JP4659441B2 - 積層鉄心及びその製造方法 - Google Patents

積層鉄心及びその製造方法 Download PDFInfo

- Publication number

- JP4659441B2 JP4659441B2 JP2004344028A JP2004344028A JP4659441B2 JP 4659441 B2 JP4659441 B2 JP 4659441B2 JP 2004344028 A JP2004344028 A JP 2004344028A JP 2004344028 A JP2004344028 A JP 2004344028A JP 4659441 B2 JP4659441 B2 JP 4659441B2

- Authority

- JP

- Japan

- Prior art keywords

- core

- piece

- insulating sheet

- pieces

- laminated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

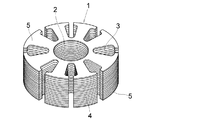

- H02K—DYNAMO-ELECTRIC MACHINES

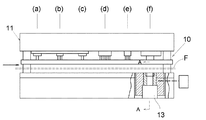

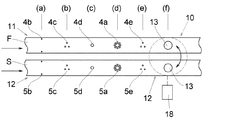

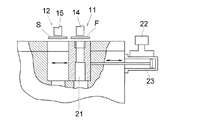

- H02K15/00—Processes or apparatus specially adapted for manufacturing, assembling, maintaining or repairing of dynamo-electric machines

- H02K15/02—Processes or apparatus specially adapted for manufacturing, assembling, maintaining or repairing of dynamo-electric machines of stator or rotor bodies

- H02K15/021—Magnetic cores

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/02—Punching blanks or articles with or without obtaining scrap; Notching

- B21D28/22—Notching the peripheries of circular blanks, e.g. laminations for dynamo-electric machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/18—Layered products comprising a layer of metal comprising iron or steel

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F41/00—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties

- H01F41/02—Apparatus or processes specially adapted for manufacturing or assembling magnets, inductances or transformers; Apparatus or processes specially adapted for manufacturing materials characterised by their magnetic properties for manufacturing cores, coils, or magnets

- H01F41/0206—Manufacturing of magnetic cores by mechanical means

- H01F41/0233—Manufacturing of magnetic circuits made from sheets

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02K—DYNAMO-ELECTRIC MACHINES

- H02K3/00—Details of windings

- H02K3/32—Windings characterised by the shape, form or construction of the insulation

- H02K3/34—Windings characterised by the shape, form or construction of the insulation between conductors or between conductor and core, e.g. slot insulation

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49009—Dynamoelectric machine

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/49009—Dynamoelectric machine

- Y10T29/49012—Rotor

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/49—Method of mechanical manufacture

- Y10T29/49002—Electrical device making

- Y10T29/4902—Electromagnet, transformer or inductor

- Y10T29/49075—Electromagnet, transformer or inductor including permanent magnet or core

- Y10T29/49078—Laminated

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/51—Plural diverse manufacturing apparatus including means for metal shaping or assembling

- Y10T29/5136—Separate tool stations for selective or successive operation on work

- Y10T29/5137—Separate tool stations for selective or successive operation on work including assembling or disassembling station

- Y10T29/5142—Separate tool stations for selective or successive operation on work including assembling or disassembling station and means to sever work from supply

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/51—Plural diverse manufacturing apparatus including means for metal shaping or assembling

- Y10T29/5192—Armature

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/5313—Means to assemble electrical device

- Y10T29/53143—Motor or generator

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/5313—Means to assemble electrical device

- Y10T29/5317—Laminated device

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Manufacture Of Motors, Generators (AREA)

- Manufacturing Cores, Coils, And Magnets (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004344028A JP4659441B2 (ja) | 2004-11-29 | 2004-11-29 | 積層鉄心及びその製造方法 |

| CN2005101254576A CN1783667B (zh) | 2004-11-29 | 2005-11-18 | 叠片铁心及其制造方法以及模具装置 |

| MYPI20055445A MY145335A (en) | 2004-11-29 | 2005-11-22 | Laminated iron core, method and die machine for manufacturing the same |

| US12/191,150 US8108988B2 (en) | 2004-11-29 | 2008-08-13 | Method of manufacturing a laminated iron core |

| US12/247,791 US7870661B2 (en) | 2004-11-29 | 2008-10-08 | Die machine for manufacturing a laminated iron core |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004344028A JP4659441B2 (ja) | 2004-11-29 | 2004-11-29 | 積層鉄心及びその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006158066A JP2006158066A (ja) | 2006-06-15 |

| JP2006158066A5 JP2006158066A5 (enExample) | 2008-01-17 |

| JP4659441B2 true JP4659441B2 (ja) | 2011-03-30 |

Family

ID=36635678

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004344028A Expired - Lifetime JP4659441B2 (ja) | 2004-11-29 | 2004-11-29 | 積層鉄心及びその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US8108988B2 (enExample) |

| JP (1) | JP4659441B2 (enExample) |

| CN (1) | CN1783667B (enExample) |

| MY (1) | MY145335A (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4659441B2 (ja) * | 2004-11-29 | 2011-03-30 | 黒田精工株式会社 | 積層鉄心及びその製造方法 |

| CN103418667A (zh) * | 2012-05-25 | 2013-12-04 | 蔡永合 | 一种与模具配合的步进装置 |

| JP2014014231A (ja) * | 2012-07-04 | 2014-01-23 | Mitsubishi Heavy Ind Ltd | 電動モータ |

| US9762096B2 (en) | 2013-02-20 | 2017-09-12 | Mitsubishi Electric Corporation | Interior permanent magnet motor |

| KR101379155B1 (ko) * | 2013-02-28 | 2014-03-27 | (주)항남 | 2 이상의 모재가 적층된 모터의 웨이트 밸런스 코어의 제조 장치 및 제조 방법 |

| DE102014017149A1 (de) * | 2014-11-17 | 2016-05-19 | Kienle + Spiess Gmbh | Verfahren zur Herstellung von Lamellenpaketen und Anlage zur Durchführung des Verfahrens |

| TWI530968B (zh) * | 2015-05-26 | 2016-04-21 | Magnetic coil structure | |

| JP6288201B1 (ja) * | 2016-09-29 | 2018-03-07 | Jfeスチール株式会社 | 電磁鋼板の打抜き加工方法及び積層鉄心の製造方法 |

| CN107707046B (zh) * | 2017-11-22 | 2024-03-29 | 杭州三相科技有限公司 | 高速电机铸铜转子铁芯及其加工方法 |

| JP7085616B2 (ja) * | 2018-03-21 | 2022-06-16 | 黒田精工株式会社 | 積層鉄心の製造装置及び製造方法 |

| EP3736062A1 (de) | 2019-05-08 | 2020-11-11 | voestalpine Stahl GmbH | Verfahren zum stanzpaketieren von blechteilen zu blechpaketen |

| JP7154264B2 (ja) * | 2020-10-06 | 2022-10-17 | 三菱電機株式会社 | コアエレメントの製造方法と製造装置 |

| CN113922607B (zh) * | 2021-12-10 | 2022-03-01 | 宁波震裕科技股份有限公司 | 电机定子铁芯成型过程中的绕线槽孔加工模具组 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1115507A (en) * | 1964-09-10 | 1968-05-29 | Mini Of The Ministerul Ind Con | Manufacturing processes of magnetic cores of stratified strips and sheets |

| US3659129A (en) * | 1970-09-15 | 1972-04-25 | Gen Electric | Insulated bar dynamoelectric machine and method of forming |

| US3882336A (en) * | 1973-12-03 | 1975-05-06 | Briggs & Stratton Corp | Electric motor armature core |

| JPS55162840A (en) * | 1979-06-06 | 1980-12-18 | Toshiba Corp | Iron core of squirrel-cage motor |

| DE3227681A1 (de) | 1982-07-24 | 1984-02-02 | Robert Bosch Gmbh, 7000 Stuttgart | Verfahren zum herstellen eines lamellenpaketes fuer anker elektrischer maschinen |

| JP2527498B2 (ja) | 1991-01-28 | 1996-08-21 | 株式会社三井ハイテック | 金型装置およびこれを用いた積層鉄心の製造方法 |

| US5163217A (en) | 1991-04-24 | 1992-11-17 | Kuroda Precision Industries Ltd. | Die for manufacturing laminated core |

| JP2552965B2 (ja) | 1991-07-31 | 1996-11-13 | 株式会社三井ハイテック | 積層鉄心製造用金型装置 |

| JP2802862B2 (ja) | 1992-10-26 | 1998-09-24 | 吉川精密株式会社 | 電動モータのコアの製造方法 |

| JP2569215Y2 (ja) * | 1992-12-16 | 1998-04-22 | 株式会社三協精機製作所 | モータの積層コア |

| US5829120A (en) * | 1993-02-15 | 1998-11-03 | Fanuc, Ltd. | Method for manufacturing a rotor for synchronous motor |

| JP3492008B2 (ja) | 1995-03-10 | 2004-02-03 | 株式会社三井ハイテック | 積層鉄心の製造方法 |

| US5799387A (en) | 1996-06-05 | 1998-09-01 | L.H. Carbide Corpordation | Lamina stack having a plurality of outer perimeter configurations and an apparatus and method for manufacturing said stack |

| IT1286450B1 (it) * | 1996-12-06 | 1998-07-08 | Corrada Spa | Articolo laminare comprendente elementi di accoppiamento del tipo a maschio-femmina |

| JP3674523B2 (ja) * | 2001-03-15 | 2005-07-20 | 三菱電機株式会社 | 回転電機の固定子及びその製造方法 |

| JP2002369431A (ja) * | 2001-06-12 | 2002-12-20 | Asmo Co Ltd | 回転電機及び回転電機製造方法 |

| JP3850232B2 (ja) | 2001-06-13 | 2006-11-29 | 株式会社山田ドビー | 積層コアの加工方法と装置 |

| JP4264273B2 (ja) * | 2003-02-25 | 2009-05-13 | 新日本製鐵株式会社 | モータのステータ鉄心の製造方法 |

| JP2005065413A (ja) * | 2003-08-12 | 2005-03-10 | Mitsui High Tec Inc | 絶縁材付き積層鉄心及びその製造方法 |

| US20060119209A1 (en) * | 2004-11-29 | 2006-06-08 | Kuroda Precision Industries Ltd. | Laminated iron core, method and die machine for manufacturing the same |

| JP4659441B2 (ja) * | 2004-11-29 | 2011-03-30 | 黒田精工株式会社 | 積層鉄心及びその製造方法 |

| JP4498154B2 (ja) | 2005-01-27 | 2010-07-07 | ファナック株式会社 | モータの製造方法、及びモータ製造装置 |

-

2004

- 2004-11-29 JP JP2004344028A patent/JP4659441B2/ja not_active Expired - Lifetime

-

2005

- 2005-11-18 CN CN2005101254576A patent/CN1783667B/zh not_active Expired - Fee Related

- 2005-11-22 MY MYPI20055445A patent/MY145335A/en unknown

-

2008

- 2008-08-13 US US12/191,150 patent/US8108988B2/en not_active Expired - Fee Related

- 2008-10-08 US US12/247,791 patent/US7870661B2/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN1783667B (zh) | 2010-05-12 |

| MY145335A (en) | 2012-01-31 |

| US8108988B2 (en) | 2012-02-07 |

| JP2006158066A (ja) | 2006-06-15 |

| CN1783667A (zh) | 2006-06-07 |

| US20090038146A1 (en) | 2009-02-12 |

| US7870661B2 (en) | 2011-01-18 |

| US20080307634A1 (en) | 2008-12-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4659441B2 (ja) | 積層鉄心及びその製造方法 | |

| CN100527569C (zh) | 马达用叠层芯的制造方法、其制造装置、及叠层夹具 | |

| EP3439808B1 (en) | Process for blanking of metal parts | |

| CN107404201B (zh) | 层叠铁心的制造方法 | |

| JP2009072014A (ja) | コアブロック、コア、電動機用ステータ、およびその電動機 | |

| JP2006353001A (ja) | 積層鉄心とその製造方法及び製造装置 | |

| JP5991241B2 (ja) | コアの製造方法 | |

| JP7459110B2 (ja) | 金属部品を製造するための多層精密打抜きプロセスおよびそのようなプロセスを実行するための精密打抜き装置 | |

| CN106849535B (zh) | 层叠铁芯及其制造方法 | |

| JP2009246297A (ja) | 積層セラミック電子部品の製造装置 | |

| CN109309412A (zh) | 定子、电机及定子的制造方法 | |

| JP7401996B2 (ja) | 金属製品の払出装置及び金属製品の製造方法 | |

| JP7137918B2 (ja) | 積層鉄心の製造方法 | |

| JP5109545B2 (ja) | 積層コアの製造方法および製造装置 | |

| US20060119209A1 (en) | Laminated iron core, method and die machine for manufacturing the same | |

| JP3842146B2 (ja) | 積層鉄心の製造方法 | |

| JP5160944B2 (ja) | 積層鉄心の製造方法及び製造装置 | |

| JP2697256B2 (ja) | 積層鉄心及びその製造方法 | |

| JP3762499B2 (ja) | 積層鉄心の製造用金型装置 | |

| JP3442559B2 (ja) | 鉄心用鋼板の打抜装置 | |

| JP2007014122A (ja) | 積層鉄心及びその鉄心単板の製造方法 | |

| JP2017169306A (ja) | 積層鉄心の製造装置及び積層鉄心の製造方法 | |

| KR20250001069A (ko) | 모터 코어용 프레스 장치 | |

| JPH05103448A (ja) | 回転電機のコアの製造方法 | |

| WO2025105482A1 (ja) | 積層鉄心の製造装置及び製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071122 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20071122 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100722 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100817 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101018 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101214 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101227 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140107 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4659441 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| EXPY | Cancellation because of completion of term |