JP5084258B2 - Cvd被覆方法 - Google Patents

Cvd被覆方法 Download PDFInfo

- Publication number

- JP5084258B2 JP5084258B2 JP2006504801A JP2006504801A JP5084258B2 JP 5084258 B2 JP5084258 B2 JP 5084258B2 JP 2006504801 A JP2006504801 A JP 2006504801A JP 2006504801 A JP2006504801 A JP 2006504801A JP 5084258 B2 JP5084258 B2 JP 5084258B2

- Authority

- JP

- Japan

- Prior art keywords

- operating state

- layer

- coating method

- substrate

- cvd coating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000576 coating method Methods 0.000 title claims description 48

- 238000000034 method Methods 0.000 claims description 89

- 239000010432 diamond Substances 0.000 claims description 77

- 229910003460 diamond Inorganic materials 0.000 claims description 75

- 239000007789 gas Substances 0.000 claims description 64

- 239000000758 substrate Substances 0.000 claims description 59

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 54

- 229910052799 carbon Inorganic materials 0.000 claims description 54

- 230000008569 process Effects 0.000 claims description 51

- 239000011248 coating agent Substances 0.000 claims description 31

- 230000003746 surface roughness Effects 0.000 claims description 15

- 239000002159 nanocrystal Substances 0.000 claims description 8

- 229910052710 silicon Inorganic materials 0.000 claims description 4

- 239000010703 silicon Substances 0.000 claims description 4

- 238000000151 deposition Methods 0.000 claims description 3

- 125000004430 oxygen atom Chemical group O* 0.000 claims description 3

- 239000010410 layer Substances 0.000 description 118

- 239000013078 crystal Substances 0.000 description 30

- 230000012010 growth Effects 0.000 description 14

- 230000015572 biosynthetic process Effects 0.000 description 13

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 12

- 230000000694 effects Effects 0.000 description 10

- 230000006911 nucleation Effects 0.000 description 9

- 238000010899 nucleation Methods 0.000 description 9

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 8

- 240000003259 Brassica oleracea var. botrytis Species 0.000 description 8

- 238000010438 heat treatment Methods 0.000 description 8

- 239000000463 material Substances 0.000 description 8

- 235000011299 Brassica oleracea var botrytis Nutrition 0.000 description 7

- 238000009499 grossing Methods 0.000 description 7

- 230000001965 increasing effect Effects 0.000 description 7

- 239000000203 mixture Substances 0.000 description 7

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 6

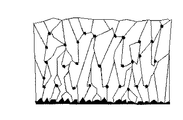

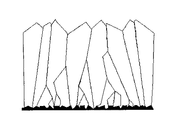

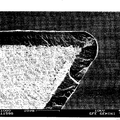

- 238000000635 electron micrograph Methods 0.000 description 6

- 239000001301 oxygen Substances 0.000 description 6

- 229910052760 oxygen Inorganic materials 0.000 description 6

- 238000005229 chemical vapour deposition Methods 0.000 description 5

- 230000007423 decrease Effects 0.000 description 5

- 239000001257 hydrogen Substances 0.000 description 5

- 229910052739 hydrogen Inorganic materials 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 5

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 4

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 4

- 239000012159 carrier gas Substances 0.000 description 4

- 238000005520 cutting process Methods 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 3

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- 229910002091 carbon monoxide Inorganic materials 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- 239000011247 coating layer Substances 0.000 description 3

- 238000009792 diffusion process Methods 0.000 description 3

- HSFWRNGVRCDJHI-UHFFFAOYSA-N Acetylene Chemical compound C#C HSFWRNGVRCDJHI-UHFFFAOYSA-N 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 125000004432 carbon atom Chemical group C* 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000008021 deposition Effects 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 229910010272 inorganic material Inorganic materials 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000013081 microcrystal Substances 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 238000007711 solidification Methods 0.000 description 2

- 230000008023 solidification Effects 0.000 description 2

- 239000002345 surface coating layer Substances 0.000 description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 2

- 229910052721 tungsten Inorganic materials 0.000 description 2

- 239000010937 tungsten Substances 0.000 description 2

- 101100491335 Caenorhabditis elegans mat-2 gene Proteins 0.000 description 1

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 1

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- 244000131743 Oldenlandia corymbosa Species 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 229910009043 WC-Co Inorganic materials 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 229910003481 amorphous carbon Inorganic materials 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 229910002090 carbon oxide Inorganic materials 0.000 description 1

- 239000011195 cermet Substances 0.000 description 1

- 238000012512 characterization method Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 238000010494 dissociation reaction Methods 0.000 description 1

- 230000005593 dissociations Effects 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 125000002534 ethynyl group Chemical group [H]C#C* 0.000 description 1

- 230000005284 excitation Effects 0.000 description 1

- -1 filament temperature Substances 0.000 description 1

- 239000010419 fine particle Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 230000001939 inductive effect Effects 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000003801 milling Methods 0.000 description 1

- 238000000059 patterning Methods 0.000 description 1

- 239000012071 phase Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000006798 recombination Effects 0.000 description 1

- 238000005215 recombination Methods 0.000 description 1

- 238000007634 remodeling Methods 0.000 description 1

- 229910052702 rhenium Inorganic materials 0.000 description 1

- WUAPFZMCVAUBPE-UHFFFAOYSA-N rhenium atom Chemical compound [Re] WUAPFZMCVAUBPE-UHFFFAOYSA-N 0.000 description 1

- 239000011435 rock Substances 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000007790 solid phase Substances 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 230000036962 time dependent Effects 0.000 description 1

- 230000008467 tissue growth Effects 0.000 description 1

- 235000012431 wafers Nutrition 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45523—Pulsed gas flow or change of composition over time

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

- C23C16/27—Diamond only

- C23C16/271—Diamond only using hot filaments

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/26—Deposition of carbon only

- C23C16/27—Diamond only

- C23C16/279—Diamond only control of diamond crystallography

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S76/00—Metal tools and implements, making

- Y10S76/12—Diamond tools

Landscapes

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Chemical Vapour Deposition (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

- Cutting Tools, Boring Holders, And Turrets (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10312777.1 | 2003-03-21 | ||

| DE10312777 | 2003-03-21 | ||

| PCT/EP2004/003014 WO2004083484A1 (de) | 2003-03-21 | 2004-03-22 | Körper mit glatter diamantschicht, sowie vorrichtung und verfahren |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006521466A JP2006521466A (ja) | 2006-09-21 |

| JP2006521466A5 JP2006521466A5 (enExample) | 2007-05-10 |

| JP5084258B2 true JP5084258B2 (ja) | 2012-11-28 |

Family

ID=33015933

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006504801A Expired - Lifetime JP5084258B2 (ja) | 2003-03-21 | 2004-03-22 | Cvd被覆方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7815735B2 (enExample) |

| JP (1) | JP5084258B2 (enExample) |

| DE (2) | DE112004000452B4 (enExample) |

| WO (1) | WO2004083484A1 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1884978B1 (en) | 2006-08-03 | 2011-10-19 | Creepservice S.à.r.l. | Process for the coating of substrates with diamond-like carbon layers |

| AT504006B1 (de) * | 2006-08-14 | 2008-05-15 | Rho Best Coating Hartstoffbesc | Werkzeuge mit kohlenstoffhaltigen beschichtungen und verfahren zu deren herstellung |

| JP2008100300A (ja) * | 2006-10-17 | 2008-05-01 | Ngk Spark Plug Co Ltd | ダイヤモンド被覆切削インサート及び切削工具 |

| KR100924287B1 (ko) * | 2007-05-10 | 2009-10-30 | 한국과학기술연구원 | 양광주가 존재하지 않는 직류 전원 플라스마 증착 장치와,양광주를 배제한 상태에서의 물질 증착 방법 및 이에 의해제조된 다이아몬드 박막 |

| KR100922543B1 (ko) * | 2007-09-14 | 2009-10-21 | 한국과학기술연구원 | 나노 결정질 다이아몬드 박막 중의 비정상 거대 입자의개재를 방지하는 방법 |

| JP5488873B2 (ja) * | 2009-07-13 | 2014-05-14 | 三菱マテリアル株式会社 | 耐欠損性と耐摩耗性にすぐれたダイヤモンド被覆工具 |

| DE112011101512A5 (de) | 2010-04-30 | 2013-12-05 | Cemecon Ag | Beschichteter Körper sowie ein Verfahren zur Beschichtung eines Körpers |

| CN102230156A (zh) * | 2011-06-21 | 2011-11-02 | 深圳市金洲精工科技股份有限公司 | 微型刀具上制备复合硬质涂层的方法及微型刀具 |

| DE102013218446A1 (de) | 2013-09-13 | 2015-03-19 | Cemecon Ag | Werkzeug sowie Verfahren zum Zerspanen von faserverstärktenMaterialien |

| US10612132B2 (en) | 2015-11-27 | 2020-04-07 | Cemecon Ag | Coating a body with a diamond layer and a hard material layer |

| EP3669014B1 (de) | 2017-08-18 | 2024-08-07 | Gühring KG | Verfahren zum beschichten temperaturempfindlicher substrate mit polykristallinem diamant |

| EP4056728A1 (en) * | 2019-11-08 | 2022-09-14 | Sumitomo Electric Hardmetal Corp. | Diamond-coated tool and method for manufacturing same |

| WO2025133335A2 (en) | 2023-12-22 | 2025-06-26 | Oerlikon Surface Solutions Ag, Pfäffikon | Plasma methods for nanodiamond coatings |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0328373A (ja) * | 1989-06-23 | 1991-02-06 | Idemitsu Petrochem Co Ltd | ダイヤモンド被覆部材およびその製造方法 |

| JPH04272179A (ja) * | 1991-02-28 | 1992-09-28 | Idemitsu Petrochem Co Ltd | ダイヤモンド被覆部材の製造方法 |

| JP2813077B2 (ja) * | 1991-05-30 | 1998-10-22 | 京セラ株式会社 | 摺動部材 |

| US5989511A (en) * | 1991-11-25 | 1999-11-23 | The University Of Chicago | Smooth diamond films as low friction, long wear surfaces |

| US5567522A (en) * | 1992-03-10 | 1996-10-22 | Sumitomo Electric Industries, Ltd. | Diamond cutting tool and method of manufacturing the same |

| JPH06279185A (ja) * | 1993-03-25 | 1994-10-04 | Canon Inc | ダイヤモンド結晶およびダイヤモンド結晶膜の形成方法 |

| JP3260986B2 (ja) * | 1994-09-30 | 2002-02-25 | 京セラ株式会社 | ダイヤモンド複合膜付部材 |

| US5505158A (en) * | 1994-11-04 | 1996-04-09 | The United States Of America As Represented By The Secretary Of The Navy | Apparatus and method for achieving growth-etch deposition of diamond using a chopped oxygen-acetylene flame |

| US5852341A (en) * | 1994-11-14 | 1998-12-22 | Crystallume | Diamond film with sharp field emission turn-on |

| JPH10130092A (ja) * | 1996-10-22 | 1998-05-19 | Toshiba Tungaloy Co Ltd | ダイヤモンド被覆焼結合金 |

| DK1408138T3 (da) * | 1997-02-05 | 2007-10-29 | Cemecon Ag | Coatinganordning |

| JPH10226597A (ja) * | 1997-02-12 | 1998-08-25 | Toshiba Tungaloy Co Ltd | ダイヤモンド被覆硬質部材 |

| JPH10287491A (ja) * | 1997-04-10 | 1998-10-27 | Toshiba Tungaloy Co Ltd | 表面粗さを調整したダイヤモンド被覆硬質部材 |

| JPH11347805A (ja) * | 1998-06-11 | 1999-12-21 | Toshiba Tungaloy Co Ltd | ダイヤモンド被覆工具部材およびその製造方法 |

| DE19914585C1 (de) * | 1999-03-31 | 2000-09-14 | Cemecon Ceramic Metal Coatings | Diamantbeschichtetes Werkzeug und Verfahren zu seiner Herstellung |

| DE19922665B4 (de) * | 1999-05-18 | 2005-05-12 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zur Herstellung von einer extrem glatten feinkristallinen Diamantschicht auf dreidimensionalen Grundkörpern und deren Verwendung |

| FR2798940B1 (fr) | 1999-09-03 | 2001-11-16 | Barros Maria Isabel De | Procede de fabrication d'une piece metallique recouverte de diamant et piece metallique obtenue au moyen d'un tel procede |

| AU2003277912A1 (en) * | 2002-09-27 | 2004-04-23 | Cemecon Ag | Coating method and coated element |

-

2004

- 2004-03-22 DE DE112004000452.7T patent/DE112004000452B4/de not_active Expired - Lifetime

- 2004-03-22 DE DE112004003154.0T patent/DE112004003154B4/de not_active Expired - Lifetime

- 2004-03-22 JP JP2006504801A patent/JP5084258B2/ja not_active Expired - Lifetime

- 2004-03-22 WO PCT/EP2004/003014 patent/WO2004083484A1/de not_active Ceased

- 2004-03-22 US US10/549,621 patent/US7815735B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2006521466A (ja) | 2006-09-21 |

| DE112004000452D2 (de) | 2006-02-09 |

| US20060219158A1 (en) | 2006-10-05 |

| DE112004003154A5 (de) | 2014-12-04 |

| DE112004000452B4 (de) | 2015-11-19 |

| DE112004003154B4 (de) | 2018-08-02 |

| WO2004083484A1 (de) | 2004-09-30 |

| US7815735B2 (en) | 2010-10-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5084258B2 (ja) | Cvd被覆方法 | |

| EP1649075B1 (en) | Cvd diamond-coated composite substrate and method for making same | |

| US5851658A (en) | Diamond coated article and process for producing thereof | |

| US20140060937A1 (en) | Polycrystalline diamond compact coated with high abrasion resistance diamond layers | |

| KR920000801B1 (ko) | 다이아몬드박막부착 초경합금의 제조방법 | |

| US20020114935A1 (en) | Graded grain size diamond layer | |

| JP4437353B2 (ja) | 被覆切削工具およびその製造方法 | |

| KR19990007993A (ko) | 기상 합성에 의해 형성된 다이아몬드 피복물 | |

| CN102933742B (zh) | 织构化的氧化铝层 | |

| JP5469676B2 (ja) | ダイヤモンド複合材料を製造する方法 | |

| JPH04232273A (ja) | 超硬質フィルムの多層構造及びその作製方法 | |

| Shen et al. | Fabrication and evaluation of monolayer diamond grinding tools by hot filament chemical vapor deposition method | |

| KR20120128595A (ko) | 표면 피복 절삭 공구 및 그 제조 방법 | |

| US20050139395A1 (en) | Drill bit with a moissanite (silicon carbide) cutting element | |

| JPH0881299A (ja) | 弓そりを低下させた合成ダイヤモンド皮膜とその製造方法 | |

| Wu et al. | Iridium coating: processes, properties and application. Part II | |

| JPH0892741A (ja) | ダイヤモンド堆積用超硬合金の表面処理方法 | |

| JP2019171546A (ja) | 表面被覆切削工具及びその製造方法 | |

| JP2019171547A (ja) | 表面被覆切削工具及びその製造方法 | |

| JP5108774B2 (ja) | 金属炭窒化物層を被覆するための方法 | |

| Yu-Feng et al. | Synthesis of Nano-Crystalline Diamond Film in Hot FilamentChemical Vapour Deposition by Adding Ar | |

| JP2797612B2 (ja) | 高い付着強度を有する人工ダイヤモンド被覆硬質焼結工具部材 | |

| Ali et al. | Tantalum carbide-graphite composite film synthesized by hot-filament chemical vapor deposition | |

| JPH06262406A (ja) | 切削工具およびその製造法 | |

| KR100484263B1 (ko) | 절삭공구에서 미세결정다이아몬드 특성을 가진 코팅막의형성방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A529 | Written submission of copy of amendment under article 34 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A529 Effective date: 20051114 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070313 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070313 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100921 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20101216 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20101224 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110314 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120111 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120409 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120416 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120710 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120821 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120904 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5084258 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150914 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |