JP5259707B2 - 非ゼオライト卑金属scr触媒 - Google Patents

非ゼオライト卑金属scr触媒 Download PDFInfo

- Publication number

- JP5259707B2 JP5259707B2 JP2010514137A JP2010514137A JP5259707B2 JP 5259707 B2 JP5259707 B2 JP 5259707B2 JP 2010514137 A JP2010514137 A JP 2010514137A JP 2010514137 A JP2010514137 A JP 2010514137A JP 5259707 B2 JP5259707 B2 JP 5259707B2

- Authority

- JP

- Japan

- Prior art keywords

- oxide

- catalyst

- tungsten

- nitrogen

- iron

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

- B01D53/9413—Processes characterised by a specific catalyst

- B01D53/9418—Processes characterised by a specific catalyst for removing nitrogen oxides by selective catalytic reduction [SCR] using a reducing agent in a lean exhaust gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/06—Silicon, titanium, zirconium or hafnium; Oxides or hydroxides thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/06—Silicon, titanium, zirconium or hafnium; Oxides or hydroxides thereof

- B01J21/066—Zirconium or hafnium; Oxides or hydroxides thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/002—Mixed oxides other than spinels, e.g. perovskite

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/10—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of rare earths

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/16—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of arsenic, antimony, bismuth, vanadium, niobium, tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

- B01J23/24—Chromium, molybdenum or tungsten

- B01J23/30—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/54—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36

- B01J23/56—Platinum group metals

- B01J23/63—Platinum group metals with rare earths or actinides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/76—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36

- B01J23/84—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36 with arsenic, antimony, bismuth, vanadium, niobium, tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

- B01J23/85—Chromium, molybdenum or tungsten

- B01J23/888—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/70—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65

- B01J29/72—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65 containing iron group metals, noble metals or copper

- B01J29/76—Iron group metals or copper

- B01J29/7615—Zeolite Beta

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/19—Catalysts containing parts with different compositions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N13/00—Exhaust or silencing apparatus characterised by constructional features

- F01N13/009—Exhaust or silencing apparatus characterised by constructional features having two or more separate purifying devices arranged in series

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/105—General auxiliary catalysts, e.g. upstream or downstream of the main catalyst

- F01N3/106—Auxiliary oxidation catalysts

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion

- F01N3/206—Adding periodically or continuously substances to exhaust gases for promoting purification, e.g. catalytic material in liquid form, NOx reducing agents

- F01N3/208—Control of selective catalytic reduction [SCR], e.g. by adjusting the dosing of reducing agent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2251/00—Reactants

- B01D2251/20—Reductants

- B01D2251/206—Ammonium compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20738—Iron

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20776—Tungsten

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/40—Mixed oxides

- B01D2255/407—Zr-Ce mixed oxides

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/50—Zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/0201—Impregnation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/024—Multiple impregnation or coating

- B01J37/0244—Coatings comprising several layers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/02—Adding substances to exhaust gases the substance being ammonia or urea

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL-COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/14—Arrangements for the supply of substances, e.g. conduits

- F01N2610/1453—Sprayers or atomisers; Arrangement thereof in the exhaust apparatus

- F01N2610/146—Control thereof, e.g. control of injectors or injection valves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A50/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE in human health protection, e.g. against extreme weather

- Y02A50/20—Air quality improvement or preservation, e.g. vehicle emission control or emission reduction by using catalytic converters

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Combustion & Propulsion (AREA)

- Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Toxicology (AREA)

- Analytical Chemistry (AREA)

- Biomedical Technology (AREA)

- Environmental & Geological Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Crystallography & Structural Chemistry (AREA)

- Catalysts (AREA)

- Exhaust Gas After Treatment (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

Description

4NO+4NH3+O2 → 4N2+6H2O (1)

4NH3+5NO2 → 4NO+6H2O (2)

3NO2+4NH3 → (7/2)N2+6H2O (3)

NO+NO2+2NH3 → 2N2+3H2O (4)

(a)セリウム及びジルコニウムからなる担体材料としての混合酸化物または複合酸化物もしくはそれらの混合物上に分散させた少なくとも一種の遷移金属、または

(b)不活性酸化物担体材料上に分散させた、単一酸化物としての酸化セリウム及び酸化ジルコニウムまたはそれらの複合酸化物もしくは該単一酸化物と該複合酸化物の混合物、の上に分散させた少なくとも一種の遷移金属

からなる非ゼオライト卑金属触媒の存在下で接触させることにより、ガス流中の窒素酸化物を窒素に転化する方法を提供する。

(a)セリウム及びジルコニウムからなる担体材料としての混合酸化物または複合酸化物もしくはそれらの混合物上に分散させた少なくとも一種の遷移金属、または

(b)不活性酸化物担体材料上に分散させた、単一酸化物としての酸化セリウム及び酸化ジルコニウムまたはそれらの複合酸化物もしくは該単一酸化物と該複合酸化物の混合物、の上に分散させた少なくとも一種の遷移金属

からなる不均質非ゼオライト卑金属触媒であって、該または各少なくとも一種の遷移金属が、VIB族金属、IB族金属、IVA族金属、VB族金属、VIIB族金属、VIII族金属及びそれらのいずれか2種類以上の混合物からなる群から選択される、触媒を提供する。

例1−触媒及び比較用触媒試料の製造方法

市販のBetaゼオライト上5重量%Fe触媒(5重量%Fe/Beta-比較例)は、下記のように調製した。5重量%Fe装填量を得るのに必要な量の硝酸鉄(Fe(NO3) 3.9H2O)を脱イオンH2O中に溶解させた。溶液の全体積は、単体試料の細孔容積に等しかった(初期的湿潤技術)。この溶液をBetaゼオライト材料に加え、得られた混合物を105℃で一晩乾燥させ、空気中、500℃で1時間か焼した。

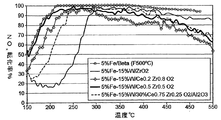

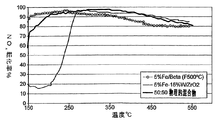

ZrO2上5重量%Fe-15重量%W触媒(5%Fe-15%W/ZrO2-比較例)、CexZr1−xO2(x=0.2) 混合酸化物上5重量%Fe-15重量%W触媒(5%Fe-15%W/Ce0.2Zr0.8O2-本発明による)、CexZr1−xO2(x=0.5) 混合酸化物上5重量%Fe-15重量%W触媒(5%Fe-15%W/Ce0.5Zr0.5O2-本発明による)及び30重量%Ce0.75Zr0.25O2- Al2O3(ガンマアルミナ上に担持されたセリウム及びジルコニウム単一または複合酸化物−30%Ce0.75Zr0.25O2/Al2O3-本発明による) は、下記のように調製した。所望の5重量%Fe及び15重量%W装填量を得るのに必要な量の硝酸鉄(Fe(NO3) 3.9H2O)及びメタタングステン酸アンモニウムを脱イオンH2O中に溶解させた。溶液の全体積は、単体試料の細孔容積に等しかった(初期的湿潤技術)。この溶液を担体材料に加え、得られた混合物を105℃で一晩乾燥させ、次いで700℃で3時間か焼した。CexZr1−xO2(x=0.5) 混合酸化物上15重量%W触媒(15%W/Ce0.5Zr0.5O2-本発明による)は、含浸媒体中に鉄を含まない以外は、類似の様式で調製した。

それぞれ例1により調製したFe/Betaゼオライト及び5重量%Fe-15重量%W/ZrO2の1:1混合物は、2種類の材料を等比率で混合することにより、調製した。

例1及び2により調製した触媒の粉末試料は、本来の試料をペレット化し、それらのペレットを粉砕し、次いで得られた粉末を255〜350μm篩に通すことにより、得た。粉末試料をSynthetic Catalyst Activity Test (SCAT)反応器中に入れ、窒素系還元体を包含する下記の合成ディーゼル排ガス混合物(入口で)、すなわち100 ppmNO、100 ppmNO2、200 ppmNH3、12%O2、4.5%H2O、4.5%CO2、200 ppmCO、100 ppmC3H6、20 ppmSO2、残部N2を使用し、空間速度45,000hr−1(ガス流量毎分2リットル)で試験した。試料を5℃/分で加熱して150〜550℃に昇温し、排ガスの組成を検出し、NOx還元を促進する試料の活性を求めた。結果を添付の図に示す。

Claims (4)

- ガス流中の窒素酸化物を窒素に転化する方法であって、

非ゼオライト卑金属触媒の存在下で、前記窒素酸化物を窒素系還元剤と接触させることを含んでなり、

前記非ゼオライト卑金属触媒が、

(a)セリウム及びジルコニウムからなる担体材料としての混合酸化物または複合酸化物或いはそれらの混合物上に分散された、鉄及びタングステン、又は

(b)不活性酸化物担体材料上に分散された、単一酸化物としての酸化セリウム及び酸化ジルコニウム、又はこれらの複合酸化物、或いは前記単一酸化物と前記複合酸化物の混合物上に分散された、鉄及びタングステンからなり、

前記触媒中の酸化物としてのセリウム及びジルコニウムの含有量が、CeXZr1−XO2(式中、X=0.1〜0.9)であり、

前記触媒に存在する鉄及びタングステンの合計重量%が、前記触媒の総重量に対して0.5〜20重量%である、転化方法。 - 前記非ゼオライト卑金属触媒が、(b)からなり、

前記不活性酸化物担体が、アルミナ、チタニア、非ゼオライトシリカ−アルミナ、セリア、ジルコニア及び、それらのいずれか二種以上の、混合物、複合酸化物及び混合酸化物からなる群から選択されてなる、請求項1に記載の方法。 - 前記非ゼオライト卑金属触媒が、前記鉄及びタングステンを含んでなるものであり、かつ、少なくとも600℃超過の温度で活性化されてなるものである、請求項1に記載の方法。

- 前記CeXZr1−XO2の式中、X=0.1〜0.5である、請求項1に記載の方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0712228A GB2450484A (en) | 2007-06-25 | 2007-06-25 | Non-Zeolite base metal catalyst |

| GB0712228.6 | 2007-06-25 | ||

| PCT/GB2008/050490 WO2009001131A1 (en) | 2007-06-25 | 2008-06-25 | Non-zeolite base metal scr catalyst |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012072322A Division JP2012152743A (ja) | 2007-06-25 | 2012-03-27 | 非ゼオライト卑金属scr触媒 |

| JP2013090540A Division JP5693643B2 (ja) | 2007-06-25 | 2013-04-23 | 非ゼオライト卑金属scr触媒 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010531227A JP2010531227A (ja) | 2010-09-24 |

| JP2010531227A5 JP2010531227A5 (ja) | 2011-09-01 |

| JP5259707B2 true JP5259707B2 (ja) | 2013-08-07 |

Family

ID=38352825

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2010514137A Expired - Fee Related JP5259707B2 (ja) | 2007-06-25 | 2008-06-25 | 非ゼオライト卑金属scr触媒 |

| JP2012072322A Pending JP2012152743A (ja) | 2007-06-25 | 2012-03-27 | 非ゼオライト卑金属scr触媒 |

| JP2013090540A Expired - Fee Related JP5693643B2 (ja) | 2007-06-25 | 2013-04-23 | 非ゼオライト卑金属scr触媒 |

Family Applications After (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012072322A Pending JP2012152743A (ja) | 2007-06-25 | 2012-03-27 | 非ゼオライト卑金属scr触媒 |

| JP2013090540A Expired - Fee Related JP5693643B2 (ja) | 2007-06-25 | 2013-04-23 | 非ゼオライト卑金属scr触媒 |

Country Status (13)

| Country | Link |

|---|---|

| US (3) | US7985391B2 (ja) |

| EP (1) | EP2170490A1 (ja) |

| JP (3) | JP5259707B2 (ja) |

| KR (2) | KR20100047232A (ja) |

| CN (1) | CN101784333B (ja) |

| AR (1) | AR068078A1 (ja) |

| BR (1) | BRPI0813118B1 (ja) |

| CA (1) | CA2692008C (ja) |

| GB (1) | GB2450484A (ja) |

| MX (1) | MX2009014156A (ja) |

| MY (1) | MY153397A (ja) |

| WO (1) | WO2009001131A1 (ja) |

| ZA (1) | ZA200909154B (ja) |

Families Citing this family (48)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2450484A (en) * | 2007-06-25 | 2008-12-31 | Johnson Matthey Plc | Non-Zeolite base metal catalyst |

| JP5305133B2 (ja) * | 2007-09-19 | 2013-10-02 | 株式会社豊田中央研究所 | 窒素酸化物浄化用触媒及びその製造方法 |

| JP5352343B2 (ja) * | 2009-05-21 | 2013-11-27 | 日立造船株式会社 | 水素製造触媒 |

| HUE027335T2 (en) * | 2010-02-01 | 2016-09-28 | Johnson Matthey Plc | Three way catalyst comprising extruded solid body |

| US8529853B2 (en) | 2010-03-26 | 2013-09-10 | Umicore Ag & Co. Kg | ZrOx, Ce-ZrOx, Ce-Zr-REOx as host matrices for redox active cations for low temperature, hydrothermally durable and poison resistant SCR catalysts |

| US8017097B1 (en) | 2010-03-26 | 2011-09-13 | Umicore Ag & Co. Kg | ZrOx, Ce-ZrOx, Ce-Zr-REOx as host matrices for redox active cations for low temperature, hydrothermally durable and poison resistant SCR catalysts |

| DE102010050312A1 (de) | 2010-11-03 | 2012-05-03 | Süd-Chemie AG | Ammoniak-Oxidationskatalysator mit geringer N2O Nebenproduktbildung |

| JP5879029B2 (ja) * | 2010-11-09 | 2016-03-08 | 日立造船株式会社 | アンモニア酸化・分解触媒 |

| US8580701B2 (en) | 2010-11-19 | 2013-11-12 | Corning Incorporated | Method of controlling Ce:Zr ratio in oxide nanoparticles |

| EP2659974B1 (en) * | 2010-12-27 | 2019-06-12 | N.E. Chemcat Corporation | Selective reduction catalyst, and exhaust gas purification device and exhaust gas purification method using same |

| US8617502B2 (en) | 2011-02-07 | 2013-12-31 | Cristal Usa Inc. | Ce containing, V-free mobile denox catalyst |

| US8911697B2 (en) * | 2011-03-03 | 2014-12-16 | Umicore Ag & Co. Kg | Catalytically active material and catalytic converter for the selective catalytic reduction of nitrogen oxides |

| EP2505581A1 (en) * | 2011-03-31 | 2012-10-03 | Stamicarbon B.V. | Zero emission urea process and plant |

| EP2522418A1 (de) | 2011-05-11 | 2012-11-14 | Sachtleben Pigment GmbH | Rohstoffe für vanadiumfreie oder vanadiumreduzierte DeNOx-Katalysatoren und Verfahren zu ihrer Herstellung |

| JP5745171B2 (ja) * | 2011-05-31 | 2015-07-08 | ジョンソン、マッセイ、パブリック、リミテッド、カンパニーJohnson Matthey Publiclimited Company | 二元機能触媒フィルター |

| GB2506776B (en) | 2011-08-03 | 2016-01-06 | Johnson Matthey Plc | Extruded honeycomb catalyst |

| JP5709005B2 (ja) * | 2011-10-26 | 2015-04-30 | トヨタ自動車株式会社 | 排ガス浄化用触媒及びその製造方法 |

| US8765085B2 (en) * | 2012-04-26 | 2014-07-01 | Basf Corporation | Base metal catalyst and method of using same |

| US8668890B2 (en) * | 2012-04-26 | 2014-03-11 | Basf Corporation | Base metal catalyst composition and methods of treating exhaust from a motorcycle |

| GB201221025D0 (en) * | 2012-11-22 | 2013-01-09 | Johnson Matthey Plc | Zoned catalysed substrate monolith |

| US9657665B2 (en) | 2013-02-25 | 2017-05-23 | Cummins Inc. | System, method, and apparatus for sulfur recovery on an SCR catalyst |

| JP2016515922A (ja) | 2013-03-14 | 2016-06-02 | ジョンソン、マッセイ、パブリック、リミテッド、カンパニーJohnson Matthey Public Limited Company | 選択的触媒的還元のための触媒としてのセリウム修飾マンガン八面体モレキュラーシーブ |

| JP6149940B2 (ja) | 2013-11-27 | 2017-06-21 | トヨタ自動車株式会社 | 内燃機関の排気浄化装置 |

| DE102014201263A1 (de) | 2014-01-23 | 2015-07-23 | Johnson Matthey Catalysts (Germany) Gmbh | Katalysator |

| DE102014205783A1 (de) | 2014-03-27 | 2015-10-01 | Johnson Matthey Public Limited Company | Katalysator sowie Verfahren zum Herstellen eines Katalysator |

| DE102014205760A1 (de) | 2014-03-27 | 2015-10-01 | Johnson Matthey Public Limited Company | Verfahren zum Herstellen eines Katalysator sowie Katalysator |

| DE102015209988A1 (de) | 2014-06-02 | 2015-12-03 | Johnson Matthey Public Limited Company | Beschichtete Artikel mit hohen KNOx/KSOx-Verhältnissen für die selektive katalytische Reduktion |

| DE102014215112A1 (de) | 2014-07-31 | 2016-02-04 | Johnson Matthey Public Limited Company | Verfahren zur Herstellung eines Katalysators sowie Katalysator-Artikel |

| MX2017003008A (es) * | 2014-09-22 | 2017-05-30 | Treibacher Ind Ag | Composiciones cataliticas de reduccion catalitica selectiva de amoniaco (scr-nh3) termicamente estables. |

| GB2535274B (en) | 2014-11-19 | 2019-06-12 | Johnson Matthey Plc | An exhaust system combining a molecular-sieve-containing SCR catalyst and a molecular-sieve-containing NOx adsorber catalyst |

| CN104549221A (zh) * | 2015-01-27 | 2015-04-29 | 中国科学院过程工程研究所 | 一种较宽使用温度的低温scr催化剂的制备方法 |

| GB2542654B (en) | 2015-06-28 | 2019-12-04 | Johnson Matthey Plc | Catalytic wall-flow filter having a membrane |

| GB2544858B (en) * | 2015-09-29 | 2020-04-15 | Johnson Matthey Plc | Catalytic filter having a soot catalyst and an SCR catalyst |

| GB2547288B (en) | 2016-02-03 | 2021-03-17 | Johnson Matthey Plc | Catalyst for oxidising ammonia |

| CN109070000A (zh) * | 2016-04-29 | 2018-12-21 | 庄信万丰股份有限公司 | 排气系统 |

| CN106140142B (zh) * | 2016-06-27 | 2017-10-13 | 北京化工大学 | 一种铬钨锆复合氧化物脱硝催化剂及其制备方法和应用 |

| GB2591673B (en) | 2016-10-28 | 2021-11-17 | Johnson Matthey Plc | Catalytic wall-flow filter with partial surface coating |

| GB2562161A (en) | 2017-03-20 | 2018-11-07 | Johnson Matthey Plc | Rear on-wall design SCRF |

| GB2562160B (en) | 2017-03-20 | 2021-06-23 | Johnson Matthey Plc | Catalytic wall-flow filter with an ammonia slip catalyst |

| WO2019042911A1 (en) | 2017-08-29 | 2019-03-07 | Rhodia Operations | USE OF A MIXED OXIDE TO ABSORB NOX |

| WO2020038222A1 (en) | 2018-08-24 | 2020-02-27 | Rhodia Operations | A microporous aluminotitanosilicate crystalline zeolite, method of preparation and applications thereof |

| CN109465007A (zh) * | 2018-11-20 | 2019-03-15 | 东北大学 | 一种铈基脱硝催化剂的制备方法 |

| CN111744490A (zh) * | 2019-03-28 | 2020-10-09 | 苏州华加星光环保工程技术有限公司 | 一种铁基脱硝催化剂及其制备方法 |

| WO2020225235A1 (en) | 2019-05-06 | 2020-11-12 | Basf Corporation | A selective catalytic reduction suspension |

| CN114340790B (zh) * | 2019-06-04 | 2024-09-06 | 丰田自动车欧洲公司 | 高度分散的金属负载的氧化物作为nh3-scr催化剂和合成过程 |

| WO2020245621A1 (en) * | 2019-06-04 | 2020-12-10 | Toyota Motor Europe | Supported oxide nh3-scr catalysts with dual site surface species and synthesis processes |

| CN115707513B (zh) * | 2021-08-19 | 2024-07-05 | 巴斯夫公司 | 用于选择性催化还原的金属氧化物催化剂 |

| CN115445627A (zh) * | 2022-09-29 | 2022-12-09 | 武汉工程大学 | 一种铈镍铜复合氧化物脱硝催化剂及其制备方法与应用 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5057946A (ja) | 1973-07-17 | 1975-05-20 | ||

| US4085193A (en) * | 1973-12-12 | 1978-04-18 | Mitsubishi Petrochemical Co. Ltd. | Catalytic process for reducing nitrogen oxides to nitrogen |

| JPS576972B2 (ja) * | 1973-12-13 | 1982-02-08 | ||

| JPS5242464A (en) | 1975-10-01 | 1977-04-02 | Hitachi Ltd | Method of reducing and removing nox in exhaust gas |

| JPS5567331A (en) * | 1978-11-14 | 1980-05-21 | Mitsubishi Heavy Ind Ltd | Catalyst and method for removing nitrogenoxide in exhaust gas |

| JPS56152742A (en) * | 1980-04-25 | 1981-11-26 | Kobe Steel Ltd | Catalyst composition for high-temperature waste gas denitration |

| DE3740289A1 (de) * | 1987-11-27 | 1989-06-08 | Degussa | Katalysator zur selektiven reduktion von stickoxiden mit ammoniak |

| JPH0256250A (ja) * | 1988-08-23 | 1990-02-26 | Sakai Chem Ind Co Ltd | 排ガス中の窒素酸化物除去用触媒 |

| US4961917A (en) * | 1989-04-20 | 1990-10-09 | Engelhard Corporation | Method for reduction of nitrogen oxides with ammonia using promoted zeolite catalysts |

| JP3283350B2 (ja) | 1992-10-26 | 2002-05-20 | 大阪瓦斯株式会社 | 酸化窒素還元触媒と酸化窒素の処理装置 |

| FR2699524B1 (fr) * | 1992-12-21 | 1995-02-10 | Rhone Poulenc Chimie | Composition à base d'un oxyde mixte de cérium et de zirconium, préparation et utilisation. |

| US5552128A (en) * | 1993-08-03 | 1996-09-03 | Mobil Oil Corporation | Selective catalytic reduction of nitrogen oxides |

| US5401478A (en) * | 1993-08-03 | 1995-03-28 | Mobil Oil Corp. | Selective catalytic reduction of nitrogen oxides |

| ATE179907T1 (de) * | 1994-11-02 | 1999-05-15 | Anglo American Res Lab Pty Ltd | Katalysator mit zirkonoxid/ceroxid träger |

| GB9802504D0 (en) | 1998-02-06 | 1998-04-01 | Johnson Matthey Plc | Improvements in emission control |

| JP4290240B2 (ja) * | 1998-05-27 | 2009-07-01 | ジョンソン・マッセイ・ジャパン・インコーポレイテッド | 排気ガス浄化用触媒および排気ガス浄化方法 |

| JP2003126694A (ja) * | 2001-10-25 | 2003-05-07 | Toyota Motor Corp | 排ガス浄化用触媒 |

| JP4102974B2 (ja) | 2002-05-13 | 2008-06-18 | 日立造船株式会社 | 高温脱硝触媒およびその製造法 |

| FR2847830B1 (fr) * | 2002-12-02 | 2005-08-12 | Irma | Procede de decomposition catalytique de n2o en n2 et o2 realise a haute temperature |

| EP1504805A1 (en) * | 2003-08-07 | 2005-02-09 | Radici Chimica Spa | Catalysts for the Decomposition of Nitrous Oxide |

| EP1516855B1 (en) * | 2003-09-15 | 2017-03-01 | Toyota Jidosha Kabushiki Kaisha | Cerium-zirconium composite metal oxide with a cerium oxide core surrounded by zirconium oxide |

| JP4756571B2 (ja) * | 2003-09-29 | 2011-08-24 | 株式会社豊田中央研究所 | 酸素貯蔵放出材 |

| US20050163691A1 (en) * | 2004-01-23 | 2005-07-28 | C.P. Kelkar | NOx reduction composition for use in FCC processes |

| JP4427356B2 (ja) * | 2004-02-27 | 2010-03-03 | 東京濾器株式会社 | 窒素酸化物浄化用触媒システム及び窒素酸化物浄化方法 |

| US7767163B2 (en) * | 2004-04-20 | 2010-08-03 | Umicore Ag & Co. Kg | Exhaust treatment devices |

| JP2006320797A (ja) * | 2005-05-17 | 2006-11-30 | Nissan Motor Co Ltd | 触媒及びその製造方法 |

| US20090099014A1 (en) | 2005-07-12 | 2009-04-16 | Masahide Miura | Exhaust gas purifying catalyst and process for producing it |

| JP2008049290A (ja) | 2006-08-25 | 2008-03-06 | Tokyo Roki Co Ltd | 窒素酸化物を浄化する触媒、方法、及び装置 |

| KR101434936B1 (ko) | 2006-10-23 | 2014-08-27 | 우미코레 아게 운트 코 카게 | 선택적 촉매 환원용 바나듐 비함유 촉매 및 이의 제조방법 |

| CN101314127B (zh) | 2007-05-31 | 2013-03-06 | 中国科学院大连化学物理研究所 | 用于选择性还原氮氧化物的氧化物催化剂及其制造方法和用途 |

| GB2450484A (en) * | 2007-06-25 | 2008-12-31 | Johnson Matthey Plc | Non-Zeolite base metal catalyst |

-

2007

- 2007-06-25 GB GB0712228A patent/GB2450484A/en not_active Withdrawn

-

2008

- 2008-06-25 KR KR1020107001549A patent/KR20100047232A/ko not_active Ceased

- 2008-06-25 US US12/666,444 patent/US7985391B2/en active Active

- 2008-06-25 CA CA2692008A patent/CA2692008C/en not_active Expired - Fee Related

- 2008-06-25 CN CN200880103482.6A patent/CN101784333B/zh active Active

- 2008-06-25 KR KR1020167009979A patent/KR101807440B1/ko not_active Expired - Fee Related

- 2008-06-25 MX MX2009014156A patent/MX2009014156A/es active IP Right Grant

- 2008-06-25 JP JP2010514137A patent/JP5259707B2/ja not_active Expired - Fee Related

- 2008-06-25 MY MYPI20095556A patent/MY153397A/en unknown

- 2008-06-25 WO PCT/GB2008/050490 patent/WO2009001131A1/en not_active Ceased

- 2008-06-25 AR ARP080102735A patent/AR068078A1/es active IP Right Grant

- 2008-06-25 EP EP08762594A patent/EP2170490A1/en not_active Ceased

- 2008-06-25 BR BRPI0813118A patent/BRPI0813118B1/pt not_active IP Right Cessation

-

2009

- 2009-12-22 ZA ZA2009/09154A patent/ZA200909154B/en unknown

-

2011

- 2011-07-05 US US13/176,230 patent/US8091351B2/en active Active

-

2012

- 2012-01-09 US US13/346,252 patent/US8367578B2/en active Active

- 2012-03-27 JP JP2012072322A patent/JP2012152743A/ja active Pending

-

2013

- 2013-04-23 JP JP2013090540A patent/JP5693643B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| KR20100047232A (ko) | 2010-05-07 |

| JP5693643B2 (ja) | 2015-04-01 |

| CN101784333B (zh) | 2014-06-04 |

| BRPI0813118A2 (pt) | 2014-12-23 |

| JP2012152743A (ja) | 2012-08-16 |

| AR068078A1 (es) | 2009-11-04 |

| US7985391B2 (en) | 2011-07-26 |

| BRPI0813118B1 (pt) | 2018-10-23 |

| GB0712228D0 (en) | 2007-08-01 |

| KR101807440B1 (ko) | 2018-01-18 |

| KR20160049026A (ko) | 2016-05-04 |

| JP2013166149A (ja) | 2013-08-29 |

| JP2010531227A (ja) | 2010-09-24 |

| US20100247409A1 (en) | 2010-09-30 |

| WO2009001131A1 (en) | 2008-12-31 |

| CN101784333A (zh) | 2010-07-21 |

| US8367578B2 (en) | 2013-02-05 |

| CA2692008C (en) | 2016-11-22 |

| GB2450484A (en) | 2008-12-31 |

| US20110263417A1 (en) | 2011-10-27 |

| CA2692008A1 (en) | 2008-12-31 |

| EP2170490A1 (en) | 2010-04-07 |

| US8091351B2 (en) | 2012-01-10 |

| MY153397A (en) | 2015-02-13 |

| ZA200909154B (en) | 2011-04-28 |

| MX2009014156A (es) | 2010-03-11 |

| US20120141347A1 (en) | 2012-06-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5259707B2 (ja) | 非ゼオライト卑金属scr触媒 | |

| KR101542754B1 (ko) | Scr 촉매 수단에 의한 엔진 배기 가스들의 처리를 위한 배기 가스 정화 시스템 | |

| KR101735851B1 (ko) | 배기 가스의 선택적 촉매 환원을 위한 촉매 조성물 | |

| EP2368628A1 (en) | Catalyst for a DeNOx-application and a process for selective catalytic reduction of nitrogen oxides | |

| WO2005044426A1 (ja) | 窒素酸化物を接触還元する方法をそのための触媒 | |

| CN101528326A (zh) | 用于选择性催化还原的无钒的催化剂及其制备方法 | |

| CA2605255A1 (en) | Catalyst and catalyst structure for reduction of nitrogen oxides, and method for catalytic reduction of nitrogen oxides | |

| CN101506481B (zh) | 用氢选择性催化还原氮氧化物 | |

| JP4901129B2 (ja) | 窒素酸化物接触還元用触媒 | |

| JP2008296224A (ja) | 窒素酸化物浄化触媒、並びにそれを用いた窒素酸化物の浄化方法及び窒素酸化物浄化装置 | |

| Iliopoulou et al. | Ag-based catalytic additives for the simultaneous reduction of NO and CO emissions from the regenerator of a FCC unit | |

| JP2009061394A (ja) | 排ガス中の窒素酸化物の接触還元除去方法 | |

| JP2004209386A (ja) | 窒素酸化物を接触還元する方法とそのための触媒 | |

| JP2004008977A (ja) | 窒素酸化物を接触的に除去するための方法とそのための装置 | |

| More | of combustion generated CO, NOx, and unburnt hydrocarbons | |

| Takahashi et al. | Improvement of catalysts for NOx storage and reduction for gasoline-fueled automotive exhaust | |

| NAWDALI et al. | GLOBAL JOURNAL OF ADVANCED ENGINEERING TECHNOLOGIES AND SCIENCES THE BEHAVIOR OF IRIDIUM BASED CATALYSTS IN THE SELECTIVE CATALYTIC REDUCTION OF NOX IN LEAN AUTOMOTIVE EXHAUST GAS CONDITIONS: A REVIEW | |

| JP2004313915A (ja) | 窒素酸化物を接触還元する方法とそのための触媒 | |

| Crocker | Development of Nitric Oxide Oxidation Catalysts for the Fast SCR Reaction |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110623 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110623 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20110712 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110714 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20110721 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20110921 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110927 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111227 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120110 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120327 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120713 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20121011 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20121018 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20130108 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130110 |

|

| TRDD | Decision of grant or rejection written | ||

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20130214 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130326 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130424 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160502 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5259707 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |