WO2011045921A1 - Dispositif fluidique à spirale - Google Patents

Dispositif fluidique à spirale Download PDFInfo

- Publication number

- WO2011045921A1 WO2011045921A1 PCT/JP2010/006064 JP2010006064W WO2011045921A1 WO 2011045921 A1 WO2011045921 A1 WO 2011045921A1 JP 2010006064 W JP2010006064 W JP 2010006064W WO 2011045921 A1 WO2011045921 A1 WO 2011045921A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- scroll

- fluid device

- housing

- scroll member

- space

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/02—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents

- F04C18/0207—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents both members having co-operating elements in spiral form

- F04C18/0215—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents both members having co-operating elements in spiral form where only one member is moving

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01C—ROTARY-PISTON OR OSCILLATING-PISTON MACHINES OR ENGINES

- F01C21/00—Component parts, details or accessories not provided for in groups F01C1/00 - F01C20/00

- F01C21/10—Outer members for co-operation with rotary pistons; Casings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/02—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents

- F04C18/0207—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents both members having co-operating elements in spiral form

- F04C18/0246—Details concerning the involute wraps or their base, e.g. geometry

- F04C18/0269—Details concerning the involute wraps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/02—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents

- F04C18/0207—Rotary-piston pumps specially adapted for elastic fluids of arcuate-engagement type, i.e. with circular translatory movement of co-operating members, each member having the same number of teeth or tooth-equivalents both members having co-operating elements in spiral form

- F04C18/0246—Details concerning the involute wraps or their base, e.g. geometry

- F04C18/0269—Details concerning the involute wraps

- F04C18/0276—Different wall heights

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/0021—Systems for the equilibration of forces acting on the pump

- F04C29/0035—Equalization of pressure pulses

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/06—Silencing

- F04C29/065—Noise dampening volumes, e.g. muffler chambers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/06—Silencing

- F04C29/068—Silencing the silencing means being arranged inside the pump housing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F04C29/12—Arrangements for admission or discharge of the working fluid, e.g. constructional features of the inlet or outlet

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2240/00—Components

- F04C2240/30—Casings or housings

Definitions

- the present invention relates to a scroll type fluid device that can be used as a compressor or an expander, and more particularly to the structure of the device housing portion.

- a spiral wrap is integrally formed on the end plate of the fixed scroll member, and a spiral wrap is integrally formed on the end plate of the movable scroll member.

- a fluid pocket which is a sealed space formed between the spiral wraps by revolving on the circular orbit while being arranged so that the side walls are in partial contact and preventing the rotation of the movable scroll member,

- the volume of the fluid pocket is changed by moving from the outer end of the spiral wrap toward the center, and in the case of an expander, the volume of the fluid pocket is changed by moving from the center to the outer end.

- a scroll-type fluid device that compresses or expands the fluid taken in the fluid pocket is well known.

- Patent Document 2 a sub-housing is provided on the outer peripheral side of the center housing, a second discharge chamber that communicates with the first discharge chamber via a communication path is provided inside, and a discharge port is provided to the second discharge chamber.

- a structure that is provided to suppress discharge pulsation and reduce noise is disclosed.

- Patent Document 1 does not present pulsation reduction means when a compressor is used.

- Patent Document 2 discloses a configuration in which the discharge chamber is devised as described above for discharge pulsation.

- the position of the second discharge chamber provided on the outer peripheral side of the center housing, which is presented in Patent Document 2 and the installation site of the communication path presented in Patent Document 1 are in a position where they interfere or are close to each other. Exists in the position. Therefore, if the volume of the second discharge chamber in Patent Document 2 is increased in order to enhance the discharge pulsation suppression and noise reduction effects, the cross-sectional area of the communication path provided in the fixed scroll member in Patent Document 1 is reduced. Undesirable suction pressure loss will occur. Therefore, from these two proposals, it is difficult to achieve both reduction of suction pressure loss, suppression of discharge pulsation, and noise reduction, and it is more difficult to achieve both of them while reducing the size and weight of the compressor. It is.

- the object of the present invention is to achieve the above-mentioned compatibility, desirably to achieve a reduction in size and weight of the apparatus, and to achieve these with a simple improved structure, and to stably obtain a good product quality. It is an object of the present invention to provide a scroll-type fluid device that can be used.

- a scroll type fluid device integrally forms a spiral wrap on an end plate of a fixed scroll member, and integrally forms a spiral wrap on an end plate of a movable scroll member.

