WO2012132095A1 - アンモニア酸化触媒、およびそれを用いた排気ガス浄化装置並びに排気ガス浄化方法 - Google Patents

アンモニア酸化触媒、およびそれを用いた排気ガス浄化装置並びに排気ガス浄化方法 Download PDFInfo

- Publication number

- WO2012132095A1 WO2012132095A1 PCT/JP2011/076490 JP2011076490W WO2012132095A1 WO 2012132095 A1 WO2012132095 A1 WO 2012132095A1 JP 2011076490 W JP2011076490 W JP 2011076490W WO 2012132095 A1 WO2012132095 A1 WO 2012132095A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- catalyst

- exhaust gas

- ammonia

- oxidation catalyst

- composite oxide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/19—Catalysts containing parts with different compositions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9436—Ammonia

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9459—Removing one or more of nitrogen oxides, carbon monoxide, or hydrocarbons by multiple successive catalytic functions; systems with more than one different function, e.g. zone coated catalysts

- B01D53/9477—Removing one or more of nitrogen oxides, carbon monoxide, or hydrocarbons by multiple successive catalytic functions; systems with more than one different function, e.g. zone coated catalysts with catalysts positioned on separate bricks, e.g. exhaust systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/06—Silicon, titanium, zirconium or hafnium; Oxides or hydroxides thereof

- B01J21/063—Titanium; Oxides or hydroxides thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/06—Silicon, titanium, zirconium or hafnium; Oxides or hydroxides thereof

- B01J21/066—Zirconium or hafnium; Oxides or hydroxides thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/06—Silicon, titanium, zirconium or hafnium; Oxides or hydroxides thereof

- B01J21/08—Silica

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/16—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of arsenic, antimony, bismuth, vanadium, niobium, tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

- B01J23/24—Chromium, molybdenum or tungsten

- B01J23/30—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/40—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals of the platinum group metals

- B01J23/42—Platinum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/54—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36

- B01J23/56—Platinum group metals

- B01J23/64—Platinum group metals with arsenic, antimony, bismuth, vanadium, niobium, tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

- B01J23/652—Chromium, molybdenum or tungsten

- B01J23/6527—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/40—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively

- B01J29/42—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively containing iron group metals, noble metals or copper

- B01J29/46—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/70—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65

- B01J29/72—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65 containing iron group metals, noble metals or copper

- B01J29/76—Iron group metals or copper

- B01J29/7615—Zeolite Beta

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/10—Noble metals or compounds thereof

- B01D2255/102—Platinum group metals

- B01D2255/1021—Platinum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/206—Rare earth metals

- B01D2255/2065—Cerium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20707—Titanium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20715—Zirconium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20776—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/30—Silica

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/40—Mixed oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/40—Mixed oxides

- B01D2255/407—Zr-Ce mixed oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/90—Physical characteristics of catalysts

- B01D2255/902—Multilayered catalyst

- B01D2255/9022—Two layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/50—Catalysts, in general, characterised by their form or physical properties characterised by their shape or configuration

- B01J35/56—Foraminous structures having flow-through passages or channels, e.g. grids or three-dimensional monoliths

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/10—Capture or disposal of greenhouse gases of nitrous oxide (N2O)

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S502/00—Catalyst, solid sorbent, or support therefor: product or process of making

- Y10S502/52712—Plural layers on a support, each layer having a distinct function

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S502/00—Catalyst, solid sorbent, or support therefor: product or process of making

- Y10S502/52712—Plural layers on a support, each layer having a distinct function

- Y10S502/52713—More than two overlapping layers

Definitions

- the present invention relates to an ammonia oxidation catalyst, an exhaust gas purification apparatus using the same, and an exhaust gas purification method. More specifically, the present invention relates to a boiler, a gas, by spraying urea water or ammonia water as a reducing component to a selective reduction catalyst.

- the present invention relates to a gas purification method.

- Exhaust gas discharged from lean combustion engines such as boilers, lean burn gasoline engines, and diesel engines contains various harmful substances derived from fuel and combustion air depending on the structure and type.

- harmful substances include hydrocarbon (HC), soluble organic fraction (also called SOF), soot, carbon monoxide (CO), nitrogen oxide (NOx), etc. It is regulated by the Air Pollution Control Law.

- HC hydrocarbon

- SOF soluble organic fraction

- SOF soot

- CO carbon monoxide

- NOx nitrogen oxide

- the combustion temperature is controlled by an operation such as supplying an optimum amount of air in accordance with the type and supply amount of the fuel, so that the incompletely combusted products such as CO and THC are controlled.

- the combustion temperature may be increased, leading to generation of NOx.

- nitrogen oxide is easily discharged because the engine is operated by lean combustion.

- the operating conditions are constantly changing, and thus it has been particularly difficult to appropriately suppress the generation of harmful substances.

- the catalyst used depends on the harmful components emitted from the engine and the exhaust gas regulations, but mainly the oxidation catalyst for purifying the SOF component, the catalyst for oxidizing and purifying the unburned gas component, and the combination of these with the filter Catalytic systems that collect and oxidize and purify components have been proposed. These catalysts mainly use noble metals such as Pt and Pd for the purpose of promoting the oxidation reaction. Diesel engines have a relatively large displacement compared to gasoline engines, etc., and the amount of exhaust gas that flows out is large.

- a catalyst system using a NOx storage catalyst or a selective reduction catalyst (hereinafter also referred to as SCR) has been proposed as a NOx purification catalyst in accordance with NOx emission regulation.

- SCR selective reduction catalyst

- Several types of reducing agents used for NOx purification are known for SCR catalysts.

- NOx is finally reduced by the following reaction formulas (1) to (3). reduced to N 2. 4NO + 4NH 3 + O 2 ⁇ 4N 2 + 6H 2 O (1) 6NO 2 + 8NH 3 + O 2 ⁇ 7N 2 + 12H 2 O (2) NO + NO 2 + 2NH 3 ⁇ 2N 2 + 3H 2 O (3)

- NH 3 gasified as a reducing component may be used, but NH 3 itself has a harmful effect such as an irritating odor. Therefore, a method has been proposed in which urea water is added as an NH 3 component from the upstream of the denitration catalyst, NH 3 is generated by thermal decomposition or hydrolysis, and denitration performance is expressed by the reaction of the above formula as a reducing agent.

- reaction formula for obtaining NH 3 by decomposition of urea is as follows.

- a purification catalyst in which a component having oxidative decomposition activity of NH 3 is arranged in the lower layer and a denitration component is arranged in the upper layer (Patent Document 5).

- Patent Document 5 This not only purifies NH 3 by NH 3 oxidation, but also NOx produced by NH 3 oxidation in the above reaction formulas (5) to (7) reacts with slip NH 3 not yet used in the oxidation reaction. It can also be interpreted as a catalyst responsible for the reaction.

- an exhaust gas purification catalyst using one or more oxides selected from titanium, tungsten, molybdenum, or vanadium see Patent Document 2

- an upper layer as a Ce—Ti—SO 4 —Zr component Also proposed is an ammonia oxidative decomposition catalyst using a mixed system of Fe and Si-Al oxide components (see Patent Document 3), and a purification catalyst using an Fe or Ce-containing zeolite in the upper layer (see Patent Document 6).

- Noble metals are also used as NH 3 oxidizing components in these catalysts responsible for NH 3 purification.

- a reverse micelle method is used to prevent the noble metal salt inside the catalyst micelle so that the contact area between the noble metal particles and the promoter component is not reduced by sintering. It has been proposed to form composite fine particles in the state in which the metal salt is present at the same time, and thereby, the co-catalyst effect of the metal compound is exhibited, and a high heat-resistant catalyst with high catalytic activity and low cost is obtained. (Patent Document 7). For example, many studies have been made on exhaust gas catalysts using Au as an alternative metal for platinum group elements in automobile catalysts.

- Patent Document 8 As an exhaust gas purification catalyst made of an Au catalyst having high CO oxidation activity, a catalyst in which Au is supported on a carrier made of a ceria-zirconia solid solution having a ceria content of 40 to 80 wt% has been proposed (Patent Document 8). )

- an object of the present invention is to supply urea water or ammonia water as a reducing component to the selective reduction catalyst by spraying, so that lean combustion of boilers, gas turbines, lean burn gasoline engines, diesel engines, etc.

- the ammonia slipped from the selective reduction catalyst is oxidized while effectively suppressing N 2 O by-product even under high space velocity (SV).

- SV space velocity

- a catalyst layer (lower layer) containing a catalyst in which a noble metal element is supported on a composite oxide (A) mainly composed of titania and silica, and substantially tungsten oxide, ceria, and zirconia are formed on the surface of the monolithic structure type carrier.

- urea or ammonia is added to the exhaust gas discharged from the lean combustion engine as a nitrogen oxide reducing agent, and the nitrogen oxide is selected by the selective reduction catalyst (SCR).

- SCR selective reduction catalyst

- a MOX ammonia oxidation catalyst

- a noble metal element is added to the composite oxide (A) mainly composed of titania and silica on the surface of the monolithic support.

- a composite layer comprising a catalyst layer (lower layer) containing a supported catalyst and a catalyst layer (upper layer) containing a composite oxide (C) composed of tungsten oxide, ceria, and zirconia.

- Ammonia characterized in that the composition of the oxide (C) is tungsten oxide: 1 to 50% by weight, ceria: 1 to 60% by weight, and zirconia: 30 to 90% by weight A oxidation catalyst.

- the composition of the composite oxide (A) is titania: 60 to 99% by weight and silica: 1 to 40% by weight.

- An ammonia oxidation catalyst is provided.

- the composite oxide (A) further contains one or more selected from zirconia or alumina, and the content thereof is 30% by weight. % Or less, an ammonia oxidation catalyst is provided.

- the composite oxide (C) has a composition of tungsten oxide: 3 to 30% by weight, ceria: 5 to 40% by weight, and zirconia: 50

- An ammonia oxidation catalyst characterized in that it is ⁇ 90% by weight is provided.

- the noble metal element supported on the composite oxide (A) contains platinum, and the content thereof is 0 per unit volume of the monolithic structure type carrier.

- an ammonia oxidation catalyst characterized in that the amount is 0.01 to 1.0 g / L.

- the coating amount of the composite oxide (A) of the catalyst layer (lower layer) is 10 to 120 g / L per unit volume of the monolithic support.

- An ammonia oxidation catalyst is provided.

- the coating amount of the composite oxide (C) in the catalyst layer (upper layer) is 30 to 150 g / unit volume of the monolithic support.

- An ammonia oxidation catalyst characterized by being L is provided.

- an oxidation catalyst having a function of oxidizing nitrogen monoxide and hydrocarbons and a particulate in the exhaust gas flow path.

- a filter that collects and removes matter, spray means for supplying urea aqueous solution or aqueous ammonia solution, selective reduction catalyst (SCR), and ammonia oxidation catalyst (AMOX) are arranged in this order.

- An exhaust gas purifying apparatus is provided.

- the selective reduction catalyst is a composite oxidation comprising a zeolite (D) containing at least an iron element, tungsten oxide, ceria, and zirconia.

- the exhaust gas exhausted from the lean combustion engine is passed through the oxidation catalyst (DOC) and the filter (DPF) using the exhaust gas purification device of the eighth or ninth aspect.

- DOC oxidation catalyst

- DPF filter

- SCR selective reduction catalyst

- NH 3 component as a reducing agent is selectively reduced, for example, from 130 to 560 ° C. from a low temperature to a high temperature.

- the slipped NH 3 is purified with high efficiency even with a low noble metal loading compared to the prior art, and a new product accompanying N 2 O by-product and NH 3 oxidation is obtained.

- Generation of NOx can be suppressed.

- no harmful heavy metal such as vanadium is contained as a catalyst component, safety is high. Furthermore, since pressure loss can be reduced, it is possible to meet demands for lower fuel consumption and higher output.

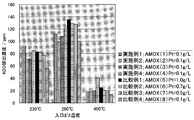

- FIG. 1 is a graph showing the ammonia conversion rate when the ammonia oxidation catalyst of the present invention (Example) or a conventional ammonia oxidation catalyst (Comparative Example) is used.

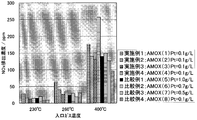

- FIG. 2 is a graph showing the N 2 O emission concentration when the ammonia oxidation catalyst of the present invention (Example) or the conventional ammonia oxidation catalyst (Comparative Example) is used.

- FIG. 3 is a graph showing the NOx emission concentration when the ammonia oxidation catalyst of the present invention (Example) or the conventional ammonia oxidation catalyst (Comparative Example) is used.

- ammonia oxidation catalyst of the present invention the exhaust gas purification apparatus using the same, and the exhaust gas purification method will be described in detail by taking a diesel engine mainly used in an automobile as an example.

- ammonia oxidation catalyst (AMOX)

- the ammonia oxidation catalyst of the present invention (hereinafter, also referred to as “the catalyst”) is a process in which urea or ammonia is added as a nitrogen oxide reducing agent to exhaust gas discharged from a lean combustion engine, and nitrogen oxidation is performed by a selective reduction catalyst (SCR).

- SCR selective reduction catalyst

- the composite oxide (A) mainly composed of titania and silica is formed on the surface of the monolithic structure type carrier.

- At least two catalyst layers having a catalyst layer (lower layer) containing a catalyst supporting a noble metal element and a catalyst layer (upper layer) containing a composite oxide (C) substantially composed of tungsten oxide, ceria and zirconia

- the composite oxide (C) has a composition of tungsten oxide: 1 to 50% by weight, ceria: 1 to 60% by weight, and zirconia: 30 to 90% by weight. It is characterized in.

- the lower catalyst layer includes a catalyst in which a noble metal element is supported on a composite oxide (A) mainly composed of titania and silica, and has an ammonia oxidation function.

- A composite oxide

- the noble metal component is one or more elements selected from platinum, palladium, or rhodium. Of these, platinum has high oxidation activity and exhibits excellent NH 3 oxidation performance, so it is desirable to contain it as a main noble metal component in the lower catalyst layer.

- the main noble metal component refers to a component that is contained in an amount of 50 wt% or more based on the total amount of noble metals used in the catalyst of the present invention, and all of the noble metals may be platinum.

- the amount of platinum used is preferably 0.01 to 1.0 g / L per unit volume of the monolithic structure type carrier when the lower layer catalyst layer component of the present invention is coated on the monolithic structure type carrier. And 0.02 to 0.5 g / L is more preferable. If it is less than 0.01 g / L, the activity of platinum cannot be fully utilized, and if it exceeds 1.0 g / L, the amount of reduction in the amount of noble metal used is not sufficient.

- the catalyst component forming the lower catalyst layer exhibits excellent oxidation performance when the noble metal is particularly Pt or Pd.

- Pt is an excellent oxidizing catalytically active species, maintaining its specific surface area high can increase the active surface and exhibit high activity. Therefore, in the present invention, it is preferable that at least platinum is supported on the composite oxide (A) mainly composed of titania and silica.

- the precious metal can be supported in a highly dispersed state, and since the heat resistance is high, the precious metal component is difficult to sinter, and the high dispersion of the precious metal during use can be maintained for a long time.

- the composite oxide (A) is an inorganic base material mainly containing titania and silica having a high specific surface area and excellent heat resistance, and can support a noble metal component such as platinum in a highly dispersed manner.

- the composition of the composite oxide (A) is preferably titania: 60 to 99% by weight and silica: 1 to 40% by weight.

- the composite oxide (A) further contains at least one of zirconia and alumina, and it is more preferable that at least one of zirconia and alumina in the composite oxide (A) is 0 to 30% by weight.

- the composite oxide (A) essentially contains titania and silica, and a composite oxide containing at least one of zirconia and alumina of 30% by weight or less, such as titania-silica, titania-silica-zirconia, titania.

- Inorganic oxides such as silica-alumina and titania-silica-zirconia-alumina can be used.

- Such inorganic oxide (inorganic base material) is, speaking in terms of the dispersibility of the noble metal component, (by the BET method, hereinafter the same) specific surface area is preferably is 30 m 2 / g or more, further 100 m 2 / What is more than g is more preferable. If the specific surface area value is 30 m 2 / g or more, the noble metal can be stably supported in a highly dispersed state.

- platinum chloride (IV) acid diammine platinum nitrite (II), platinic acid amine solution, chloroplatinic acid, platinum nitrate, dinitrodiammine palladium, palladium nitrate, chloride

- a metal salt such as palladium, rhodium (III) chloride, or rhodium nitrate (III)

- the content of the composite oxide (A) in the lower catalyst layer is 10 to 120 g / L, preferably 15 to 100 g / L, per unit volume of the monolithic structure type carrier.

- the reason is that if the composite oxide (A) is too much, an excessive amount is supported in order to improve the dispersibility of Pt. As a result, the pressure loss may increase and the price may be increased. This is because the degree of dispersion cannot be ensured, and NH 3 oxidation is not promoted and NH 3 slip may occur.

- the lower layer coated with the integral catalyst carrier of the present invention may have a material having a NOx purification function, in addition to the composite oxide (A) as the inorganic base material.

- Materials having NOx purification function include transition oxides such as titania, zirconia, tungsten oxide, ceria, lanthanum, praseodymium, samarium, gadolinium, neodymium, etc. as well as composite oxide (C) and zeolite (D) described later.

- Transition oxides such as titania, zirconia, tungsten oxide, ceria, lanthanum, praseodymium, samarium, gadolinium, neodymium, etc.

- C composite oxide

- D zeolite

- the upper catalyst layer is composed of a composite oxide (C) composed of tungsten oxide, ceria, and zirconia as an essential component and does not include a noble metal component, and NOx present with slip NH 3. That is, it has the function of promoting NOx purification by reacting with NOx produced by oxidation of slip NH 3 or NOx that has not been sufficiently purified by the SCR catalyst.

- C composite oxide

- the composite oxide (C) is composed of tungsten oxide: 1 to 50% by weight, ceria: 1 to 60% by weight, and zirconia: 30 to 90% by weight, and more preferably tungsten oxide: 3 to The composition is 30% by weight, ceria: 5 to 40% by weight, and sirconia: 50 to 90% by weight.

- tungsten oxide includes not only tungsten oxide but also tungsten element alone.

- each component in the composite oxide (C) is considered as follows, for example.

- Ceria is known as a NOx adsorption functional material, and also has the function of promoting the SCR reaction between NH 3 and NOx by promoting NOx adsorption in this material system.

- Zirconia functions as a dispersion-holding material for highly dispersing other components in a thermally stable state.

- tungsten oxide has strong acidity and has a large adsorption power for urea and ammonia, which are alkali components. Therefore, the use of tungsten oxide increases the denitration performance.

- starting materials having forms such as nitrates, sulfates, carbonates, acetates, and chlorides containing tungsten, cerium, and zirconium are dissolved in an aqueous solution at a time, and then mixed, resulting in a precipitate by adjusting pH, etc.

- Solids obtained by sedimentation or evaporation to dryness may be calcined, or after the oxides are formed by performing the above treatment on a single or multiple metal salts, the remaining metal salts are It may be carried at once or sequentially.

- Each element is manufactured by adding all elements at once, or by first producing a core powder from one or several kinds of elements and then loading the remaining elements at once or sequentially, so that each element has an optimal composition.

- the composite oxide (C) contained in can be prepared.

- the coating amount of the composite oxide (C) is 30 to 150 g / L, more preferably 30 to 120 g / L, per unit volume of the monolithic structure type carrier.

- the amount is less than 30 g / L, the reaction between NH 3 and NOx decreases, the SCR function becomes insufficient, and the NH 3 adsorption capacity decreases, so NH 3 that could not come into contact with Pt in the lower catalyst layer slips. There is.

- the catalyst upper layer of the present invention may contain a material having a NOx purification function, in addition to the composite oxide (C).

- Materials having NOx purification function include zeolite (D) described later, transition metal oxides such as titania, zirconia and tungsten oxide, rare earth oxides such as ceria, lanthanum, praseodymium, samarium, gadolinium and neodymium, gallium oxide , Iron oxides such as tin oxide, or complex oxides thereof.

- the monolithic structure type carrier in the present invention is not particularly limited by the type.

- a honeycomb structure type carrier a sheet-like structure knitted with a fine fibrous material, and a felt-like noncombustible structure made of a relatively thick fibrous material can be used.

- a honeycomb structure type carrier is preferable, and a honeycomb structure type carrier whose surface is coated with a catalyst component may be hereinafter referred to as a honeycomb structure type catalyst.

- the type of the honeycomb structure type carrier is not particularly limited, and can be selected from known honeycomb structure type carriers. Such a type includes a flow-through type carrier and a wall-flow type carrier used for DPF and CSF.

- the present catalyst only purifies slip NH 3 after the selective reduction catalyst (SCR). Since it is used as an object, a flow-through type carrier is preferable.

- the honeycomb structure has an arbitrary overall shape, and can be appropriately selected according to the structure of the exhaust system to be applied, such as a cylindrical shape, a quadrangular prism shape, or a hexagonal prism shape.

- an appropriate number of holes can be determined in consideration of the type of exhaust gas to be processed, gas flow rate, pressure loss, removal efficiency, etc. It is preferably about 10 to 1500 per square inch, particularly preferably 100 to 900. If the cell density per square inch is 10 or more, the contact area between the exhaust gas and the catalyst can be secured, and a sufficient exhaust gas purification function can be obtained, and the cell density per square inch should be 1500 or less. In this case, no significant exhaust gas pressure loss occurs, so that the performance of the internal combustion engine is not impaired.

- the lower layer when the catalyst component of the present invention is used by coating it on a permeable structural carrier such as ceramics, the lower layer component penetrates the structural carrier, and all or part of the lower layer is a structural carrier. And may be integrated. Further, the structural carrier may be composed of lower layer components, and the upper layer components may be coated thereon. In some cases, a bottom layer is provided between the lower layer and the structural support for the purpose of improving the adhesion of the catalyst layer. In this case, the relationship between the bottom layer and the lower layer is the same as the relationship between the structural support and the lower layer. It is. Further, in such a honeycomb structure type carrier, the thickness of the cell wall is preferably 2 to 12 mil (milli inch), more preferably 4 to 8 mil.

- the material of the honeycomb structure type carrier includes metals such as stainless steel and ceramics such as cordierite.

- a sheet-like structure knitted from a fine fibrous material and a felt-like non-combustible structure made of a relatively thick fibrous material can be used.

- the coating amount is 200 to 900 holes per square inch and the cell wall thickness is 4 to 8 mil.

- the upper layer has a coating amount of 50% or more of the lower layer, and the total coating amount of the upper layer and lower layer is preferably 40 g / L or more, more preferably 50 g / L or more per unit volume.

- the upper limit of the coating amount is not particularly limited as long as the production cost does not increase, the pores of the honeycomb are clogged, or the back pressure of the exhaust gas does not increase remarkably, but the flow-through type honeycomb carrier is not limited. Is preferably about 230 g / L or less, and more preferably about 170 g / L. Although it depends on the cell density of the carrier used, when a honeycomb structure having an actual cell density is used, the back pressure rises when the catalyst is loaded in an amount exceeding 230 g / L, and the performance of the combustion engine is increased. May interfere.

- a solid acid, a binder, or the like can be mixed and used in addition to the above materials.

- solid acids include WO 3 / ZrO 2 , WO 3 / TiO 2 , SO 3 / ZrO 2 , metallosilicates, etc.

- binders include alumina, silica, titania, silica-alumina, zirconia and their A sol, gel, solution, or the like is preferably used.

- each layer is not particularly limited and may be, for example, 1 to 430 ⁇ m, and particularly preferably 20 to 250 ⁇ m.

- the thickness of the upper layer is preferably 40 to 250 ⁇ m, and the thickness of the lower layer is preferably 1 to 180 ⁇ m.

- the thickness of each layer may be non-uniform, but the average value is preferably within the above range. If the thickness of each layer is too thin, the catalyst component will be insufficient and it will be difficult to perform the function as a layer. On the other hand, if it is too thick, gas diffusibility will be reduced and mass transfer will be hindered.

- a lower layer catalyst material, an upper layer catalyst material, and an integral structure type carrier are prepared.

- the catalyst material is produced by mixing an additive such as a binder or a surfactant with an aqueous medium as necessary to form a slurry mixture, coating the monolithic support, drying and firing. That is, the catalyst material and the aqueous medium are mixed at a predetermined ratio to obtain a slurry mixture.

- the aqueous medium may be used in such an amount that each catalyst component can be uniformly dispersed in the slurry.

- the lower layer catalyst material contains a noble metal component containing at least platinum and a composite oxide (A) mainly composed of titania and silica as an inorganic base material.

- the noble metal component can also be supported on an inorganic base material in advance.

- a metal catalyst component and an inorganic base material are mixed in an aqueous medium to prepare a slurry.

- a known method can be adopted as appropriate.

- An example thereof is as follows. First, as raw materials for precious metal components, compounds such as nitrates, sulfates, carbonates, acetates, specifically platinum (IV) chloride, diammineplatinum (II) nitrite, amine hydroxide platinate, chloroplatinic acid , Platinum nitrate, dinitrodiammine palladium, palladium nitrate, palladium chloride, rhodium (III) chloride, rhodium (III) nitrate. From these, a noble metal component raw material is selected and dissolved in water or an organic solvent to form a solution. Note that water or a solvent obtained by adding a water-soluble organic solvent to water is hereinafter referred to as “aqueous medium”.

- this noble metal component raw material solution is mixed with an inorganic base material together with an aqueous medium, dried at 50 to 200 ° C. to remove the solvent, and then fired at 300 to 1200 ° C.

- a known catalyst material may be blended as a binder or the like.

- known catalyst materials include alumina, silica, titania, zirconia, silica-alumina, ceria, alkali metal materials, alkaline earth metal materials, transition metal materials, rare earth metal materials, silver, silver salts, and the like. If necessary, a dispersant and a pH adjuster can be used in combination.

- the catalyst composition is applied to the monolithic support as a slurry mixture to coat the catalyst composition.

- a coating method is not particularly limited, but a wash coat method is preferable.

- drying and firing are performed to obtain a monolithic structure type catalyst on which the catalyst composition is supported.

- the drying temperature is preferably from 100 to 300 ° C, more preferably from 100 to 200 ° C.

- the firing temperature is preferably 300 to 700 ° C., more preferably 400 to 600 ° C.

- the drying time is preferably 0.5 to 2 hours, and the firing time is preferably 1 to 3 hours.

- a heating means it can carry out by well-known heating means, such as an electric furnace and a gas furnace.

- the upper catalyst material contains a composite oxide (C) substantially consisting of tungsten oxide, ceria, and zirconia, and separately from this, zeolite can be blended as necessary as an upper catalyst material.

- C composite oxide

- zeolite can be blended as necessary as an upper catalyst material.

- the thickness of the layer may vary depending on the part of the honeycomb. It is in the range of 1 to 250 ⁇ m, more preferably in the range of 20 to 250 ⁇ m. If the upper layer is too thin and less than 5 ⁇ m, the gas diffusibility may decrease. If the total layer is too thick and exceeds 430 ⁇ m, there is a concern about the load on the engine due to an increase in pressure loss. Particularly preferred thicknesses are the upper layer: 40 to 250 ⁇ m and the lower layer: 1 to 180 ⁇ m.

- an exhaust gas flow path collects and removes oxidation catalyst (DOC) having a function of oxidizing nitric oxide and hydrocarbons and particulate matter in an exhaust gas passage.

- An exhaust gas purification catalyst device is configured by arranging a filter (DPF), a spray means for supplying an aqueous urea solution or an aqueous ammonia solution, a selective reduction catalyst (SCR), and the ammonia oxidation catalyst (AMOX) in this order. Is done.

- Diesel engines have a relatively low exhaust gas temperature compared to gasoline engines due to their structural characteristics, and the temperature is generally room temperature to 700 ° C.

- the exhaust gas temperature is particularly low during start-up and low loads. However, when the temperature of the exhaust gas is low, the temperature of the catalyst does not rise sufficiently, the purification performance is not sufficiently exhibited, and NOx in the exhaust gas is easily exhausted without being sufficiently purified.

- an oxidation catalyst that oxidizes HC and CO in the exhaust gas, and a filter that collects combustible particle components contained in the exhaust gas (DPF) is arranged.

- DOC oxidation catalyst

- a known platinum or a catalyst mainly composed of activated alumina on which at least one of palladium is supported can be used.

- the carrier of the oxidation catalyst activated alumina containing La can be used, and a catalyst containing ⁇ -type zeolite ion-exchanged with cerium may be used.

- the DOC preferably contains a platinum component or a palladium component as a noble metal component, and the amount of the noble metal component is preferably 0.1 to 4 g / L, more preferably 0.5 to 3 g / L in terms of metal. . And the noble metal component is too much becomes a high cost, sometimes not too little Suitable NO 2 / NOx ratio.

- the noble metal component preferably contains 30 to 100 w% platinum in terms of metal, and more preferably 50 to 100 w% platinum.

- Many diesel oils used in diesel automobile fuel contain 50 ppm or more of sulfur components, and exhaust gases containing such sulfur components may poison noble metals in the catalyst components. Palladium tends to be easily poisoned by sulfur, whereas platinum tends to be hardly poisoned by sulfur. Therefore, it is preferable to use platinum as a precious metal component as a main component in the DOC used in the present invention.

- the combustible particle components collected by the DPF are then burned and removed, and the DPF function is regenerated.

- NO 2 is used for burning soot in the DPF. Combustion of soot by NO 2 is milder than oxygen and hardly induces damage to the DPF due to combustion heat.

- Some DPFs are coated with an oxidation catalyst for the purpose of promoting this combustion regeneration, and are called CSFs. In the present invention, DPF includes CSF unless otherwise specified.

- An SCR catalyst is disposed after the DOC and DPF.

- the combustion engine to which the present invention is applied ranges from a small automobile having a displacement of about 1 L to a heavy-duty diesel engine having a displacement of more than 50 L, and exhausted from these diesel engines.

- NOx in the exhaust gas varies greatly depending on its operating state, combustion control method, and the like.

- the SCR catalyst which purifies NOx in the exhaust gas discharged from these diesel engines can also be selected according to the diversity of diesel engine exhaust amount exceeding about 1L to more than 50L.

- a NOx occlusion catalyst may be used separately from the SCR, which is referred to as LNT (Lean NOx Trap).

- LNT Lean NOx Trap

- the NOx occluded in the LNT purifies the NOx using HC and CO, which are reducing components in the exhaust gas, as a reducing agent, but the SCR may be combined with such an LNT.

- a selective catalytic reduction catalyst formed by coating the surface of a monolithic support with a catalyst layer containing a composite oxide comprising at least an iron element and a tungsten oxide, ceria, and zirconia.

- a composite oxide in addition to the composite oxide (C) that is a component of the catalyst, a material obtained by adding silica to the composite oxide (C) can also be used.

- Zeolite (D) described below is preferred as the zeolite that is a component of the SCR catalyst.

- examples of the zeolite (D) include ⁇ -type and MFI-type zeolites having a three-dimensional pore structure, and zeolites such as A, X, Y, MOR, CHA, and SAPO. Among them, ⁇ -type zeolite or MFI-type zeolite is preferable.

- the ⁇ -type zeolite preferably used in the present catalyst is classified, for example, as a tetragonal synthetic zeolite whose unit cell composition is represented by the following average composition formula.

- M m / x [Al m Si (64-m) O 128 ] .pH 2 O (Wherein M is a cationic species, x is the valence of M, m is a number greater than 0 and less than 64, and p is a number greater than or equal to 0)

- This ⁇ -type zeolite has a relatively complicated three-dimensional pore structure composed of linear pores having a relatively large diameter and unidirectionally aligned pores and curved pores intersecting with the pores. And diffusion of gas molecules such as NH 3 are easy.

- such a structure has only a linear hole in which mordenite, faujasite, etc. are aligned in one direction, whereas it is a unique structure, and because it is such a complicated hole structure, ⁇ -zeolite is highly effective because it is difficult to cause structural breakdown due to heat and has high stability.

- zeolite needs to have an acid point capable of adsorbing a basic compound such as NH 3 , but the number of acid points varies depending on the Si / Al ratio.

- zeolite with a low Si / Al ratio has a large number of acid sites, but the degree of deterioration is large in durability in the presence of water vapor, and on the contrary, zeolite with a high Si / Al ratio is excellent in heat resistance.

- NH 3 is adsorbed on the acid sites of the zeolite, and these serve as active sites to reduce and remove nitrogen oxides such as NO 2, so the one with more acid sites (the one with a lower Si / Al ratio). This is advantageous for the denitration reaction.

- a molar ratio of SiO 2 and Al 2 O 3 (hereinafter abbreviated as SAR) by component analysis is generally used.

- SAR has a trade-off relationship between durability and activity, but considering these, the SAR of zeolite is preferably 15 to 300, more preferably 17 to 60. Such characteristics are also possessed by ⁇ -type zeolite and MFI-type zeolite.

- the zeolite (D) contains a zeolite containing an iron element as a main component.

- zeolite has a cation as a counter ion as a solid acid point. As the cation, ammonium ions and protons are generally used.

- an iron element is added as a cation species to the ⁇ -type zeolite used in the present catalyst.

- Fe- ⁇ an iron element added as a cation species to the ⁇ -type zeolite used in the present catalyst.

- Fe- ⁇ an iron element added as a cation species to the ⁇ -type zeolite used in the present catalyst.

- NO is oxidized to NO 2 on the zeolite surface to increase the reaction activity with NH 3

- the framework structure of the zeolite is It is thought that it is stabilized and contributes to the improvement of heat resistance.

- the amount of Fe added to the zeolite is preferably 0.1 to 5 wt%, more preferably 0.5 to 4.5 wt% in terms of Fe 2 O 3 .

- the amount of the iron element exceeds 5 wt% in terms of Fe 2 O 3 , the number of active solid acid points cannot be secured and the activity is lowered. If the amount of iron element is less than 0.1 wt% in terms of Fe 2 O 3 , it is not preferable because sufficient NOx purification performance cannot be obtained and exhaust gas purification performance is lowered. In addition, although all of the iron element added as an ion exchange seed may be ion-exchanged, a part thereof may exist in the state of iron oxide.

- the method for supporting the iron element may be an ion exchange method or an impregnation method.

- a metal catalyst component it is desirable that at least a part of the zeolite is ion-exchanged with the metal catalyst component.

- the metal catalyst component may not be completely ion-exchanged, and a part thereof may exist as an oxide.

- Zeolite to which such an iron element is added can be purchased in various grades from major zeolite manufacturers, and can also be produced as described in JP-A-2005-502451.

- nitrates, acetates, chlorides and the like containing iron element may be solubilized in an aqueous solution, and then zeolite may be added and supported by an impregnation method.

- the precipitate obtained by adjusting the pH with the above may be dried and calcined, or the zeolite may be immersed in an aqueous solution of nitrate, acetate, chloride, etc.

- the firing temperature is preferably 300 to 800 ° C, more preferably 400 to 600 ° C.

- a heating means it can carry out by well-known heating means, such as an electric furnace and a gas furnace.

- MFI type zeolite As a zeolite having a three-dimensional pore structure preferable as a zeolite of the present catalyst, for example, MFI type zeolite is also known as an SCR component.

- the Si / Al ratio of the MFI type zeolite is also the same as that of the ⁇ type zeolite described above.

- the MFI type zeolite contains an iron element like the ⁇ type zeolite.

- the MFI-type zeolite containing an iron element may be hereinafter referred to as “Fe-MFI”.

- the zeolite species may be used in combination with one or more of various types of zeolite such as A, X, Y, MOR, CHA, and SAPO.

- the total proportion of the various ⁇ -type zeolites or MFI-type zeolites in the total zeolite is preferably 50 to 100%.

- the zeolite may contain other transition metals, rare earth metals, noble metals, and the like.

- transition metals such as nickel, cobalt, zirconium and copper, and rare earth metals such as cerium, lanthanum, praseodymium and neodymium.

- noble metals such as gold, silver, platinum, palladium, rhodium, iridium, ruthenium, niobium, tungsten, tantalum, ceria, cerium-zirconium composite oxide, lanthanum oxide, alumina, silica, zirconia, vanadia, tin, gallium, etc.

- Materials that can generally be used as catalyst materials such as alkali elements and alkaline earth elements, can be appropriately added within a range that does not impair the object of the present invention.

- composition of the material system in which silica is added to the composite oxide (C) is as follows: silica: 20% by weight or less, tungsten oxide: 1-50% by weight, ceria: 1-60% by weight, and zirconia: 30-90% by weight More preferred are silica: 5 wt% or less, tungsten oxide: 3-30 wt%, ceria: 5-40 wt%, and zirconia: 50-90 wt%.

- the coating amount is preferably 10 to 80% by weight with respect to the entire catalyst layer.

- the SCR catalyst When the reducing agent is urea, the SCR catalyst includes a composite oxide (E) as a hydrolysis component of the urea component in addition to the zeolite (D) or the composite oxide (C) as the denitration component. It is desirable to contain.

- the composite oxide (E) is preferably a composite oxide substantially composed of titania, silica, and zirconia. More preferably, the composition is titania: 70 to 95% by weight, silica: 1 to 10% by weight, and zirconia: 5 to 20% by weight.

- the coating amount of the zeolite (D), composite oxide (C) and urea hydrolysis component (E) constituting the catalyst layer is preferably 200 to 350 g / L, more preferably 220 to 330 g / L. . If the coating amount is too small, the denitration effect may not be obtained sufficiently. If the coating amount is too large, the pores of the honeycomb may be clogged, the exhaust gas back pressure may increase significantly, and the engine performance may be reduced. is there.

- the coating amount of zeolite (D) is 10 to 80% by weight with respect to the entire catalyst layer, and the coating amount of composite oxide (C) is 10 to 80% with respect to the entire catalyst layer. It is preferable that the coating amount of the composite oxide (E) is 1 to 30% by weight with respect to the entire catalyst layer.

- the SCR catalyst may be coated with a single layer structure on a monolithic structure type carrier, but it may be formed by coating and laminating two or more layers.

- composite oxide (C) which can contain silica, and substantially titania, silica and zirconia

- the catalyst layer containing the composite oxide (E) made of is coated in two upper and lower layers.

- the lower layer contains 50 to 90% by weight of zeolite (D), 10 to 40% by weight of composite oxide (C), and 1 to 30% by weight of composite oxide (E), while the upper layer contains zeolite (D).

- the coating amount of the lower layer is preferably 20 to 50% by weight, and the coating amount of the upper layer is preferably 50 to 80% by weight.

- the coating amount of the upper layer is 30 to 45% by weight, and the coating amount of the upper layer is 55 to 70% by weight.

- the present catalyst having an NH 3 purification function is disposed downstream of the SCR catalyst.

- the catalyst is excellent in NH 3 purifying performance with respect to exhaust gas flow, it is possible to oxidize NH 3 coming slipping from the SCR catalyst efficiently.

- the ammonia oxidation catalyst (AMOX) of the present invention is disposed at the rear stage of the SCR catalyst, and the slip NH 3 is oxidized and purified. Further, the NOx generated by NOx or NH 3 oxidation flowing out SCR catalyst, is reacted with a slip NH 3 that is not already being used in the oxidation reaction promotes NOx purification. That is, NO and NO 2 in the exhaust gas flow into the upper layer of AMOX, react with the supplied NH 3, and are reduced to nitrogen, and then surplus ammonia is supplied to the upper layer of the catalyst and partially adsorbed and retained. Is done.

- NO that passes through the upper layer and reaches the lower layer is oxidized to NO 2 by the noble metal component (Pt), this NO 2 moves to the upper layer, reacts with NH 3 adsorbed and held in the upper layer, and N 2 It is discharged as H 2 O. Then, in the lower layer react with NH 3 to NO 2, which is oxidized from NO to NO 2 by the noble metal is adsorbed and held in the lower layer is discharged as N 2 and H 2 O. In this way, the NOx purification may be further improved by AMOX.

- the performance of the NH 3 oxidation catalyst is high, it is possible to oxidize and purify NH 3 from a lower temperature as long as the amount of the noble metal supported is the same as that of the conventional catalyst technology.

- NH 3 oxidation purification performance equivalent to the above can be obtained.

- the temperature of exhaust gas exhausted from automobile diesel engines covers a wide range, and when this is divided into a low temperature range of about 150 to 250 ° C. and a high temperature range of about 300 to 600 ° C., the NH 3 oxidation of the present invention.

- the catalyst Since the catalyst has excellent NOx purification activity in the low temperature range and excellent heat resistance, if a SCR catalyst with excellent denitration performance in the high temperature range is selected and placed in the previous stage, a wide temperature range from the low temperature range to the high temperature range is possible. High denitration performance can be demonstrated.

- an integral structure carrier that is, a honeycomb flow-through cordierite carrier (300 cells, 5 mil, ⁇ 25.4 mm ⁇ 24 mm length) is immersed in the slurry A, and the catalyst loading per unit volume is 30 g / L. It was applied by a wash coat method. Then, it was dried at 150 ° C. for 1 hour and calcined at 500 ° C. for 2 hours in an air atmosphere to obtain catalyst B with a lower layer applied.

- a honeycomb flow-through cordierite carrier 300 cells, 5 mil, ⁇ 25.4 mm ⁇ 24 mm length

- Table 1 has shown content of each component by a weight part when a W / Ce / Zr material is 100 weight part. Then, by using the NH 3 oxidation catalysts obtained were carried out following the catalyst performance evaluation. The evaluation results of the catalyst performance are shown in FIGS.

- Pt-supported titania powder and water Pt terms 0 as the base material .332 wt%

- an integral structure carrier that is, a honeycomb flow-through cordierite carrier (300 cells, 5 mil, ⁇ 25.4 mm ⁇ 24 mm length) is immersed in the slurry F, and the catalyst loading per unit volume is 30 g / L. It was applied by a wash coat method. Then, it was dried at 150 ° C. for 1 hour, and calcined at 500 ° C. for 2 hours in an air atmosphere to obtain a catalyst G coated with a lower layer.

- a honeycomb flow-through cordierite carrier 300 cells, 5 mil, ⁇ 25.4 mm ⁇ 24 mm length

- Example 3 Production of NH 3 oxidation catalyst AMOX (3); Instead of titania powder D with a base material for the noble metal-supported (90wt% TiO 2 / 10wt% SiO 2), was used titania powder E (80wt% TiO 2 / 15wt % SiO 2 / 5wt% Al 2 O 3) Except that, AMOX (3) shown in Table 1 was obtained in the same manner as in the method described in Example 2. Then, by using the NH 3 oxidation catalyst obtained was carried catalyst performance evaluation in the same manner as described in Example 1. The evaluation results of the catalyst performance are shown in FIGS.

- Example 4 Production of NH 3 oxidation catalyst AMOX (4); AMOX (4) shown in Table 1 was obtained in the same manner as in Example 3 except that the amount of the catalyst supported on the upper layer was changed to 110 g / L and changed to 55 g / L. Then, by using the NH 3 oxidation catalyst obtained was carried catalyst performance evaluation in the same manner as described in Example 1. The evaluation results of the catalyst performance are shown in FIGS.

- the slurry L was immersed in an integral structure carrier, that is, a honeycomb flow-through cordierite carrier (300 cells / 5 mil, ⁇ 25.4 mm ⁇ 24 mm length), and the catalyst loading per unit volume was 85 g / L. It was applied by a wash coat method so that Then, it was dried at 150 ° C. for 1 hour, and calcined at 500 ° C. for 2 hours in an air atmosphere to obtain catalyst H with a lower layer applied. The lower layer-coated catalyst H thus obtained carries 1.0 g / L of Pt per unit volume.

- an integral structure carrier that is, a honeycomb flow-through cordierite carrier (300 cells / 5 mil, ⁇ 25.4 mm ⁇ 24 mm length)

- the catalyst loading per unit volume was 85 g / L. It was applied by a wash coat method so that Then, it was dried at 150 ° C. for 1 hour, and calcined at 500 ° C. for 2 hours in an air atmosphere to obtain catalyst H with

- the lower layer-coated catalyst H was immersed in this slurry I and applied by a wash coat method so that the amount of the catalyst supported per unit volume was 115 g / L. Then, it was dried at 150 ° C. for 1 hour, and calcined at 500 ° C. for 2 hours in an air atmosphere to obtain a comparative AMOX (5) shown in Table 1.

- the numerical value of Table 1 has shown content of each component by a weight part when Fe zeolite is 100 weight part.

- Comparative Example 2 In Comparative Example 1, ammonia concentration was changed except that the noble metal concentration of the Pt-supported titania powder under the ammonia oxidation catalyst AMOX (5) was changed so that the final amount of Pt supported per unit volume of the catalyst was 0.7 g / L. An ammonia oxidation catalyst AMOX (6) was obtained in the same manner as the oxidation catalyst AMOX (5). Similarly, it was installed in a model gas test apparatus and the catalyst performance was evaluated. The evaluation results of the catalyst performance are shown in FIGS.

- Comparative Example 3 In Comparative Example 1, except that the noble metal concentration of the Pt-supported titania powder under the ammonia oxidation catalyst AMOX (5) was changed so that the final amount of Pt supported per unit volume of the catalyst was 0.5 g / L. An ammonia oxidation catalyst AMOX (7) was obtained in the same manner as the oxidation catalyst AMOX (5). Similarly, it was installed in a model gas test apparatus and the catalyst performance was evaluated. The evaluation results of the catalyst performance are shown in FIGS.

- Comparative Example 4 In Comparative Example 1, except that the noble metal concentration of the Pt-supported titania powder under the ammonia oxidation catalyst AMOX (5) was changed so that the final amount of Pt supported per unit volume of the catalyst was 0.1 g / L. An ammonia oxidation catalyst AMOX (8) was obtained in the same manner as the oxidation catalyst AMOX (5).

- the ammonia oxidation catalysts AMOX (1) to (4) contain a specific composite oxide as a catalyst component of the present invention, so that although the amount of Pt is small.

- the NH 3 conversion at 230 ° C. is excellent.

- N 2 O emission concentration is low, it can be seen that excellent N 2 O ability of suppressing the formation.

- the NOx emission concentration is not inferior even though the amount of Pt is small.

- the ammonia oxidation catalysts AMOX (5) to (8) do not contain a specific complex oxide unlike the present invention, so that the graph shows a large amount of Pt.

- the NH 3 conversion rate at 230 ° C. is low, and as shown in FIG. 2, the N 2 O emission concentration is high and the N 2 O production suppressing ability is inferior. Further, as shown in FIG. Since the amount is large, it can be seen that the NOx emission concentration is relatively low.

- the present invention is widely applicable to the removal technology of nitrogen oxides exhausted from automobiles such as diesel engines whose fuel is light oil, and the purification of slip NH 3 . Further, the present invention can be applied to exhaust gas emitted from a combustion engine using gasoline, heavy oil, biofuel such as alcohol as a fuel, biofuel and light oil, or mixed fuel of biofuel and gasoline. Furthermore, the present invention is also effective when used in combination with an exhaust gas purification catalyst device that involves regeneration of a filter on which combustible particle components are deposited.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Biomedical Technology (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Environmental & Geological Engineering (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Crystallography & Structural Chemistry (AREA)

- Catalysts (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

- Exhaust Gas After Treatment (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201180069695.3A CN103442805B (zh) | 2011-03-31 | 2011-11-17 | 氨氧化催化剂以及使用了其的废气净化装置和废气净化方法 |

| US14/008,460 US8865615B2 (en) | 2011-03-31 | 2011-11-17 | Ammonia oxidation catalyst, exhaust gas purification device using same, and exhaust gas purification method |

| EP11861929.5A EP2692430A4 (en) | 2011-03-31 | 2011-11-17 | AMMONIA COXIDATION CATALYST, EXHAUST GAS CLEANING DEVICE THEREFOR AND EXHAUST GAS CLEANING PROCESS |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011077177A JP5732297B2 (ja) | 2011-03-31 | 2011-03-31 | アンモニア酸化触媒、および排気ガス浄化装置並びに排気ガス浄化方法 |

| JP2011-077177 | 2011-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012132095A1 true WO2012132095A1 (ja) | 2012-10-04 |

Family

ID=46929894

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2011/076490 Ceased WO2012132095A1 (ja) | 2011-03-31 | 2011-11-17 | アンモニア酸化触媒、およびそれを用いた排気ガス浄化装置並びに排気ガス浄化方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US8865615B2 (enExample) |

| EP (1) | EP2692430A4 (enExample) |

| JP (1) | JP5732297B2 (enExample) |

| CN (1) | CN103442805B (enExample) |

| WO (1) | WO2012132095A1 (enExample) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9611773B2 (en) | 2012-11-22 | 2017-04-04 | Johnson Matthey Public Limited Company | Zoned catalysed substrate monolith |

| DE102018121503A1 (de) | 2017-09-05 | 2019-03-07 | Umicore Ag & Co. Kg | Abgasreinigung mit NO-Oxidationskatalysator und SCR-aktivem Partikelfilter |

| CN111992223A (zh) * | 2020-08-03 | 2020-11-27 | 山东清硕环境科技有限公司 | 一种用于燃气锅炉烟气净化的催化剂及其制备方法 |

| JPWO2021065577A1 (enExample) * | 2019-10-03 | 2021-04-08 | ||

| CN114832829A (zh) * | 2022-04-08 | 2022-08-02 | 南京工业大学 | 一种燃气尾气高温脱硝催化剂及其制备方法 |

| CN116059957A (zh) * | 2021-10-29 | 2023-05-05 | 中国石油化工股份有限公司 | 用于烟气脱汞脱硝的催化吸附剂及其制备方法和应用及燃煤电厂烟气的处理方法 |

| US11865517B2 (en) * | 2020-08-18 | 2024-01-09 | Umicore Ag & Co. Kg | Catalyst for reducing ammonia emissions |

Families Citing this family (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011103346B4 (de) * | 2011-02-16 | 2014-06-26 | Mtu Friedrichshafen Gmbh | Verfahren zur modellbasierten Bestimmung der Temperaturverteilung einer Abgasnachbehandlungseinheit |

| WO2013165309A1 (en) * | 2012-05-03 | 2013-11-07 | Scania Cv Ab | Exhaust aftertreatment system and method pertaining to such a system |

| TW201502356A (zh) * | 2013-02-21 | 2015-01-16 | Exxonmobil Upstream Res Co | 氣渦輪機排氣中氧之減少 |

| JP6326580B2 (ja) * | 2013-04-24 | 2018-05-23 | 株式会社 Acr | NOx還元触媒手段を備えた排気ガス浄化装置 |

| CN105246590A (zh) | 2013-07-11 | 2016-01-13 | 沙特基础工业全球技术公司 | 镧系氧化物减少催化剂烧结的用途 |

| US9849441B2 (en) | 2013-12-09 | 2017-12-26 | Cataler Corporation | Exhaust gas purifying catalyst |

| US8883102B1 (en) * | 2014-01-14 | 2014-11-11 | Ford Global Technologies, Llc | Methods for controlling nitrous oxide emissions |

| JP2017512279A (ja) * | 2014-02-27 | 2017-05-18 | ジョンソン、マッセイ、パブリック、リミテッド、カンパニーJohnson Matthey Public Limited Company | 排気ガス再循環回路にn2o触媒を有する排気システム |

| RU2677024C2 (ru) * | 2014-02-28 | 2019-01-15 | Сканиа Св Аб | Система обработки выхлопных газов и способ обработки потока выхлопных газов |

| CN103816891B (zh) * | 2014-03-04 | 2017-01-25 | 中国科学院生态环境研究中心 | 一种铈钼锆复合氧化物催化剂、其制备方法及用途 |

| JP6345774B2 (ja) | 2014-06-06 | 2018-06-20 | 国立研究開発法人産業技術総合研究所 | アンモニア吸着材 |

| WO2016004151A1 (en) * | 2014-07-02 | 2016-01-07 | Johnson Matthey Public Limited Company | Perovskite with an ovlerlayer scr component as an ammonia oxidation catalyst and a system for exhaust emission control on diesel engines |

| JP2016043320A (ja) * | 2014-08-25 | 2016-04-04 | エヌ・イーケムキャット株式会社 | 尿素加水分解触媒及び尿素加水分解材料を用いた選択還元触媒 |

| SE539803C2 (en) | 2015-06-05 | 2017-12-05 | Scania Cv Ab | A method and a system for determining a composition of a gas mix in a vehicle |

| US10201807B2 (en) * | 2015-06-18 | 2019-02-12 | Johnson Matthey Public Limited Company | Ammonia slip catalyst designed to be first in an SCR system |

| WO2016205509A1 (en) * | 2015-06-18 | 2016-12-22 | Johnson Matthey Public Limited Company | Ammonia slip catalyst with low n2o formation |

| EP3317013A4 (en) * | 2015-07-01 | 2019-03-20 | BASF Corporation | CATALYSTS FOR REMOVING STAIN OXIDE FOR EXHAUST SYSTEMS |

| CN106362582A (zh) * | 2015-07-24 | 2017-02-01 | 中船重工海博威(江苏)科技发展有限公司 | 一种催化氧化处理含氨废气的方法及装置 |

| CN105370350A (zh) * | 2015-10-28 | 2016-03-02 | 苏州莲池环保科技发展有限公司 | 一种汽车三元催化器的封装方法 |

| CN105435620A (zh) * | 2015-12-07 | 2016-03-30 | 山东骏飞化工有限公司 | 一种脱硝剂及其制备方法 |

| DE102015225579A1 (de) * | 2015-12-17 | 2017-06-22 | Umicore Ag & Co. Kg | Verfahren zur Verhinderung der Kontamination eines SCR-Katalysators mit Platin |

| CN106944130A (zh) * | 2017-03-09 | 2017-07-14 | 无锡威孚环保催化剂有限公司 | 一种净化柴油机尾气的scr‑aoc组合催化剂及其制备方法 |

| GB201705158D0 (en) * | 2017-03-30 | 2017-05-17 | Johnson Matthey Plc | Catalyst article for use in a emission treatment system |

| CN111036241B (zh) * | 2018-10-12 | 2022-11-15 | 中国石油化工股份有限公司 | 规整结构催化剂及其制备方法和应用以及含氨废气催化氧化处理方法 |

| WO2020210295A1 (en) * | 2019-04-11 | 2020-10-15 | Basf Corporation | Selective ammonia oxidation catalyst |

| CN110075907A (zh) * | 2019-05-08 | 2019-08-02 | 中自环保科技股份有限公司 | 一种用于柴油车尾气净化的氨氧化催化剂及其制备方法 |

| CN112536061B (zh) * | 2019-09-23 | 2023-05-02 | 中国石油化工股份有限公司 | 一种废气处理催化剂及其制备方法 |

| JP6921261B1 (ja) * | 2020-03-26 | 2021-08-18 | 株式会社キャタラー | 排ガス浄化触媒装置 |

| BR112022020204A2 (pt) * | 2020-04-09 | 2022-11-22 | Basf Corp | Catalisador para a oxidação de no, método para preparar um catalisador para a oxidação de no, uso de um catalisador e sistema de tratamento de gases de escape |

| CN111841624A (zh) * | 2020-07-08 | 2020-10-30 | 凯龙蓝烽新材料科技有限公司 | 一种高效amox整体式催化剂的制备方法 |

| CN114247450B (zh) * | 2020-12-28 | 2024-07-02 | 中化学环保催化剂有限公司 | 一种催化组合物、催化剂层、催化装置和气体处理系统 |

| JP7295188B2 (ja) * | 2021-09-21 | 2023-06-20 | 株式会社キャタラー | 排ガス浄化触媒装置 |

| CN114797893B (zh) * | 2022-04-25 | 2023-08-11 | 昆明理工大学 | 一种氨氧化催化剂及其制备方法和应用 |

Citations (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07289897A (ja) * | 1994-03-02 | 1995-11-07 | Nippon Shokubai Co Ltd | アンモニア分解用触媒およびその触媒を用いるアンモニアの分解方法 |

| JPH07328438A (ja) | 1994-06-08 | 1995-12-19 | Mitsubishi Heavy Ind Ltd | アンモニア分解用触媒 |

| JPH105591A (ja) | 1996-06-20 | 1998-01-13 | Babcock Hitachi Kk | 排ガス浄化用触媒およびそれを用いた排ガス浄化装置 |

| JP2002502927A (ja) | 1998-02-06 | 2002-01-29 | ジョンソン、マッセイ、パブリック、リミテッド、カンパニー | 排ガス中のNOxの還元機構 |

| JP2004524962A (ja) | 2001-03-12 | 2004-08-19 | エンゲルハード・コーポレーシヨン | N2oの触媒による選択的還元及びそのための触媒 |

| JP2005502451A (ja) | 2001-09-07 | 2005-01-27 | エンゲルハード・コーポレーシヨン | NOx還元用の水熱的に安定な金属による助触媒作用を受けているゼオライトベータ |

| JP2005238195A (ja) | 2004-02-27 | 2005-09-08 | Tokyo Roki Co Ltd | 窒素酸化物浄化用触媒システム及び窒素酸化物浄化方法 |

| JP2007504945A (ja) * | 2003-09-10 | 2007-03-08 | エンゲルハード・コーポレーシヨン | 多層化アンモニア酸化触媒 |

| JP2008264703A (ja) | 2007-04-20 | 2008-11-06 | Nissan Motor Co Ltd | 排気ガス浄化触媒及びその製造方法 |

| JP2008279334A (ja) | 2007-05-09 | 2008-11-20 | Ne Chemcat Corp | 選択還元型触媒、およびそれを用いた排気ガス浄化装置並びに排気ガス浄化方法 |

| JP2008296107A (ja) | 2007-05-30 | 2008-12-11 | Toyota Motor Corp | 排ガス浄化用触媒及びその製造方法 |

| JP2009291764A (ja) * | 2008-06-09 | 2009-12-17 | Tokyo Roki Co Ltd | 内燃機関用の排ガス浄化フィルタ、及び内燃機関用の排ガス浄化装置 |

| JP2010209783A (ja) * | 2009-03-10 | 2010-09-24 | Toyota Industries Corp | 排気ガス浄化装置 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04145606A (ja) * | 1990-10-05 | 1992-05-19 | Murata Mfg Co Ltd | 巻線型インダクタ |

