JP6898436B2 - 異なる流動性組成物を容器に同時に充填するためのシステム及び方法 - Google Patents

異なる流動性組成物を容器に同時に充填するためのシステム及び方法 Download PDFInfo

- Publication number

- JP6898436B2 JP6898436B2 JP2019513793A JP2019513793A JP6898436B2 JP 6898436 B2 JP6898436 B2 JP 6898436B2 JP 2019513793 A JP2019513793 A JP 2019513793A JP 2019513793 A JP2019513793 A JP 2019513793A JP 6898436 B2 JP6898436 B2 JP 6898436B2

- Authority

- JP

- Japan

- Prior art keywords

- container

- carrier

- route

- unit operating

- station

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67242—Apparatus for monitoring, sorting or marking

- H01L21/67276—Production flow monitoring, e.g. for increasing throughput

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B65/00—Details peculiar to packaging machines and not otherwise provided for; Arrangements of such details

- B65B65/003—Packaging lines, e.g. general layout

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C49/00—Blow-moulding, i.e. blowing a preform or parison to a desired shape within a mould; Apparatus therefor

- B29C49/42—Component parts, details or accessories; Auxiliary operations

- B29C49/4205—Handling means, e.g. transfer, loading or discharging means

- B29C49/42093—Transporting apparatus, e.g. slides, wheels or conveyors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B59/00—Arrangements to enable machines to handle articles of different sizes, to produce packages of different sizes, to vary the contents of packages, to handle different types of packaging material, or to give access for cleaning or maintenance purposes

- B65B59/003—Arrangements to enable adjustments related to the packaging material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B65/00—Details peculiar to packaging machines and not otherwise provided for; Arrangements of such details

- B65B65/003—Packaging lines, e.g. general layout

- B65B65/006—Multiple parallel packaging lines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G54/00—Non-mechanical conveyors not otherwise provided for

- B65G54/02—Non-mechanical conveyors not otherwise provided for electrostatic, electric, or magnetic

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67B—APPLYING CLOSURE MEMBERS TO BOTTLES JARS, OR SIMILAR CONTAINERS; OPENING CLOSED CONTAINERS

- B67B1/00—Closing bottles, jars or similar containers by applying stoppers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67B—APPLYING CLOSURE MEMBERS TO BOTTLES JARS, OR SIMILAR CONTAINERS; OPENING CLOSED CONTAINERS

- B67B3/00—Closing bottles, jars or similar containers by applying caps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C3/00—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids

- B67C3/02—Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus

- B67C3/22—Details

- B67C3/24—Devices for supporting or handling bottles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C7/00—Concurrent cleaning, filling, and closing of bottles; Processes or devices for at least two of these operations

- B67C7/0006—Conveying; Synchronising

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C7/00—Concurrent cleaning, filling, and closing of bottles; Processes or devices for at least two of these operations

- B67C7/0006—Conveying; Synchronising

- B67C7/002—General lay-out of bottle-handling machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67C—CLEANING, FILLING WITH LIQUIDS OR SEMILIQUIDS, OR EMPTYING, OF BOTTLES, JARS, CANS, CASKS, BARRELS, OR SIMILAR CONTAINERS, NOT OTHERWISE PROVIDED FOR; FUNNELS

- B67C7/00—Concurrent cleaning, filling, and closing of bottles; Processes or devices for at least two of these operations

- B67C7/0006—Conveying; Synchronising

- B67C7/004—Conveying; Synchronising the containers travelling along a circular path

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/418—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS] or computer integrated manufacturing [CIM]

- G05B19/41815—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS] or computer integrated manufacturing [CIM] characterised by the cooperation between machine tools, manipulators and conveyor or other workpiece supply system, workcell

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B2210/00—Specific aspects of the packaging machine

- B65B2210/02—Plurality of alternative input or output lines or plurality of alternative packaging units on the same packaging line for improving machine flexibility

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B2210/00—Specific aspects of the packaging machine

- B65B2210/04—Customised on demand packaging by determining a specific characteristic, e.g. shape or height, of articles or material to be packaged and selecting, creating or adapting a packaging accordingly, e.g. making a carton starting from web material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B59/00—Arrangements to enable machines to handle articles of different sizes, to produce packages of different sizes, to vary the contents of packages, to handle different types of packaging material, or to give access for cleaning or maintenance purposes

- B65B59/001—Arrangements to enable adjustments related to the product to be packaged

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G2201/00—Indexing codes relating to handling devices, e.g. conveyors, characterised by the type of product or load being conveyed or handled

- B65G2201/02—Articles

- B65G2201/0235—Containers

- B65G2201/0261—Puck as article support

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/32—Operator till task planning

- G05B2219/32391—Machining center, pallet stocker, setup station, conveyor, control unit

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B2219/00—Program-control systems

- G05B2219/30—Nc systems

- G05B2219/40—Robotics, robotics mapping to robotics vision

- G05B2219/40554—Object recognition to track object on conveyor

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- General Physics & Mathematics (AREA)

- Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Quality & Reliability (AREA)

- General Engineering & Computer Science (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

- Basic Packing Technique (AREA)

- Electroluminescent Light Sources (AREA)

Description

本明細書で使用する場合、用語「キャッピング」は、任意の適切な種類のクロージャを容器に適用することを指し、キャップを容器に適用することが挙げられるが、これらに限定されない。

Claims (9)

- 異なる流動性材料を異なる容器に同時に分注するためのものであることを特徴とするシステムであって、当該システムは、

流動性材料を保持するための、少なくとも1つの第1の容器、及び少なくとも1つの第2の容器と、

送路システムに沿って配置されたユニット操作ステーションを含む、該送路システムと、

流動性材料を分注するための少なくとも1つの充填ユニット操作ステーションを含む、前記ユニット操作ステーションと、

前記送路システムに沿って推進可能な複数の搬送体であって、

第1の容器及び第2の容器が、同一又は異なる搬送体に配置され、

各搬送体は、前記第1の容器及び前記第2の容器が前記少なくとも1つの充填ユニット操作ステーションに配送されるように、前記送路システムに沿って、独立してルート設定可能である、複数の搬送体と、

を含み、

前記第1の容器及び前記第2の容器は、前記少なくとも1つの充填ユニット操作ステーションにより分配される1つ以上の流動性材料を受け入れ、前記少なくとも1つの充填ユニット操作ステーションは、流動性材料を分配するように構成されることにより、前記第1の容器中の第1の流動性組成物及び前記第2の容器中の第2の流動性組成物は、以下の、

前記第1の容器中の前記第1の流動性組成物と、前記第2の容器中の前記第2の流動性組成物における、少なくとも1つの成分の有無又は種類が異なること、及び/又は、

前記第1の容器中の前記第1の流動性組成物および前記第2の容器中の前記第2の流動性組成物は、少なくとも1つの共通成分を有し、および、以下の関係、

(a)前記2種類の流動性組成物において、存在する量が多い方の前記成分の重量パーセントを、前記2種類の流動性組成物において、存在する量が少ない方の前記同一の成分の重量パーセントで割ることによって決定される、前記2種類の流動性組成物における前記同一の成分の重量パーセントの差が、約1.1以上であること、および、

(b)前記第1の容器及び前記第2の容器の両方に共通する前記成分のうちの少なくとも1つの重量パーセントが、前記2種類の流動性組成物において少なくとも2%の量であり、前記2種類の流動性組成物における前記同一の成分の重量パーセントの差が、2%以上であること、

のうちの少なくとも一方が存在すること、

のうちの1つ以上において、互いに異なり、

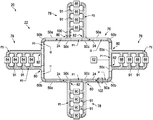

前記送路システムは、

閉ループを形成した1次経路を画定する1次運送部と、

前記1次運送部から延び、入口位置及び出口位置にて前記1次経路と交差した2次経路を画定する2次運送部と、を含み、前記少なくとも1つの充填ユニット操作ステーションは、前記2次運送部に沿って配置されており、

特定の2次運送部に位置する充填ユニット操作ステーションはそれぞれ、並列に配列された異なるユニット運送区間に沿って配置されていることを特徴とするシステム。 - 前記第1の容器は、ある容積、外観、及び形状を有し、前記第2の容器は、前記第1の容器の容積、外観、及び形状のうちの1つ以上と異なる、容積、外観、及び形状のうちの1つ以上をそれぞれ有することを特徴とする請求項1に記載のシステム。

- 前記送路システムは、前記搬送体が磁石を含む、リニア同期モータシステムであり、前記搬送体は、電磁力を使用して前記送路システムに沿って推進可能であることを特徴とする請求項1に記載のシステム。

- 1つの充填ユニット操作ステーションは、前記第1の容器及び前記第2の容器に、異なる流動性材料を分配するように構成されたことを特徴とする請求項1に記載のシステム。

- 2つ以上の充填ユニット操作ステーションを含み、前記2つ以上の充填ユニット操作ステーションのうちのいずれかは、他の充填ユニット操作ステーションにより分配される流動性材料とは異なる流動性材料を分配するように構成されたことを特徴とする請求項1に記載のシステム。

- 前記第1の容器及び前記第2の容器は、同一搬送体に配置されていることを特徴とする請求項1に記載のシステム。

- 前記第1の容器及び前記第2の容器は、異なる搬送体に配置されていることを特徴とする請求項1に記載のシステム。

- 流動性材料を分配するための前記少なくとも1つのユニット操作ステーションは、流動性材料を分配するための複数のユニット操作ステーションを含み、ある充填ユニット操作ステーションにおいて第1の流動性材料が第1の容器へと、別の充填ユニット操作ステーションにおいて第2の流動性材料が第2の容器へと、独立して分配されるように、少なくとも2つの異なる搬送体について、異なるユニット操作ステーションへと同時にルート設定可能であり、前記第1の流動性材料と前記第2の流動性材料とは異なることを特徴とする請求項1に記載のシステム。

- 異なる流動性材料を異なる容器に同時に分配する方法であって、

(a)請求項1に記載のシステムを提供するステップと、

(b)搬送体上に第1の空の容器を載せて、第1の容器を載せた搬送体を形成するステップと、

(c)搬送体上に第2の空の容器を載せて、第2の容器を載せた搬送体を形成するステップと、

(d)前記第1の容器を載せた搬送体を、第1の流動性材料を容器に分配するように構成された充填ユニット操作ステーションに送るステップと、

(e)前記第2の容器を載せた搬送体を、第2の流動性材料を容器に分配するように構成された充填ユニット操作ステーションに送るステップであって、前記第1の流動性材料と前記第2の流動性材料とは異なる、該ステップと、

(f)前記第1の流動性材料の前記第1の容器への分配と、前記第2の流動性材料の前記第2の容器への分配を、同時に行うステップと、

を含むことを特徴とする方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201662385299P | 2016-09-09 | 2016-09-09 | |

| US62/385,299 | 2016-09-09 | ||

| PCT/US2017/050631 WO2018049125A1 (en) | 2016-09-09 | 2017-09-08 | System and method for simultaneously filling containers with different fluent compositions |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019531981A JP2019531981A (ja) | 2019-11-07 |

| JP6898436B2 true JP6898436B2 (ja) | 2021-07-07 |

Family

ID=59901613

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2019513793A Active JP6898436B2 (ja) | 2016-09-09 | 2017-09-08 | 異なる流動性組成物を容器に同時に充填するためのシステム及び方法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US10643875B2 (ja) |

| EP (1) | EP3509954B1 (ja) |

| JP (1) | JP6898436B2 (ja) |

| CN (1) | CN109661352B (ja) |

| CA (1) | CA3035965C (ja) |

| MX (1) | MX2019002782A (ja) |

| PH (1) | PH12019500508A1 (ja) |

| WO (1) | WO2018049125A1 (ja) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022114419A1 (de) | 2022-06-08 | 2023-12-14 | Krones Aktiengesellschaft | Vorrichtung zum Fördern von Behältern und deren Verwendung |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4194378B1 (en) * | 2016-09-09 | 2024-11-20 | The Procter & Gamble Company | System and method for independently routing vehicles and delivering containers and closures to unit operation stations |

| JP6898436B2 (ja) | 2016-09-09 | 2021-07-07 | ザ プロクター アンド ギャンブル カンパニーThe Procter & Gamble Company | 異なる流動性組成物を容器に同時に充填するためのシステム及び方法 |

| WO2018049119A1 (en) | 2016-09-09 | 2018-03-15 | The Procter & Gamble Company | Methods for simultaneously producing different products on a single production line |

| US10996232B2 (en) | 2016-09-09 | 2021-05-04 | The Procter & Gamble Company | System and method for independently routing container-loaded vehicles to create different finished products |

| US10558201B2 (en) | 2016-09-09 | 2020-02-11 | The Procter & Gamble Company | System and method for producing products based upon demand |

| EP3509795B1 (en) * | 2016-09-09 | 2020-07-29 | The Procter and Gamble Company | Vacuum holder with extensible skirt gasket |

| CA3035540C (en) | 2016-09-09 | 2021-04-06 | The Procter & Gamble Company | Track system for creating finished products |

| MX2019002780A (es) | 2016-09-09 | 2019-09-04 | Procter & Gamble | Sistema y método para llenar simultáneamente recipientes de formas y/o tamaños diferentes. |

| EP3458390A4 (en) | 2017-03-06 | 2020-07-29 | ATS Automation Tooling Systems Inc. | LINEAR MOTOR CONVEYOR SYSTEM WITH UNDROLLER AND PROCESS FOR DESIGNING AND CONFIGURING THE SAME |

| CN109422079B (zh) * | 2017-08-28 | 2021-05-07 | 台达电子工业股份有限公司 | 输送系统 |

| DE102017010970A1 (de) * | 2017-11-27 | 2019-05-29 | Khs Corpoplast Gmbh | Temperiervorrichtung für die Temperaturkonditionierung von Vorformlingen und Verfahren zum Betreiben einer solchen Temperiervorrichtung |

| EP3774552B1 (en) * | 2018-04-10 | 2023-03-22 | The Procter & Gamble Company | Method and apparatus for flexibly assembling packages of absorbent articles |

| US11144042B2 (en) | 2018-07-09 | 2021-10-12 | Rockwell Automation Technologies, Inc. | Industrial automation information contextualization method and system |

| US11403541B2 (en) | 2019-02-14 | 2022-08-02 | Rockwell Automation Technologies, Inc. | AI extensions and intelligent model validation for an industrial digital twin |

| US11086298B2 (en) | 2019-04-15 | 2021-08-10 | Rockwell Automation Technologies, Inc. | Smart gateway platform for industrial internet of things |

| DE112019007227T5 (de) * | 2019-04-16 | 2021-12-30 | Yamaha Hatsudoki Kabushiki Kaisha | Linearfördersystem, Steuerverfahren für ein Linearfördersystem, Steuerprogramm für ein Linearfördersystem und Aufzeichnungsmedium |

| IT201900006338A1 (it) * | 2019-04-24 | 2020-10-24 | Universal Pack S R L | Metodo per confezionare prodotti e relativo apparato di confezionamento |

| CN114502471A (zh) | 2019-07-30 | 2022-05-13 | 安海斯-布希英博有限公司 | 物品拾取和处理设备 |

| US12110141B2 (en) | 2019-07-30 | 2024-10-08 | Anheuser-Busch Inbev S.A. | Packaging apparatus |

| US20220281697A1 (en) * | 2019-07-30 | 2022-09-08 | Anheuser-Busch Inbev S.A. | A beverage plan and conveying sysem for beverage containers |

| US12269629B2 (en) | 2019-07-30 | 2025-04-08 | Anheuser-Busch Inbev S.A. | Packaging apparatus for secondary packages |

| ES3027759T3 (en) | 2019-07-30 | 2025-06-17 | Anheuser Busch Inbev Sa | Denesting apparatus |

| EP4003719A1 (en) | 2019-07-30 | 2022-06-01 | Anheuser-Busch InBev S.A. | Shaping tool for secondary packages |

| US11435726B2 (en) | 2019-09-30 | 2022-09-06 | Rockwell Automation Technologies, Inc. | Contextualization of industrial data at the device level |

| US11841699B2 (en) | 2019-09-30 | 2023-12-12 | Rockwell Automation Technologies, Inc. | Artificial intelligence channel for industrial automation |

| EP4072947A1 (en) * | 2019-12-09 | 2022-10-19 | Sidel Participations | A machine for moving and handling containers adapted to contain a pourable product |

| WO2021115559A1 (en) * | 2019-12-09 | 2021-06-17 | Sidel Participations | Method and machine for filling containers with a pourable product |

| US11249462B2 (en) | 2020-01-06 | 2022-02-15 | Rockwell Automation Technologies, Inc. | Industrial data services platform |

| US11726459B2 (en) | 2020-06-18 | 2023-08-15 | Rockwell Automation Technologies, Inc. | Industrial automation control program generation from computer-aided design |

| US20220027529A1 (en) * | 2020-07-21 | 2022-01-27 | Rockwell Automation Technologies, Inc. | Controls system based digital twin for supervisory control of independent cart technology tracks and lines |

| DE102020120295A1 (de) * | 2020-07-31 | 2022-02-03 | Krones Aktiengesellschaft | Vorrichtung zum Ausstatten von Behältern |

| JP2025038411A (ja) * | 2023-09-07 | 2025-03-19 | 花王株式会社 | 攪拌方法及びこれを用いた製品の製造方法 |

Family Cites Families (235)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3403634A (en) | 1964-07-22 | 1968-10-01 | Docutel Inc | Automatically controlled railway passenger vehicle system |

| FR1581104A (ja) | 1968-07-23 | 1969-09-12 | ||

| US3687082A (en) | 1970-09-10 | 1972-08-29 | Avco Corp | Automatic electric power supply and speed control system for automated driverless vehicles |

| JPS5232137B2 (ja) * | 1971-12-29 | 1977-08-19 | ||

| US3796163A (en) | 1972-07-12 | 1974-03-12 | Kearney & Trecker Corp | Manufacturing system |

| US3878821A (en) | 1973-11-15 | 1975-04-22 | Norman C White | Combustion engine with double-ended pistons and transfer passages |

| JPS5853099U (ja) | 1981-10-06 | 1983-04-11 | 麒麟麦酒株式会社 | 物品の回転保持装置 |

| GB2185720B (en) | 1986-01-27 | 1989-11-01 | Daifuku Kk | Conveyor system utilizing linear motor |

| US4805761A (en) | 1987-07-14 | 1989-02-21 | Totsch John W | Magnetic conveyor system for transporting wafers |

| JP2511166B2 (ja) | 1990-03-20 | 1996-06-26 | 富士通株式会社 | 搬送システム |

| US5023495A (en) | 1990-04-17 | 1991-06-11 | Hitachi Metals & Shicoh Engine | Moving-magnet type linear d.c. brushless motor having plural moving elements |

| US5208762A (en) | 1990-12-06 | 1993-05-04 | Baxter International Inc. | Automated prescription vial filling system |

| US5233534A (en) | 1991-05-24 | 1993-08-03 | Gerber Garment Technology, Inc. | Production system for garments or other products |

| US5251741A (en) | 1991-06-28 | 1993-10-12 | Kabushiki Kaisha Toshiba | Carrying apparatus having carrier levitated by magnetic force |

| JPH0551087A (ja) | 1991-08-19 | 1993-03-02 | Mitsubishi Heavy Ind Ltd | 液体充填包装ラインの容器搬送方法及び装置 |

| US5713180A (en) | 1991-09-24 | 1998-02-03 | H. G. Kalish, Inc. | System for transporting containers for use with an apparatus to process containers such as a tablet filling monoblock |

| DE4133114C2 (de) * | 1991-10-05 | 1996-11-21 | Michael Rupp | Fördersystem für Stückgut |

| JP2652501B2 (ja) | 1993-04-08 | 1997-09-10 | 花王株式会社 | 充填方法及び装置 |

| JP3467598B2 (ja) * | 1993-04-20 | 2003-11-17 | 株式会社紀文食品 | 容器充填封止装置 |

| GB9322641D0 (en) * | 1993-11-03 | 1993-12-22 | Diversey Equipment Technologie | Dispenser |

| US5555504A (en) | 1994-06-10 | 1996-09-10 | Johnson & Johnson Vision Products, Inc. | Production line tracking and quality control system |

| DE19546870A1 (de) | 1994-12-16 | 1996-06-20 | Univ Dresden Tech | Linearantrieb für verpacktes Stückgut |

| DE59503520D1 (de) | 1995-02-07 | 1998-10-15 | Hermann Kronseder | Transportstern für Gefässe |

| DE19505997A1 (de) | 1995-02-21 | 1996-08-22 | 4 P Nicolaus Kempten Gmbh | Eingruppierung |

| US5826633A (en) | 1996-04-26 | 1998-10-27 | Inhale Therapeutic Systems | Powder filling systems, apparatus and methods |

| US5771657A (en) | 1996-05-07 | 1998-06-30 | Merck Medco Managed Care, Inc. | Automatic prescription filling, sorting and packaging system |

| DE19629716C2 (de) | 1996-07-25 | 2001-07-05 | Emo Elektromotorenwerk Kamenz | Vorrichtung zum Einzug einer Papierbahn in einer Druckmaschine |

| US5797330A (en) | 1996-07-31 | 1998-08-25 | Li; Zhengzhong | Mass transit system |

| EP1009359A1 (en) | 1996-09-06 | 2000-06-21 | Merck & Co., Inc. | Customer specific packaging line |

| US5803797A (en) | 1996-11-26 | 1998-09-08 | Micron Technology, Inc. | Method and apparatus to hold intergrated circuit chips onto a chuck and to simultaneously remove multiple intergrated circuit chips from a cutting chuck |

| US5869139A (en) | 1997-02-28 | 1999-02-09 | International Business Machines Corporation | Apparatus and method for plating pin grid array packaging modules |

| ATE352452T1 (de) | 1997-05-02 | 2007-02-15 | Automation Tooling Syst | Modulares fördersystem mit mehreren beweglichen elementen unter unabhängiger steuerung |

| JP3436070B2 (ja) | 1997-05-15 | 2003-08-11 | 株式会社ダイフク | 搬送設備 |

| US6004025A (en) | 1997-05-16 | 1999-12-21 | Life Technologies, Inc. | Automated liquid manufacturing system |

| WO1998054599A2 (en) | 1997-05-28 | 1998-12-03 | Peter Haagensen | Primal tracking |

| US6011508A (en) | 1997-10-31 | 2000-01-04 | Magnemotion, Inc. | Accurate position-sensing and communications for guideway operated vehicles |

| JP3742207B2 (ja) * | 1997-12-11 | 2006-02-01 | 菊水化学工業株式会社 | 缶入り塗料の製造方法 |

| US6101952A (en) | 1997-12-24 | 2000-08-15 | Magnemotion, Inc. | Vehicle guidance and switching via magnetic forces |

| US6240335B1 (en) | 1998-12-14 | 2001-05-29 | Palo Alto Technologies, Inc. | Distributed control system architecture and method for a material transport system |

| DE19859955C2 (de) | 1998-12-28 | 2002-06-13 | Alusuisse Tech & Man Ag | Palette für eine Fördervorrichtung insbesondere in einer Anlage zum Bearbeiten von Behältern |

| EP1038782A1 (en) | 1999-03-22 | 2000-09-27 | The Procter & Gamble Company | In line production of solid objects |

| JP4671374B2 (ja) | 1999-04-06 | 2011-04-13 | 財団法人鉄道総合技術研究所 | 物体搬送装置 |

| TNSN00088A1 (fr) | 1999-04-26 | 2002-05-30 | Int Paper Co | Systeme et methode a mouvement variable |

| DE29908095U1 (de) | 1999-05-06 | 2000-09-14 | Cooper Power Tools GmbH & Co., 73463 Westhausen | Transportsystem |

| AU6341200A (en) | 1999-07-02 | 2001-01-22 | Magnemotion, Inc. | System for inductive transfer of power, communication and position sensing to a guideway-operated vehicle |

| US20020007867A1 (en) * | 1999-07-07 | 2002-01-24 | Kikusui Chemical Industries Co., Ltd. | Method for manufacturing/handling fluid component packaged goods, manufacture/handling instructing data code for use in this method and fluid component packaged goods affixed by this manufacture/handling instructing data code |

| JP2001044854A (ja) | 1999-07-29 | 2001-02-16 | Fujitsu Ltd | 符号化支援装置、復号化支援装置、無線送信機および無線受信機 |

| US6354781B1 (en) | 1999-11-01 | 2002-03-12 | Chartered Semiconductor Manufacturing Company | Semiconductor manufacturing system |

| WO2001038124A1 (en) | 1999-11-23 | 2001-05-31 | Magnemotion, Inc. | Modular linear motor tracks and methods of fabricating same |

| DE50103365D1 (de) | 2000-02-09 | 2004-09-30 | Sig Pack Systems Ag Beringen | Vorrichtung zum Transportieren von Produkten zwischen mindestens zwei Stationen |

| US6781524B1 (en) | 2000-03-17 | 2004-08-24 | Magnemotion, Inc. | Passive position-sensing and communications for vehicles on a pathway |

| US7204192B2 (en) | 2001-07-02 | 2007-04-17 | Magna Force, Inc. | Apparatus, systems and methods for levitating and moving objects |

| US7011728B2 (en) | 2001-07-19 | 2006-03-14 | Berry Plastics Corporation | Container-labeling and-printing synchronization apparatus and process |

| CN1310460C (zh) | 2001-08-01 | 2007-04-11 | 西门子公司 | 单载波系统和多载波系统之间数据通信的方法 |

| US6845298B2 (en) | 2001-08-31 | 2005-01-18 | Force Flow | Diluting system and method |

| US6983701B2 (en) | 2001-10-01 | 2006-01-10 | Magnemotion, Inc. | Suspending, guiding and propelling vehicles using magnetic forces |

| WO2003029651A2 (en) | 2001-10-01 | 2003-04-10 | Magnemotion, Inc. | Synchronous machine design and manufacturing |

| US6571934B1 (en) | 2001-11-14 | 2003-06-03 | Dade Behring Inc. | Bi-directional magnetic sample rack conveying system |

| US7134258B2 (en) | 2001-12-05 | 2006-11-14 | R.A. Jones & Co. Inc. | Packaging apparatus and methods |

| JP2003233422A (ja) * | 2002-02-06 | 2003-08-22 | Mitsubishi Electric Corp | 搬送システムおよびその制御方法 |

| AU2003248622A1 (en) | 2002-06-05 | 2003-12-22 | Jacobs Automation Llc | Controlled motion system |

| US7988398B2 (en) | 2002-07-22 | 2011-08-02 | Brooks Automation, Inc. | Linear substrate transport apparatus |

| US6892512B2 (en) | 2002-08-07 | 2005-05-17 | Medco Health Solutions, Inc. | Automated prescription filling system/method with automated labeling and packaging system/method automated order consolidation system/method |

| EP1547225A4 (en) | 2002-10-01 | 2007-04-11 | Magnemotion Inc | SUSPENSION, GUIDANCE AND PROPULSION OF VEHICLES USING MAGNETIC FORCES |

| JP2004182274A (ja) * | 2002-12-02 | 2004-07-02 | Seiko Corp | 容器処理システムにおける容器ホルダー |

| US7264426B2 (en) | 2003-06-25 | 2007-09-04 | The Boeing Company | Apparatus and methods for servo-controlled manufacturing operations |

| US8271139B2 (en) | 2003-10-17 | 2012-09-18 | Asahi Kasei Bioprocess, Inc. | Multi-stage accurate blending system and method |

| US20050095087A1 (en) | 2003-10-30 | 2005-05-05 | Sullivan Robert P. | Automated material handling system |

| US7248938B2 (en) | 2003-12-31 | 2007-07-24 | Vigilistics, Inc. | Method and system for monitoring batch product manufacturing |

| US8738804B2 (en) | 2004-01-08 | 2014-05-27 | International Business Machines Corporation | Supporting transactions in a data network using router information |

| JP5203700B2 (ja) | 2004-05-07 | 2013-06-05 | マグネモーション インコーポレイテッド | 輸送手段及び輸送方法 |

| US7478749B2 (en) | 2004-05-17 | 2009-01-20 | Thermal Solutions, Inc. | Food preparation system |

| US7654203B2 (en) | 2004-06-22 | 2010-02-02 | The Texas A&M University System | Freight transportation system and method |

| DE102004048515A1 (de) | 2004-10-06 | 2006-04-13 | Krones Ag | Sortiervorrichtung und Fördervorrichtung für Stückgut sowie Verfahren zum Sortieren oder Fördern von Stückgut |

| US8483869B2 (en) | 2005-07-19 | 2013-07-09 | Amazon Technologies, Inc. | Method and system for fulfilling requests in an inventory system |

| CN101489849A (zh) | 2005-07-22 | 2009-07-22 | 麦克纳莫绅有限公司 | 车辆的导轨启动的磁性转辙 |

| DE102006002704A1 (de) | 2006-01-19 | 2007-08-02 | Henkel Kgaa | Verfahren und Vorrichtung zur Überwachung einer Produktionslinie |

| US9821992B2 (en) | 2006-03-06 | 2017-11-21 | The Coca-Cola Company | Juice dispensing system |

| SE529882C2 (sv) | 2006-03-24 | 2007-12-18 | Swedish Electroforming Technol | Anordning och förfarande för att fixera en matrisskiva vid elektroplätering |

| US7885821B2 (en) | 2006-04-03 | 2011-02-08 | Michael Tait | Package pickup indicator system |

| US7456593B1 (en) | 2006-04-10 | 2008-11-25 | Anorad Corporation | Direct drive transport system |

| US8308418B2 (en) | 2006-05-09 | 2012-11-13 | Taiwan Semiconductor Manufacturing Co., Ltd. | High efficiency buffer stocker |

| US9436184B2 (en) | 2006-06-09 | 2016-09-06 | Amazon Technologies, Inc. | Method and system for transporting inventory items |

| US7912574B2 (en) | 2006-06-19 | 2011-03-22 | Kiva Systems, Inc. | System and method for transporting inventory items |

| US8074578B2 (en) | 2006-07-05 | 2011-12-13 | Magnemotion, Inc. | Linear synchronous motor power control system and methods |

| GB0616458D0 (en) | 2006-08-18 | 2006-09-27 | Meadwestvaco Packaging Systems | Metering apparatus with independent tool drive means |

| US7770364B1 (en) | 2006-10-19 | 2010-08-10 | Medco Health Solutions, Inc. | Systems for branding containers |

| KR100800285B1 (ko) | 2006-11-20 | 2008-02-01 | (주)제이브이엠 | 약제 관리 시스템 및 그 처리방법 |

| JP2008137738A (ja) | 2006-11-30 | 2008-06-19 | Asyst Technologies Japan Inc | 天井走行搬送装置 |

| DE102007025822A1 (de) | 2007-06-02 | 2008-12-18 | Lars Bergmann | Kombinierbares Flächenelement mit einer Vielzahl von ansteuerbaren Wandlerelementen |

| JP2009000290A (ja) | 2007-06-21 | 2009-01-08 | Yuyama Manufacturing Co Ltd | 錠剤充填装置 |

| CN201080430Y (zh) | 2007-07-09 | 2008-07-02 | 谢舜星 | 充填机的充填设备自动化定位系统 |

| DE102007059611B4 (de) | 2007-12-11 | 2010-09-02 | Gerhard Schubert Gmbh | Verfahren und Vorrichtung zum Transportieren von Objekten |

| DE102008040204A1 (de) | 2008-07-07 | 2010-01-14 | Robert Bosch Gmbh | Vorrichtung und Verfahren zum Transportieren von Produkten mit Linearantrieb |

| US8609371B2 (en) | 2008-08-12 | 2013-12-17 | Allylix, Inc. | Isoprenoid compounds |

| US9046890B2 (en) | 2008-09-05 | 2015-06-02 | Fanuc Robotics America, Inc. | Line tracking data over Ethernet |

| US8511555B2 (en) | 2008-09-12 | 2013-08-20 | William J. Babcock | Tag communication, identification, and tracking apparatus and system |

| US7954712B2 (en) | 2008-09-12 | 2011-06-07 | Transparent Visibility Holdings, LLC | Product, asset, and device tracking, identification, and pricing system |

| US8627639B2 (en) | 2008-09-19 | 2014-01-14 | Walgreen Co. | Method and system for determining an order of fill for a plurality of pills in a multi-dose medicament container |

| FR2939000B1 (fr) * | 2008-11-24 | 2012-10-26 | Oreal | Procede de fabrication de parfum au sein d'un systeme comportant un serveur et au moins deux terminaux interactifs de formulation de parfums |

| DE102008059622A1 (de) | 2008-11-28 | 2010-06-02 | Krones Ag | Einrichtung zum Verpacken von Artikeln |

| JP5365905B2 (ja) | 2008-12-04 | 2013-12-11 | 澁谷工業株式会社 | 物品処理装置 |

| US8616134B2 (en) | 2009-01-23 | 2013-12-31 | Magnemotion, Inc. | Transport system powered by short block linear synchronous motors |

| US8967051B2 (en) | 2009-01-23 | 2015-03-03 | Magnemotion, Inc. | Transport system powered by short block linear synchronous motors and switching mechanism |

| US9032880B2 (en) | 2009-01-23 | 2015-05-19 | Magnemotion, Inc. | Transport system powered by short block linear synchronous motors and switching mechanism |

| US8336700B2 (en) | 2009-04-08 | 2012-12-25 | Ima North America, Inc. | Transport system for moving a plurality of containers through a plurality of work stations |

| EP3395473B1 (de) | 2009-07-07 | 2021-03-31 | Fill Gesellschaft m.b.H. | Verfahren zum giessen |

| JP5413584B2 (ja) * | 2009-08-18 | 2014-02-12 | 澁谷工業株式会社 | 物品処理システム |

| WO2011091108A1 (en) | 2010-01-21 | 2011-07-28 | Siemens Healthcare Diagnostics Inc. | Magnetic conveyor systems, apparatus and methods including moveable magnet |

| US9073684B2 (en) | 2010-03-04 | 2015-07-07 | Vern M. Bailey | Method and apparatus for non-linear dispensing of specific items on demand |

| DE102010003350A1 (de) | 2010-03-26 | 2011-09-29 | Krones Ag | Verfahren zum Herstellen von Kunststoffbehältern |

| US20110241845A1 (en) | 2010-04-06 | 2011-10-06 | Sullivan Robert P | Automated Material Handling System with Identification Features |

| DE102010018153B4 (de) | 2010-04-22 | 2023-11-02 | Krones Aktiengesellschaft | Transporteinrichtung und Transportverfahren für Behälterbehandlungsanlage sowie Behälterbehandlungsanlage mit solcher Transporteinrichtung |

| WO2011140568A2 (en) | 2010-05-07 | 2011-11-10 | Skinit, Inc. | Systems and methods of on demand manufacturing of customized products |

| KR20110134722A (ko) | 2010-06-09 | 2011-12-15 | (주)에이브 | 소비자 맞춤형 화장품 제조방법 |

| FR2963321B1 (fr) | 2010-07-28 | 2012-08-17 | Sidel Participations | Installation de conditionnement de lots de produits |

| EP2420450A1 (en) | 2010-08-17 | 2012-02-22 | Aseptic Technologies | Apparatus for filling a product into a container under aseptic conditions |

| IT1401529B1 (it) | 2010-08-18 | 2013-07-26 | Tenova Spa | Metodo e sistema di controllo e tracking della carica di materiale trasportata da un convogliatore continuo di alimentazione di un forno metallurgico, particolarmente un forno elettrico per la produzione di acciaio |

| DE102010035496A1 (de) | 2010-08-25 | 2012-03-01 | Krones Aktiengesellschaft | Fördervorrichtung zum Fördern von Vorformlingen |

| US8684652B2 (en) | 2010-10-15 | 2014-04-01 | Sanofi-Aventis U.S. Llc | Apparatus and method for loading and unloading containers |

| EP2444171A1 (de) | 2010-10-22 | 2012-04-25 | Siemens VAI Metals Technologies GmbH | Transportsystem, Transportwagen und Verfahren zum Transport von Metallbunde |

| WO2012056838A1 (ja) | 2010-10-26 | 2012-05-03 | 村田機械株式会社 | 搬送システム |

| WO2012122414A2 (en) | 2011-03-09 | 2012-09-13 | Tension Envelope Corporation | Linear dispensing system with universal escapement |

| DE102011016855B4 (de) | 2011-04-13 | 2023-05-04 | Krones Aktiengesellschaft | Verfahren und Vorrichtung zum Transportieren von Behältnissen oder Behältnisgebinden |

| WO2012145789A1 (en) | 2011-04-28 | 2012-11-01 | Svida Pty Ltd | Medication management |

| DE102011075445A1 (de) | 2011-05-06 | 2012-11-08 | Robert Bosch Gmbh | Transportvorrichtung |

| DE102011101255A1 (de) | 2011-05-11 | 2012-11-15 | Krones Aktiengesellschaft | Vorrichtung und Verfahren zum Transportieren von Behältnissen |

| KR20140036178A (ko) | 2011-05-13 | 2014-03-25 | 베크만 컬터, 인코포레이티드 | 실험실 제품 이송 요소 및 경로 배열 구조체 |

| WO2012170636A1 (en) | 2011-06-07 | 2012-12-13 | Magnemotion, Inc. | Versatile control of a linear synchronous motor propulsion system |

| US20130018850A1 (en) | 2011-07-12 | 2013-01-17 | Kevin Houlihan | System And Method For Product Customization Synchronization |

| DE102011079076A1 (de) | 2011-07-13 | 2013-01-17 | Krones Aktiengesellschaft | Transportmittel für Behälter und Verfahren zum Transport von Behältern |

| JP5333537B2 (ja) | 2011-07-22 | 2013-11-06 | 村田機械株式会社 | 移動体システムと移動体の走行制御方法 |

| US8805574B2 (en) | 2011-08-24 | 2014-08-12 | Amazon Technologies, Inc. | System and method for configuring workstations |

| DE102011112300A1 (de) | 2011-09-02 | 2013-03-07 | Khs Gmbh | Transportsystem für Packmitteln sowie Vorrichtung zum Behandeln von Packmitteln mit einem solchen Transportsystem |

| EP2589968A1 (en) | 2011-11-04 | 2013-05-08 | Roche Diagnostics GmbH | Laboratory sample distribution system, laboratory system and method of operating |

| EP2589967A1 (en) | 2011-11-04 | 2013-05-08 | Roche Diagnostics GmbH | Laboratory sample distribution system and corresponding method of operation |

| EP2589966A1 (en) | 2011-11-04 | 2013-05-08 | Roche Diagnostics GmbH | Laboratory sample distribution system and corresponding method of operation |

| JP2015502692A (ja) | 2011-11-14 | 2015-01-22 | エプコス アクチエンゲゼルシャフトEpcos Ag | 寄生容量が低減されたmemsマイクロフォン |

| TW201323301A (zh) | 2011-12-06 | 2013-06-16 | Askey Technology Jiang Su Ltd | 上料管控系統及方法 |

| US20130152516A1 (en) | 2011-12-11 | 2013-06-20 | Michael Sammons | Apparatus for making, handling, and filling pouches |

| MY171044A (en) | 2011-12-27 | 2019-09-23 | Intevac Inc | System architecture for combined static and pass-by processing |

| DE102011090044A1 (de) | 2011-12-28 | 2013-07-04 | Siemens Healthcare Diagnostics Products Gmbh | Transportsystem und Verfahren zum Betrieb |

| DE102012201059A1 (de) | 2012-01-25 | 2013-07-25 | Krones Ag | Eine Vorrichtung und ein Verfahren zum Ausleiten von Produkten, insbesondere Füllgutbehältern wie Flaschen |

| US9726686B2 (en) | 2012-02-03 | 2017-08-08 | Siemens Healthcare Diagnostics Inc. | Encoding scheme embedded into an automation track surface |

| US9315334B2 (en) | 2012-02-03 | 2016-04-19 | Siemens Healthcare Diagnostics Inc. | Intelligent bidirectional multifunctional carrier and integrated automation system for material distribution and transportation |

| EP2810185B1 (en) | 2012-02-03 | 2019-05-15 | Siemens Healthcare Diagnostics Inc. | Power source for an automation system mechanism |

| WO2013116669A1 (en) | 2012-02-03 | 2013-08-08 | Siemens Healthcare Diagnostic Inc. | Status displaying sample carrier |

| IL218327A (en) | 2012-02-26 | 2013-05-30 | Elbit Systems Ltd | Safe emergency landing of unmanned aerial vehicles |

| US9725247B2 (en) | 2012-03-14 | 2017-08-08 | I.M.A. Industria Macchine Automatiche S.P.A. | Apparatus for moving containers |

| JP2015515421A (ja) | 2012-04-13 | 2015-05-28 | ドクター ピー インスティチュート エルエルシー | モジュール型充填装置及び方法 |

| DE102012206295A1 (de) * | 2012-04-17 | 2013-10-17 | Krones Ag | Abfüllanlage für Behälter und Verfahren zum Betreiben der Abfüllanlage |

| US9204920B2 (en) | 2012-05-02 | 2015-12-08 | Covidien Lp | External reader for device management |

| EP2847109B1 (en) | 2012-05-11 | 2017-12-20 | Siemens Healthcare Diagnostics Inc. | Method and system for transporting sample tubes |

| EP2852823A4 (en) | 2012-05-22 | 2016-02-24 | Siemens Healthcare Diagnostics | LINEAR DIRECT ACCESSORIES |

| JP6177895B2 (ja) | 2012-05-24 | 2017-08-09 | シーメンス・ヘルスケア・ダイアグノスティックス・インコーポレーテッドSiemens Healthcare Diagnostics Inc. | 知能オートメーションパック用非接触光エンコーディングスキーム |

| DE102012210329A1 (de) | 2012-06-19 | 2013-12-19 | Robert Bosch Gmbh | Zufuhrvorrichtung |

| US9150366B2 (en) | 2012-08-08 | 2015-10-06 | The Coca-Cola Company | Automated dispensing system with magnetic drive device |

| CN102837138B (zh) | 2012-08-13 | 2014-12-31 | 广州明珞汽车装备有限公司 | 多车型共线柔性总拼 |

| JP6342900B2 (ja) | 2012-09-20 | 2018-06-13 | マグネモーション インコーポレイテッド | 短ブロック線形同期モータおよび切り替え機構 |

| WO2014059322A1 (en) | 2012-10-11 | 2014-04-17 | Siemens Healthcare Diagnostics Inc. | Multiple slot place and pick carrier |

| WO2014059134A1 (en) | 2012-10-11 | 2014-04-17 | Siemens Healthcare Diagnostics Inc. | Automation maintenance carrier |

| US9470702B2 (en) | 2012-10-11 | 2016-10-18 | Siemens Healthcare Diagnostics Inc. | Automation maintenance carrier auto-loader |

| KR101421679B1 (ko) | 2012-10-30 | 2014-07-24 | 안명구 | 개인별 맞춤 영양제 조제장치 |

| CA2890131C (en) | 2012-11-01 | 2020-12-29 | Siemens Healthcare Diagnostics Inc. | Multiple carrier and sleeve tray |

| KR102177981B1 (ko) | 2012-12-05 | 2020-11-13 | 브라코 이미징 에스.피.에이. | 유체 전달 시스템용 검증 기술 |

| CN104853990B (zh) | 2012-12-11 | 2017-03-15 | 诺华股份有限公司 | 用于将产品包装放入运输容器中的方法和包装设备 |

| DE102012223340A1 (de) | 2012-12-17 | 2014-06-18 | Beiersdorf Ag | Individuell auf den einzelnen Anwender zugeschnittene kosmetische Zubereitung und das Verfahren zur Herstellung derselben |

| ITTO20121141A1 (it) | 2012-12-24 | 2014-06-25 | Cavanna Spa | Dispositivo per la presa ed il trasferimento di prodotti individuali |

| JP6032418B2 (ja) | 2013-01-08 | 2016-11-30 | 澁谷工業株式会社 | リニア搬送装置 |

| CA2897572C (en) | 2013-01-11 | 2023-06-20 | Siemens Healthcare Diagnostics Inc. | Multiple payload type carrier |

| EP2754614B1 (de) | 2013-01-14 | 2015-06-24 | Edwin Kohl | Anlage und Verfahren zur personenbezogenen Befüllung von Blisterpackungen mit Medikamenten |

| WO2014110587A1 (en) | 2013-01-14 | 2014-07-17 | Siemens Healthcare Diagnostics Inc. | Test menu expansion system and method |

| WO2014113401A1 (en) | 2013-01-15 | 2014-07-24 | Siemens Healthcare Diagnostics Inc. | Automation tube positioning methodology |

| WO2014113568A1 (en) | 2013-01-17 | 2014-07-24 | Siemens Healthcare Diagnostics Inc. | Hybrid method for collision avoidance and object carrier management |

| US20140230660A1 (en) * | 2013-02-19 | 2014-08-21 | Zhengxu He | Scalable automated cooking system having small footprint and reduced labor cost |

| US9684006B2 (en) | 2013-03-08 | 2017-06-20 | Siemens Healthcare Diagnostics Inc. | Surface markings for an optically guided device |

| US9122566B2 (en) | 2013-03-08 | 2015-09-01 | Bastian Solutions, Llc | Robotic material handling system |

| CA2908528C (en) | 2013-03-12 | 2018-04-24 | Panacea Biomatx, Inc. | Method and system for making customized formulations for individuals |

| US9132873B1 (en) | 2013-03-14 | 2015-09-15 | Kuka Systems Corporation North America | Flexible conveyance system |

| BR112015021155B1 (pt) | 2013-03-14 | 2021-02-17 | Kuka Systems Corporation North America | Sistema de transporte flexível para fabricação em linha de montagem e método de montarcomponentes |

| DE112014001703A5 (de) | 2013-03-28 | 2015-12-17 | Kiefel Gmbh | Transportsystem, kunststoffverarbeitende Fügeanlage, Verfahren zum Betreiben einer kunststoffverarbeitenden Fügeanlage sowie damit hergestelltes Produkt |

| EP2786946A1 (de) * | 2013-04-04 | 2014-10-08 | Knapp AG | Magnetfördertechnik für ein Transportsystem |

| US20140316546A1 (en) | 2013-04-18 | 2014-10-23 | Blacknight Holdings, Llc | Method And System For Direct Additive Manufacturing From An Advertisement |

| ES2522793B1 (es) | 2013-05-15 | 2015-08-10 | Pfm Ibérica Packaging Machinery, S.A. | Dispositivo para el transporte en una línea de envasado de envases flexibles sujetados suspendidos |

| DE102013105687B4 (de) | 2013-06-03 | 2025-08-28 | Krones Ag | Vorrichtung zum Transportieren von Behältnissen mit magnetischem Antrieb |

| JP2016527498A (ja) | 2013-07-19 | 2016-09-08 | ヴィルコ・アーゲー | デバイスをインライン試験する方法及び試験装置 |

| US9542069B2 (en) | 2013-09-03 | 2017-01-10 | Mifaktory Ltd | System and method for creating on-demand products |

| DE102013218402B4 (de) | 2013-09-13 | 2024-11-28 | Krones Ag | Vorrichtung und Verfahren zum Durchführen von Sonderfunktionen einer Transporteinrichtung in einer Behälterbehandlungsanlage |

| DE102013218403A1 (de) | 2013-09-13 | 2015-03-19 | Krones Ag | Vorrichtung und Verfahren zum Transport von Behältern in einer Behälterbehandlungsanlage |

| DE102013218391A1 (de) | 2013-09-13 | 2015-03-19 | Krones Ag | Vorrichtung und Verfahren zum Bewegen von Transportelementen in einer Behälterbehandlungsanlage |

| DE102013218394B4 (de) | 2013-09-13 | 2024-10-24 | Krones Ag | Vorrichtung und Verfahren zur Wartung von Transportelementen in einer Behälterbehandlungsanlage |

| DE102013218399A1 (de) | 2013-09-13 | 2015-03-19 | Krones Ag | Behälterbehandlungsanlage mit einem Ofen und einer Blasformvorrichtung mit Individual-Antrieb von Trägern für Preforms |

| DE102013218389B4 (de) | 2013-09-13 | 2023-01-12 | Krones Ag | Vorrichtung und Verfahren zum Schalten einer passiven Weiche für Transportsysteme mit Linearmotoren |

| KR102331404B1 (ko) | 2013-09-21 | 2021-11-25 | 마그네모션, 인코포레이티드 | 패키징 등에 사용되는 리니어 모터 운송 |

| ITTO20130858A1 (it) | 2013-10-23 | 2015-04-24 | Cavanna Spa | Sistema e procedimento per il confezionamento di prodotti |

| US20150159585A1 (en) | 2013-12-06 | 2015-06-11 | Caterpillar Inc. | System and method for repair of cast component |

| CA2932911A1 (en) | 2013-12-06 | 2015-06-11 | R.A Jones & Co. | Variable pitch packaging apparatus and methods |

| EP2889238A1 (en) | 2013-12-31 | 2015-07-01 | Sidel S.p.a. Con Socio Unico | Transfer device for transferring articles along a path |

| ES2810803T3 (es) | 2014-02-06 | 2021-03-09 | Caljan As | Sistemas y métodos para empaquetar artículos y documentación asociada |

| WO2015126839A1 (en) | 2014-02-19 | 2015-08-27 | Siemens Healthcare Diagnostics Inc. | Mother daughter tube carrier for aliquoters |

| EP2921433B1 (en) | 2014-03-21 | 2016-09-28 | Cavanna S.p.A. | Conveyor for a packaging line |

| EP2927695B1 (de) | 2014-03-31 | 2018-08-22 | Roche Diagniostics GmbH | Probenverteilungssystem und Laborautomatisierungssystem |

| JP6335603B2 (ja) | 2014-04-15 | 2018-05-30 | キヤノン株式会社 | 台車搬送システム |

| JP6313642B2 (ja) | 2014-04-18 | 2018-04-18 | キヤノン株式会社 | リニアモータ制御装置及びリニアモータ制御システム |

| DE102014106400A1 (de) | 2014-04-25 | 2015-11-12 | Weber Maschinenbau Gmbh Breidenbach | Individueller transport von lebensmittelportionen |

| WO2016011464A2 (en) | 2014-07-08 | 2016-01-21 | VILJOEN, Alwyn Johannes Jacobus | Custom nutritional supplement composition production system and method |

| EP2965653A1 (en) | 2014-07-09 | 2016-01-13 | Thule IP AB | Backpack with torso length adjustment mechanism |

| DE102014214697A1 (de) | 2014-07-25 | 2016-01-28 | Robert Bosch Gmbh | Vorrichtung zum Befüllen eines Behältnisses |

| JP6514316B2 (ja) | 2014-07-25 | 2019-05-15 | ロベルト・ボッシュ・ゲゼルシャフト・ミト・ベシュレンクテル・ハフツングRobert Bosch Gmbh | 搬送装置 |

| DE102014215536A1 (de) | 2014-08-06 | 2016-02-11 | Volkswagen Aktiengesellschaft | Bordnetzanordnung und Verfahren zum Betreiben eines Bordnetzes eines elektrisch antreibbaren Fortbewegungsmittels mit einer Brennstoffzelle |

| EP2995381A1 (en) | 2014-09-09 | 2016-03-16 | Roche Diagniostics GmbH | Set of sample container carriers for a laboratory sample distribution system, laboratory sample distribution system and laboratory automation system |

| EP2995958A1 (en) | 2014-09-15 | 2016-03-16 | Roche Diagniostics GmbH | Method of operating a laboratory sample distribution system, laboratory sample distribution system and laboratory automation system |

| WO2016044063A1 (en) | 2014-09-19 | 2016-03-24 | Niagara Bottling, Llc | Direct to store supply chain system and method |

| EP3002222B1 (en) | 2014-09-30 | 2017-04-12 | Cavanna S.p.A. | Method and system for grouping individual products into product groups and for feeding said product groups to handling means, in particular for feeding them to a packaging machine, for example of the "flow pack" type or a caser packer or the like |

| US9611107B2 (en) | 2014-12-08 | 2017-04-04 | Rockwell Automation Technologies, Inc. | Linear drive transport system and method |

| EP3034415B1 (de) | 2014-12-19 | 2017-03-22 | UHLMANN PAC-SYSTEME GmbH & Co. KG | Verfahren zum Übertragen von Packgut in Behältnisse und zum Weitertransport der befüllten Behältnisse |

| EP3034414B1 (de) | 2014-12-19 | 2017-02-22 | UHLMANN PAC-SYSTEME GmbH & Co. KG | Verfahren zum Übertragen von Packgut in Behältnisse und zum Weitertransport der befüllten Behältnisse |

| DE102015103833B3 (de) | 2015-03-16 | 2016-02-11 | Groninger GmbH & Co. KG | Verbessertes Transportsystem, insbesondere für eine Füll- und Verschließanlage für pharmazeutische oder kosmetische Objekte |

| EP3095739A1 (en) | 2015-05-22 | 2016-11-23 | Roche Diagniostics GmbH | Method of operating a laboratory sample distribution system, laboratory sample distribution system and laboratory automation system |

| AT517219B1 (de) | 2015-06-23 | 2016-12-15 | Bernecker + Rainer Industrie-Elektronik Ges M B H | Verfahren und Langstatorlinearmotor zur Übergabe einer Transporteinheit an einer Übergabeposition |

| EP3121603A1 (en) | 2015-07-22 | 2017-01-25 | Roche Diagnostics GmbH | Sample container carrier, laboratory sample distribution system and laboratory automation system |

| EP3173885A1 (de) | 2015-11-24 | 2017-05-31 | Siemens Aktiengesellschaft | Verfahren und steuereinrichtung zur steuerung einer bewegung eines linearantriebs mit mindestens einem läufer |

| ITUB20159552A1 (it) | 2015-12-18 | 2017-06-18 | Elbi Int Spa | Procedimento per la determinazione di almeno una caratteristica di funzionamento variabile di un sistema idraulico |

| DE102015226141A1 (de) | 2015-12-21 | 2017-06-22 | Krones Ag | Lineares Transportsystem mit minimaler Transportteilung |

| DE102015226139A1 (de) | 2015-12-21 | 2017-06-22 | Krones Ag | Lineares Transportsystem mit minimaler Transportteilung |

| AT518353B1 (de) | 2016-02-05 | 2018-06-15 | B & R Ind Automation Gmbh | Verfahren zum Steuern der Bewegung einer Transporteinheit |

| ITUB20161148A1 (it) | 2016-02-29 | 2017-08-29 | Vismunda Srl | Sistema di movimentazione a navette indipendenti e coordinate, per automazione industriale |

| WO2018049119A1 (en) | 2016-09-09 | 2018-03-15 | The Procter & Gamble Company | Methods for simultaneously producing different products on a single production line |

| EP4194378B1 (en) | 2016-09-09 | 2024-11-20 | The Procter & Gamble Company | System and method for independently routing vehicles and delivering containers and closures to unit operation stations |

| MX2019002780A (es) | 2016-09-09 | 2019-09-04 | Procter & Gamble | Sistema y método para llenar simultáneamente recipientes de formas y/o tamaños diferentes. |

| CA3035540C (en) | 2016-09-09 | 2021-04-06 | The Procter & Gamble Company | Track system for creating finished products |

| JP6898436B2 (ja) | 2016-09-09 | 2021-07-07 | ザ プロクター アンド ギャンブル カンパニーThe Procter & Gamble Company | 異なる流動性組成物を容器に同時に充填するためのシステム及び方法 |

| US10558201B2 (en) | 2016-09-09 | 2020-02-11 | The Procter & Gamble Company | System and method for producing products based upon demand |

| US10996232B2 (en) | 2016-09-09 | 2021-05-04 | The Procter & Gamble Company | System and method for independently routing container-loaded vehicles to create different finished products |

| EP3509795B1 (en) | 2016-09-09 | 2020-07-29 | The Procter and Gamble Company | Vacuum holder with extensible skirt gasket |

-

2017

- 2017-09-08 JP JP2019513793A patent/JP6898436B2/ja active Active

- 2017-09-08 WO PCT/US2017/050631 patent/WO2018049125A1/en not_active Ceased

- 2017-09-08 MX MX2019002782A patent/MX2019002782A/es unknown

- 2017-09-08 EP EP17768933.8A patent/EP3509954B1/en active Active

- 2017-09-08 CA CA3035965A patent/CA3035965C/en active Active

- 2017-09-08 US US15/698,674 patent/US10643875B2/en active Active

- 2017-09-08 CN CN201780054391.7A patent/CN109661352B/zh active Active

-

2019

- 2019-03-08 PH PH12019500508A patent/PH12019500508A1/en unknown

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102022114419A1 (de) | 2022-06-08 | 2023-12-14 | Krones Aktiengesellschaft | Vorrichtung zum Fördern von Behältern und deren Verwendung |

| US12384633B2 (en) | 2022-06-08 | 2025-08-12 | Krones Ag | Device for conveying containers and use thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| US20180076069A1 (en) | 2018-03-15 |

| CA3035965C (en) | 2022-01-11 |

| CA3035965A1 (en) | 2018-03-15 |

| CN109661352B (zh) | 2021-12-03 |

| PH12019500508A1 (en) | 2019-11-25 |

| US10643875B2 (en) | 2020-05-05 |

| CN109661352A (zh) | 2019-04-19 |

| WO2018049125A1 (en) | 2018-03-15 |

| EP3509954A1 (en) | 2019-07-17 |

| MX2019002782A (es) | 2019-09-04 |

| JP2019531981A (ja) | 2019-11-07 |

| EP3509954B1 (en) | 2021-10-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6898436B2 (ja) | 異なる流動性組成物を容器に同時に充填するためのシステム及び方法 | |

| JP6756910B2 (ja) | 最終製品を製造するための軌道システム | |

| US12060254B2 (en) | System and method for independently routing vehicles and delivering containers and closures to unit operation systems | |

| JP6820408B2 (ja) | 異なる形状及び/又はサイズの容器を同時に充填するためのシステム及び方法 | |

| CN109661624B (zh) | 用于独立地引导装载容器的载具以创建不同成品的系统和方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190415 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200316 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200324 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200609 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20201124 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20210202 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210511 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210610 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6898436 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |