JP5114113B2 - ワークキャリア - Google Patents

ワークキャリア Download PDFInfo

- Publication number

- JP5114113B2 JP5114113B2 JP2007173987A JP2007173987A JP5114113B2 JP 5114113 B2 JP5114113 B2 JP 5114113B2 JP 2007173987 A JP2007173987 A JP 2007173987A JP 2007173987 A JP2007173987 A JP 2007173987A JP 5114113 B2 JP5114113 B2 JP 5114113B2

- Authority

- JP

- Japan

- Prior art keywords

- insert

- opening

- groove

- work

- locking

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

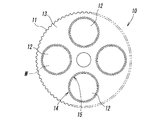

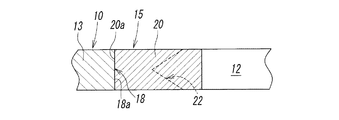

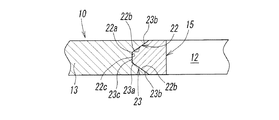

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/27—Work carriers

- B24B37/28—Work carriers for double side lapping of plane surfaces

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B7/00—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor

- B24B7/10—Single-purpose machines or devices

- B24B7/16—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings

- B24B7/17—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings for simultaneously grinding opposite and parallel end faces, e.g. double disc grinders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B7/00—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor

- B24B7/20—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground

- B24B7/22—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground for grinding inorganic material, e.g. stone, ceramics, porcelain

- B24B7/24—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor characterised by a special design with respect to properties of the material of non-metallic articles to be ground for grinding inorganic material, e.g. stone, ceramics, porcelain for grinding or polishing glass

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Ceramic Engineering (AREA)

- Inorganic Chemistry (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007173987A JP5114113B2 (ja) | 2007-07-02 | 2007-07-02 | ワークキャリア |

| TW097121414A TW200914199A (en) | 2007-07-02 | 2008-06-09 | Workpiece carrier |

| KR1020080057302A KR20090004521A (ko) | 2007-07-02 | 2008-06-18 | 워크 캐리어 |

| DE102008030067A DE102008030067A1 (de) | 2007-07-02 | 2008-06-27 | Werkstückträger |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007173987A JP5114113B2 (ja) | 2007-07-02 | 2007-07-02 | ワークキャリア |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009012086A JP2009012086A (ja) | 2009-01-22 |

| JP5114113B2 true JP5114113B2 (ja) | 2013-01-09 |

Family

ID=40092746

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007173987A Active JP5114113B2 (ja) | 2007-07-02 | 2007-07-02 | ワークキャリア |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5114113B2 (enExample) |

| KR (1) | KR20090004521A (enExample) |

| DE (1) | DE102008030067A1 (enExample) |

| TW (1) | TW200914199A (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR200484471Y1 (ko) * | 2017-01-26 | 2017-09-08 | (주)엔티에스엘 | 반도체 웨이퍼의 연마 공정에 사용되는 캐리어 |

| KR20180012690A (ko) | 2016-07-27 | 2018-02-06 | 스피드팸 가부시키가이샤 | 워크 캐리어 및 워크 캐리어의 제조 방법 |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010179375A (ja) * | 2009-02-03 | 2010-08-19 | Sumco Corp | 被研磨物キャリア及び研磨製品の製造方法 |

| JP5452984B2 (ja) * | 2009-06-03 | 2014-03-26 | 不二越機械工業株式会社 | ウェーハの両面研磨方法 |

| JP5233888B2 (ja) * | 2009-07-21 | 2013-07-10 | 信越半導体株式会社 | 両面研磨装置用キャリアの製造方法、両面研磨装置用キャリア及びウェーハの両面研磨方法 |

| JP4605564B1 (ja) * | 2009-09-28 | 2011-01-05 | 株式会社白崎製作所 | 脆性薄板研磨装置用ホルダ、およびその製造方法 |

| KR101135744B1 (ko) * | 2010-09-20 | 2012-04-16 | 주식회사 엘지실트론 | 웨이퍼 수용장치 및 이를 포함하는 웨이퍼 연마장치 |

| JP2012111001A (ja) * | 2010-11-25 | 2012-06-14 | Nikon Corp | ワークキャリア及び該ワークキャリアを備えた研磨装置 |

| JP5847789B2 (ja) | 2013-02-13 | 2016-01-27 | 信越半導体株式会社 | 両面研磨装置用キャリアの製造方法およびウエーハの両面研磨方法 |

| JP6443370B2 (ja) * | 2016-03-18 | 2018-12-26 | 信越半導体株式会社 | 両面研磨装置用のキャリアの製造方法およびウェーハの両面研磨方法 |

| JP6800402B2 (ja) * | 2016-10-06 | 2020-12-16 | スピードファム株式会社 | ワークキャリア及びワークキャリアの製造方法 |

| WO2018163721A1 (ja) * | 2017-03-06 | 2018-09-13 | 信越半導体株式会社 | 両面研磨装置用キャリア |

| JP6840639B2 (ja) * | 2017-03-06 | 2021-03-10 | 信越半導体株式会社 | 両面研磨装置用キャリア |

| JP6792106B2 (ja) * | 2017-03-30 | 2020-11-25 | スピードファム株式会社 | ワークキャリア及びワークキャリアの製造方法 |

| JP2019034357A (ja) * | 2017-08-10 | 2019-03-07 | 住友電工焼結合金株式会社 | ワークキャリア、両頭平面研削盤及びワークの両面研磨加工方法 |

| KR101864155B1 (ko) * | 2018-01-19 | 2018-06-04 | (주)엔티에스엘 | 반도체 웨이퍼의 연마 공정에 사용되는 캐리어 |

| JP2020191376A (ja) | 2019-05-22 | 2020-11-26 | 信越半導体株式会社 | 両面研磨装置用キャリアおよびその製造方法 |

| KR102199135B1 (ko) * | 2019-06-27 | 2021-01-06 | 주식회사 이포스 | 기판 연마용 캐리어 및 이를 포함하는 기판 연마 장치 |

| JP7276246B2 (ja) * | 2020-05-19 | 2023-05-18 | 信越半導体株式会社 | 両面研磨装置用キャリアの製造方法及びウェーハの両面研磨方法 |

| JP7565591B2 (ja) * | 2021-01-06 | 2024-10-11 | 不二越機械工業株式会社 | ウェハ研磨用キャリアおよびウェハ研磨装置 |

| CN113510614A (zh) * | 2021-08-03 | 2021-10-19 | 菲特晶(南京)电子有限公司 | 一种双面研磨机用游轮结构 |

| CN115071045A (zh) * | 2022-06-20 | 2022-09-20 | 王达 | 一种研抛载具的制作方法 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01114264U (enExample) * | 1988-01-29 | 1989-08-01 | ||

| JP2000288922A (ja) | 1999-03-31 | 2000-10-17 | Hoya Corp | 研磨用キャリア及び研磨方法並びに情報記録媒体用基板の製造方法 |

| JP3439726B2 (ja) * | 2000-07-10 | 2003-08-25 | 住友ベークライト株式会社 | 被研磨物保持材及びその製造方法 |

| JP2003305637A (ja) | 2002-04-15 | 2003-10-28 | Shirasaki Seisakusho:Kk | 脆性薄板の研磨用ホルダ |

| JP2006068895A (ja) | 2004-08-02 | 2006-03-16 | Showa Denko Kk | 研磨用キャリア及び磁気記録媒体用シリコン基板の製造方法並びに磁気記録媒体用シリコン基板 |

-

2007

- 2007-07-02 JP JP2007173987A patent/JP5114113B2/ja active Active

-

2008

- 2008-06-09 TW TW097121414A patent/TW200914199A/zh unknown

- 2008-06-18 KR KR1020080057302A patent/KR20090004521A/ko not_active Ceased

- 2008-06-27 DE DE102008030067A patent/DE102008030067A1/de not_active Withdrawn

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20180012690A (ko) | 2016-07-27 | 2018-02-06 | 스피드팸 가부시키가이샤 | 워크 캐리어 및 워크 캐리어의 제조 방법 |

| KR200484471Y1 (ko) * | 2017-01-26 | 2017-09-08 | (주)엔티에스엘 | 반도체 웨이퍼의 연마 공정에 사용되는 캐리어 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20090004521A (ko) | 2009-01-12 |

| TWI359719B (enExample) | 2012-03-11 |

| JP2009012086A (ja) | 2009-01-22 |

| TW200914199A (en) | 2009-04-01 |

| DE102008030067A1 (de) | 2009-01-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5114113B2 (ja) | ワークキャリア | |

| US12434348B2 (en) | Retaining ring having inner surfaces with features | |

| US7186171B2 (en) | Composite retaining ring | |

| US20120251250A1 (en) | Round cutting insert with reverse anti-rotation feature | |

| US20220339755A1 (en) | Retaining ring design | |

| JP2010179375A (ja) | 被研磨物キャリア及び研磨製品の製造方法 | |

| TWI813551B (zh) | 具間隔物之墊修整器及具此墊修整器之晶圓化學機械平坦化系統 | |

| KR100546355B1 (ko) | 국부 단차 형성용 삽입 패드를 구비하는 cmp 장치 | |

| WO2009048234A2 (en) | Retainer ring of cmp machine | |

| US20130316627A1 (en) | Wafer carrier for batch wafer polishing in wafer polishing machines | |

| KR20150114408A (ko) | 연마 방법 및 보유 지지구 | |

| JP5057325B2 (ja) | 研磨パッド | |

| KR20210008995A (ko) | 기판의 연마 장치용 캐리어 헤드의 리테이너 링 | |

| KR102708235B1 (ko) | 기판의 연마 장치용 캐리어 헤드의 리테이너 링 | |

| KR102509353B1 (ko) | 리테이너 링 | |

| US7131901B2 (en) | Polishing pad and fabricating method thereof | |

| JP2018058176A (ja) | ワークキャリア及びワークキャリアの製造方法 | |

| JP6489327B2 (ja) | カップ型回転砥石 | |

| KR101026574B1 (ko) | 양면 연마 장치용 캐리어와 프레이트 및 이를 이용한 양면 연마 장치 | |

| KR102031741B1 (ko) | 연삭 휠 | |

| KR102725363B1 (ko) | 리테이너링 | |

| WO2022024482A1 (ja) | フレーム | |

| JP2005125445A (ja) | キャリア | |

| JP2008073777A (ja) | 軟質材加工用回転工具 | |

| JP2008137088A (ja) | 軟質材加工用回転工具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100224 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120222 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120306 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120426 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120925 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121015 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151019 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5114113 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |