JP4991663B2 - 蒸気タービン動翼組立体 - Google Patents

蒸気タービン動翼組立体 Download PDFInfo

- Publication number

- JP4991663B2 JP4991663B2 JP2008231617A JP2008231617A JP4991663B2 JP 4991663 B2 JP4991663 B2 JP 4991663B2 JP 2008231617 A JP2008231617 A JP 2008231617A JP 2008231617 A JP2008231617 A JP 2008231617A JP 4991663 B2 JP4991663 B2 JP 4991663B2

- Authority

- JP

- Japan

- Prior art keywords

- blade

- shroud

- hole

- rod

- shaped member

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/22—Blade-to-blade connections, e.g. for damping vibrations

- F01D5/225—Blade-to-blade connections, e.g. for damping vibrations by shrouding

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/22—Blade-to-blade connections, e.g. for damping vibrations

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D11/00—Preventing or minimising internal leakage of working-fluid, e.g. between stages

- F01D11/005—Sealing means between non relatively rotating elements

- F01D11/006—Sealing the gap between rotor blades or blades and rotor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D25/00—Component parts, details, or accessories, not provided for in, or of interest apart from, other groups

- F01D25/04—Antivibration arrangements

- F01D25/06—Antivibration arrangements for preventing blade vibration

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D5/00—Blades; Blade-carrying members; Heating, heat-insulating, cooling or antivibration means on the blades or the members

- F01D5/12—Blades

- F01D5/26—Antivibration means not restricted to blade form or construction or to blade-to-blade connections or to the use of particular materials

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/31—Application in turbines in steam turbines

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

Description

|Gb|<|U43|

|Ga|<|U45|

|Gb|<|U45|

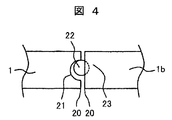

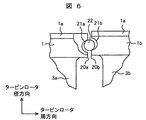

この結果、タービン運転時において、シュラウド41aよりもシュラウド41bの変位が大きい場合、タービンの回転時は、棒状の部材22はシュラウド41aの孔42aの上側と接触し、同時に、棒状の部材22はシュラウド41bの孔42bの下側と接触することになる。

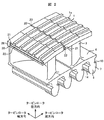

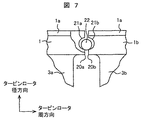

3 羽根部

4 プラットフォーム部

5 翼根元部

6 翼溝

8 タービンロータ

9 固定ピン

19 蒸気タービン動翼

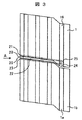

21,21a,21b,31,42a,42b 孔

22,32 棒状の部材

Claims (11)

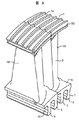

- 羽根部と、前記羽根部の先端に設けられたシュラウドと、

タービンロータの外周部に設けられた翼溝と嵌合するタービンロータの径方向内周側に突出した翼根元部と、

前記羽根部と前記翼根元部との間に設けられたプラットフォーム部と、

前記翼根元部と前記翼溝との間に設けられたピンと、

隣り合う翼の相対する前記シュラウドの面間に形成される孔と、

前記孔の内に、前記孔との間に間隙を有して設けられた棒状の部材とを有し、

前記孔と前記棒状の部材の組立時における間隙を、タービン回転時の隣り合う前記シュラウド面の孔の変位差より小さくした蒸気タービン動翼組立体。 - 請求項1において、前記シュラウドの先端にフィンシールが形成されている蒸気タービン動翼組立体。

- 請求項1において、前記孔と前記棒状の部材との間隙を、前記翼根元部及び前記翼溝と前記ピンとの間隙以上とした蒸気タービン動翼組立体。

- 請求項1において、前記孔が前記タービンロータの軸方向に貫通していない蒸気タービン動翼組立体。

- 請求項4において、前記孔の貫通していない部位が、前記シュラウドの左右で、蒸気の流れ方向に対して、前後相対する位置にある蒸気タービン動翼組立体。

- 請求項1において、隣り合う前記シュラウドと周方向にオーバーラップする部位を有する蒸気タービン動翼組立体。

- 請求項6において、前記オーバーラップする部位が蒸気の流れ方向に対して下流側に位置する前記シュラウドに、前記棒状の部材が挿入される穴が穿孔されている蒸気タービン動翼組立体。

- 請求項1において、前記棒状部材は前記シュラウドを構成する翼材よりも比重が軽い蒸気タービン動翼組立体。

- 請求項1において、前記棒状部材は前記シュラウドを構成する翼材よりも磨耗しやすい材料とした蒸気タービン動翼組立体。

- 羽根部と、前記羽根部の先端に設けられたシュラウドと、

タービンロータの外周部に設けられた翼溝と嵌合するタービンロータの径方向内周側に突出した翼根元部と、

前記羽根部と前記翼根元部との間に設けられたプラットフォーム部と、

隣り合う翼の相対する前記シュラウドの面間に形成される孔と、

前記孔の内に、前記孔との間に間隙を有して設けられた棒状の部材とを有し、

前記孔と前記棒状の部材の組立時における間隙を、タービン回転時の隣り合う前記シュラウド面の孔の変位差より小さくした蒸気タービン動翼組立体。 - 請求項10において、前記棒状の部材は、前記孔に挿設後、前記孔の端部におけるシュラウド部をかしめて、前記孔内に封入されている蒸気タービン動翼組立体。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008231617A JP4991663B2 (ja) | 2007-09-11 | 2008-09-10 | 蒸気タービン動翼組立体 |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007234858 | 2007-09-11 | ||

| JP2007234858 | 2007-09-11 | ||

| JP2008231617A JP4991663B2 (ja) | 2007-09-11 | 2008-09-10 | 蒸気タービン動翼組立体 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012102003A Division JP5272094B2 (ja) | 2007-09-11 | 2012-04-27 | タービン動翼組立体 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2009085214A JP2009085214A (ja) | 2009-04-23 |

| JP4991663B2 true JP4991663B2 (ja) | 2012-08-01 |

Family

ID=40534394

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008231617A Expired - Fee Related JP4991663B2 (ja) | 2007-09-11 | 2008-09-10 | 蒸気タービン動翼組立体 |

| JP2012102003A Expired - Fee Related JP5272094B2 (ja) | 2007-09-11 | 2012-04-27 | タービン動翼組立体 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2012102003A Expired - Fee Related JP5272094B2 (ja) | 2007-09-11 | 2012-04-27 | タービン動翼組立体 |

Country Status (3)

| Country | Link |

|---|---|

| US (2) | US8257044B2 (ja) |

| JP (2) | JP4991663B2 (ja) |

| KR (2) | KR101120578B1 (ja) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5090287B2 (ja) * | 2008-08-07 | 2012-12-05 | 株式会社日立製作所 | タービン動翼とその固定構造 |

| US8277189B2 (en) * | 2009-11-12 | 2012-10-02 | General Electric Company | Turbine blade and rotor |

| US20110158814A1 (en) * | 2009-12-31 | 2011-06-30 | General Electric Company | Turbine engine rotor blades and rotor wheels |

| JP5380371B2 (ja) * | 2010-06-04 | 2014-01-08 | 株式会社日立製作所 | タービン動翼 |

| FR2963381B1 (fr) * | 2010-07-27 | 2015-04-10 | Snecma | Etancheite inter-aubes pour une roue de turbine ou de compresseur de turbomachine |

| JP5591152B2 (ja) * | 2011-02-28 | 2014-09-17 | 三菱重工業株式会社 | タービン動翼 |

| US8821125B2 (en) | 2012-02-06 | 2014-09-02 | Alstom Technology Ltd. | Turbine blade having improved flutter capability and increased turbine stage output |

| US10309235B2 (en) | 2012-08-27 | 2019-06-04 | United Technologies Corporation | Shiplap cantilevered stator |

| JP6134878B2 (ja) * | 2012-09-27 | 2017-05-31 | 三菱日立パワーシステムズ株式会社 | タービンの静翼制振構造 |

| US9194238B2 (en) * | 2012-11-28 | 2015-11-24 | General Electric Company | System for damping vibrations in a turbine |

| EP2803821A1 (en) * | 2013-05-13 | 2014-11-19 | Siemens Aktiengesellschaft | Blade device, blade system, and corresponding method of manufacturing a blade system |

| KR101513062B1 (ko) * | 2013-10-16 | 2015-04-17 | 두산중공업 주식회사 | 증기터빈 |

| DE102013224199A1 (de) * | 2013-11-27 | 2015-05-28 | MTU Aero Engines AG | Gasturbinen-Laufschaufel |

| FR3014942B1 (fr) * | 2013-12-18 | 2016-01-08 | Snecma | Aube, roue a aubes et turbomachine ; procede de fabrication de l'aube |

| JP6270531B2 (ja) * | 2014-02-21 | 2018-01-31 | 三菱日立パワーシステムズ株式会社 | 動翼体及び回転機械 |

| US10375901B2 (en) | 2014-12-09 | 2019-08-13 | Mtd Products Inc | Blower/vacuum |

| US10281045B2 (en) | 2015-02-20 | 2019-05-07 | Rolls-Royce North American Technologies Inc. | Apparatus and methods for sealing components in gas turbine engines |

| US9759079B2 (en) | 2015-05-28 | 2017-09-12 | Rolls-Royce Corporation | Split line flow path seals |

| US10458263B2 (en) | 2015-10-12 | 2019-10-29 | Rolls-Royce North American Technologies Inc. | Turbine shroud with sealing features |

| EP3269933A1 (de) * | 2016-07-14 | 2018-01-17 | Siemens Aktiengesellschaft | Schaufelverband für eine strömungsmaschine |

| KR101864486B1 (ko) * | 2016-07-22 | 2018-06-04 | 두산중공업 주식회사 | 냉각 유로를 갖는 터빈 |

| US10301955B2 (en) | 2016-11-29 | 2019-05-28 | Rolls-Royce North American Technologies Inc. | Seal assembly for gas turbine engine components |

| US10443420B2 (en) | 2017-01-11 | 2019-10-15 | Rolls-Royce North American Technologies Inc. | Seal assembly for gas turbine engine components |

| US10577977B2 (en) | 2017-02-22 | 2020-03-03 | Rolls-Royce Corporation | Turbine shroud with biased retaining ring |

| EP3438410B1 (en) | 2017-08-01 | 2021-09-29 | General Electric Company | Sealing system for a rotary machine |

| US10443389B2 (en) | 2017-11-09 | 2019-10-15 | Douglas James Dietrich | Turbine blade having improved flutter capability and increased turbine stage output |

| US10724535B2 (en) * | 2017-11-14 | 2020-07-28 | Raytheon Technologies Corporation | Fan assembly of a gas turbine engine with a tip shroud |

| US10718226B2 (en) | 2017-11-21 | 2020-07-21 | Rolls-Royce Corporation | Ceramic matrix composite component assembly and seal |

| US10927692B2 (en) | 2018-08-06 | 2021-02-23 | General Electric Company | Turbomachinery sealing apparatus and method |

| KR102111662B1 (ko) * | 2018-09-21 | 2020-05-15 | 두산중공업 주식회사 | 댐핑 장치를 구비하는 터빈 블레이드 |

| IT201900013854A1 (it) | 2019-08-02 | 2021-02-02 | Ge Avio Srl | Motore a turbina con guarnizioni ad incastro. |

| US11781440B2 (en) * | 2021-03-09 | 2023-10-10 | Rtx Corporation | Scalloped mateface seal arrangement for CMC platforms |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5776208A (en) | 1980-10-30 | 1982-05-13 | Toshiba Corp | Turbine vane |

| FR2501336B1 (fr) | 1981-03-09 | 1986-02-28 | Cibie Projecteurs | Ensemble d'emission de lumiere pour vehicules automobiles |

| JPS57158901U (ja) * | 1981-03-31 | 1982-10-06 | ||

| JPS57210104A (en) | 1981-06-17 | 1982-12-23 | Hitachi Ltd | Device for securing moving vane of turbine |

| JPS58176402A (ja) | 1982-04-10 | 1983-10-15 | Toshiba Corp | タ−ビン動翼の制振装置 |

| JPS63150002A (ja) | 1986-12-13 | 1988-06-22 | ダイワ精工株式会社 | スキ−靴 |

| GB8705216D0 (en) | 1987-03-06 | 1987-04-08 | Rolls Royce Plc | Rotor assembly |

| JPS63150002U (ja) * | 1987-03-25 | 1988-10-03 | ||

| JPH0586803A (ja) * | 1991-09-25 | 1993-04-06 | Mitsubishi Heavy Ind Ltd | トリプルピン翼 |

| JPH08303205A (ja) * | 1995-05-11 | 1996-11-19 | Hitachi Ltd | タービン動翼 |

| JPH11148305A (ja) | 1997-11-17 | 1999-06-02 | Hitachi Ltd | タービン動翼 |

| JP2000204901A (ja) | 1999-01-08 | 2000-07-25 | Mitsubishi Heavy Ind Ltd | 軸流回転機械における動翼の制振構造 |

| JP3933130B2 (ja) | 2001-08-03 | 2007-06-20 | 株式会社日立製作所 | タービン動翼 |

| US7080971B2 (en) * | 2003-03-12 | 2006-07-25 | Florida Turbine Technologies, Inc. | Cooled turbine spar shell blade construction |

| DE10340773A1 (de) * | 2003-09-02 | 2005-03-24 | Man Turbomaschinen Ag | Rotor einer Dampf- oder Gasturbine |

| JP2006076638A (ja) * | 2004-09-10 | 2006-03-23 | Yasutaka Matsuo | おにぎり包装シート |

| JP2007231868A (ja) | 2006-03-02 | 2007-09-13 | Hitachi Ltd | 蒸気タービン動翼およびそれを用いた蒸気タービン並びに蒸気タービン発電プラント |

| US8579590B2 (en) * | 2006-05-18 | 2013-11-12 | Wood Group Heavy Industrial Turbines Ag | Turbomachinery blade having a platform relief hole, platform cooling holes, and trailing edge cutback |

| US7534090B2 (en) * | 2006-06-13 | 2009-05-19 | General Electric Company | Enhanced bucket vibration system |

| JP2007332893A (ja) * | 2006-06-16 | 2007-12-27 | Mitsubishi Heavy Ind Ltd | 軸流タービン翼の制振及びフレッティング防止構造 |

| EP1941967A1 (en) * | 2007-01-08 | 2008-07-09 | ALSTOM Technology Ltd | Method and device for pin removal in a confined space |

| US7976281B2 (en) * | 2007-05-15 | 2011-07-12 | General Electric Company | Turbine rotor blade and method of assembling the same |

-

2008

- 2008-09-10 JP JP2008231617A patent/JP4991663B2/ja not_active Expired - Fee Related

- 2008-09-10 KR KR1020080089269A patent/KR101120578B1/ko not_active Expired - Fee Related

- 2008-09-10 US US12/207,901 patent/US8257044B2/en not_active Expired - Fee Related

-

2011

- 2011-12-08 KR KR1020110131318A patent/KR101199553B1/ko not_active Expired - Fee Related

-

2012

- 2012-04-27 JP JP2012102003A patent/JP5272094B2/ja not_active Expired - Fee Related

- 2012-08-03 US US13/566,382 patent/US8591194B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| JP2009085214A (ja) | 2009-04-23 |

| US8591194B2 (en) | 2013-11-26 |

| KR101120578B1 (ko) | 2012-03-09 |

| KR101199553B1 (ko) | 2012-11-12 |

| JP2012140971A (ja) | 2012-07-26 |

| KR20090027165A (ko) | 2009-03-16 |

| US20090097980A1 (en) | 2009-04-16 |

| US8257044B2 (en) | 2012-09-04 |

| KR20120005420A (ko) | 2012-01-16 |

| US20120301311A1 (en) | 2012-11-29 |

| JP5272094B2 (ja) | 2013-08-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4991663B2 (ja) | 蒸気タービン動翼組立体 | |

| JP4886735B2 (ja) | タービン動翼組立体および蒸気タービン | |

| US8231352B2 (en) | Vibration damper assembly | |

| JP5852249B2 (ja) | ガスタービン | |

| CN102536331B (zh) | 结合了阻尼器和密封销的涡轮机叶片及其相关方法 | |

| JP2005113916A (ja) | ターボ機械のブレードダンパおよびターボ機械のブレードダンパの組立方法 | |

| WO2013041361A1 (en) | Impingement cooling of turbine blades or vanes | |

| KR20150069539A (ko) | 터보기계 냉간 간극 조정 | |

| CA2735493A1 (en) | Turbine blade retention device | |

| JP2012052523A (ja) | タービンブレード組立体 | |

| EP2803821A1 (en) | Blade device, blade system, and corresponding method of manufacturing a blade system | |

| JP2010230007A (ja) | ターボ機械のロータ組立体とその組立方法 | |

| US10072508B2 (en) | Turbomachine rotor with optimised bearing surfaces | |

| EP2601385B1 (en) | Turbomachine rotor with blade roots with adjusting protrusions | |

| EP2151545B1 (en) | Turbine blade and fixation structure thereof | |

| US7503751B2 (en) | Apparatus and method for attaching a rotor blade to a rotor | |

| US10006296B2 (en) | Shroud for pre-twisted airfoils | |

| US20170268536A1 (en) | Rotor, axial compressor, installation method | |

| JP6785555B2 (ja) | 動翼のタービンロータへの組付方法 | |

| CN105723053A (zh) | 涡轮机的轮叶锁定组件和固定方法 | |

| JP7217330B1 (ja) | タービンロータ及びその製造方法 | |

| JP4871919B2 (ja) | タービン動翼の固定構造 | |

| JP5881430B2 (ja) | 翼根バネ、これを備えているタービンロータ及びガスタービン | |

| CN110603372A (zh) | 用于减小涡轮发动机的盘和间隔件的相对旋转运动的销 | |

| JP5703923B2 (ja) | スクロールハウジングの位置決め構造及び過給機 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100326 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20110922 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20111004 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111205 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120410 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120507 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150511 Year of fee payment: 3 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313111 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |