JP4981663B2 - 切替弁 - Google Patents

切替弁 Download PDFInfo

- Publication number

- JP4981663B2 JP4981663B2 JP2007514673A JP2007514673A JP4981663B2 JP 4981663 B2 JP4981663 B2 JP 4981663B2 JP 2007514673 A JP2007514673 A JP 2007514673A JP 2007514673 A JP2007514673 A JP 2007514673A JP 4981663 B2 JP4981663 B2 JP 4981663B2

- Authority

- JP

- Japan

- Prior art keywords

- valve

- valve body

- chamber

- fluid passage

- working fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K11/00—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves

- F16K11/02—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit

- F16K11/04—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only lift valves

- F16K11/044—Multiple-way valves, e.g. mixing valves; Pipe fittings incorporating such valves with all movable sealing faces moving as one unit comprising only lift valves with movable valve members positioned between valve seats

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K27/00—Construction of housing; Use of materials therefor

- F16K27/02—Construction of housing; Use of materials therefor of lift valves

- F16K27/0263—Construction of housing; Use of materials therefor of lift valves multiple way valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K27/00—Construction of housing; Use of materials therefor

- F16K27/02—Construction of housing; Use of materials therefor of lift valves

- F16K27/029—Electromagnetically actuated valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K31/00—Actuating devices; Operating means; Releasing devices

- F16K31/02—Actuating devices; Operating means; Releasing devices electric; magnetic

- F16K31/06—Actuating devices; Operating means; Releasing devices electric; magnetic using a magnet, e.g. diaphragm valves, cutting off by means of a liquid

- F16K31/0603—Multiple-way valves

- F16K31/0624—Lift valves

- F16K31/0627—Lift valves with movable valve member positioned between seats

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

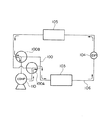

- F25B13/00—Compression machines, plants or systems, with reversible cycle

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B41/00—Fluid-circulation arrangements

- F25B41/20—Disposition of valves, e.g. of on-off valves or flow control valves

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F7/00—Magnets

- H01F7/06—Electromagnets; Actuators including electromagnets

- H01F7/08—Electromagnets; Actuators including electromagnets with armatures

- H01F7/16—Rectilinearly-movable armatures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F25—REFRIGERATION OR COOLING; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS; MANUFACTURE OR STORAGE OF ICE; LIQUEFACTION SOLIDIFICATION OF GASES

- F25B—REFRIGERATION MACHINES, PLANTS OR SYSTEMS; COMBINED HEATING AND REFRIGERATION SYSTEMS; HEAT PUMP SYSTEMS

- F25B2313/00—Compression machines, plants or systems with reversible cycle not otherwise provided for

- F25B2313/027—Compression machines, plants or systems with reversible cycle not otherwise provided for characterised by the reversing means

- F25B2313/02732—Compression machines, plants or systems with reversible cycle not otherwise provided for characterised by the reversing means using two three-way valves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/86622—Motor-operated

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86574—Supply and exhaust

- Y10T137/8667—Reciprocating valve

- Y10T137/86686—Plural disk or plug

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86493—Multi-way valve unit

- Y10T137/86879—Reciprocating valve unit

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Electromagnetism (AREA)

- Power Engineering (AREA)

- Magnetically Actuated Valves (AREA)

- Multiple-Way Valves (AREA)

Description

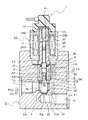

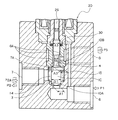

2 弁部

2A バルブハウジング(弁本体)

3 第1弁座

4 第2弁座

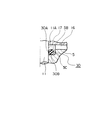

5 軸受部

5A 案内孔

5B 穴周面

5C 接触面

6 第1流体通路

6A 第1連通路

7 第2流体通路

7A 第2連通路

8 第3流体通路

8A 第3連通路

10 弁体

10A 第1弁面

10B 第2弁面

11 軸部

11A 外周面

14 弁室

15 補助通路

16 導入路

17 収容室

20 ソレノイド部

21 本体

22 コイル部

23 スリーブ

23A 内周面

24 可動吸引子

24A 外周面

25 固定吸引子

25A 案内面

26 ソレノイドロッド

26A 外周摺動面

30 シールリング(シール手段)

30A 内周面

30B 側面

42 第1ばね(第1ばね手段)

41 補助ばね(第2ばね手段)

P1 第1作動流体

P2 第2作動流体

P2A 第3作動流体

P3 第4作動流体

従って、A1=A3であるから、F1=K1−K2となる。

ただし、A1は第1受圧面積。

P1は第1流体通路6から導入される第1作動流体の圧力。

A3は軸部11の断面積。

K1は第1ばね42の力。

K2は補助ばね41の力。

また、ソレノイド部20に電流が印加される場合には、弁部10はF2の力により作動して閉弁する。このF2は、次の式のような力になる。

F2=P1×A1−P1×A3+K1−K2+Sとなる。

従って、A1=A3であるから、F2=K1−K2+Sとなる。

ただし、Sはソレノイド部20の吸引力。

このため、弁体10は作動流体の力を受けることなく作動できる。

F1=P1×A1−P1×A3+K1−K2となる。

従って、A1=A3であるから、F1=K1−K2となる。つまり、この項は、第1実施例と同じである。

ただし、A1は第1受圧面積。

P1は第1流体通路6から導入される第1作動流体の圧力。

A3は軸部11の断面積。

K1は第1ばね42の力。

K2は補助ばね41の力。

次に、ソレノイド部20に電流が印加される場合には、弁部10はF2の力により作動して閉弁する。このF2は、次の式に示す力になる。

F2=P1×A1−P2A×A2+P3×A2+K1−K2+Sとなる。

従って、A1=A2=A3であり、PA2=P3であるから、F1=K1−K2+Sとなる。

ただし、Sはソレノイド部20の吸引力。

このため、弁体10は作動流体の力を受けることなく作動できる。

Claims (10)

- 流入流体通路と流出流体通路とに連通する弁室を切り替える切替弁であって、

第1弁座と前記第1弁座と対向する第2弁座とを有する弁室と、

前記弁室の前記第1弁座の周りの第1弁口に連通して作用流体を前記弁室に流入させる第1流体通路と、

前記弁室に連通して作用流体を前記弁室から流出させまたは前記弁室に流入させる第2流体通路と、

前記弁室の前記第2弁座の周りの第2弁口に連通して作用流体を前記弁室から流出させる第3流体通路と、

前記弁室に配置されて前記第1弁座と前記第2弁座とに交互に離接する弁体と、

前記弁体と連結する軸部と、

前記軸部の移動を案内する案内孔が形成される軸受部と、

前記軸受部の上面の前記案内孔の周囲に設けられ、穴周面と穴底面により形成される凹状の収容室と、

側面が前記収容室の前記穴底面に接触し、内周面が前記軸部の外周面に接触し、外周面が前記収容室の前記穴周面には接触しないようになっており、前記弁室と前記収容室との間をシールするシール手段と、

前記収容室と前記第1流体通路とを連通する補助通路と、

前記軸部に連結してソレノイドロッドを作動させるソレノイド部と、を具備し、

前記第1弁座と前記弁体が接合した周りの内面で前記第1流体通路からの作動流体の圧力を受ける第1受圧面積と、

前記収容室内の前記第1流体通路からの作動流体の圧力を受ける前記軸部の第3受圧面積とをほぼ同一面積にした切替弁。 - 前記弁体の前記第1受圧面積と、前記軸部の前記第3受圧面積と、前記第2弁座と前記弁体の第2弁面が接合する周りの内面で第2作動流体の圧力を受ける第2受圧面積とをほぼ同一面積にしたことを特徴とする請求項1に記載の切替弁。

- 前記ソレノイド部が前記弁体を前記第1弁座に閉弁させる吸引力に対抗して前記弁体を前記第1弁座から開弁する第1ばね手段と、前記第1ばね手段に対向する第2ばね手段を有することを特徴とする請求項1に記載の切替弁。

- 前記ソレノイド部が前記弁体を前記第1弁座に閉弁させる吸引力に対抗して前記弁体を前記第1弁座から開弁する第1ばね手段と、前記第1ばね手段に対向する第2ばね手段を有することを特徴とする請求項2に記載の切替弁。

- 前記軸部の前記弁体に連結する側の外径寸法を前記ソレノイドロッドの外径寸法とほぼ同一寸法にしたことを特徴とする請求項1に記載の切替弁。

- 前記軸部の前記弁体に連結する側の外径寸法を前記ソレノイドロッドの外径寸法とほぼ同一寸法にしたことを特徴とする請求項2に記載の切替弁。

- 前記軸部の前記弁体に連結する側の外径寸法を前記ソレノイドロッドの外径寸法とほぼ同一寸法にしたことを特徴とする請求項3に記載の切替弁。

- 前記軸部の前記弁体に連結する側の外径寸法を前記ソレノイドロッドの外径寸法とほぼ同一寸法にしたことを特徴とする請求項4に記載の切替弁。

- 前記収容室の前記穴周面は、前記シール手段が作用流体により押圧されて弾性変形する際に、前記シール手段の前記外周面が接触しない大きさに形成されることを特徴とする請求項1に記載の切替弁。

- 前記軸受部は、前記第1流体通路と前記第2流体通路と前記第3流体通路と前記弁室とが形成されたバルブハウジングに取り付けられることを特徴とする請求項1に記載の切替弁。

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007514673A JP4981663B2 (ja) | 2005-04-27 | 2006-04-21 | 切替弁 |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2005130202 | 2005-04-27 | ||

| JP2005130202 | 2005-04-27 | ||

| PCT/JP2006/308419 WO2006118052A1 (ja) | 2005-04-27 | 2006-04-21 | 切替弁 |

| JP2007514673A JP4981663B2 (ja) | 2005-04-27 | 2006-04-21 | 切替弁 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JPWO2006118052A1 JPWO2006118052A1 (ja) | 2008-12-18 |

| JP4981663B2 true JP4981663B2 (ja) | 2012-07-25 |

Family

ID=37307852

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007514673A Active JP4981663B2 (ja) | 2005-04-27 | 2006-04-21 | 切替弁 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7987871B2 (ja) |

| EP (1) | EP1876380B1 (ja) |

| JP (1) | JP4981663B2 (ja) |

| KR (1) | KR101266120B1 (ja) |

| CN (1) | CN101166926B (ja) |

| WO (1) | WO2006118052A1 (ja) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5233852B2 (ja) * | 2009-06-11 | 2013-07-10 | アイシン・エィ・ダブリュ株式会社 | 電磁弁装置 |

| US8316888B2 (en) | 2009-06-17 | 2012-11-27 | Eaton Corporation | Fluid-biased hydraulic control valve |

| US8443839B2 (en) * | 2009-10-20 | 2013-05-21 | Eaton Corporation | Fluid-biased hydraulic control valve with armature piston |

| JP2011089732A (ja) * | 2009-10-26 | 2011-05-06 | Fuji Koki Corp | ヒートポンプ装置 |

| EP2536966A4 (en) * | 2010-02-18 | 2013-08-21 | Nt Consulting Int Pty Ltd | MAGNET COIL VALVE |

| JP5726426B2 (ja) * | 2010-03-17 | 2015-06-03 | 株式会社不二工機 | 三方電動弁及び該弁を備えたヒートポンプ装置 |

| EP2564005B1 (de) * | 2010-04-01 | 2014-10-15 | Dorma GmbH&Co. Kg | Hydraulisches magnetwegeventil |

| KR101572574B1 (ko) * | 2010-08-12 | 2015-12-01 | 한온시스템 주식회사 | 팽창밸브 및 이를 구비한 차량용 공조장치 |

| JP5572809B2 (ja) * | 2010-09-30 | 2014-08-20 | 株式会社テージーケー | 制御弁 |

| CN102619998A (zh) * | 2011-01-26 | 2012-08-01 | 浙江三花汽车零部件股份有限公司 | 热力膨胀阀 |

| DE102011015976A1 (de) * | 2011-04-04 | 2012-10-04 | Bieri Hydraulik Ag | Ventil |

| JP6067587B2 (ja) * | 2012-01-12 | 2017-01-25 | イーグル工業株式会社 | ソレノイドバルブ |

| CN102878734B (zh) * | 2012-10-26 | 2014-10-15 | 温岭市恒发空调部件有限公司 | 一种膨胀阀 |

| JP6240104B2 (ja) * | 2015-02-06 | 2017-11-29 | トヨタ自動車株式会社 | 液圧ブレーキシステム |

| US11318923B2 (en) * | 2016-03-30 | 2022-05-03 | Autoliv Nissin Brake Systems Japan Co., Ltd. | Solenoid valve, vehicle brake hydraulic pressure control apparatus and solenoid valve fabrication method |

| JP6626789B2 (ja) * | 2016-06-28 | 2019-12-25 | 株式会社不二工機 | 可変容量型圧縮機用制御弁 |

| JP2018066291A (ja) * | 2016-10-18 | 2018-04-26 | サンデン・オートモーティブコンポーネント株式会社 | 可変容量圧縮機の制御弁 |

| KR102363894B1 (ko) * | 2017-09-22 | 2022-02-17 | 엘지전자 주식회사 | 실외기 및 그를 갖는 공기조화기 |

| US10663079B2 (en) * | 2017-10-20 | 2020-05-26 | Goodrich Corporation | Electro-pneumatic valve with pressurized container |

| DE102018208893A1 (de) * | 2018-06-06 | 2019-12-12 | Robert Bosch Gmbh | Direktgesteuertes hydraulisches Wegeventil |

| JP2019219006A (ja) * | 2018-06-20 | 2019-12-26 | アズビルTaco株式会社 | 電磁弁 |

| JP6951706B2 (ja) * | 2018-07-17 | 2021-10-20 | 株式会社不二工機 | 流路切換弁およびその組立方法 |

| JP7153170B2 (ja) * | 2018-08-27 | 2022-10-14 | サンデン株式会社 | 複合弁及びそれを用いた車両用空気調和装置 |

| WO2020116322A1 (ja) * | 2018-12-05 | 2020-06-11 | 株式会社不二工機 | 弁装置 |

| KR102744359B1 (ko) * | 2019-04-03 | 2024-12-18 | 이구루코교 가부시기가이샤 | 용량 제어 밸브 |

| CN110925457A (zh) * | 2019-12-26 | 2020-03-27 | 鞍山电磁阀有限责任公司 | 外置先导式电磁阀 |

| EP3879152A1 (en) | 2020-03-11 | 2021-09-15 | Danfoss A/S | Actuator of a refrigerant valve, valve arrangement comprising a refrigerant valve and an actuator and method for mounting an actuator of a refrigerant valve to the refrigerant valve |

| JP7311789B2 (ja) * | 2020-03-13 | 2023-07-20 | 浜名湖電装株式会社 | 電磁弁 |

| KR102862886B1 (ko) | 2020-04-22 | 2025-09-23 | 이구루코교 가부시기가이샤 | 용량 제어 밸브 |

| JP7523249B2 (ja) * | 2020-04-27 | 2024-07-26 | 川崎重工業株式会社 | 弁装置 |

| US11293564B2 (en) * | 2020-06-05 | 2022-04-05 | Automatic Switch Company | Valve silencing choke |

| EP4264148A1 (en) * | 2020-12-17 | 2023-10-25 | Bereva S.r.l. | Thermodynamic cycle reversing group for refrigeration circuits with reversible thermodynamic cycle and refrigeration circuit with reversible thermodynamic cycle comprising such reversing group |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4910371B1 (ja) * | 1969-07-05 | 1974-03-09 | ||

| JPH01158282A (ja) * | 1987-09-10 | 1989-06-21 | Diesel Kiki Co Ltd | 両座電磁弁 |

| JPH08247361A (ja) * | 1995-02-17 | 1996-09-27 | Deublin Co | 流体結合装置のシール機構 |

| JPH10196797A (ja) * | 1997-01-16 | 1998-07-31 | Smc Corp | シール構造 |

| JPH10332020A (ja) * | 1997-06-03 | 1998-12-15 | Ckd Corp | ガス制御バルブ |

| JP2003074736A (ja) * | 2001-09-04 | 2003-03-12 | Smc Corp | 電磁弁 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1193775A (ja) * | 1959-11-04 | |||

| US2404514A (en) * | 1944-11-18 | 1946-07-23 | Westinghouse Air Brake Co | Valve device |

| CH416252A (de) * | 1963-11-27 | 1966-06-30 | Teves Kg Alfred | Aufschlagventil |

| JPS5223595B2 (ja) | 1972-05-31 | 1977-06-25 | ||

| DE2262247A1 (de) * | 1972-12-20 | 1974-06-27 | Teves Gmbh Alfred | Elektromagnetisches ventil |

| CA1021225A (en) * | 1974-06-28 | 1977-11-22 | General Signal Corporation | Quick-acting valve assembly |

| JPS6312293Y2 (ja) * | 1980-10-08 | 1988-04-08 | ||

| JPS6056431B2 (ja) | 1980-10-09 | 1985-12-10 | 三菱電機株式会社 | プラズマエツチング装置 |

| US4844122A (en) * | 1987-09-10 | 1989-07-04 | Diesel Kiki Co., Ltd. | Electromagnetic valve with two opposed valve seats |

| DE58909504D1 (de) * | 1989-01-28 | 1995-12-21 | Kuhnke Gmbh Kg H | Kraftausgeglichenes Hubventil. |

| US5718264A (en) * | 1996-06-10 | 1998-02-17 | Sturman Industries | High speed 3-way control valve |

| US5836230A (en) * | 1996-08-27 | 1998-11-17 | Oded E. Sturman | High speed 2-way control valve |

-

2006

- 2006-04-21 US US11/919,080 patent/US7987871B2/en active Active

- 2006-04-21 EP EP20060745550 patent/EP1876380B1/en active Active

- 2006-04-21 CN CN2006800146609A patent/CN101166926B/zh active Active

- 2006-04-21 JP JP2007514673A patent/JP4981663B2/ja active Active

- 2006-04-21 WO PCT/JP2006/308419 patent/WO2006118052A1/ja not_active Ceased

- 2006-04-21 KR KR1020077024870A patent/KR101266120B1/ko active Active

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS4910371B1 (ja) * | 1969-07-05 | 1974-03-09 | ||

| JPH01158282A (ja) * | 1987-09-10 | 1989-06-21 | Diesel Kiki Co Ltd | 両座電磁弁 |

| JPH08247361A (ja) * | 1995-02-17 | 1996-09-27 | Deublin Co | 流体結合装置のシール機構 |

| JPH10196797A (ja) * | 1997-01-16 | 1998-07-31 | Smc Corp | シール構造 |

| JPH10332020A (ja) * | 1997-06-03 | 1998-12-15 | Ckd Corp | ガス制御バルブ |

| JP2003074736A (ja) * | 2001-09-04 | 2003-03-12 | Smc Corp | 電磁弁 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20080015399A (ko) | 2008-02-19 |

| CN101166926A (zh) | 2008-04-23 |

| JPWO2006118052A1 (ja) | 2008-12-18 |

| EP1876380A4 (en) | 2011-08-17 |

| US20090038697A1 (en) | 2009-02-12 |

| CN101166926B (zh) | 2010-08-04 |

| EP1876380B1 (en) | 2013-01-02 |

| WO2006118052A1 (ja) | 2006-11-09 |

| US7987871B2 (en) | 2011-08-02 |

| EP1876380A1 (en) | 2008-01-09 |

| KR101266120B1 (ko) | 2013-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4981663B2 (ja) | 切替弁 | |

| JP4246975B2 (ja) | 容量制御弁 | |

| US8413685B2 (en) | Control valve | |

| JP5080612B2 (ja) | 流路切換弁 | |

| JP4888912B2 (ja) | シール構造およびそのシール構造を用いた制御弁 | |

| EP2910874A1 (en) | Pilot operated electromagnetic valve | |

| JP5341433B2 (ja) | 三方切換弁 | |

| CN115507183A (zh) | 电磁阀 | |

| JP2004092734A (ja) | 四方切換弁 | |

| CN113028120A (zh) | 电磁切换阀 | |

| CN109990115B (zh) | 电磁切换阀 | |

| JP7321521B2 (ja) | 開閉弁 | |

| JP2001208224A (ja) | 四方切換弁 | |

| JPH0132389B2 (ja) | ||

| JP2004144151A (ja) | 流路切換弁 | |

| JP2022186293A (ja) | 電気的駆動弁 | |

| JP2007113617A (ja) | 切換弁装置 | |

| JPH02120581A (ja) | 冷凍サイクル用四方弁 | |

| JPH028566A (ja) | 冷凍サイクル用四方弁 | |

| JPS63285380A (ja) | 冷凍サイクル用四方弁 | |

| JPS63180779A (ja) | 冷凍サイクル用四方弁 | |

| JPH02133763A (ja) | 冷凍サイクル用四方弁 | |

| JPS6372974A (ja) | 四方弁 | |

| JPS62180184A (ja) | 冷凍サイクル用四方弁 | |

| JPH0718491B2 (ja) | 冷凍サイクル用四方弁 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090120 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110621 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110804 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110804 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110902 |

|

| A072 | Dismissal of procedure [no reply to invitation to correct request for examination] |

Free format text: JAPANESE INTERMEDIATE CODE: A072 Effective date: 20120125 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120214 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120302 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120327 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120420 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150427 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4981663 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |