WO2013061813A1 - エアロールユニット - Google Patents

エアロールユニット Download PDFInfo

- Publication number

- WO2013061813A1 WO2013061813A1 PCT/JP2012/076604 JP2012076604W WO2013061813A1 WO 2013061813 A1 WO2013061813 A1 WO 2013061813A1 JP 2012076604 W JP2012076604 W JP 2012076604W WO 2013061813 A1 WO2013061813 A1 WO 2013061813A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- shaft

- air

- collar

- bearing

- roll unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C13/00—Rolls, drums, discs, or the like; Bearings or mountings therefor

- F16C13/02—Bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C32/00—Bearings not otherwise provided for

- F16C32/06—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings

- F16C32/0603—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion

- F16C32/0614—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings

- F16C32/0618—Bearings not otherwise provided for with moving member supported by a fluid cushion formed, at least to a large extent, otherwise than by movement of the shaft, e.g. hydrostatic air-cushion bearings supported by a gas cushion, e.g. an air cushion the gas being supplied under pressure, e.g. aerostatic bearings via porous material

Definitions

- the air roll unit when the air roll unit is in operation, if the air supply to the air bearing is shut off due to a failure or an excessive impact is applied to the roll, the air bearing and the shaft come into contact with each other and the shaft is damaged. Sometimes. Depending on the degree of damage, the shaft must be replaced. In particular, when the roll and the shaft are integrally formed, when replacing the shaft, the roll must also be replaced at the same time, which increases the cost.

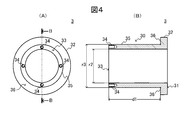

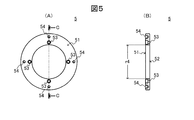

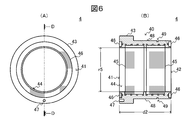

- an air roll unit 1 includes a roll 2 having a shaft 21, a cylindrical collar 3 attached to the shaft 21, and an air bearing 4 that supports the collar 3 in a non-contact manner.

- a thrust plate 5 that restricts the movement of the air bearing 4 in the thrust direction

- a detent plate 6 that prevents the collar 3 from rotating relative to the shaft 21, and a housing 7 that holds the air bearing 4. .

- the air bearing 4 is attached to the collar 3 so that the flange 43 and the flange 32 of the collar 3 face each other.

- the collar 3 can be supported in the radial direction without contact (specifically, a compressed air layer L1 for a radial bearing described later between the outer peripheral surface 35 of the collar 3 and the inner peripheral surface 44 of the air bearing 4). 9)

- the inner diameter r5 of the air bearing 4 is set to be larger than the outer diameter r3 of the collar 3 by twice the thickness of the radial air compression compressed air layer L1.

- FIG. 8A is a front view of the housing 7, and FIG. 8B is a cross-sectional view taken along the line FF of FIG. 8A.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Magnetic Bearings And Hydrostatic Bearings (AREA)

- Rolls And Other Rotary Bodies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201280052166.7A CN103890419B (zh) | 2011-10-26 | 2012-10-15 | 空气辊单元 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-235514 | 2011-10-26 | ||

| JP2011235514A JP5997428B2 (ja) | 2011-10-26 | 2011-10-26 | エアロールユニット |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013061813A1 true WO2013061813A1 (ja) | 2013-05-02 |

Family

ID=48167646

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/076604 Ceased WO2013061813A1 (ja) | 2011-10-26 | 2012-10-15 | エアロールユニット |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP5997428B2 (enExample) |

| WO (1) | WO2013061813A1 (enExample) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6387254B2 (ja) * | 2014-06-23 | 2018-09-05 | オイレス工業株式会社 | 軸受装置およびロール装置 |

| JP2016041946A (ja) * | 2014-08-15 | 2016-03-31 | オイレス工業株式会社 | ロール装置 |

| KR102413815B1 (ko) * | 2021-11-29 | 2022-06-28 | (주)지우텍 | 마찰이 없는 광학필름용 가이드 롤러 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5876822U (ja) * | 1981-11-20 | 1983-05-24 | 三菱重工業株式会社 | 油膜軸受 |

| JPS6293013A (ja) * | 1985-10-18 | 1987-04-28 | Kubota Ltd | 圧延用組立ロ−ル |

| JPS62258217A (ja) * | 1986-04-30 | 1987-11-10 | Nippon Seiko Kk | ロ−ルの支持装置 |

| JPH01249349A (ja) * | 1988-02-19 | 1989-10-04 | Man Roland Druckmas Ag | 輪転印刷機のローラ軸受 |

-

2011

- 2011-10-26 JP JP2011235514A patent/JP5997428B2/ja active Active

-

2012

- 2012-10-15 WO PCT/JP2012/076604 patent/WO2013061813A1/ja not_active Ceased

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5876822U (ja) * | 1981-11-20 | 1983-05-24 | 三菱重工業株式会社 | 油膜軸受 |

| JPS6293013A (ja) * | 1985-10-18 | 1987-04-28 | Kubota Ltd | 圧延用組立ロ−ル |

| JPS62258217A (ja) * | 1986-04-30 | 1987-11-10 | Nippon Seiko Kk | ロ−ルの支持装置 |

| JPH01249349A (ja) * | 1988-02-19 | 1989-10-04 | Man Roland Druckmas Ag | 輪転印刷機のローラ軸受 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2013092223A (ja) | 2013-05-16 |

| CN103890419A (zh) | 2014-06-25 |

| JP5997428B2 (ja) | 2016-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102400942B (zh) | 用于压缩机中的空气轴承和马达冷却的轴 | |

| US10525562B2 (en) | Rotary table device | |

| WO2013061813A1 (ja) | エアロールユニット | |

| WO2010134473A1 (ja) | チャック装置 | |

| US10001170B2 (en) | Rolling bearing | |

| JP5851780B2 (ja) | エアベアリングユニット | |

| EP3382223A1 (en) | Spindle device | |

| JP2014035054A (ja) | 静圧気体軸受ユニット | |

| JP6585593B2 (ja) | 機械部品 | |

| WO2009104542A1 (ja) | 気体軸受スピンドル | |

| JP2006167821A (ja) | 装着物の取り付け方法及びスピンドル装置 | |

| JP2009068649A (ja) | スピンドル装置 | |

| CN104024668A (zh) | 静压气体轴承装置 | |

| JP5169570B2 (ja) | ロール装置 | |

| US10284048B2 (en) | Electric motor for suppressing entry of foreign substances | |

| CN103890419B (zh) | 空气辊单元 | |

| JP2009197942A (ja) | 気体軸受スピンドル | |

| WO2015125958A1 (ja) | ロール装置 | |

| JPH11303870A (ja) | 多孔質気体軸受及びこれを用いたスピンドル装置 | |

| JP2001336527A (ja) | 静圧磁気複合軸受スピンドル装置 | |

| JP5888663B2 (ja) | スピンドルモータ | |

| US20110053459A1 (en) | Slow speed spindle for micropunch grinding | |

| JP2006194203A (ja) | エアタービンスピンドル | |

| JP4478942B2 (ja) | 軸受固定装置 | |

| JP2020109290A (ja) | 真空ポンプ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12843080 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 12843080 Country of ref document: EP Kind code of ref document: A1 |