- Both scroll members are arranged such that the angles of the spiral wraps are shifted from each other and the side walls of the spiral wraps are in partial contact, and the orbiting scroll member revolves on a circular track while preventing rotation.

- the volume of the fluid pocket by moving the fluid pocket, which is a sealed space formed between the two spiral wraps, from the outer end of the spiral wrap toward the center or from the center to the outer end.

- this corridor space is formed by effectively using the location on the front housing side on the outer peripheral side of the spiral wrap of the fixed scroll member, the outer peripheral side of the spiral wrap of the fixed scroll member

- various measures can be taken with respect to the location on the rear housing side (that is, the location on the rear housing side with respect to the corridor-like space and the location that differs in the apparatus axial direction that does not interfere with the location of the corridor-like space) It becomes possible. For example, as will be described later, it is possible to efficiently form the second discharge chamber without particularly increasing the size of the compressor at this portion. By forming such a second discharge chamber, discharge pulsation is reduced and noise is reduced. Is possible.

- the movable scroll member has the corridor-like space at a phase angle at which the distance between the spiral wrap outer peripheral end inner surface and the spiral wrap outer surface of the fixed scroll member facing the movable scroll member is maximum.

- the cross sectional area A1 of the port cross-sectional area A2 provided in the front housing is A2 / 2 ⁇ A1 ⁇ A2 It can be set as the structure which satisfy

- a pair of fluid pockets having a phase angle shifted by approximately 180 degrees are formed between the spiral scrolls of the fixed scroll member and the movable scroll member. However, it is assumed that the fluid flows from the suction port provided in the front housing through the gallery space.

- the corridor-like space is located on the opposite side of the fixed scroll member with the end plate of the movable scroll member interposed therebetween, or the suction chamber for the suction fluid or the discharge chamber for the expansion fluid It is possible to have a structure that is always open. In such a structure, the corridor-like space is always opened to the suction chamber for suction fluid or the discharge chamber for expansion fluid, so that it is possible to move the fluid without causing large pressure loss or pulsation between them. Stable operation can be realized.

- the front housing is provided with a port that directly faces the corridor-like space.

- the fluid sucked from the suction port always flows directly into the corridor-like space as it is, and is taken into the fluid pocket via the fluid. Therefore, a desired suction path is always stably formed, and stable operation is possible.

- the concave outer surface of the outer shell shell having a predetermined thickness can be formed with respect to the wall forming the wall surface facing the shaped space.

- a concave outer surface is formed on the outer surface of the outer shell of the center housing adjacent to the corridor-like space, so that the apparatus can be reduced in size and weight by the amount corresponding to the concave outer surface. It becomes possible.

- the meat stealer can take a form opening toward the rear housing. At that time, it can be formed as a device internal space that is not directly opened to the outside of the device, thereby allowing various functions to be performed.

- the meat stealing portion communicates with a first discharge chamber (a discharge chamber for fluid compressed by a spiral wrap) formed in the rear housing via a throttle portion. It can be set as the structure which forms. If such a second discharge chamber is formed following the first discharge chamber in the path of the discharge fluid, the second discharge chamber can have a buffer function against a fluid pulsation in the discharge path, and a silencer function, It is possible to obtain excellent discharge pulsation reduction and noise reduction effects.

- the meat stealing portion communicates with a first discharge chamber (a discharge chamber for fluid compressed by a spiral wrap) formed in the rear housing via a throttle portion. It can be set as the structure which forms. If such a second discharge chamber is formed following the first discharge chamber in the path of the discharge fluid, the second discharge chamber can have a buffer function against a fluid pulsation in the discharge path, and a silencer function, It is possible to obtain excellent discharge pulsation reduction and noise reduction effects.

- the structure of the throttle portion is not particularly limited.

- the throttle portion is formed by an inner contour of a gasket for sealing between the center housing and the rear housing and an opening contour of the second discharge chamber. Is possible. In this way, it is not necessary to add a special member for forming the throttle portion.

- a filter is provided between the oil storage chamber and the discharge chamber. By installing the filter, it is possible to prevent foreign matters from flowing in when the oil returns. Moreover, it is preferable that the oil storage chamber and the corridor-like space communicate with each other through an orifice. An appropriate oil return amount can be ensured by the presence of the orifice.

- a discharge chamber and a suction chamber are formed in the rear housing via a partition wall, and the suction chamber serves as the meat stealing portion.

- a structure that communicates with the corridor-like space via a section that is, a space similar to the above-described second discharge chamber is formed by the meat stealing portion, but this space portion is used as a part of the suction path.

- this configuration is effective when it is necessary to provide a suction port and a discharge port in the rear housing due to restrictions on the arrangement of the equipment. Even in such a case, before the fluid is taken into the fluid pocket in the corridor space It can be formed as an effective space for reducing the suction pressure loss.

- the configuration of the scroll type fluid device according to the present invention can be applied to both the scroll type compressor and the scroll type expander.

- the suction pressure loss is reduced, the discharge pulsation is reduced, the noise is reduced.

- the center housing can be further reduced in weight. Further, since the thick portion is eliminated and each portion can be configured to be relatively thin and have a relatively uniform thickness, it is possible to further reduce the weight of the center housing and thus the entire apparatus. In addition, when the center housing is formed by casting or the like, defects such as a cast hole can be made difficult to occur because the thickness can be made uniform, and the manufacturing quality is stabilized.

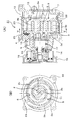

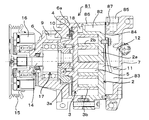

- the movable scroll member 3 is revolved on a circular orbit while being prevented from rotating via a rotation preventing mechanism 4, and a fluid pocket 5 (a pair of sealed pockets) formed between the spiral wraps 2b and 3b.

- the fluid pocket formed is moved from the outer end of the spiral wrap toward the center (in the case of an expander, the fluid pocket is moved from the center toward the outer end).

- the volume is changed in the direction in which the volume is reduced, and the fluid (for example, refrigerant gas) taken into the fluid pocket 5 from the outer end side of the spiral wrap is compressed.

- the housing of the compressor 1 includes a front housing 6, a rear housing 7, and a center housing 8 disposed therebetween.

- the suction fluid is introduced into a suction chamber 10 from a suction port 9 provided in the front housing 6, and a part thereof is taken into the fluid pocket 5 through a gallery-like space described later. And subjected to compression.

- the compressed fluid is discharged into a discharge chamber 12 formed in the rear housing 7 through a discharge hole 11 formed in the center portion of the end plate 2 a of the fixed scroll member 2, and from there through a discharge port 13. Discharged outside.

- the fixed scroll member 2 is formed integrally with the center housing 8 inside a center housing 8 disposed between the front housing 6 and the rear housing 7. Then, with the end plate 2a of the fixed scroll member 2 as a reference for the position in the height direction, the height of the end surface 8b of the outer shell 8a of the center housing 8 is higher than the height of the spiral wrap 2b of the fixed scroll member 2. Is set too low.

- a corridor-like space 18 extending in the direction is formed. In this embodiment, the corridor space 18 communicates with the suction chamber 10 located on the opposite side of the fixed scroll member 2 with the end plate 3a of the movable scroll member 3 interposed therebetween.

- the corridor space 18 is formed by utilizing a part of the portion occupied by the center housing 8 when viewed in the apparatus axial direction. Therefore, the corridor space 18 is utilized by using the remaining portion. It is possible to form the meat stealing portion 19 as shown in the figure adjacent to the.

- the meat stealing portion 19 can be formed without increasing the special device outer shape as compared with the structure in which the above-described conventional sub-housing is provided and the second discharge chamber is provided. Therefore, it is possible to reliably reduce the size and weight as compared with such a conventional structure. Since the volume of the discharge chamber 12 can be substantially increased by forming the meat stealing portion 19 in the illustrated example, it is possible to reduce the discharge pulsation and to reduce the noise through it.

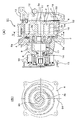

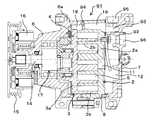

- FIG. 2 shows a scroll compressor as a scroll fluid device according to a second embodiment of the present invention.

- the bottomed meat stealing portion 23 formed in the center housing 22 opens toward the front housing 24 compared to the scroll compressor 1 shown in FIG. ing.

- a corridor space 25 is formed so as to communicate with the opening side of the bottomed meat stealing portion 23.

- it is set as the structure where the cross-sectional area of the meat stealing part 23 extended with an appropriate length in the apparatus circumferential direction is changing in the apparatus circumferential direction.

- the width of the meat stealing part 23 in FIG. The wide part is formed deeper than the narrow part.

- the suction fluid can be sucked more smoothly through the corridor-like space 25 in which the cross-sectional area is appropriately changed as compared with the first embodiment. This makes it possible to further reduce the suction pressure loss.

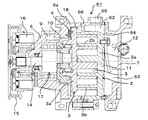

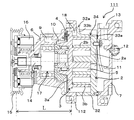

- FIG. 3 shows a scroll compressor as a scroll type fluid device according to a third embodiment of the present invention.

- the center housing according to the present invention is lighter than the above-described meat stealer.

- the relationship between the corridor space and the cross-sectional area of the suction port is shown.

- the fluid pocket 5 of the spiral wrap 2 b of the fixed scroll member 2 is provided on the outer surface side of the outer shell 32 a of the center housing 32.

- FIG. 4 shows a scroll compressor as a scroll fluid device according to the fourth embodiment of the present invention.

- the front housing 42 is provided with a suction port 44 that directly faces the corridor space 43.

- 4B in FIG. 4B indicates the inner periphery of the front housing 42.

- the fluid sucked from the suction port 44 can always flow directly into the corridor space 43 and is taken into the fluid pocket 5 from there, so that the desired suction path is always stable.

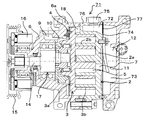

- the discharge port 85 is provided not on the center housing 86 side but on the rear housing 7 side, and the fluid from the second discharge chamber 82 is discharged through the communication hole 87. It is discharged from the port 85 to the outside.

- the position at which the discharge port is arranged can be appropriately selected according to the arrangement environment of the compressor, the relationship with other peripheral devices, and the like. Since other configurations are the same as those in the first embodiment, the same reference numerals as those in FIG. 1 are attached to FIGS.

- FIG. 9 shows a scroll compressor as a scroll fluid device according to the ninth embodiment of the present invention.

- the meat stealing portion 19 opened toward the rear housing 7 side in the scroll compressor 41 shown in FIG. 4 is replaced with the rear housing 7 as shown in FIG.

- the suction chamber 93 is formed in the rear housing 7 via a partition wall 92, and the suction chamber 93 communicates with the corridor space 18 and the communication path 94 via the meat stealing portion 19. It is the structure connected through.

- FIG. 11 shows a scroll compressor as a scroll fluid device according to an eleventh embodiment of the present invention.

- the scroll compressor 111 shown in FIG. 11 has the same configuration as the scroll compressor 31 shown in FIG. 3, but in the eleventh embodiment, the compressor 111 is mounted at a predetermined location.

- the mounting boss 112 for this purpose is arranged farther from the position of the pulley 15 in the illustrated example than the clutch portion. That is, the distance L between the pulley 15 and the mount boss 112 is set larger. Conversely, it is possible to make L smaller. In this way, it is possible to design freely in consideration of the mounting convenience of the compressor 111. Since other configurations are the same as those in the first embodiment, the same reference numerals as those in FIG.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Rotary Pumps (AREA)

- Applications Or Details Of Rotary Compressors (AREA)

Abstract

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IN2607DEN2012 IN2012DN02607A (fr) | 2009-10-15 | 2010-10-12 | |

| US13/498,004 US20120263615A1 (en) | 2009-10-15 | 2010-10-12 | Scroll Fluidic Device |

| CN201080044204.5A CN102575672B (zh) | 2009-10-15 | 2010-10-12 | 涡旋式流体装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2009-238234 | 2009-10-15 | ||

| JP2009238234A JP5421725B2 (ja) | 2009-10-15 | 2009-10-15 | スクロール型流体装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2011045921A1 true WO2011045921A1 (fr) | 2011-04-21 |

Family

ID=43875977

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2010/006064 WO2011045921A1 (fr) | 2009-10-15 | 2010-10-12 | Dispositif fluidique à spirale |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20120263615A1 (fr) |

| JP (1) | JP5421725B2 (fr) |

| CN (1) | CN102575672B (fr) |

| IN (1) | IN2012DN02607A (fr) |

| WO (1) | WO2011045921A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107429693A (zh) * | 2015-03-20 | 2017-12-01 | 三菱重工汽车空调系统株式会社 | 涡旋压缩机 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5782296B2 (ja) * | 2011-05-13 | 2015-09-24 | サンデンホールディングス株式会社 | スクロール型圧縮機 |

| JP2016023612A (ja) * | 2014-07-23 | 2016-02-08 | サンデンホールディングス株式会社 | スクロール型流体機械 |

| KR102238358B1 (ko) * | 2017-03-15 | 2021-04-12 | 엘지전자 주식회사 | 로터리 압축기 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09158859A (ja) * | 1995-12-06 | 1997-06-17 | Nippon Soken Inc | スクロール型圧縮機 |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4477238A (en) * | 1983-02-23 | 1984-10-16 | Sanden Corporation | Scroll type compressor with wrap portions of different axial heights |

| JPS60101295A (ja) * | 1983-11-08 | 1985-06-05 | Sanden Corp | 圧縮容量可変型のスクロ−ル型圧縮機 |

| JP3206221B2 (ja) * | 1993-06-15 | 2001-09-10 | 株式会社豊田自動織機製作所 | スクロール型圧縮機 |

| JP3144611B2 (ja) * | 1993-10-15 | 2001-03-12 | 株式会社豊田自動織機製作所 | スクロール型圧縮機 |

| JP3882343B2 (ja) * | 1998-06-12 | 2007-02-14 | 株式会社デンソー | スクロール型圧縮機 |

| JP2000087882A (ja) * | 1998-09-11 | 2000-03-28 | Sanden Corp | スクロール型圧縮機 |

| JP2001140775A (ja) * | 1999-11-17 | 2001-05-22 | Sanden Corp | スクロール型圧縮機 |

| JP2003013872A (ja) * | 2001-06-28 | 2003-01-15 | Toyota Industries Corp | スクロール型圧縮機およびスクロール型圧縮機の冷媒圧縮方法 |

| JP3918814B2 (ja) * | 2004-01-15 | 2007-05-23 | ダイキン工業株式会社 | 流体機械 |

| JP5067022B2 (ja) * | 2007-06-04 | 2012-11-07 | 株式会社豊田自動織機 | 電動圧縮機 |

-

2009

- 2009-10-15 JP JP2009238234A patent/JP5421725B2/ja active Active

-

2010

- 2010-10-12 CN CN201080044204.5A patent/CN102575672B/zh active Active

- 2010-10-12 WO PCT/JP2010/006064 patent/WO2011045921A1/fr active Application Filing

- 2010-10-12 US US13/498,004 patent/US20120263615A1/en not_active Abandoned

- 2010-10-12 IN IN2607DEN2012 patent/IN2012DN02607A/en unknown

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH09158859A (ja) * | 1995-12-06 | 1997-06-17 | Nippon Soken Inc | スクロール型圧縮機 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107429693A (zh) * | 2015-03-20 | 2017-12-01 | 三菱重工汽车空调系统株式会社 | 涡旋压缩机 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102575672A (zh) | 2012-07-11 |

| IN2012DN02607A (fr) | 2015-09-04 |

| JP2011085066A (ja) | 2011-04-28 |

| JP5421725B2 (ja) | 2014-02-19 |

| US20120263615A1 (en) | 2012-10-18 |

| CN102575672B (zh) | 2015-09-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7802972B2 (en) | Rotary type compressor | |

| JP6187123B2 (ja) | スクロール型圧縮機 | |

| JP2007170253A (ja) | スクロール圧縮機 | |

| JP2009030469A (ja) | スクロール圧縮機 | |

| JP5421725B2 (ja) | スクロール型流体装置 | |

| JP4992948B2 (ja) | スクロール圧縮機 | |

| KR101133300B1 (ko) | 로터리 압축기 | |

| JP2005264827A (ja) | スクロール圧縮機 | |

| JP4822943B2 (ja) | 流体機械 | |

| JP6633305B2 (ja) | スクロール圧縮機 | |

| JP3408808B2 (ja) | スクロール型圧縮機 | |

| JP4604968B2 (ja) | スクロール圧縮機 | |

| JP4844642B2 (ja) | スクロール圧縮機 | |

| JP5355361B2 (ja) | 密閉型回転圧縮機 | |

| JP4408310B2 (ja) | スクロール型圧縮機 | |

| JP4484912B2 (ja) | スクロール圧縮機 | |

| JP3422744B2 (ja) | スクロール型圧縮機 | |

| JP2008274877A (ja) | 密閉型圧縮機 | |

| JPH09158865A (ja) | スクロール圧縮機 | |

| JP6098265B2 (ja) | 圧縮機 | |

| JP7483638B2 (ja) | スクロール圧縮機 | |

| JP2019056336A (ja) | スクロール型流体機械 | |

| JP2005188431A (ja) | 圧縮機 | |

| JP4301120B2 (ja) | スクロール圧縮機 | |

| JP5916419B2 (ja) | スクロール圧縮機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201080044204.5 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 10823189 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 13498004 Country of ref document: US |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2607/DELNP/2012 Country of ref document: IN |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 10823189 Country of ref document: EP Kind code of ref document: A1 |