JP6654887B2 - 樹脂材料供給装置及び方法並びに圧縮成形装置 - Google Patents

樹脂材料供給装置及び方法並びに圧縮成形装置 Download PDFInfo

- Publication number

- JP6654887B2 JP6654887B2 JP2015250316A JP2015250316A JP6654887B2 JP 6654887 B2 JP6654887 B2 JP 6654887B2 JP 2015250316 A JP2015250316 A JP 2015250316A JP 2015250316 A JP2015250316 A JP 2015250316A JP 6654887 B2 JP6654887 B2 JP 6654887B2

- Authority

- JP

- Japan

- Prior art keywords

- resin material

- folded

- horizontal portion

- flexible sheet

- compression molding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/18—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29B—PREPARATION OR PRETREATMENT OF THE MATERIAL TO BE SHAPED; MAKING GRANULES OR PREFORMS; RECOVERY OF PLASTICS OR OTHER CONSTITUENTS OF WASTE MATERIAL CONTAINING PLASTICS

- B29B11/00—Making preforms

- B29B11/02—Making preforms by dividing preformed material, e.g. sheets, rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/34—Feeding the material to the mould or the compression means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the groups H01L21/18 - H01L21/326 or H10D48/04 - H10D48/07 e.g. sealing of a cap to a base of a container

- H01L21/56—Encapsulations, e.g. encapsulation layers, coatings

- H01L21/565—Moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/18—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles

- B29C2043/181—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles encapsulated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/34—Feeding the material to the mould or the compression means

- B29C2043/3405—Feeding the material to the mould or the compression means using carrying means

- B29C2043/3416—Feeding the material to the mould or the compression means using carrying means conveyor belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/32—Component parts, details or accessories; Auxiliary operations

- B29C43/34—Feeding the material to the mould or the compression means

- B29C2043/3405—Feeding the material to the mould or the compression means using carrying means

- B29C2043/3427—Feeding the material to the mould or the compression means using carrying means hopper, vessel, chute, tube, conveying screw, for material in discrete form, e.g. particles or powder or fibres

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/42—Wire connectors; Manufacturing methods related thereto

- H01L2224/47—Structure, shape, material or disposition of the wire connectors after the connecting process

- H01L2224/48—Structure, shape, material or disposition of the wire connectors after the connecting process of an individual wire connector

- H01L2224/4805—Shape

- H01L2224/4809—Loop shape

- H01L2224/48091—Arched

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/93—Batch processes

- H01L2224/95—Batch processes at chip-level, i.e. with connecting carried out on a plurality of singulated devices, i.e. on diced chips

- H01L2224/97—Batch processes at chip-level, i.e. with connecting carried out on a plurality of singulated devices, i.e. on diced chips the devices being connected to a common substrate, e.g. interposer, said common substrate being separable into individual assemblies after connecting

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/15—Details of package parts other than the semiconductor or other solid state devices to be connected

- H01L2924/181—Encapsulation

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015250316A JP6654887B2 (ja) | 2015-12-22 | 2015-12-22 | 樹脂材料供給装置及び方法並びに圧縮成形装置 |

| TW105130601A TWI597147B (zh) | 2015-12-22 | 2016-09-22 | 樹脂材料供給裝置及方法、以及壓縮成形裝置 |

| KR1020160157761A KR101891894B1 (ko) | 2015-12-22 | 2016-11-24 | 수지 재료 공급 장치 및 방법, 그리고 압축 성형 장치 |

| CN201611174792.XA CN107030952B (zh) | 2015-12-22 | 2016-12-19 | 树脂材料供给装置及方法、以及压缩成形装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015250316A JP6654887B2 (ja) | 2015-12-22 | 2015-12-22 | 樹脂材料供給装置及び方法並びに圧縮成形装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2017113941A JP2017113941A (ja) | 2017-06-29 |

| JP2017113941A5 JP2017113941A5 (enExample) | 2018-11-15 |

| JP6654887B2 true JP6654887B2 (ja) | 2020-02-26 |

Family

ID=59231227

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2015250316A Active JP6654887B2 (ja) | 2015-12-22 | 2015-12-22 | 樹脂材料供給装置及び方法並びに圧縮成形装置 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP6654887B2 (enExample) |

| KR (1) | KR101891894B1 (enExample) |

| CN (1) | CN107030952B (enExample) |

| TW (1) | TWI597147B (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019193834A (ja) * | 2019-06-25 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

| JP2019193820A (ja) * | 2019-06-20 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

| JP2019193822A (ja) * | 2019-06-20 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10199299B1 (en) * | 2017-08-07 | 2019-02-05 | Micron Technology, Inc. | Semiconductor mold compound transfer system and associated methods |

| CN114589852B (zh) * | 2022-03-17 | 2024-11-29 | 黄高维 | 一种工业生产用树脂井盖上料装置 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5815153Y2 (ja) * | 1973-06-16 | 1983-03-26 | 株式会社クボタ | プレスセイケイソウチ ニ オケル カナガタ ヘノ ザイリヨウキヨウキユウケンセイケイヒンハンシユツソウチ |

| JPS5981123A (ja) * | 1982-11-01 | 1984-05-10 | Toyota Motor Corp | 圧縮成形用金型に可塑化樹脂材料を供給する方法および装置 |

| JPS6389311A (ja) * | 1986-10-03 | 1988-04-20 | Mikuni Seisakusho:Kk | スタンピング成形型の加熱成形用基材の供給方法 |

| JPH0449127U (enExample) * | 1990-08-30 | 1992-04-24 | ||

| US6096379A (en) * | 1998-03-20 | 2000-08-01 | Eckhoff; Paul S. | Radiation processing apparatus and method |

| JP2000326328A (ja) * | 1999-05-24 | 2000-11-28 | Meiwa Ind Co Ltd | 加熱軟化樹脂シートの搬送方法 |

| JP2003171009A (ja) * | 2001-12-04 | 2003-06-17 | Sainekkusu:Kk | 半導体封止用粉状樹脂供給装置 |

| JP4791851B2 (ja) * | 2006-02-24 | 2011-10-12 | Towa株式会社 | 電子部品の樹脂封止成形装置 |

| JP2008114512A (ja) * | 2006-11-07 | 2008-05-22 | Trinc:Kk | 除電機能を持つ樹脂成型機および樹脂成型用除電方法 |

| JP5693931B2 (ja) * | 2010-11-25 | 2015-04-01 | アピックヤマダ株式会社 | 樹脂モールド装置 |

| JP5793806B2 (ja) * | 2011-08-17 | 2015-10-14 | アピックヤマダ株式会社 | 樹脂モールド装置 |

| KR101439596B1 (ko) * | 2012-04-09 | 2014-09-17 | (주)엘지하우시스 | 태양전지 밀봉재용 eva 시트 제조장치 |

| CN103846432A (zh) * | 2012-12-05 | 2014-06-11 | 兴化市东旭机械有限公司 | 一种钨粉装填装置 |

-

2015

- 2015-12-22 JP JP2015250316A patent/JP6654887B2/ja active Active

-

2016

- 2016-09-22 TW TW105130601A patent/TWI597147B/zh active

- 2016-11-24 KR KR1020160157761A patent/KR101891894B1/ko active Active

- 2016-12-19 CN CN201611174792.XA patent/CN107030952B/zh active Active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019193820A (ja) * | 2019-06-20 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

| JP2019193822A (ja) * | 2019-06-20 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

| JP2019193834A (ja) * | 2019-06-25 | 2019-11-07 | 株式会社オリンピア | 遊技機 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20170074749A (ko) | 2017-06-30 |

| KR101891894B1 (ko) | 2018-08-24 |

| JP2017113941A (ja) | 2017-06-29 |

| CN107030952B (zh) | 2019-12-31 |

| TWI597147B (zh) | 2017-09-01 |

| TW201722670A (zh) | 2017-07-01 |

| CN107030952A (zh) | 2017-08-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6654887B2 (ja) | 樹脂材料供給装置及び方法並びに圧縮成形装置 | |

| CN102543773B (zh) | 树脂模制装置 | |

| TWI768846B (zh) | 樹脂模塑裝置 | |

| TWI793538B (zh) | 樹脂模製裝置及清潔方法 | |

| TWI657030B (zh) | 薄膜搬送裝置及薄膜搬送方法以及樹脂模製裝置 | |

| WO2018029934A1 (ja) | 樹脂供給装置、プレスユニット及び樹脂モールド装置 | |

| JP6721738B2 (ja) | 樹脂モールド装置 | |

| KR20170113022A (ko) | 수지 성형 장치, 수지 성형 방법, 필름 반송용 롤러 및 수지 성형 장치용 필름 공급 장치 | |

| JP7134926B2 (ja) | 樹脂成形装置、及び樹脂成形品の製造方法 | |

| KR200474313Y1 (ko) | 자동차용 클립 이송장치 | |

| TWI787792B (zh) | 樹脂模塑裝置 | |

| JP6284764B2 (ja) | 樹脂撒布方法、被樹脂封止部品の樹脂封止方法、樹脂撒布装置、被樹脂封止部品の樹脂封止装置、および樹脂封止成形品製造装置 | |

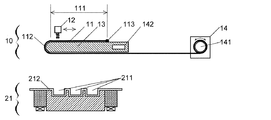

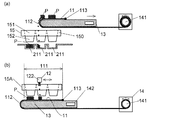

| CN106273168B (zh) | 压缩成形装置的树脂材料供给装置及方法、压缩成形装置及方法 | |

| JP4600830B2 (ja) | シート状部材の移載方法及びその装置 | |

| JP5720424B2 (ja) | 化学処理装置 | |

| TW201634246A (zh) | 製胎機切割站 | |

| JP7116871B2 (ja) | 塗布装置、及び塗布・乾燥硬化方法 | |

| JP2950322B1 (ja) | 被処理物取扱方法及び被処理物取扱装置 | |

| KR101202459B1 (ko) | 단품 필름의 코팅 장치 및 방법, 및 이를 구비한 단품 필름의 코팅 및 건조 시스템 및 방법 | |

| KR20140113793A (ko) | 오링 벨트 및 지지베어링이 설치된 심플형 컨베이어 장치 | |

| JP6522817B2 (ja) | 樹脂成形品の製造方法、被樹脂封止部品の樹脂封止方法、および樹脂成形装置 | |

| JP2005183423A (ja) | 導電性ボールの供給装置および供給方法 | |

| KR20190063405A (ko) | 기판 반출 장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20181003 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20181003 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20190930 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20191008 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191113 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200114 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200131 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6654887 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |