WO2014126060A1 - シートベルト用リトラクタ - Google Patents

シートベルト用リトラクタ Download PDFInfo

- Publication number

- WO2014126060A1 WO2014126060A1 PCT/JP2014/053081 JP2014053081W WO2014126060A1 WO 2014126060 A1 WO2014126060 A1 WO 2014126060A1 JP 2014053081 W JP2014053081 W JP 2014053081W WO 2014126060 A1 WO2014126060 A1 WO 2014126060A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- lock

- lock arm

- rotation

- seat belt

- displacement

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R22/00—Safety belts or body harnesses in vehicles

- B60R22/34—Belt retractors, e.g. reels

- B60R22/36—Belt retractors, e.g. reels self-locking in an emergency

- B60R22/405—Belt retractors, e.g. reels self-locking in an emergency responsive to belt movement and vehicle movement

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R22/00—Safety belts or body harnesses in vehicles

- B60R22/34—Belt retractors, e.g. reels

- B60R2022/3419—Belt retractors, e.g. reels with end lock preventing means

Definitions

- the present invention relates to a seat belt retractor which winds webbing of a seat belt around a rotatable winding drum.

- a vehicle such as a car is equipped with a seat belt device provided with a retractor in order to protect an occupant seated in a seat.

- the occupant wears the webbing (seat belt) pulled out from the winding drum of the retractor, and is restrained by the webbing to the seat.

- the webbing is rapidly pulled out due to the movement of the occupant, the rotation of the winding drum in the pulling direction is stopped by the lock mechanism of the retractor, and the pulling of the webbing is stopped.

- the webbing removed from the occupant is taken up by the rotating winding drum and stored in the retractor until it is pulled out next time.

- the lock mechanism may be erroneously operated due to the reaction stop of the rotation of the winding drum.

- the locking mechanism is activated, the rotation of the take-up drum in the pulling direction is stopped and the webbing can not be pulled out of the take-up drum.

- the webbing can not be taken up, and an end lock occurs in the retractor.

- a retractor which suppresses rotation of a flywheel for operating a lock mechanism by a friction spring (see Patent Document 1).

- Patent No. 4758967 gazette

- the present invention has been made in view of the above-mentioned conventional problems, and an object thereof is to reliably suppress the occurrence of end lock in the seat belt retractor when the webbing is wound up.

- the present invention relates to a take-up drum rotatable in a take-up direction and a draw-out direction of a webbing, and a displacement member which rotates together with the take-up drum and is displaceable in a lock operating direction according to acceleration in the draw-out direction of the take-up drum.

- a seat belt retractor comprising: a restricting member for restricting displacement, wherein the restricting member is separated from the displacing member at the time of rotation of the take-up drum in the pull-out direction, and at the time of rotation of the take-up drum in the take-up direction.

- the displacement member engages with the pressing portion of the regulating member and presses the regulating member by the pressing portion.

- a seat belt retractor having an engaging portion to maintain.

- the occurrence of end lock in the seat belt retractor can be reliably suppressed.

- FIG. 2 is a cross-sectional view of the seat belt retractor taken along line X2-X2 of FIG. 1 in the arrow direction.

- FIG. 2 is a cross-sectional view of the seat belt retractor taken along line X2-X2 of FIG. 1 in the arrow direction.

- FIG. 20 is a cross-sectional view of a Y2 part of FIG. It is a figure which shows the operation

- the retractor is a webbing take-up device that takes up webbing of a seat belt, and is provided in a seat belt device for a vehicle.

- a seat belt device provided with a retractor is mounted on a vehicle and protects an occupant seated on a seat by webbing (seat belt).

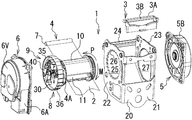

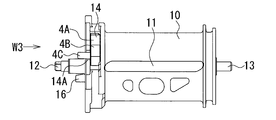

- FIG. 1 is a perspective view of the retractor 1 of the present embodiment.

- FIG. 2 is a perspective view showing the disassembled retractor 1 viewed from the direction W1 of FIG. 1, and shows the retractor 1 disassembled into a plurality of units.

- the belt-like webbing 2 is indicated by a dotted line.

- the retractor 1 is fixed to the end of the housing unit 3, the take-up drum unit 4 having the take-up drum 10 of the webbing 2, the take-up spring unit 5, the mechanism cover unit 6, and the webbing 2. It has a locking pin 7.

- the winding spring unit 5 and the mechanism cover unit 6 are fixed to the side surface of the housing unit 3.

- the take-up spring unit 5 and the mechanism cover unit 6 cover both axial ends of the take-up drum unit 4 outside the housing unit 3 and rotatably support the take-up drum unit 4.

- the webbing 2 is inserted into the insertion portion 11 of the winding drum 10, and the retaining pin 7 prevents the webbing 2 from coming off the insertion portion 11.

- the end of the webbing 2 is attached to the winding drum 10.

- the take-up spring unit 5 is a take-up means for taking up the webbing 2 on the take-up drum 10, and rotates the take-up drum 10 in a rotational direction M (referred to as a take-up direction) when taking up the webbing 2.

- the webbing 2 is taken up by the rotating winding drum 10 and stored in the retractor 1. From the state, the webbing 2 is pulled out from the retractor 1 while rotating the winding drum 10 in a rotation direction (referred to as a pulling-out direction) P when the webbing 2 is pulled out.

- the take-up drum unit 4 has a clutch unit 8 and rotates in the take-up direction M and the draw-out direction P in the retractor 1.

- the winding drum 10 normally rotates with the clutch unit 8 and rotates independently from the clutch unit 8 in an emergency or the like.

- the mechanism cover unit 6 covers the clutch unit 8 of the winding drum unit 4 and constitutes a lock mechanism 9 that stops the rotation of the winding drum 10 together with the clutch unit 8.

- the lock mechanism 9 is lock means for locking the take-up drum 10 rotating in the pull-out direction P.

- the lock mechanism 9 By the operation of the lock mechanism 9, the drawing of the webbing 2 is stopped.

- FIG. 3 and 4 are perspective views of the retractor 1 completely disassembled, showing the retractor 1 viewed from different directions.

- 3 shows the retractor 1 viewed from the same direction as FIG. 1

- FIG. 4 shows the retractor 1 viewed from the W2 direction of FIG.

- the units 3 to 6 of the retractor 1 are assembled by combining a plurality of parts.

- the retractor 1 is manufactured by combining the plurality of units 3 to 6.

- each part of these retractors 1 will be described in detail in order.

- the housing unit 3 has a housing 20 for housing the winding drum 10, and a protector 3A formed of a synthetic resin.

- the housing 20 includes a back plate portion 21 fixed to the vehicle body, a pair of side wall portions 22 and 23 (first side wall portion 22 and second side wall portion 23) projecting from both side edges of the back plate portion 21 It comprises a fixed plate 24 fixed to the side wall portions 22 and 23.

- the protector 3 ⁇ / b> A includes the passing portion 3 ⁇ / b> B of the webbing 2 and is attached to the upper edge portion of the back plate portion 21.

- the webbing 2 is passed through the passage portion 3B of the protector 3A, and passes through the passage portion 3B at the time of winding and drawing.

- the housing 20 has a circular first opening 25 formed in the first side wall 22, a plurality of lock teeth 26 projecting inside the first opening 25, and a second opening 25 formed in the second side wall 23. 2 has an opening 27.

- the plurality of lock teeth 26 have a triangular shape and are formed on the entire inner periphery of the first opening 25.

- the winding drum 10 is inserted into the first opening 25 and accommodated in the housing 20. Further, both ends of the winding drum 10 are disposed in the first opening 25 and the second opening 27, respectively, and the clutch unit 8 is disposed on the side of the first side wall 22. In that state, the mechanism cover unit 6 is attached to the first side wall 22, and the take-up spring unit 5 is attached to the second side wall 23.

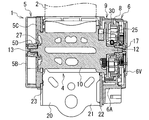

- FIG. 5 is a cross-sectional view of the retractor 1 when the X1-X1 line of FIG. 1 is viewed in the arrow direction

- FIG. 6 is a cross-sectional view of the retractor 1 when the X2-X2 line of FIG. 1 is viewed in the arrow direction.

- the winding drum 10 in a state in which the axial center of the winding drum 10 coincides with the center of the first opening 25, the winding drum 10 is disposed in the housing 20, the first opening 25, and the second opening 27. Rotate.

- the winding drum 10 has a pair of shafts 12 and 13 (a first shaft 12 and a second shaft 13) projecting laterally along the axial center.

- the mechanism cover unit 6 is combined with the clutch unit 8 to rotatably support the first shaft 12.

- the take-up spring unit 5 is coupled to the second shaft 13 to rotatably support the second shaft 13.

- the take-up spring unit 5 (see FIGS. 3 and 4) has a spiral spring 5A, a spring case 5B for housing the spiral spring 5A, a spring sheet 5C in contact with the second side wall 23 of the housing 20, and a spring shaft 5D.

- the outer end K1 of the spiral spring 5A is fixed to the spring case 5B, and the inner end K2 of the spiral spring 5B is fixed to the spring shaft 5D.

- the spring sheet 5C is attached to the spring case 5B and covers the spiral spring 5A in the spring case 5B. In that state, the spring shaft 5D is rotatably attached to the spring case 5B and the spring sheet 5C.

- the second shaft 13 of the winding drum 10 is inserted into the support hole 5E, rotatably supported by the spring sheet 5C, and fixed to the spring shaft 5D.

- the spring shaft 5D rotates integrally with the winding drum 10, and transmits the biasing force of the spiral spring 5A to the winding drum 10.

- the winding spring unit 5 always biases the winding drum 10 in the winding direction M of the webbing 2 by the spiral spring 5A.

- the spiral spring 5A is wound by the rotation of the winding drum 10.

- the winding drum unit 4 and the winding drum 10 are rotated in the winding direction M by the biasing of the spiral spring 5A, and the webbing 2 is wound around the winding drum 10.

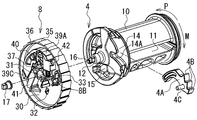

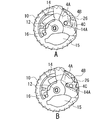

- FIG. 7 is a perspective view of the disassembled take-up drum unit 4 and shows the take-up drum 10 and the clutch unit 8 viewed from the same direction as FIG.

- FIG. 8 is a perspective view of the disassembled clutch unit 8 and is an enlarged view of the clutch unit 8 of FIG.

- the take-up drum unit 4 includes a take-up drum 10 rotatable in the take-up direction M and the draw-out direction P of the webbing 2, a movable pawl 4A engaged with lock teeth 26 of the housing 20, and a clutch unit 8 And a cap 17.

- the movable pawl 4A includes an engaging claw 4B engaged with the lock tooth 26 and an interlocking pin 4C projecting laterally.

- the interlocking pin 4C moves from the guiding portion (penetration portion) 14A of the pawl accommodating portion 14 toward the clutch unit 8 Stand out.

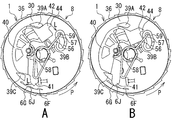

- FIG. 9 is a front view of the winding drum 10 accommodating the movable pawl 4A

- FIG. 10 is a side view of the winding drum 10 viewed from the W3 direction of FIG.

- the lock teeth 26 of the housing 20 are shown by dotted lines.

- the movable pawl 4A is movably accommodated in the pawl accommodating portion 14 and moves in the inward and outward direction of the pawl accommodating portion 14.

- the interlocking pin 4C slides on the guiding portion 14A and moves along the guiding portion 14A.

- the movable pawl 4A is shown in the non-locking position (the position shown in FIG. 10A) in which the engaging claw 4B does not engage with the locking tooth 26 and in the locking position (FIG. 10B) in which the engaging claw 4B engages with the locking tooth 26.

- the engagement claw 4B engages with the lock tooth 26, and the movement of the movable pawl 4A is blocked.

- the take-up drum 10 rotating in the pull-out direction P is pressed by the movable pawl 4A, the take-up drum 10 is locked, and the rotation of the take-up drum 10 in the pull-out direction P is stopped. Therefore, the movable pawl 4A, together with the clutch unit 8, forms a part of the lock mechanism 9.

- the clutch unit 8 (see FIGS. 7 and 8) includes a circular locking clutch 30, a lock arm 40 displaceably connected to the locking clutch 30, a return spring 8A, and a sensor spring 8B.

- the locking clutch 30 is a rotating body that rotates with the winding drum 10 and is rotatable relative to the winding drum 10.

- the first shaft 12 of the winding drum 10 is inserted into the central hole 31 of the locking clutch 30, and the cap 17 is fixed to the tip of the first shaft 12 protruding from the central hole 31.

- the locking clutch 30 is rotatably coupled to the winding drum 10.

- the locking clutch 30 has a spring holder 32 formed on the winding drum 10 side, and the return spring 8A is attached to the spring holder 32.

- the return spring 8 A and the spring holder 32 are disposed in the recess 15 of the winding drum 10 in a state where the return spring 8 A is contracted.

- the interlocking pin 4C of the movable pawl 4A is inserted into the guide groove 33 of the locking clutch 30, and the cylindrical protrusion 16 (see FIG. 3) of the winding drum 10 is inserted into the through groove 34 of the locking clutch 30.

- the projection 16 is formed on the side surface of the winding drum 10 and moves in the through groove 34 in the rotational direction of the winding drum 10.

- the locking clutch 30 (see FIGS. 7 and 8) is biased in the pull-out direction P of the webbing 2 by the return spring 8A, and normally rotates with the winding drum 10. At that time, the movable pawl 4A is maintained in the non-locking position in the pawl accommodating portion 14. In an emergency or the like, with the locking clutch 30 locked, the take-up drum 10 rotates with the movable pawl 4A in the pull-out direction P with respect to the stopped locking clutch 30. Along with this, the interlocking pin 4C of the movable pawl 4A is pushed by the locking clutch 30, and moves in the guide groove 33.

- the interlocking pin 4 ⁇ / b> C is guided by the guide groove 33 and moves along the guide groove 33 radially outward of the locking clutch 30.

- the movable pawl 4A moves to the lock position, and the engagement claw 4B of the movable pawl 4A engages with the lock tooth 26 (see FIG. 10).

- the engagement claw 4B At the time of engagement between the engagement claw 4B and the lock tooth 26, the engagement claw 4B contacts the lock tooth 26, and along with the rotation of the winding drum 10 in the pull-out direction P, the engagement claw 4B is in the radial direction of the locking clutch 30. Move outwards. Thereby, the engagement claws 4B move along the lock teeth 26 toward the bottom of the lock teeth 26. When the engagement claw 4B reaches the bottom of the lock tooth 26, the engagement claw 4B completely engages with the lock tooth 26, and the engagement between the movable pawl 4A (the engagement claw 4B) and the lock tooth 26 is completed. Do.

- the engagement claws 4B and the lock teeth 26 are formed in such a manner as to engage with each other.

- the lock mechanism 9 moves the movable pawl 4A as described above while the winding drum 10 rotates by a predetermined amount in the pull-out direction P, and engages the movable pawl 4A with the lock tooth 26.

- the winding drum 10 is locked by the lock mechanism 9, and the rotation of the winding drum 10 in the pulling direction P is stopped.

- the locking clutch 30 rotates relative to the take-up drum 10 in the pull-out direction P with the biasing of the return spring 8A (see FIGS. 7 and 8).

- the interlocking pin 4 ⁇ / b> C is pushed by the locking clutch 30 and moves in the guide groove 33.

- the interlocking pin 4 ⁇ / b> C is guided by the guide groove 33 and moves along the guide groove 33 radially inward of the locking clutch 30.

- the movable pawl 4A is separated from the lock tooth 26 by the movement of the interlocking pin 4C and returns to the non-locking position. As a result, the lock of the winding drum 10 by the lock mechanism 9 is released.

- the locking clutch 30 includes a ratchet wheel 36 having a plurality of teeth 35, an arm support 37 rotatably supporting the lock arm 40, and a support pin 38 supporting the sensor spring 8B.

- the ratchet wheel 36 is an annular member formed on the outer periphery of the locking clutch 30 and is rotatable with the winding drum 10.

- the plurality of teeth 35 are inclined so as to stop only the rotation of the ratchet wheel 36 in the pull-out direction P, and are formed on the entire outer periphery of the ratchet wheel 36.

- the lock arm 40 has a through hole 43 formed between one end (engaging end) 41 and the other end (free end) 42 in the longitudinal direction, and is formed in a curved shape.

- the lock arm 40 is attached to the arm support 37 and is rotatably coupled to the locking clutch 30.

- the lock arm 40 is disposed inside the ratchet wheel 36 and rotates about the arm support 37.

- the sensor spring 8B is disposed between the other end 42 of the lock arm 40 and the support pin 38, and biases the other end 42 in the pull-out direction P. By this biasing, the other end 42 of the lock arm 40 contacts the first stopper 39A of the locking clutch 30.

- the lock arm 40 is rotatable with the winding drum 10 and rotates with the winding drum 10 and the locking clutch 30 in the pull-out direction P and the winding direction M. Under normal conditions, the other end 42 of the lock arm 40 is maintained in contact with the first stopper 39A of the locking clutch 30 by the biasing of the sensor spring 8B.

- a predetermined acceleration that is, when the acceleration (rotational acceleration) of the withdrawal direction P of the winding drum 10 rotating in the withdrawal direction P exceeds the predetermined acceleration

- a delay due to inertia occurs in the lock arm 40 with respect to the rotating locking clutch 30.

- the lock arm 40 rotates while compressing the sensor spring 8 B, and the one end portion 41 of the lock arm 40 is displaced radially outward of the locking clutch 30.

- the lock mechanism 9 of the retractor 1 operates.

- the lock arm 40 is a displacement member that can be displaced in the lock actuation direction according to the acceleration in the pull-out direction P of the winding drum 10, and is displaced in the predetermined lock actuation direction in response to the acceleration.

- the lock operating direction is a direction for operating the lock mechanism 9, in which the one end 41 of the lock arm 40 is displaced radially outward of the locking clutch 30.

- the lock mechanism 9 is actuated by the lock arm 40 displaced in the lock actuation direction.

- the lock arm 40 may be displaced, or the lock arm 40 may be displaced relative to the winding drum 10 and the locking clutch 30.

- the lock arm 40 may be displaced relative to the winding drum 10 and the locking clutch 30 while being displaced. Therefore, the displacement of the lock arm 40 includes such displacement in each aspect.

- the lock arm 40 is coupled to the locking clutch 30 so as to be displaceable in the lock actuation direction and rotates together with the locking clutch 30.

- the arm support 37 is a support for the displacement member, and the lock arm 40 is displaced in the lock operation direction by rotation.

- the lock arm 40 is displaced in both directions by rotating in the direction opposite to the lock actuation direction and the lock actuation direction. Due to the biasing of the sensor spring 8 B, the lock arm 40 is displaced (rotated) in the direction opposite to the lock actuation direction, and one end 41 of the lock arm 40 is displaced radially inward of the locking clutch 30.

- the lock mechanism 9 (see FIG. 2) is actuated by the displacement of the lock arm 40 in the lock operation direction, and stops the rotation of the take-up drum 10 in the pull-out direction P.

- the lock mechanism 9 is actuated by the rotation stop of the drawing direction P of the ratchet wheel 36 to stop the rotation of the take-up drum 10 in the drawing direction P.

- the retractor 1 is provided in the mechanism cover unit 6 with means for stopping the lock arm 40 displaced in the locking direction (lock arm stopping means), and means for stopping the rotation of the ratchet wheel 36 (ratchet wheel stop Means).

- lock arm stopping means means for stopping the lock arm 40 displaced in the locking direction

- ratchet wheel stop Means means for stopping the rotation of the ratchet wheel 36

- the locking clutch 30 is stopped.

- the movable pawl 4A of the lock mechanism 9 moves to the lock position with the rotation of the take-up drum 10 in the pull-out direction P, and the take-up drum 10 is locked.

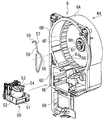

- the mechanism cover unit 6 (see FIGS. 3 and 4) includes an acceleration sensor 50 for detecting the acceleration of the vehicle, a mechanism cover 6A for accommodating the clutch unit 8, a restricting member 56 for restricting the displacement of the lock arm 40, and a retractor. It has switching means 60 which switches the state of 1.

- the acceleration sensor 50 is a ratchet wheel stop unit, and is an emergency lock activation device that activates the lock mechanism 9 in an emergency of the vehicle.

- the acceleration sensor 50 also has a sensor holder 51, an inertial mass 52, and a sensor lever 53.

- the inertial mass body 52 is formed of a metal sphere and is movably disposed in the recess of the sensor holder 51.

- the sensor lever 53 covers the inertial mass body 52 from above and is attached to the sensor holder 51 so as to be vertically movable.

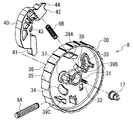

- FIG. 11 is a perspective view of the acceleration sensor 50, the mechanism cover 6A, and the regulating member 56.

- the mechanism cover 6A includes a cylindrical clutch housing 6B for housing the locking clutch 30, a sensor housing 6C for housing the acceleration sensor 50, and a sensor cover for covering the acceleration sensor 50 in the sensor housing 6C. It has 6D. With the acceleration sensor 50 attached to the sensor housing 6C, the lock claw 54 of the sensor lever 53 protrudes upward and is disposed at the opening 6E of the clutch housing 6B.

- FIG. 12 is a cross-sectional view of the mechanism cover unit 6 viewed from the W4 direction of FIG. 11, and also shows the locking clutch 30 housed in the clutch housing portion 6B.

- the inertial mass 52 is movably held between the sensor holder 51 and the sensor lever 53.

- a vehicle emergency for example, a collision, a sudden brake

- the inertial mass 52 moves on the sensor holder 51 by the inertial force to move the sensor lever 53. Push upwards.

- the lock claw 54 of the sensor lever 53 moves into the clutch housing 6B and meshes with the teeth 35 of the ratchet wheel 36.

- the teeth 35 of the ratchet wheel 36 mesh with the lock claws 54 of the sensor lever 53 only when the ratchet wheel 36 rotates in the pull-out direction P.

- the locking wheel 54 locks the ratchet wheel 36 (locking clutch 30), and the rotation of the ratchet wheel 36 in the pulling direction P is stopped.

- the lock mechanism 9 operates to lock the winding drum 10 by the movable pawl 4A.

- the lock mechanism 9 stops the rotation of the take-up drum 10 in the pull-out direction P, and the pull-out of the webbing 2 stops. Therefore, the acceleration sensor 50 and the lock mechanism 9 constitute a vehicle body sensitive lock mechanism which stops the pulling of the webbing 2 in response to the rapid change of the speed of the vehicle.

- the inertial mass 52 moves to the original position by gravity. Thereafter, the winding drum 10 is released from the load of the webbing 2 and can rotate in the winding direction M. As the take-up drum 10 and the locking clutch 30 rotate in the take-up direction M, the lock claws 54 separate from the teeth 35 of the ratchet wheel 36 and move out of the clutch accommodation portion 6B. At the same time, the locking of the ratchet wheel 36 (locking clutch 30) is released. Further, the lock of the winding drum 10 by the lock mechanism 9 is released, and the webbing 2 can be pulled out and wound up.

- the mechanism cover 6A (see FIG. 11) includes an annular wall 6F formed in the clutch housing 6B, a stop 6G formed on the inner periphery of the annular wall 6F, and a central support located at the center of the annular wall 6F. 6H and an insertion hole 6I penetrating the center support 6H.

- a cap 17 (see FIG. 7) fixed to the first shaft 12 is inserted into the insertion hole 6I, and the first shaft 12 of the winding shaft 10 is rotatably supported by the center support portion 6H.

- the locking clutch 30, the ratchet wheel 36, and the lock arm 40 are accommodated in the clutch accommodation portion 6B (see FIGS. 11 and 12).

- a ratchet wheel 36 is disposed between the inner periphery of the clutch housing 6B and the outer periphery of the annular wall 6F, and the lock arm 40 is disposed inside the annular wall 6F.

- the center support portion 6H is also a support member support portion that rotatably supports the control member 56, and is formed of an annular convex portion that protrudes into the clutch storage portion 6B.

- the restricting member 56 has a pressing portion 57 for pressing the lock arm 40 and an attaching portion 58 attached to the central support 6H.

- the restriction member 56 is formed in a predetermined shape by bending the wire, and the attachment portion 58 is a clip that is fitted into the center support portion 6H.

- the pressing portion 57 of the regulating member 56 has a linear shape, and is disposed outward in the radial direction of the locking clutch 30 from the center support portion 6H (attachment portion 58).

- the tip end portion of the pressing portion 57 is bent toward the lock arm 40, and the lock arm 40 contacts the bent portion (contact portion 59) of the pressing portion 57.

- the restriction member 56 is adjacent to the lock arm 40 inside the annular wall 6F, and rotates in the winding direction M and the drawing direction P about the center support portion 6H. During normal rotation of the winding drum 10, the regulating member 56 rotates in conjunction with the rotation of the locking clutch 30 and the lock arm 40.

- the stopper 6G is a lock arm stopper and has a plurality of engaging teeth 6J formed on the entire inner periphery of the annular wall 6F.

- the engagement tooth 6J is an engagement portion of the stop portion 6G engaged with the lock arm 40 displaced in the lock operation direction, and engages with one end 41 of the lock arm 40. Further, the plurality of engagement teeth 6J protrude toward the lock arm 40 and incline so as to stop only the rotation in the pull-out direction P of the lock arm 40 and the locking clutch 30. Only when the locking clutch 30 rotates in the pull-out direction P, the one end portion 41 of the lock arm 40 engages with the engagement tooth 6J of the stop portion 6G in a hooked manner.

- FIG. 13 is a view showing an operation of the lock arm 40 at the time of pulling out the webbing 2, and shows a part of the stop portion 6G and the clutch unit 8.

- the lock operation direction L of the lock arm 40 is indicated by an arrow.

- the pressing portion 57 of the regulating member 56 is separated from the other end 42 of the lock arm 40 by the rotation of the winding drum 10 in the pull-out direction P, and contacts the second stopper 39 B of the locking clutch 30.

- the pressing portion 57 is pushed in the pull-out direction P by the second stopper 39 B, and the restriction member 56 rotates in the pull-out direction P together with the locking clutch 30.

- the holding portion 57 is maintained in a state of being separated from the lock arm 40 (a state in which the displacement of the lock arm 40 in the lock operation direction L is not restricted) during rotation of the take-up drum 10 in the pullout direction P. Allowing 40 displacement in the lock actuation direction L.

- the lock arm 40 responds to the acceleration in the pull-out direction P of the take-up drum 10 (See FIG. 13B). Along with this, the lock arm 40 is displaced by rotation and contacts the third stopper 39C of the locking clutch 30. Further, one end 41 of the lock arm 40 approaches the stop 6G and engages with the engagement tooth 6J. The stopper 6G engages with the lock arm 40 displaced in the lock actuation direction L to stop the lock arm 40.

- the lock arm 40 holds the lock arm 40 displaced in the lock actuating direction L by engagement with the stop 6G (engagement teeth 6J), and the lock arm 40 and the lock rotate together with the winding drum 10 The rotation of the clutch 30 is stopped. Further, the lock arm 40 is maintained in the stopped state at the stop portion 6G, and in that state, the lock mechanism 9 starts to operate with the rotation of the take-up drum 10 in the pull-out direction P.

- the locking clutch 30 is locked by the lock arm 40, and the rotation of the locking clutch 30 in the pulling direction P is stopped.

- the lock mechanism 9 operates to lock the winding drum 10 by the movable pawl 4A.

- the lock mechanism 9 stops the rotation of the take-up drum 10 in the pull-out direction P, and the pull-out of the webbing 2 stops.

- the stop portion 6G of the lock arm 40 constitutes a part of the lock mechanism 9.

- the stop portion 6G and the lock mechanism 9 constitute a webbing sensitive lock mechanism that stops the webbing 2 being pulled out in response to the rapid pulling out of the webbing 2.

- the locking of the locking clutch 30 is released.

- the lock arm 40 is released from the stop 6G and displaced in the opposite direction to the lock actuation direction L.

- the winding drum 10 is released from the load of the webbing 2 and rotates in the winding direction M according to the winding of the webbing 2.

- the locking clutch 30 rotates relative to the take-up drum 10 in the pull-out direction P, and the lock of the take-up drum 10 by the lock mechanism 9 is released. After that, the webbing 2 can be pulled out and taken up.

- FIG. 14 is a view showing the operation of the lock arm 40 at the time of winding of the webbing 2, and shows a part of the stop portion 6G and the clutch unit 8.

- the locking clutch 30 and the lock arm 40 rotate integrally with the winding drum 10 in the winding direction M.

- the pressing portion 57 of the regulating member 56 contacts the other end 42 of the lock arm 40 and is pushed in the winding direction M by the other end 42.

- the restricting member 56 rotates in the winding direction M together with the lock arm 40.

- the lock mechanism 9 may be operated erroneously due to the reaction stop of the rotation of the winding drum 10. That is, with respect to the locking clutch 30 whose rotation has been stopped, the lock arm 40 is displaced in the lock operation direction L (here, the winding direction M) by inertia force, and the lock mechanism 9 is operated.

- the lock mechanism 9 operates, the rotation of the take-up drum 10 in the pull-out direction P is stopped, and the webbing 2 can not be pulled out of the take-up drum 10.

- the webbing 2 can not be taken up, and an end lock occurs in the retractor 1.

- the restricting member 56 restricts the displacement of the lock arm 40 in the lock actuation direction L due to the reaction stop of the rotation stop of the winding drum 10 in the winding direction M, and the actuation of the lock mechanism 9. To prevent.

- FIG. 15 is a view showing a restricting member 56 which restricts the displacement of the lock arm 40.

- FIG. 15A is an enlarged view of a part of FIG. 14B

- FIG. 15B is an enlarged view of a Y1 portion of FIG. 15A.

- the pressing portion 57 (contact portion 59) of the regulating member 56 separates from the lock arm 40 when the winding drum 10 rotates in the pull-out direction P.

- the pressing portion 57 presses the lock arm 40 which contacts the lock arm 40 and is displaced in the lock operation direction L as illustrated.

- the pressing portion 57 contacts the other end 42 of the lock arm 40 by the rotation of the winding drum 10 in the winding direction M, and contacts the lock arm 40 while the winding drum 10 rotates in the winding direction M. It is maintained in the Further, the pressing portion 57 presses the lock arm 40 displaced in the lock operation direction L by reaction of the rotation stop of the winding drum 10 in the winding direction M.

- the lock arm 40 has an engaging portion 44 that engages with the pressing portion 57 of the regulating member 56 when displaced in the locking direction L.

- the engagement portion 44 is a convex portion formed on the other end portion 42 of the lock arm 40 and protrudes in the lock operation direction L side.

- the sliding portion 45 of the lock arm 40 is a portion close to the engagement portion 44 of the lock arm 40.

- the pressing portion 57 slides on the sliding portion 45 to approach the engaging portion 44 or separate from the engaging portion 44. In this state, the engaging portion 44 does not engage with the pressing portion 57, and the restricting member 56 slides in the sliding direction 45 and rotates in the winding direction M together with the lock arm 40.

- the pressing portion 57 and the engaging portion 44 approach each other, and the engaging portion 44 engages with the pressing portion 57.

- the pressing portion 57 slides the sliding portion 45 formed of a flat surface or a curved surface toward the engaging portion 44 and contacts the engaging portion 44.

- the engaging portion 44 formed of the convex portion comes in contact with and is caught by the contact portion 59 of the pressing portion 57, stops the movement of the pressing portion 57, and engages with the pressing portion 57.

- the engaging portion 44 restrains the pressing portion 57 of the regulating member 56 to block the movement (including sliding and rotation) of the pressing portion 57. The movement of the pressing portion 57 is blocked by the engaging portion 44, and the regulating member 56 is stopped.

- the engaging member 44 of the lock arm 40 maintains the restricting member 56 in a state (restricted state) in which the lock arm 40 is pressed by the pressing portion 57 to restrict the displacement of the lock arm 40. Further, the holding portion 57 is held in the state of holding the lock arm 40 by engaging with the engaging portion 44, and stops the displacement of the lock arm 40 in the locking operation direction L.

- the restricting member 56 presses the engaging portion 44 displaced together with the lock arm 40 by the pressing portion 57 to restrict the displacement of the lock arm 40 in the lock operation direction L.

- the engaging portion 44 of the lock arm 40 has an engaging surface 46 that contacts the pressing portion 57 of the regulating member 56, and engages with the pressing portion 57 at the engaging surface 46.

- the engagement surface 46 is a flat surface or a curved surface, and is formed so as not to apply a force in the direction of moving the pressing portion 57 to the pressing portion 57.

- the rotation center N1 of the restriction member 56 is disposed at a position different from the rotation center N2 of the lock arm 40 by the center support portion 6H which is the restriction member support portion.

- the rotation radius R2 of the engagement portion 44 is set larger than the rotation radius R1 of the pressing portion 57.

- the rotation radius R2 of the engagement portion 44 is the distance from the rotation center N2 of the lock arm 40 to the contact point between the engagement portion 44 and the pressing portion 57, and the rotation radius R1 of the pressing portion 57 is the rotation center N1 of the regulating member 56. To the contact point between the engaging portion 44 and the pressing portion 57.

- the displacement direction (rotational trajectory) S2 due to the rotation of the engaging portion 44 is set in a direction intersecting the rotational direction (rotational trajectory) S1 of the pressing portion 57 (contact portion 59).

- the engaging portion 44 is displaced in the direction of pressing the pressing portion 57 of the regulating member 56 together with the lock arm 40, and the front of the displacement direction S2.

- the normal T of the engaging surface 46 passes through the rotation center N1 of the regulating member 56. Therefore, the pressing portion 57 is pressed against the center support portion 6H by the engaging portion 44, and only the force directed to the rotation center N1 is applied to the pressing portion 57.

- the force applied from the engaging portion 44 prevents the movement of the pressing portion 57, and the regulating member 56 is maintained in the regulated state. Further, the operation of the lock mechanism 9 due to the displacement of the lock arm 40 is prevented, and the occurrence of end lock in the retractor 1 is suppressed.

- the engagement portion 44 is displaced in the opposite direction of the displacement direction S2 by the biasing of the sensor spring 8B. Smoothly separate from the pressing portion 57. Thereby, the engagement between the engaging portion 44 and the pressing portion 57 is released.

- the surface of the lock arm 40 and the restricting member 56 that contacts the engaging portion 44 of the pressing portion 57 may be formed into a curved surface, or may be formed into a flat surface or a shape having a corner.

- the pressing portion 57 may be in line contact with the engaging portion 44 or may be in point or surface contact with the engaging portion 44.

- the engagement portion 44 may be formed such that the normal T of the engagement surface 46 is offset from the rotation center N1 of the restriction member 56. For example, by shifting the normal T of the engagement surface 46 toward the rotation center N2 of the lock arm 40, a force in the opposite direction to the rotation direction S1 is applied from the engagement portion 44 to the pressing portion 57.

- a portion (such as a hook-like portion) that interferes with the rotation of the pressing portion 57 may be formed in the engaging portion 44.

- the engaging portion 44 more reliably restrains the pressing portion 57, and the regulating member 56 is stably maintained in the state where the locking arm 40 is pressed by the pressing portion 57.

- the holding portion 57 may be held in the engaging portion 44 by the static frictional force of the holding portion 57 and the engaging portion 44 so that the engaging portion 44 is engaged with the holding portion 57.

- the contact point between the engaging portion 44 and the pressing portion 57 is connected to the rotation center N1 of the regulating member 56, and a virtual line is drawn to the contact point and the rotation center N1.

- the angle (normal angle) between the imaginary line and the normal T to the engagement surface 46 is equal to or less than the friction angle ⁇ , the pressing portion 57 is held by the engagement portion 44 by a static friction force.

- the friction angle ⁇ is about 8.5 degrees. Therefore, when the normal angle is not more than 8.5 degrees, the engaging portion 44 is maintained in the state of being engaged with the pressing portion 57 regardless of the direction of the normal T of the engaging surface 46.

- the normal T may be shifted from the rotation center N1 of the restriction member 56 in the rotation direction S1 of the pressing portion 57. Further, the direction of the normal T may be changed so as to satisfy the condition that the normal angle is equal to or less than the friction angle ⁇ . As long as the condition that the normal angle is equal to or less than the friction angle ⁇ is satisfied, an error may occur in the normal angle.

- the lock mechanism 9 is operated depending on the speed of the winding drum 10 in the winding direction M, the method of stopping the webbing 2, etc. End lock may occur.

- the end lock occurs (see FIG. 13)

- the one end 41 of the lock arm 40 engages with the engagement tooth 6J of the stop 6G, whereby the lock arm 40 engages with the stop 6G.

- the retractor 1 of this embodiment (see FIG. 3) is provided with release means 18 for releasing the engagement between the lock arm 40 and the stop portion 6G while the lock mechanism 9 is operated. Even if an end lock occurs in the retractor 1, the release means 18 releases the engagement between the lock arm 40 and the stop portion 6G to release the end lock of the retractor 1.

- the release means 18 has a protrusion 16 formed on the winding drum 10 and a through groove 34 formed on the locking clutch 30. The projection 16 protrudes from the winding drum 10 toward the lock arm 40 and moves in the through groove 34 in the rotational direction of the winding drum 10. Also, the protrusion 16 penetrates the through groove 34 and contacts the lock arm 40.

- FIGS. 16 and 17 are diagrams showing the operation of the retractor 1 at the time of the end lock, and the main parts of the retractor 1 are shown in the same manner as FIG. 16 and 17 show a part of the stop portion 6G and the clutch unit 8 as well as a cross section of the lock arm 40.

- the movable pawl 4A and a part of the lock teeth 26 are also shown in FIG. 16 and FIG. 17 by seeing through a part of the locking clutch 30.

- the protrusion 16 is disposed in a recess 47 formed in the lock arm 40 and moves within the recess 47 to contact the lock arm 40.

- the lock arm 40 is displaced in the lock operation direction L, and the stop portion 6G engages with the lock arm 40 to stop the lock arm 40.

- the locking clutch 30 is locked and stopped by the lock arm 40.

- the winding drum 10 is rotated in the pulling direction P by pulling out the webbing 2 from the retractor 1.

- the operation of the lock mechanism 9 is started, and the lock mechanism 9 stops the rotation of the take-up drum 10.

- the projection 16 moves in the pull-out direction P and contacts the lock arm 40 (see FIG. 16C). Accordingly, the protrusion 16 is a contact member that moves with the rotation of the take-up drum 10 in the pull-out direction P and contacts the lock arm 40.

- the projection 16 pushes a portion on the one end portion 41 side of the lock arm 40 in the pull-out direction P (see FIG. 16D). Therefore, the projection 16 is also a rotation transmission member that directly pushes the lock arm 40 and transmits the rotation of the take-up drum 10 in the pull-out direction P to the lock arm 40.

- the release means 18 has a transmission mechanism 19 for transmitting the rotation of the winding drum 10 to the lock arm 40 by means of the projection 16.

- the lock arm 40 is removed from the stopping portion 6G by the transmission mechanism 19, and the end lock of the retractor 1 is released.

- the transmission mechanism 19 moves in the pull-out direction P of the take-up drum 10.

- the rotation (the force of rotation) is transmitted to the lock arm 40.

- the transmission mechanism 19 has the rotation transmission member including the projection 16.

- the protrusion 16 contacts the lock arm 40 as the winding direction of the take-up drum 10 rotates and pushes the lock arm 40.

- the transmission mechanism 19 applies a force to the lock arm 40 to displace the lock arm 40 in a direction (release direction) in which the engagement with the stop 6G is released.

- the lock arm 40 is disengaged from the stop 6G by the transmission mechanism 19 of the release means 18, and the engagement between the lock arm 40 and the stop 6G is released (see FIG. 17A).

- the release means 18 releases the engagement between the lock arm 40 and the stop 6G.

- the engagement between the lock arm 40 and the stop portion 6G is released in a state where the movable pawl 4A engages with the lock tooth 26 with the rotation of the take-up drum 10 in the pull-out direction P.

- the engagement claw 4B of the movable pawl 4A is in contact with the lock tooth 26

- the engagement between the lock arm 40 and the stop portion 6G is released.

- the engagement claw 4B moves along the lock tooth 26 to reach the bottom of the lock tooth 26, and the movable pawl 4A and the lock tooth 26 engage. Complete.

- the engagement between the lock arm 40 and the stop portion 6G may be released in a state where the engagement claw 4B can contact the lock tooth 26 with the rotation of the take-up drum 10 in the pullout direction P. .

- the engagement between the lock arm 40 and the stop portion 6G is released in a state where the engagement claw 4B does not contact the lock tooth 26.

- the locking clutch 30 rotates relative to the take-up drum 10 in the pull-out direction P due to the biasing of the return spring 8A, and the movable pawl 4A moves toward the non-locking position.

- the engagement claws 4B are at positions where they can contact the lock teeth 26, and contact the lock teeth 26 as the take-up drum 10 rotates in the pull-out direction P. Thereafter, with the rotation of the take-up drum 10 in the pull-out direction P, the engagement of the movable pawl 4A and the lock teeth 26 is completed.

- FIG. 18 is a view showing a process of releasing the engagement between the lock arm 40 and the stopper 6G, and shows the lock arm 40 and the stopper 6G in an enlarged manner.

- the release means 18 pushes the lock arm 40 by the transmission mechanism 19 and displaces the lock arm 40 in the release direction while moving the lock arm 40 along the stopping portion 6G.

- the projection 16 of the transmission mechanism 19 pushes the one end 41 of the lock arm 40 toward the engagement tooth 6J of the stop 6G (arrow Q1).

- the one end portion 41 of the lock arm 40 starts to move along the engagement surface of the engagement tooth 6J, and moves toward the tip of the engagement tooth 6J (arrow Q2).

- the lock arm 40 rotates about the arm support 37, and the arm support 37 of the lock arm 40 moves (arrow Q3). Also, after the arm support 37 starts to move, the locking clutch 30 is pushed by the arm support 37 in the winding direction M. As a result, while the lock arm 40 rotates in the winding direction M together with the locking clutch 30, the one end 41 of the lock arm 40 moves toward the tip of the engagement tooth 6J. At the same time, the lock arm 40 rotates around the rotation center N2 (arm support portion 37) in the opposite direction (release direction) of the lock actuation direction L, and the entire lock arm 40 is displaced in the direction away from the engagement tooth 6J.

- the projection 16 of the transmission mechanism 19 contacts the contact surface (contact portion) 47 A of the lock arm 40 in the recess 47 of the lock arm 40.

- the recess 47 is formed on the winding drum 10 side of the lock arm 40, and the contact surface 47A is a smooth inner surface of the recess 47.

- the projection 16 slides along the contact surface 47A in the recess 47, and smoothly moves toward the one end 41 of the lock arm 40. Along with this movement, the projection 16 pushes one end 41 of the lock arm 40 toward the engagement tooth 6J of the stop 6G without obstructing the movement of the lock arm 40.

- the lock arm 40 and the locking clutch 30 are rotated by the projection 16 and the engagement tooth 6J of the stop portion 6G, and the lock arm 40 is displaced.

- the releasing means 18 rotates the lock arm 40 in the releasing direction (here, the winding direction M) away from the stopping portion 6G together with the locking clutch 30 by the force received by the locking arm 40 from the stopping portion 6G. Displace.

- the lock arm 40 moves toward the tip of the engagement tooth 6J in a state of being engaged with the engagement tooth 6J.

- the engagement tooth 6J applies a force to the lock arm 40 to move the lock arm 40 and the locking clutch 30 while moving the lock arm 40 displaced in the release direction.

- the lock arm 40 rotates around the rotation center N2 with the movement along the engagement teeth 6J. In this manner, the engagement tooth 6J rotates the lock arm 40, which is displaced in the release direction, while moving the lock arm 40 toward the tip while engaging with the lock arm 40, and the lock arm 40 together with the locking clutch 30. Apply rotating force.

- the winding drum 10 rotates in the winding direction M, and the locking clutch 30 rotates relative to the winding drum 10 in the pulling direction P (see FIG. 17C). Since the locking of the locking clutch 30 is released before the webbing 2 is wound, the rotation of the locking clutch 30 in the pulling direction P starts early after the winding drum 10 rotates in the winding direction M. Further, the interlocking pin 4C of the movable pawl 4A is guided by the guide groove 33, and the engaging claw 4B of the movable pawl 4A is moved to a position where it is disengaged from the lock tooth 26.

- the acceleration sensor 50 is activated by vibration of the vehicle or the like, and the lock claw 54 of the sensor lever 53 may mesh with the teeth 35 of the ratchet wheel 36.

- the rotation of the locking clutch 30 in the winding direction M by the release means 18 may be used to remove the lock claw 54 from the tooth 35. Thereby, the stop of the ratchet wheel 36 by the acceleration sensor 50 is released.

- the protrusion 16 of the winding drum 10 may be brought into contact with the outer surface of the lock arm 40 to push the lock arm 40.

- the rotation of the winding drum 10 may be transmitted to the lock arm 40 by bringing the protrusion (rotational transmission member) formed on the lock arm 40 into contact with the side surface of the winding drum 10.

- the rotation of the winding drum 10 may be indirectly transmitted to the lock arm 40 via the rotation transmission member without being directly transmitted to the lock arm 40.

- the interlocking pin 4C of the movable pawl 4A may be used as a rotation transmission member.

- the other end 42 of the lock arm 40 is partially formed toward the guide groove 33, and the interlocking pin 4C is formed toward the other end 42 of the lock arm 40.

- the other end 42 of the lock arm 40 and the interlocking pin 4C are formed in a contactable shape, and the other end 42 of the lock arm 40 is pushed by the interlocking pin 4C moving in the guide groove 33. Thereby, the rotation of the winding drum 10 is transmitted to the lock arm 40, and the lock arm 40 is displaced in the release direction.

- the locking clutch 30 may be pushed in the winding direction M by the interlocking pin 4 C of the movable pawl 4 A moving in the guide groove 33.

- the interlocking pin 4C moves in the guide groove 33 and the locking clutch 30 is taken up in the winding direction M Press to

- the locking clutch 30 rotates in the winding direction M

- the lock arm 40 is displaced in the direction away from the stop portion 6G.

- the disengagement of the lock arm 40 and the stopper 6G is assisted.

- the lock arm 40 or the locking clutch 30 has a play

- the lock arm 40 is displaced in the release direction also by the play.

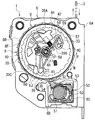

- the switching unit 60 switches the state of the retractor 1 between an automatic lock state (ALR) and an emergency lock state (ELR) according to the purpose of use.

- ALR automatic lock state

- ELR emergency lock state

- the webbing 2 can not be pulled out, and only the winding of the webbing 2 is possible.

- the retractor 1 is switched to the automatic lock state.

- the emergency lock state the webbing 2 can be taken up and pulled out.

- the winding drum 10 is locked by the lock mechanism 9. As a result, the rotation of the winding drum 10 in the pulling direction P is stopped, and the pulling of the webbing 2 is stopped.

- the switching means 60 includes an operation member 61 for operating the lock mechanism 9, an arm-shaped arrangement member 62 for arranging the operation member 61 at a predetermined position, a disk-shaped moving member 70 for moving the arrangement member 62, and an arrangement member.

- a first biasing means 63 which is biasing means, a second biasing means 64 which is biasing means for the operating member, and a speed reduction mechanism 80 are provided.

- the reduction gear mechanism 80 has a drive gear 81, an intermediate gear 82, and a driven gear 83, and is connected to the winding drum 10 and the moving member 70 by a plurality of combined gears 81, 82, 83.

- the operation member 61 and the placement member 62 are rotatably attached to a cylindrical rotation shaft (rotation shaft) 6K formed on the mechanism cover 6A (see FIG. 3).

- the first biasing means 63 is composed of an elastically deformable biasing member (spring, rubber, elastic member, etc.) (here, a tension coil spring), and is attached to the placement member 62 and the mechanism cover 6A.

- the second biasing means 64 comprises a resiliently deformable biasing member (spring, rubber, elastic member, etc.) (here, a torsion spring), and is attached to the actuating member 61 and the mechanism cover 6A.

- the center hole 71 of the moving member 70 is rotatably attached to the annular support 6L of the mechanism cover 6A, and the moving member 70 rotates around the annular support 6L.

- the cap 17 fixed to the first shaft 12 is inserted into the insertion hole 6I and disposed in the annular support 6L.

- the drive gear 81 is fixed to the cap 17 in the annular support 6L, and rotates integrally with the first shaft 12 and the cap 17 of the winding drum 10 at the center of the moving member 70.

- the driven gear 83 is an internal gear formed on the inner convex portion 72 of the moving member 70, and is larger than the drive gear 81 and the intermediate gear 82.

- the intermediate gear 82 has a first gear 82A larger than the drive gear 81, and a second gear 82B smaller than the first gear 82A (see FIG. 4), and is rotatably attached to the outer surface cover 6V.

- the first gear 82A meshes with the drive gear 81, and the second gear 82B meshes with the driven gear 83.

- the outer surface cover 6V is attached to the mechanism cover 6A to cover the switching means 60.

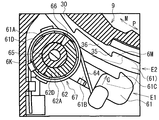

- FIG. 19 is a side view of the retractor 1 viewed from the W5 direction of FIG. 4 and shows the mechanism cover unit 6 from which the outer surface cover 6V has been removed.

- FIG. 19 also shows the ratchet wheel 36 of the locking clutch 30 housed in the mechanism cover 6A (clutch housing 6B). The ratchet wheel 36 is exposed at the opening 6M of the clutch housing 6B.

- a part of the operation member 61 and a part of the disposition member 62 moved from the position shown by the solid line are shown by the dotted line.

- the drive gear 81 rotates integrally with the cap 17.

- the rotation of the drive gear 81 causes the first gear 82A to rotate, and the intermediate gear 82 rotates at a rotational speed that is slower than the rotational speed of the drive gear 81.

- Due to the rotation of the second gear 82B of the intermediate gear 82 the driven gear 83 rotates at a rotational speed slower than the rotational speed of the intermediate gear 82, and the moving member 70 rotates in conjunction with the rotation of the winding drum 10.

- the speed reduction mechanism 80 decelerates the rotation of the winding drum 10 and transmits it to the moving member 70, and rotates the moving member 70 at a rotational speed that is slower than the rotational speed of the winding drum 10.

- the moving member 70 is rotated by a predetermined angle of 360 ° or less.

- the moving member 70 rotates in the direction opposite to the rotation direction of the winding drum 10.

- the operation member 61 and the placement member 62 are rotatably attached to one rotation shaft 6K so as to overlap in the axial direction of the rotation shaft 6K, and are interlocked and rotatably combined.

- the actuating member 61 is disposed on the ratchet wheel 36 side with respect to the moving member 70, and the arranging member 62 is disposed along the surface of the moving member 70 on the inner convex portion 72 side.

- the moving member 70 is a cam member that moves the placement member 62 by rotation, and is a control member that controls the position of the actuating member 61 by the placement member 62.

- the arranging member 62 is a cam follower that follows the moving member 70 and is a switching lever that switches the state of the retractor 1.

- the actuating member 61 is an interlocking member interlocked with the placement member 62, and is an actuating switch (switching switch) for switching between actuation and non-actuation of the lock mechanism 9.

- the lock mechanism 9 is actuated by the operation member 61 to stop only the rotation of the take-up drum 10 in the pull-out direction P, and allows the take-up drum 10 to rotate in the take-up direction M.

- the actuating member 61 is a meshing member that meshes with the teeth 35 of the ratchet wheel 36 in the mechanism cover 6A, and stops the rotation in the pulling direction P of the ratchet wheel 36 by meshing with the teeth 35.

- the lock mechanism 9 operates in response to the rotation stop of the drawing direction P of the ratchet wheel 36 due to the engagement of the actuating member 61 and the teeth 35. Therefore, the switching means 60 provided with the actuating member 61 is also a ratchet wheel stopping means.

- the actuating member 61 and the arranging member 62 rotate around the rotation shaft 6K and move in the same rotational direction. That is, the retractor 1 includes rotation means 65 for moving the operation member 61 and the placement member 62 by rotation, and the rotation means 65 has one rotation shaft 6K.

- the arranging member 62 is rotationally moved together with the actuating member 61 by the rotating means 65 (arrow H in FIG. 19). Further, in conjunction with the movement (rotation) of the placement member 62, the actuating member 61 is in the inoperative position E1 (the position shown by the solid line in FIG. 19) at which the lock mechanism 9 is not actuated It moves (rotates) to a position (indicated by a dotted line in FIG. 19).

- the inoperative position E1 of the actuating member 61 is a position where the actuating member 61 does not mesh with the teeth 35 of the ratchet wheel 36 (non meshing position). Further, the actuating position E2 of the actuating member 61 is a position (meshing position) in which the actuating member 61 meshes with the teeth 35 of the ratchet wheel 36. The actuating member 61 is moved from the non-operating position E1 (non-engagement position) to the operating position E2 (engagement position) by the placement member 62 to operate the lock mechanism 9.

- the actuating member 61 approaches the ratchet wheel 36 or separates from the ratchet wheel 36. Further, similarly to the lock claw 54 of the acceleration sensor 50, the actuating member 61 meshes with the teeth 35 of the ratchet wheel 36 in the clutch housing 6B at the opening 6M. Thereby, the rotation of the ratchet wheel 36 is stopped, and the lock mechanism 9 is operated.

- the second biasing means 64 always biases the operating member 61 toward the operating position E2.

- the operating member 61 is pressed against the ratchet wheel 36 by the second biasing means 64 when contacting the ratchet wheel 36.

- the disposition member 62 moves the actuating member 61 to the inoperative position E1 by the first biasing means 63 (the direction in which the actuating member 61 is separated from the ratchet wheel 36) (here, the radius of the moving member 70). Always inward).

- the actuating member 61 is biased to rotate counterclockwise by the second biasing means 64, and the positioning member 62 is biased to rotate clockwise by the first biasing means 63. ing.

- the placement member 62 is positioned radially inward of the moving member 70 and It is arrange

- the first position F1 of the disposition member 62 is a position where the actuating member 61 is disposed at the inoperative position E1, and the actuating member 61 is disposed at the inoperative position E1 by the disposition member 62.

- the placement member 62 moves in a direction to move the actuating member 61 to the actuating position E2 (direction to move the actuating member 61 closer to the ratchet wheel 36) (here, radially outward of the moving member 70). It is disposed at a second position F2 outside the one position F1 (the position shown by a dotted line in FIG. 19).

- the second position F2 is a position where the actuating member 61 is disposed at the actuating position E2, and the actuating member 61 is disposed at the actuating position E2 by the placement member 62.

- the arrangement member 62 is arranged at the first position F1 and the second position F2 by the rotation of the rotation means 65.

- the placement member 62 moves with the actuating member 61 to place the actuating member 61 in the inoperative position E1 and the operative position E2.

- the first biasing means 63 biases the placement member 62 toward the first position F1.

- the biasing force of the first biasing means 63 is larger than the biasing force of the second biasing means 64.

- the biasing member moves to the first position F1, and the actuating member 61 moves to the inoperative position E1.

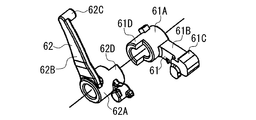

- FIG. 20 is a perspective view of the actuating member 61 and the placement member 62

- FIG. 21 is a cross-sectional view of the Y2 portion of FIG.

- the placement member 62 is a contact portion 62C including a cylindrical attachment portion 62A attached to the rotation shaft 6K, an arm portion 62B projecting from the attachment portion 62A, and a projection formed at the tip of the arm portion 62B.

- the contact portion 62C moves in contact with the moving member 70

- the arm portion 62B rotates about the mounting portion 62A, and the arranging member 62 moves.

- the operating member 61 has a cylindrical attachment portion 61A attached to the rotation shaft 6K, an arm portion 61B projecting from the attachment portion 61A, and a meshing pawl 61C formed at the tip of the arm portion 61B.

- the meshing pawl 61 ⁇ / b> C is a meshing portion (meshing claw) formed on the actuating member 61, and moves integrally with the actuating member 61.

- the arm 61B rotates around the mounting portion 61A, whereby the actuating member 61 moves, and the meshing pawl 61C meshes with the teeth 35 of the ratchet wheel 36.

- the meshing pawl 61C and the teeth 35 of the mesh wheel 36 are formed to mesh only when the ratchet wheel 36 rotates in the pull-out direction P.

- the meshing pawl 61C constitutes a part of the lock mechanism 9, and the lock mechanism 9 includes a ratchet wheel 36 and a meshing pawl 61C.

- the actuating member 61 arranges the meshing pawl 61C in a position to mesh with the tooth 35 by movement to the actuating position E2, and arranges the meshing pawl 61C in a position not meshing with the tooth 35 by movement to the inoperative position E1.

- the lock mechanism 9 operates with the engagement of the teeth 35 and the meshing pawl 61C.

- the meshing pawl 61C When the ratchet wheel 36 rotates in the take-up direction M, the meshing pawl 61C relatively slides on the outer surface of the tooth 35 and rides over the tooth 35 at the tip of the tooth 35.

- the actuating member 61 moves to the first position F1

- the actuating member 61 is pushed by the placement member 62 to rotate and maintain the gap 66 while maintaining the gap 66 Move to E1.

- the actuating member 61 moves to the actuation position E2 while maintaining the gap 66 by the biasing of the second biasing means 64 along with the movement of the placement member 62 Do.

- the meshing pawl 61C of the actuating member 61 meshes only with the teeth 35 of the ratchet wheel 36 rotating in the pull-out direction P.

- the meshing pawl 61C is pushed by the teeth 35.

- the actuating member 61 is displaced along the teeth 35 while narrowing the gap 66, and climbs over the plurality of teeth 35 in order.

- the retractor 1 includes the displacement mechanism 67 of the actuating member 61 configured as described above.

- the meshing pawl 61C of the actuating member 61 is rotated along the teeth 35 of the ratchet wheel 36 which rotates with the winding drum 10 in the winding direction M by the displacement mechanism 67. Displace.

- the meshing pawl 61C can be reliably maintained in a state in which it can be meshed with the plurality of teeth 35.

- the meshing pawl 61C meshes with the teeth 35 again.

- the placement member 62 moves with the actuating member 61 to move the actuating member 61 between the inoperative position E1 and the operative position E2.

- the actuating member 61 and the arranging member 62 control the rotatable direction of the ratchet wheel 36 and switch the state of the retractor 1.

- the ratchet wheel 36 becomes rotatable in the winding direction M and the pulling direction P, and the state of the retractor 1 is switched to the emergency lock state.

- the actuating member 61 is moved to the actuating position E2 by the arranging member 62, the ratchet wheel 36 can be rotated only in the winding direction M, and the state of the retractor 1 is switched to the automatic lock state.

- the arranging member 62 is arranged at the first position F1 and the second position F2, and arranges the actuating member 61 in the inoperative position E1 and the operative position E2.

- the moving member 70 rotates in conjunction with the rotation of the winding drum 10, and moves the placement member 62 to the first position F1 and the second position F2 along with the rotation.

- the moving member 70 includes the inner convex portion 72, the outer convex portion 73 surrounding the inner convex portion 72, a first maintaining portion 74 for maintaining the arranging member 62 at the first position F1, a changing portion 75, and the arranging member It has a moving part 76 for moving 62, a second maintaining part 77 for keeping the placement member 62 at the second position F2, and a releasing part 78.

- the inner convex portion 72 is an annular convex portion formed on the inner side in the radial direction of the moving member 70.

- the outer convex portion 73 is an annular convex portion formed on the outer side in the radial direction of the moving member 70, and is formed on the outer side of the inner convex portion 72 on one surface of the moving member 70.

- the center of the inner convex portion 72 and the center of the outer convex portion 73 coincide with the rotation center of the moving member 70, and the outer convex portion 73 is formed to have a diameter larger than the diameter of the inner convex portion 72.

- the first holding portion 74 is formed of an annular path between the inner convex portion 72 and the outer convex portion 73 (second holding portion 77). In the first maintaining portion 74, the placement member 62 (contact portion 62C) is disposed in the vicinity of the inner convex portion 72 without contacting the inner convex portion 72, and moves relatively along the inner convex portion 72.

- FIGS. 22 to 24 are views showing the operation of the placement member 62 accompanying the rotation of the moving member 70, and show the retractor 1 in the same manner as FIG. 22C is a cross-sectional view of the retractor 1 when the X3-X3 line of FIG. 22B is viewed in the arrow direction, and FIG. 23B is a cross-sectional view of the retractor 1 when the X4-X4 line of FIG. 23A is in the arrow direction.

- the winding drum 10 is rotated in the pull-out direction P or the winding direction M by pulling out or winding the webbing 2

- the moving member 70 is rotated in the direction opposite to the rotation direction of the winding drum 10 by the speed reduction mechanism 80. Rotate.

- the arranging member 62 moves relatively in the circumferential direction of the moving member 70, and also moves relatively along the portions 74 to 77 of the moving member 70.

- the contact portion 62C of the placement member 62 is disposed in the first holding portion 74 (see FIG. 22A). As a result, the placement member 62 is maintained at the first position F1, and the operation member 61 is maintained at the non-operation position E1. In this state, when the moving member 70 is rotated by the pulling out of the webbing 2, the arranging member 62 (contact portion 62C) is relatively moved along the first maintaining portion 74. Further, along with the drawing and winding of the webbing 2, the placement member 62 moves relatively in the circumferential direction of the moving member 70 in the first holding portion 74.

- the contact portion 62C is disposed in the first maintaining portion 74 until the webbing 2 is pulled out from the winding drum 10 by a predetermined length (predetermined drawing length), and the arranging member 62 is moved to the first position F1 by the first maintaining portion 74. Maintained. As a result, the state of the retractor 1 is maintained in the emergency lock state.

- the arranging member 62 When the webbing 2 is pulled out from the winding drum 10 by a predetermined length (see FIGS. 22B and 22C), the arranging member 62 is relatively displaced along the changing portion 75, and the changing portion 75 causes the position of the arranging member 62 to move. Is changed from the first maintaining unit 74 to the moving position by the moving unit 76.

- the moving position by the moving unit 76 is a position at which the arranging member 62 can be moved by the moving unit 76.

- the placement member 62 is moved by the moving unit 76 after being moved to the movement position.

- the changing portion 75 is a slope inclined from the first holding portion 74 toward the tip of the moving portion 76, and is formed at the end of the first holding portion 74.

- the contact portion 62 ⁇ / b> C of the placement member 62 contacts the changing portion 75 and moves relatively toward the moving portion 76.

- the disposition member 62 elastically deforms and is displaced along the change portion 75 in a direction away from the moving member 70.

- the placement member 62 climbs over the moving part 76 and returns to the original shape, and the contact part 62C is placed at a position where it can contact the moving part 76.

- the changing unit 75 changes the position of the placement member 62 from the first maintaining unit 74 to the moving position by the moving unit 76. Therefore, the placement member 62 is maintained at the first position F1 by the first retaining portion 74 until the webbing 2 is completely pulled out of the winding drum 10.

- the moving part 76 of the moving member 70 moves the arranging member 62 from the first position F1 to the second position F2 as the moving member 70 rotates. Move (see FIG. 23C).

- the moving portion 76 is an inclined portion that inclines toward the second holding portion 77, and is formed from the inner convex portion 72 to the outer convex portion 73 (second holding portion 77).

- the arranging member 62 contacts the moving portion 76 and gradually moves along the moving portion 76, and the moving portion 76 moves from the first position F1 to the second position F2.

- the moving unit 76 is also a guiding unit that guides the placement member 62 from the first position F1 to the second position F2.

- the moving portion 76 is an inclined convex portion which is inclined from the moving position by the moving portion 76 toward the second maintaining portion 77 in the rotational direction of the moving member 70, and the front end portion of the second maintaining portion 77 It connects. Further, when the webbing 2 completely pulled out of the winding drum 10 is wound on the winding drum 10, the placement member 62 is moved by the moving unit 76. At this time, the contact portion 62C of the placement member 62 is guided by the moving portion 76 in a state of being pressed against the moving portion 76 by the biasing of the first biasing means 63 and moves toward the second maintaining portion 77. .

- the placement member 62 moves radially outward of the moving member 70 and moves from the first position F1 to the second position F2 (see FIG. 24A).

- the actuating member 61 moves from the inoperative position E1 to the operative position E2, and the state of the retractor 1 is switched from the emergency lock state to the automatic lock state.

- the second holding portion 77 is an arc portion formed in an arc shape on the radially outer side of the first holding portion 74, and surrounds a portion of the first holding portion 74.

- the placement member 62 is in contact with the second maintaining portion 77 and maintained at the second position F2 by the second maintaining portion 77.

- the second holding portion 77 is an arc-shaped convex portion that constitutes a part of the outer convex portion 73, and is formed in a predetermined length along the circumferential direction of the moving member 70.

- the contact part 62C of the arrangement member 62 smoothly moves from the moving part 76 to the second maintaining part 77 because the outer convex part 73 is partially absent. Further, the contact portion 62C is in contact with the second holding portion 77, and is pressed against the second holding portion 77 by the biasing of the first biasing means 63. The placement member 62 is held by the second holding part 77 by the contact part 62C being pressed by the second holding part 77. Thus, the placement member 62 is maintained at the second position F2 during winding of the webbing 2 that has been completely pulled out.

- the actuating member 61 is maintained at the actuating position E2 by the disposition member 62 being maintained at the second position F2.

- the state of the retractor 1 is maintained in the automatic lock state, and only the rotation of the take-up drum 10 in the pulling direction P is stopped by the lock mechanism 9.

- the placement member 62 contact portion 62C

- the placement member 62 is maintained at the second position F2 by the second maintaining portion 77 until the webbing 2 is wound around the winding drum 10 by a predetermined length (a predetermined winding length).

- a predetermined length a predetermined winding length

- the placement member 62 is disengaged from the terminal end 79 of the second holding portion 77 and is directed toward the first holding portion 74 by the release portion 78. To be released. The placement member 62 is disengaged from the end 79 before the webbing 2 is completely wound on the winding drum 10.

- the contact portion 62C of the disposition member 62 comes out of the second retaining portion 77 after reaching the end portion 79 because the outer convex portion 73 is partially absent.

- the contact portion 62C is released from the state of being pressed by the second maintaining portion 77, and the placement member 62 is released from the second maintaining portion 77.

- the release portion 78 of the moving member 70 is a portion following the end portion 79 and comprises a release area formed from the second holding portion 77 to the first holding portion 74. In the release portion 78, the placement member 62 moves from the second maintaining portion 77 to the first maintaining portion 74 inward in the radial direction of the moving member 70 without contacting the moving member 70.

- the releasing portion 78 removes the arranging member 62 from the second maintaining portion 77. It releases toward the 1st maintenance part 74 (refer to Drawing 19).

- the placement member 62 is immediately moved from the second holding portion 77 (second position F2) to the first holding portion 74 (first position F1) by the urging of the first urging means 63.

- the operating member 61 moves from the operating position E2 to the non-operating position E1, and the state of the retractor 1 is switched from the automatic lock state to the emergency lock state. Thereafter, the webbing 2 is taken up on the take-up drum 10 or pulled out of the take-up drum 10.

- the restricting member 56 is maintained by the engaging portion 44 in the restricting state in which the lock arm 40 is held by the holding portion 57. Therefore, when the webbing 2 is wound up, the occurrence of the end lock in the retractor 1 can be reliably suppressed. Further, regardless of the magnitude of the frictional force generated between the attachment portion 58 of the regulating member 56 and the center support portion 6H, the regulating member 56 can be stably maintained in the regulated state. Since the occurrence of end lock is suppressed by one restriction member 56, an increase in the number of parts of the retractor 1 can be prevented.

- the restricting member 56 holds the engaging portion 44 by the holding portion 57 and restricts the displacement of the lock arm 40 in the lock operation direction L. Thereby, the displacement of the lock arm 40 can be reliably regulated while maintaining the engagement portion 44 in the state of being engaged with the pressing portion 57. Further, since the engaging portion 44 is a convex portion hooked on the pressing portion 57, the engagement between the engaging portion 44 and the pressing portion 57 and the release of the engagement can be smoothly performed.