 10 to 500 mg / L. Is preferred.

- polyacrylic acid salt

- concentration in the boiler water is in the above range according to the concentration rate of the steam generating facility.

- the polyacrylic acid (salt) is preferably added as an aqueous solution having a concentration of 0.1 to 30% by weight, particularly 0.5 to 10% by weight, using deionized water.

- Iron in water is usually insoluble in water such as iron hydroxide or iron oxide, while water-soluble is dissolved and dissociated in water and exists as iron ions. is doing.

- iron when iron is included in the water supply in excess of 0.3 mg / L, including suspended and dissolved, for example, when it is contained at a high concentration of 0.4 to 5.0 mg / L It is preferable to use polymethacrylic acid (salt) together with polyacrylic acid (salt).

- Polymethacrylic acid is not particularly limited, and those satisfying the following weight average molecular weight conditions are preferably used.

- the polymethacrylate include sodium salt and potassium salt of the polymethacrylic acid.

- Polymethacrylate can be produced by adding together with polymethacrylic acid, alkali metal hydroxides such as sodium hydroxide and potassium hydroxide, alkali metal carbonates such as sodium carbonate and potassium carbonate, and the like.

- the weight average molecular weight of the polymethacrylic acid used in the present invention is preferably 1,000 or more and 100,000 or less, more preferably 5,000 or more and 60,000 or less.

- weight average molecular weight of polymethacrylic acid is less than 1,000, sufficient iron scale prevention effect may not be obtained, and if the weight average molecular weight of polymethacrylic acid exceeds 100,000, the effect decreases.

- polymethacrylate it is only necessary that the weight average molecular weight of polymethacrylic acid serving as a base of polymethacrylate satisfies the above conditions.

- the amount of polymethacrylic acid (salt) added is such that the concentration in the water of the steam generating part of the steam generating facility, that is, the concentration in the boiler water is 1 to 1,000 mg / L, particularly 10 to 500 mg / L. It is preferable.

- polymethacrylic acid salt

- concentration in the boiler water is in the above range according to the concentration ratio of the steam generating facility.

- the polymethacrylic acid (salt) is preferably added as an aqueous solution having a concentration of 0.1 to 30% by weight, particularly 0.5 to 20% by weight, prepared using deionized water.

- additive components such as a pH adjuster, an oxygen scavenger, and an anticorrosion agent are provided at any point in the system of the steam generation facility as necessary.

- An effective amount of an agent, a scale dispersant and the like can be added.

- the pH of the boiler water is preferably 11.0 or more, and preferably 12.0 or less from the viewpoint of preventing corrosion in the boiler can or the steam generating equipment system.

- Examples of a method for adjusting the pH of boiler water to 11.0 or higher include a method of adding an alkaline agent and a method of adjusting the concentration rate by adjusting the blow amount and / or the amount of water supply. Among these, a method of adding an alkaline agent is preferable from the viewpoint of easy pH adjustment.

- alkali agents for adjusting pH examples include alkali metal hydroxides, alkali metal carbonates, alkali metal phosphates, neutralizing amines, and the like.

- Examples of the alkali metal hydroxide include sodium hydroxide, potassium hydroxide, and lithium hydroxide.

- Examples of the alkali metal carbonate include sodium carbonate and potassium carbonate.

- Examples of the alkali metal phosphate include phosphorus. Examples thereof include trisodium acid and sodium hydrogen phosphate.

- neutralizing amines examples include monoethanolamine, cyclohexylamine, morpholine, diethylethanolamine, monoisopropanolamine, 3-methoxypropylamine, 2-amino-2-methyl-1-propanol and the like.

- alkali agents neutralizing amines migrate to the steam condensate system, so if added at a high concentration, odors are generated in the steam and condensate, or the pH of the steam condensate system rises too much, and there is a copper-based material in the system. May cause corrosion.

- an alkali agent an alkali metal hydroxide, an alkali metal carbonate, and an alkali metal phosphate are preferable, and sodium hydroxide, potassium hydroxide, sodium carbonate, etc. are more preferable from an economical viewpoint.

- the above alkaline agents can be used singly or in combination of two or more.

- Alkaline agents are also preferably added to make-up water or water supply, similar to the scale remover.

- the steam generating facility is a circulation type, it may be added to the condensate.

- the steam generation facility preferably has pH measuring means on the upstream side and / or the downstream side of the boiler can.

- oxygen scavengers include various hydroxylamines such as hydrazine, carbohydrazide and diethylhydroxylamine, N-amino heterocyclic compounds such as 1-aminopyrrolidine and 1-amino-4-methylpiperazine, hydroquinone, hydrolyzed and condensed types Tannins (acids) and salts thereof, erythorbic acid and ascorbic acid and salts thereof, aldonic acids and salts thereof such as gluconic acid and alpha glucoheptonic acid, sugars such as glucose (monosaccharides and polysaccharides), sulfurous acid and meta Examples thereof include sulfite-based substances such as bisulfite and salts thereof. You may use these individually by 1 type or in combination of 2 or more types.

- anticorrosive examples include polycarboxylic acids such as succinic acid, citric acid and malic acid, oxycarboxylic acids and salts thereof. You may use these individually by 1 type or in combination of 2 or more types.

- the scale remover of the present invention contains various water treatment agent components such as the aforementioned pH adjuster, oxygen scavenger, anticorrosive, and scale dispersant as required, as long as the object of the present invention is not impaired. Also good.

- the scale remover of the present invention may be one obtained by integrating polyacrylic acid (salt) and polymethacrylic acid (salt), and these may be supplied separately.

- polyacrylic acid salt

- polymethacrylic acid salt

- polymethacrylic acid is usually dissolved in deionized water and used as an aqueous solution having a concentration of 0.1 to 30% by weight, particularly 0.5 to 20% by weight.

- CaCl 2 is used as Ca hardness

- MgCl 2 is used as Mg hardness

- Na 2 SiO 3 is used as silica

- FeCl 2 is used as Fe.

- Synthetic water A Synthetic water with Ca hardness 20 mg CaCO 3 / L, Mg hardness 10 mg CaCO 3 / L, silica concentration 15 mg / L, sodium carbonate concentration 30 mg / L

- Synthetic water B silica concentration 15 mg / L, weight average shown in Table 1 Synthetic water having a molecular weight of polyacrylic acid or polymaleic acid concentration of 10 mg / L and sodium carbonate concentration of 32 mg / L

- a strainer with a diameter of 20 mm and 60 mesh was installed in the blow line.

- This stainless steel test boiler was adjusted to have a pressure of 2.0 MPa, an evaporation amount of 9.0 L / h, a blow rate of 1.0 L / h, and a concentration factor of 10 times while supplying synthetic water A, and was operated for 24 hours. .

- the heat transfer tube with the scale attached after operation was taken out and weighed to calculate the scale attached amount. Thereafter, the heat transfer tube was again inserted into the stainless steel test boiler, and the scale removal step was performed by operating with synthetic water B under the same operating conditions for 3 days.

- the heat transfer tube was taken out and weighed to calculate the scale adhesion amount, and the scale removal rate was calculated from the scale adhesion amount before and after the scale removal step.

- the scale removal rate is low when the weight average molecular weight of the polyacrylic acid is 20,000 or less, and the scale removal rate is high when the weight average molecular weight exceeds 20,000 and 170,000 or less. It can be seen that the scale removal effect is high.

- polymaleic acid was found to have a certain degree of scale removal effect, but a large amount of deposits were observed on the blow strainer, and most of the strainer was covered, and it was just before the blockage. This was presumed to be due to the gelled product produced by the reaction between the hardness component and polymaleic acid.

- Synthetic water C Synthetic water with Ca hardness 40 mg CaCO 3 / L, Mg hardness 20 mg CaCO 3 / L, silica concentration 30 mg / L, sodium carbonate concentration 30 mg / L, Fe concentration 1 mg / L

- Synthetic water D silica concentration 30 mg / L, chemical Synthetic water having a polyacrylic acid concentration of 5 mg / L of the weight average molecular weight described in Table 2 as 1 and a concentration of 5 mg / L, 2 mg of Fe concentration of 1 mg / L of Fe, and 32 mg / L of sodium carbonate as drug 2 (however, In Comparative Example II-1, Drug 1 and Drug 2 are not added, and in Comparative Examples II-2 to 8-8, Drug 2 is not added.)

- This stainless steel test boiler was adjusted to a pressure of 0.7 MPa, an evaporation amount of 11.7 L / h, a blow rate of 1.3 L / h, and a concentration factor of 10 times while supplying synthetic water C, and was operated for 21 hours. .

- the heat transfer tube with the scale attached after operation was taken out and weighed to calculate the scale attached amount. Thereafter, the heat transfer tube was inserted again into the stainless steel test boiler, and tested with synthetic water D under the same operating conditions, and the scale removal step was performed. Similarly, after the operation, the heat transfer tube was taken out and weighed to calculate the scale adhesion amount, and the scale removal amount was calculated from the scale adhesion amount before and after the scale removal step.

- the amount of scale removal is evaluated by taking out the heat transfer tube every 3 days, weighing it, and inserting it again, performing the scale removal process for a total of 9 days, and removing the scale after the scale removal process for 9 days (scale removal)

- scale removal The ratio of the total scale that could be removed in 9 days relative to the scale attached at the start of the process was calculated.

- Table 2 shows the following.

- Comparative Example II-11 uses two types of polymers together, but its removal effect is low. Similarly, Comparative Examples II-9 and II-10 have a low removal effect.

- the scale is removed at a constant rate even after the number of days has passed. This is because by using polymethacrylic acid in combination, the scale removal effect by polyacrylic acid having a high weight average molecular weight is kept constant while preventing iron scale adhesion.

- Test Example III Examples III-1 to 6, Comparative Examples III-1 to 4

- a test piece made of steel SPCC, 15 ⁇ 50 ⁇ 10 mm, # 400 polishing

- the synthetic water contained in was supplied under the same conditions as in Test Example II, and a corrosive confirmation test was conducted.

- the pH in the boiler can was adjusted to 11.3.

- Corrosion rate (mdd) test piece corrosion weight loss (mg) / (Surface area of test piece (dm 2 ) ⁇ test period (day)) (1)

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Wood Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Medicinal Chemistry (AREA)

- General Engineering & Computer Science (AREA)

- Thermal Sciences (AREA)

- Physics & Mathematics (AREA)

- Hydrology & Water Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Emergency Medicine (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Preventing Corrosion Or Incrustation Of Metals (AREA)

- Detergent Compositions (AREA)

- Cleaning And De-Greasing Of Metallic Materials By Chemical Methods (AREA)

- Air Humidification (AREA)

Priority Applications (11)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| BR112016017693-6A BR112016017693B1 (pt) | 2014-02-13 | 2015-01-26 | Removedor de incrustação para remover incrustações depositadas em um sistema de uma instalação de geração de vapor |

| CN201580008475.8A CN105980317A (zh) | 2014-02-13 | 2015-01-26 | 蒸气产生设备的垢去除方法和垢去除剂 |

| US15/115,493 US10384966B2 (en) | 2014-02-13 | 2015-01-26 | Method for removing scale and scale remover in steam generating facility |

| PL15748848.7T PL3106439T3 (pl) | 2014-02-13 | 2015-01-26 | Sposób usuwania kamienia kotłowego dla instalacji do wytwarzania pary |

| KR1020167021274A KR20160120723A (ko) | 2014-02-13 | 2015-01-26 | 증기 발생 설비의 스케일 제거 방법 및 스케일 제거제 |

| ES15748848T ES2943022T3 (es) | 2014-02-13 | 2015-01-26 | Método de eliminación de incrustación para instalaciones de generación de vapor |

| MYPI2016702811A MY183247A (en) | 2014-02-13 | 2015-01-26 | Method for removing scale and scale remover in steam generating facility |

| EP15748848.7A EP3106439B1 (en) | 2014-02-13 | 2015-01-26 | Scale removal method for steam generating facilities |

| SG11201606348VA SG11201606348VA (en) | 2014-02-13 | 2015-01-26 | Scale removal method and scale removal agent for steam generating facilities |

| PH12016501568A PH12016501568A1 (en) | 2014-02-13 | 2016-08-08 | Method for removing scale and scale remover in steam generating facility |

| US15/935,850 US10703659B2 (en) | 2014-02-13 | 2018-03-26 | Scale remover in steam generating facility |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014-025459 | 2014-02-13 | ||

| JP2014025459A JP5800044B2 (ja) | 2014-02-13 | 2014-02-13 | 蒸気発生設備のスケール除去方法及びスケール除去剤 |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US15/115,493 A-371-Of-International US10384966B2 (en) | 2014-02-13 | 2015-01-26 | Method for removing scale and scale remover in steam generating facility |

| US15/935,850 Division US10703659B2 (en) | 2014-02-13 | 2018-03-26 | Scale remover in steam generating facility |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015122264A1 true WO2015122264A1 (ja) | 2015-08-20 |

Family

ID=53800012

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/052012 Ceased WO2015122264A1 (ja) | 2014-02-13 | 2015-01-26 | 蒸気発生設備のスケール除去方法及びスケール除去剤 |

Country Status (13)

| Country | Link |

|---|---|

| US (2) | US10384966B2 (enExample) |

| EP (1) | EP3106439B1 (enExample) |

| JP (1) | JP5800044B2 (enExample) |

| KR (1) | KR20160120723A (enExample) |

| CN (1) | CN105980317A (enExample) |

| BR (1) | BR112016017693B1 (enExample) |

| ES (1) | ES2943022T3 (enExample) |

| MY (1) | MY183247A (enExample) |

| PH (1) | PH12016501568A1 (enExample) |

| PL (1) | PL3106439T3 (enExample) |

| SG (1) | SG11201606348VA (enExample) |

| TW (1) | TWI642636B (enExample) |

| WO (1) | WO2015122264A1 (enExample) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5800044B2 (ja) | 2014-02-13 | 2015-10-28 | 栗田工業株式会社 | 蒸気発生設備のスケール除去方法及びスケール除去剤 |

| CN105753182A (zh) * | 2016-03-08 | 2016-07-13 | 佛山市聚成生化技术研发有限公司 | 一种苯乙烯酮-马来酸酐-丁二烯-丁烯醇阻垢剂的制备方法及所制备的阻垢剂 |

| CN106838874B (zh) * | 2016-12-25 | 2019-01-18 | 大庆让胡路区轩鸿科技有限公司 | 一种无损型锅炉除垢的方法 |

| CN109323237B (zh) * | 2018-09-14 | 2020-01-07 | 福建宁德核电有限公司 | 核级聚丙烯酸分散剂用于核电厂蒸汽发生器湿保养的方法 |

| CN111748147B (zh) * | 2019-03-28 | 2022-04-05 | 合肥杰事杰新材料股份有限公司 | 一种阻垢聚丙烯材料及其制备方法 |

| KR102144295B1 (ko) * | 2019-04-19 | 2020-08-13 | 최영환 | 보일러 자동 세관 시스템 |

| JP7083365B2 (ja) * | 2020-03-12 | 2022-06-10 | 栗田工業株式会社 | ボイラにおける蒸発管の腐食疲労の抑制方法 |

| JP7050840B2 (ja) * | 2020-03-12 | 2022-04-08 | 栗田工業株式会社 | ボイラにおける蒸発管の腐食疲労の抑制方法 |

| CN115448472A (zh) * | 2022-08-17 | 2022-12-09 | 中核武汉核电运行技术股份有限公司 | 一种核级聚丙烯酸高温高压最优在线添加工艺 |

| CN116947224A (zh) * | 2023-09-21 | 2023-10-27 | 山东上远环保科技有限公司 | 一种循环水处理剂及其制备方法 |

| US12146825B1 (en) * | 2024-06-24 | 2024-11-19 | King Fahd University Of Petroleum And Minerals | System and methods for assessment of scale deposits in pipelines |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59189998A (ja) * | 1983-04-12 | 1984-10-27 | ケメツド・コ−ポレ−シヨン | スケ−ルの除去方法 |

| JPS6365999A (ja) * | 1981-11-05 | 1988-03-24 | ナルコ ケミカル カンパニー | ボイラー系のスケール防止用ポリマー組成物 |

| JP2000154996A (ja) * | 1998-08-19 | 2000-06-06 | Miura Co Ltd | ボイラのスケ―ル除去方法 |

| WO2005116296A1 (ja) * | 2004-05-25 | 2005-12-08 | Kurita Water Industries Ltd. | 冷却水の処理方法及び処理薬剤 |

| JP2008006369A (ja) * | 2006-06-29 | 2008-01-17 | Kurita Water Ind Ltd | スケール防止方法 |

| JP2010172816A (ja) * | 2009-01-29 | 2010-08-12 | Kurita Water Ind Ltd | スケール防止剤、およびスケール防止方法 |

| JP2013022535A (ja) * | 2011-07-22 | 2013-02-04 | Kurita Water Ind Ltd | ボイラ水系のスケール除去方法 |

| WO2013058115A1 (ja) * | 2011-10-18 | 2013-04-25 | 栗田工業株式会社 | 蒸気発生器の水側缶内における鉄スケール防止方法 |

| WO2013140913A1 (ja) * | 2012-03-19 | 2013-09-26 | 栗田工業株式会社 | エコノマイザを有するボイラの水処理方法 |

| WO2014162992A1 (ja) * | 2013-04-02 | 2014-10-09 | 栗田工業株式会社 | 蒸気発生設備のスケール除去方法 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA863696A (en) | 1971-02-16 | L. Salutsky Murrell | Control of scaling in evaporators | |

| GB1433221A (en) | 1973-03-27 | 1976-04-22 | Ciba Geigy Ag | Water treatment |

| CA2042341C (en) * | 1990-05-23 | 2001-06-12 | Judy H. Bardsley | Silica scale inhibition |

| JP2923039B2 (ja) | 1990-11-28 | 1999-07-26 | 三菱重工業株式会社 | スケールの除去組成物 |

| CN1068313A (zh) | 1991-07-08 | 1993-01-27 | 化学工业部天津化工研究院 | 锅炉水处理剂 |

| JP2002273478A (ja) | 2001-03-21 | 2002-09-24 | Jsr Corp | スケール防止方法 |

| DE102007019428A1 (de) * | 2006-07-07 | 2008-10-30 | Henkel Ag & Co. Kgaa | Wasch-, Reinigungs- und Pflegemittel 2 |

| DE102006047229A1 (de) * | 2006-10-04 | 2008-04-10 | Henkel Kgaa | Wasch- oder Reinigungsmittelabgabesystem |

| JP5786277B2 (ja) | 2010-03-31 | 2015-09-30 | 栗田工業株式会社 | スケール除去方法及びスケール除去剤 |

| DE102013204824A1 (de) * | 2013-03-15 | 2014-09-18 | Henkel Ag & Co. Kgaa | Reinigungsmittel für harte Oberflächen enthaltend Phosphorsäureester eines Polyether-modifizierten Alkylalkohols |

| JP5800044B2 (ja) | 2014-02-13 | 2015-10-28 | 栗田工業株式会社 | 蒸気発生設備のスケール除去方法及びスケール除去剤 |

-

2014

- 2014-02-13 JP JP2014025459A patent/JP5800044B2/ja active Active

-

2015

- 2015-01-26 EP EP15748848.7A patent/EP3106439B1/en active Active

- 2015-01-26 PL PL15748848.7T patent/PL3106439T3/pl unknown

- 2015-01-26 WO PCT/JP2015/052012 patent/WO2015122264A1/ja not_active Ceased

- 2015-01-26 CN CN201580008475.8A patent/CN105980317A/zh active Pending

- 2015-01-26 ES ES15748848T patent/ES2943022T3/es active Active

- 2015-01-26 BR BR112016017693-6A patent/BR112016017693B1/pt active IP Right Grant

- 2015-01-26 MY MYPI2016702811A patent/MY183247A/en unknown

- 2015-01-26 SG SG11201606348VA patent/SG11201606348VA/en unknown

- 2015-01-26 US US15/115,493 patent/US10384966B2/en active Active

- 2015-01-26 KR KR1020167021274A patent/KR20160120723A/ko not_active Ceased

- 2015-02-04 TW TW104103753A patent/TWI642636B/zh active

-

2016

- 2016-08-08 PH PH12016501568A patent/PH12016501568A1/en unknown

-

2018

- 2018-03-26 US US15/935,850 patent/US10703659B2/en active Active

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6365999A (ja) * | 1981-11-05 | 1988-03-24 | ナルコ ケミカル カンパニー | ボイラー系のスケール防止用ポリマー組成物 |

| JPS59189998A (ja) * | 1983-04-12 | 1984-10-27 | ケメツド・コ−ポレ−シヨン | スケ−ルの除去方法 |

| JP2000154996A (ja) * | 1998-08-19 | 2000-06-06 | Miura Co Ltd | ボイラのスケ―ル除去方法 |

| WO2005116296A1 (ja) * | 2004-05-25 | 2005-12-08 | Kurita Water Industries Ltd. | 冷却水の処理方法及び処理薬剤 |