| JP3436567B2 (ja) * | 1993-06-23 | 2003-08-11 | バブコック日立株式会社 | 排ガス浄化触媒およびその製造方法 |

| US5679313A (en) * | 1994-06-08 | 1997-10-21 | Mitsubishi Jukogyo Kabushiki Kaisha | Ammonia decomposition catalysts |

| US7541310B2 (en) * | 2003-10-16 | 2009-06-02 | Conocophillips Company | Silica-alumina catalyst support, catalysts made therefrom and methods of making and using same |

| JP4547930B2 (ja) * | 2004-02-17 | 2010-09-22 | 日産自動車株式会社 | 触媒、触媒の調製方法及び排ガス浄化用触媒 |

| JP2007296514A (ja) * | 2006-04-07 | 2007-11-15 | Ngk Insulators Ltd | 触媒体とその製造方法 |

| FR2907444B1 (fr) * | 2006-10-20 | 2008-12-19 | Rhodia Recherches & Tech | Composition a acidite elevee a base d'oxydes de zirconium,de silicium et d'au moins un autre element choisi parmi le titane,l'aluminium,le tungstene,le molybdene,le cerium,le fer et le manganese |

| US8636959B2 (en) * | 2007-05-09 | 2014-01-28 | N.E. Chemcat Corporation | Selective catalytic reduction type catalyst, and exhaust gas purification equipment and purifying process of exhaust gas using the same |

| US8119558B2 (en) * | 2008-03-14 | 2012-02-21 | Süd-Chemie Inc. | Ultra high temperature shift catalyst with low methanation |

| JP5422087B2 (ja) * | 2008-08-08 | 2014-02-19 | 本田技研工業株式会社 | 低貴金属担持三元触媒 |

| US8148295B2 (en) * | 2009-02-16 | 2012-04-03 | Millennium Inorganic Chemicals, Inc. | Catalyst promoters in vanadium-free mobile catalyst |

| US7879759B2 (en) * | 2009-02-16 | 2011-02-01 | Augustine Steve M | Mobile DeNOx catalyst |

| US7968492B2 (en) * | 2009-05-11 | 2011-06-28 | Millennium Inorganic Chemicals, Inc. | Layered catalyst to improve selectivity or activity of manganese containing vanadium-free mobile catalyst |

| US20120328499A1 (en) * | 2010-06-30 | 2012-12-27 | N.E. Chemcat Corporation | Exhaust gas purification catalyst apparatus using selective reduction-type catalyst and exhaust gas purification method |

| DE102010050312A1 (de) * | 2010-11-03 | 2012-05-03 | Süd-Chemie AG | Ammoniak-Oxidationskatalysator mit geringer N2O Nebenproduktbildung |

| US8617502B2 (en) * | 2011-02-07 | 2013-12-31 | Cristal Usa Inc. | Ce containing, V-free mobile denox catalyst |

| CN103476495B (zh) * | 2011-03-31 | 2016-01-20 | 恩亿凯嘉股份有限公司 | 氨氧化催化剂以及使用了其的废气净化装置和废气净化方法 |

-

2011

- 2011-03-31 JP JP2011077177A patent/JP5732297B2/ja active Active

- 2011-11-17 US US14/008,460 patent/US8865615B2/en not_active Expired - Fee Related

- 2011-11-17 EP EP11861929.5A patent/EP2692430A4/en not_active Withdrawn

- 2011-11-17 CN CN201180069695.3A patent/CN103442805B/zh active Active

- 2011-11-17 WO PCT/JP2011/076490 patent/WO2012132095A1/ja not_active Ceased

Patent Citations (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH07289897A (ja) * | 1994-03-02 | 1995-11-07 | Nippon Shokubai Co Ltd | アンモニア分解用触媒およびその触媒を用いるアンモニアの分解方法 |

| JPH07328438A (ja) | 1994-06-08 | 1995-12-19 | Mitsubishi Heavy Ind Ltd | アンモニア分解用触媒 |

| JPH105591A (ja) | 1996-06-20 | 1998-01-13 | Babcock Hitachi Kk | 排ガス浄化用触媒およびそれを用いた排ガス浄化装置 |

| JP2002502927A (ja) | 1998-02-06 | 2002-01-29 | ジョンソン、マッセイ、パブリック、リミテッド、カンパニー | 排ガス中のNOxの還元機構 |

| JP2004524962A (ja) | 2001-03-12 | 2004-08-19 | エンゲルハード・コーポレーシヨン | N2oの触媒による選択的還元及びそのための触媒 |

| JP2005502451A (ja) | 2001-09-07 | 2005-01-27 | エンゲルハード・コーポレーシヨン | NOx還元用の水熱的に安定な金属による助触媒作用を受けているゼオライトベータ |

| JP2007504945A (ja) * | 2003-09-10 | 2007-03-08 | エンゲルハード・コーポレーシヨン | 多層化アンモニア酸化触媒 |

| JP2005238195A (ja) | 2004-02-27 | 2005-09-08 | Tokyo Roki Co Ltd | 窒素酸化物浄化用触媒システム及び窒素酸化物浄化方法 |

| JP2008264703A (ja) | 2007-04-20 | 2008-11-06 | Nissan Motor Co Ltd | 排気ガス浄化触媒及びその製造方法 |

| JP2008279334A (ja) | 2007-05-09 | 2008-11-20 | Ne Chemcat Corp | 選択還元型触媒、およびそれを用いた排気ガス浄化装置並びに排気ガス浄化方法 |

| JP2008296107A (ja) | 2007-05-30 | 2008-12-11 | Toyota Motor Corp | 排ガス浄化用触媒及びその製造方法 |

| JP2009291764A (ja) * | 2008-06-09 | 2009-12-17 | Tokyo Roki Co Ltd | 内燃機関用の排ガス浄化フィルタ、及び内燃機関用の排ガス浄化装置 |

| JP2010209783A (ja) * | 2009-03-10 | 2010-09-24 | Toyota Industries Corp | 排気ガス浄化装置 |

Non-Patent Citations (2)

| Title |

|---|

| M. UESHIMA ET AL.: "New Technology for Selective Catalytic Oxidation of Ammonia to Nitrogen", RES. CHEM. INTERMED., vol. 24, no. 2, May 1998 (1998-05-01), pages 133 - 141, XP055127193 * |

| See also references of EP2692430A4 |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9611773B2 (en) | 2012-11-22 | 2017-04-04 | Johnson Matthey Public Limited Company | Zoned catalysed substrate monolith |

| DE102018121503A1 (de) | 2017-09-05 | 2019-03-07 | Umicore Ag & Co. Kg | Abgasreinigung mit NO-Oxidationskatalysator und SCR-aktivem Partikelfilter |

| JPWO2021065577A1 (enExample) * | 2019-10-03 | 2021-04-08 | ||

| WO2021065577A1 (ja) * | 2019-10-03 | 2021-04-08 | エヌ・イーケムキャット株式会社 | 排ガス浄化装置 |

| JP7510430B2 (ja) | 2019-10-03 | 2024-07-03 | エヌ・イーケムキャット株式会社 | 排ガス浄化装置 |

| CN111992223A (zh) * | 2020-08-03 | 2020-11-27 | 山东清硕环境科技有限公司 | 一种用于燃气锅炉烟气净化的催化剂及其制备方法 |

| US11865517B2 (en) * | 2020-08-18 | 2024-01-09 | Umicore Ag & Co. Kg | Catalyst for reducing ammonia emissions |

| CN116059957A (zh) * | 2021-10-29 | 2023-05-05 | 中国石油化工股份有限公司 | 用于烟气脱汞脱硝的催化吸附剂及其制备方法和应用及燃煤电厂烟气的处理方法 |

| CN114832829A (zh) * | 2022-04-08 | 2022-08-02 | 南京工业大学 | 一种燃气尾气高温脱硝催化剂及其制备方法 |

| CN114832829B (zh) * | 2022-04-08 | 2023-09-26 | 南京工业大学 | 一种燃气尾气高温脱硝催化剂及其制备方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN103442805B (zh) | 2015-11-25 |

| US20140065044A1 (en) | 2014-03-06 |

| US8865615B2 (en) | 2014-10-21 |

| JP5732297B2 (ja) | 2015-06-10 |

| JP2012210570A (ja) | 2012-11-01 |

| EP2692430A4 (en) | 2015-04-15 |

| CN103442805A (zh) | 2013-12-11 |