| JP2008006369A (ja) * | 2006-06-29 | 2008-01-17 | Kurita Water Ind Ltd | スケール防止方法 |

| JP2010172816A (ja) * | 2009-01-29 | 2010-08-12 | Kurita Water Ind Ltd | スケール防止剤、およびスケール防止方法 |

| JP2013022535A (ja) * | 2011-07-22 | 2013-02-04 | Kurita Water Ind Ltd | ボイラ水系のスケール除去方法 |

| WO2013058115A1 (ja) * | 2011-10-18 | 2013-04-25 | 栗田工業株式会社 | 蒸気発生器の水側缶内における鉄スケール防止方法 |

| WO2013140913A1 (ja) * | 2012-03-19 | 2013-09-26 | 栗田工業株式会社 | エコノマイザを有するボイラの水処理方法 |

| WO2014162992A1 (ja) * | 2013-04-02 | 2014-10-09 | 栗田工業株式会社 | 蒸気発生設備のスケール除去方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3106439A4 * |

Also Published As

| Publication number | Publication date |

|---|---|

| PH12016501568B1 (en) | 2016-09-14 |

| US20180215637A1 (en) | 2018-08-02 |

| US10703659B2 (en) | 2020-07-07 |

| BR112016017693B1 (pt) | 2022-08-09 |

| MY183247A (en) | 2021-02-18 |

| PH12016501568A1 (en) | 2016-09-14 |

| EP3106439A1 (en) | 2016-12-21 |

| TW201538438A (zh) | 2015-10-16 |

| BR112016017693A2 (enExample) | 2017-08-08 |

| US20170050873A1 (en) | 2017-02-23 |

| JP5800044B2 (ja) | 2015-10-28 |

| PL3106439T3 (pl) | 2023-06-19 |

| EP3106439A4 (en) | 2017-08-02 |

| KR20160120723A (ko) | 2016-10-18 |

| EP3106439B1 (en) | 2023-03-22 |

| SG11201606348VA (en) | 2016-09-29 |

| ES2943022T3 (es) | 2023-06-08 |

| JP2015150484A (ja) | 2015-08-24 |

| TWI642636B (zh) | 2018-12-01 |

| US10384966B2 (en) | 2019-08-20 |

| CN105980317A (zh) | 2016-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5800044B2 (ja) | 蒸気発生設備のスケール除去方法及びスケール除去剤 | |

| EP3063311B1 (en) | Corrosion inhibiting compositions and methods | |

| JP5773091B2 (ja) | 蒸気発生設備のスケール除去方法 | |

| JP5786277B2 (ja) | スケール除去方法及びスケール除去剤 | |

| JP2013194256A (ja) | 防食方法 | |

| JP5900064B2 (ja) | エコノマイザを有するボイラの水処理方法 | |

| JP5891630B2 (ja) | ボイラ水系のスケール除去方法 | |

| JP2003159597A (ja) | 水処理剤 | |

| JP6314560B2 (ja) | 蒸気発生設備の水処理方法 | |

| JP5909956B2 (ja) | ボイラにおけるエコノマイザの腐食抑制方法 | |

| JP5691697B2 (ja) | 蒸気発生設備の水処理方法 | |

| JP2013068341A (ja) | ボイラにおけるエコノマイザの防食方法 | |

| JP5862193B2 (ja) | 蒸気発生器の水側缶内における鉄スケール防止方法 | |

| JP6156494B2 (ja) | 蒸気発生設備の水処理方法 | |

| JP5879699B2 (ja) | ボイラ給水系の防食方法 | |

| JP5640608B2 (ja) | 酸素除去方法及び酸素除去剤 | |

| JP2009299161A (ja) | 水系の金属腐食抑制方法 | |

| JP2003160889A (ja) | 水処理剤 | |

| JP2012184465A (ja) | ボイラ給水系及びボイラ缶内の防食方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15748848 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15115493 Country of ref document: US |

|

| ENP | Entry into the national phase |

Ref document number: 20167021274 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 12016501568 Country of ref document: PH |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112016017693 Country of ref document: BR |

|

| REEP | Request for entry into the european phase |

Ref document number: 2015748848 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2015748848 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: IDP00201605346 Country of ref document: ID |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 112016017693 Country of ref document: BR Kind code of ref document: A2 Effective date: 20160729 |