JP4632018B2 - 強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ - Google Patents

強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ Download PDFInfo

- Publication number

- JP4632018B2 JP4632018B2 JP2003355046A JP2003355046A JP4632018B2 JP 4632018 B2 JP4632018 B2 JP 4632018B2 JP 2003355046 A JP2003355046 A JP 2003355046A JP 2003355046 A JP2003355046 A JP 2003355046A JP 4632018 B2 JP4632018 B2 JP 4632018B2

- Authority

- JP

- Japan

- Prior art keywords

- ferroelectric

- film

- electrode

- particles

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims description 45

- 238000004519 manufacturing process Methods 0.000 title claims description 36

- 239000003990 capacitor Substances 0.000 title claims description 23

- 239000000463 material Substances 0.000 claims description 75

- 239000010410 layer Substances 0.000 claims description 49

- 239000002245 particle Substances 0.000 claims description 41

- 238000004070 electrodeposition Methods 0.000 claims description 26

- 239000002994 raw material Substances 0.000 claims description 22

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical group [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 claims description 15

- 239000012792 core layer Substances 0.000 claims description 15

- 150000002500 ions Chemical class 0.000 claims description 15

- 239000011248 coating agent Substances 0.000 claims description 12

- 238000000576 coating method Methods 0.000 claims description 12

- 238000001652 electrophoretic deposition Methods 0.000 claims description 4

- 239000007864 aqueous solution Substances 0.000 description 24

- KWYUFKZDYYNOTN-UHFFFAOYSA-M Potassium hydroxide Chemical compound [OH-].[K+] KWYUFKZDYYNOTN-UHFFFAOYSA-M 0.000 description 18

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 11

- 238000010438 heat treatment Methods 0.000 description 10

- 239000013078 crystal Substances 0.000 description 9

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 8

- 239000002904 solvent Substances 0.000 description 7

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 6

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 6

- 239000000243 solution Substances 0.000 description 6

- 229910010413 TiO 2 Inorganic materials 0.000 description 5

- 239000000203 mixture Substances 0.000 description 5

- 238000000059 patterning Methods 0.000 description 5

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Chemical compound [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 5

- 239000000758 substrate Substances 0.000 description 5

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 4

- 229910052797 bismuth Inorganic materials 0.000 description 4

- 229910052697 platinum Inorganic materials 0.000 description 4

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N 2-Butanone Chemical compound CCC(C)=O ZWEHNKRNPOVVGH-UHFFFAOYSA-N 0.000 description 3

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 description 3

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- JCXGWMGPZLAOME-UHFFFAOYSA-N bismuth atom Chemical compound [Bi] JCXGWMGPZLAOME-UHFFFAOYSA-N 0.000 description 3

- 150000001768 cations Chemical class 0.000 description 3

- 239000000470 constituent Substances 0.000 description 3

- 150000002576 ketones Chemical class 0.000 description 3

- 239000011159 matrix material Substances 0.000 description 3

- 230000005012 migration Effects 0.000 description 3

- 238000013508 migration Methods 0.000 description 3

- 229910052759 nickel Inorganic materials 0.000 description 3

- 229910052709 silver Inorganic materials 0.000 description 3

- 239000004332 silver Substances 0.000 description 3

- SYBYTAAJFKOIEJ-UHFFFAOYSA-N 3-Methylbutan-2-one Chemical compound CC(C)C(C)=O SYBYTAAJFKOIEJ-UHFFFAOYSA-N 0.000 description 2

- 229910015902 Bi 2 O 3 Inorganic materials 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 229910004356 Ti Raw Inorganic materials 0.000 description 2

- YRKCREAYFQTBPV-UHFFFAOYSA-N acetylacetone Chemical compound CC(=O)CC(C)=O YRKCREAYFQTBPV-UHFFFAOYSA-N 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- 150000001450 anions Chemical class 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- DQUIAMCJEJUUJC-UHFFFAOYSA-N dibismuth;dioxido(oxo)silane Chemical compound [Bi+3].[Bi+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O.[O-][Si]([O-])=O DQUIAMCJEJUUJC-UHFFFAOYSA-N 0.000 description 2

- -1 for example Chemical compound 0.000 description 2

- 229910052746 lanthanum Inorganic materials 0.000 description 2

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 2

- XNLICIUVMPYHGG-UHFFFAOYSA-N pentan-2-one Chemical compound CCCC(C)=O XNLICIUVMPYHGG-UHFFFAOYSA-N 0.000 description 2

- FDPIMTJIUBPUKL-UHFFFAOYSA-N pentan-3-one Chemical compound CCC(=O)CC FDPIMTJIUBPUKL-UHFFFAOYSA-N 0.000 description 2

- 239000011148 porous material Substances 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- 238000010532 solid phase synthesis reaction Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- AFPIWWDEGJLLCL-UHFFFAOYSA-N 1,3,2,4$l^{2}-dioxasilaplumbetane 2-oxide Chemical compound [Pb+2].[O-][Si]([O-])=O AFPIWWDEGJLLCL-UHFFFAOYSA-N 0.000 description 1

- QQZOPKMRPOGIEB-UHFFFAOYSA-N 2-Oxohexane Chemical compound CCCCC(C)=O QQZOPKMRPOGIEB-UHFFFAOYSA-N 0.000 description 1

- NLXLAEXVIDQMFP-UHFFFAOYSA-N Ammonium chloride Substances [NH4+].[Cl-] NLXLAEXVIDQMFP-UHFFFAOYSA-N 0.000 description 1

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 description 1

- 229910021193 La 2 O 3 Inorganic materials 0.000 description 1

- 229910018250 LaSi Inorganic materials 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 229910004121 SrRuO Inorganic materials 0.000 description 1

- 239000005456 alcohol based solvent Substances 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-N ammonia Natural products N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 1

- 235000011114 ammonium hydroxide Nutrition 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- XKENYNILAAWPFQ-UHFFFAOYSA-N dioxido(oxo)germane;lead(2+) Chemical compound [Pb+2].[O-][Ge]([O-])=O XKENYNILAAWPFQ-UHFFFAOYSA-N 0.000 description 1

- 230000005684 electric field Effects 0.000 description 1

- 238000001962 electrophoresis Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- XYIBRDXRRQCHLP-UHFFFAOYSA-N ethyl acetoacetate Chemical compound CCOC(=O)CC(C)=O XYIBRDXRRQCHLP-UHFFFAOYSA-N 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229910001867 inorganic solvent Inorganic materials 0.000 description 1

- 239000003049 inorganic solvent Substances 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000001459 lithography Methods 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000004570 mortar (masonry) Substances 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 230000010287 polarization Effects 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 238000003980 solgel method Methods 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G11—INFORMATION STORAGE

- G11C—STATIC STORES

- G11C11/00—Digital stores characterised by the use of particular electric or magnetic storage elements; Storage elements therefor

- G11C11/21—Digital stores characterised by the use of particular electric or magnetic storage elements; Storage elements therefor using electric elements

- G11C11/22—Digital stores characterised by the use of particular electric or magnetic storage elements; Storage elements therefor using electric elements using ferroelectric elements

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/018—Dielectrics

- H01G4/06—Solid dielectrics

- H01G4/08—Inorganic dielectrics

- H01G4/12—Ceramic dielectrics

- H01G4/1209—Ceramic dielectrics characterised by the ceramic dielectric material

- H01G4/1236—Ceramic dielectrics characterised by the ceramic dielectric material based on zirconium oxides or zirconates

- H01G4/1245—Ceramic dielectrics characterised by the ceramic dielectric material based on zirconium oxides or zirconates containing also titanates

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/33—Thin- or thick-film capacitors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G7/00—Capacitors in which the capacitance is varied by non-mechanical means; Processes of their manufacture

- H01G7/06—Capacitors in which the capacitance is varied by non-mechanical means; Processes of their manufacture having a dielectric selected for the variation of its permittivity with applied voltage, i.e. ferroelectric capacitors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02109—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates

- H01L21/02112—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer

- H01L21/02172—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides

- H01L21/02197—Forming insulating materials on a substrate characterised by the type of layer, e.g. type of material, porous/non-porous, pre-cursors, mixtures or laminates characterised by the material of the layer the material containing at least one metal element, e.g. metal oxides, metal nitrides, metal oxynitrides or metal carbides the material having a perovskite structure, e.g. BaTiO3

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/314—Inorganic layers

- H01L21/316—Inorganic layers composed of oxides or glassy oxides or oxide based glass

- H01L21/31691—Inorganic layers composed of oxides or glassy oxides or oxide based glass with perovskite structure

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L28/00—Passive two-terminal components without a potential-jump or surface barrier for integrated circuits; Details thereof; Multistep manufacturing processes therefor

- H01L28/40—Capacitors

- H01L28/55—Capacitors with a dielectric comprising a perovskite structure material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/02104—Forming layers

- H01L21/02107—Forming insulating materials on a substrate

- H01L21/02225—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer

- H01L21/0226—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process

- H01L21/02282—Forming insulating materials on a substrate characterised by the process for the formation of the insulating layer formation by a deposition process liquid deposition, e.g. spin-coating, sol-gel techniques, spray coating

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10B—ELECTRONIC MEMORY DEVICES

- H10B53/00—Ferroelectric RAM [FeRAM] devices comprising ferroelectric memory capacitors

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Materials Engineering (AREA)

- Ceramic Engineering (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Physics & Mathematics (AREA)

- Inorganic Chemistry (AREA)

- Semiconductor Memories (AREA)

- Semiconductor Integrated Circuits (AREA)

- Formation Of Insulating Films (AREA)

Description

第1強誘電体原料の粒子を、水熱電着法により電極に電着させて強誘電体初期核層を形成する工程と、

第2強誘電体原料の粒子を帯電させる工程と、

帯電させた前記第2強誘電体原料の粒子を、泳動電着法により前記強誘電体初期核層の上に電着させて強誘電体材料膜を形成する工程と、

前記強誘電体材料膜を熱処理する工程と、を含む。

前記第2強誘電体原料の粒子の表面が多孔質層で覆われたコーティング粒子を形成する工程と、

前記多孔質層にイオンを吸着させる工程と、を含むことができる。

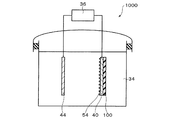

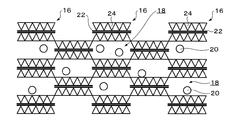

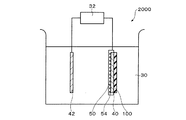

本実施の形態にかかる強誘電体膜の製造方法について説明する。図1〜5は、実施の形態にかかる強誘電体膜の製造方法を模式的に示す図である。強誘電体膜としては、特に限定されず、たとえば、ペロブスカイト構造を有する強誘電体膜(たとえば、PbZrTiO系)や層状ペロブスカイト構造を有する強誘電体膜(たとえば、BiLaTiO系、BiTiO系、SrBiTaO系)などがあげられる。

本実施例では、PbZrTiO系(以下、PZT系という)強誘電体膜を作製した。

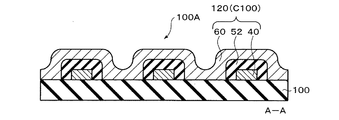

図6は、強誘電体メモリを模式的に示す図であり、図7は、メモリセルアレイの一部を拡大して示す平面図であり、図8は、図7のA−A線に沿った断面図である。平面図において、( )内の数字は最上層より下の層を示す。

Claims (8)

- 第1強誘電体原料の溶液を用いて、水熱電着法により電極に電着させて強誘電体初期核層を形成する工程と、

第2強誘電体原料の粒子を帯電させる工程と、

帯電させた前記第2強誘電体原料の粒子を、泳動電着法により前記強誘電体初期核層の上に電着させて強誘電体材料膜を形成する工程と、

前記強誘電体材料膜を熱処理することにより、結晶化する工程と、を含む、強誘電体膜の製造方法。 - 請求項1において、

前記強誘電体初期核層は島状に形成される、強誘電体膜の製造方法。 - 請求項1または2において、

前記第2強誘電体原料はアモルファス状である、強誘電体膜の製造方法。 - 請求項1〜3のいずれかにおいて、

前記第2強誘電体原料の粒子を帯電させる工程は、

前記第2強誘電体原料の粒子の表面が多孔質層で覆われたコーティング粒子を形成する工程と、

前記多孔質層にイオンを吸着させる工程と、を含む、強誘電体膜の製造方法。 - 請求項4において、

前記多孔質層はシリケートである、強誘電体膜の製造方法。 - 請求項1〜5のいずれかに記載の強誘電体膜の製造方法により形成された、強誘電体膜。

- 請求項6に記載の強誘電体膜を有する、強誘電体キャパシタ。

- 請求項6に記載の強誘電体膜を有する、強誘電体メモリ。

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003355046A JP4632018B2 (ja) | 2003-10-15 | 2003-10-15 | 強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ |

| US10/960,001 US7056750B2 (en) | 2003-10-15 | 2004-10-08 | Ferroelectric film, method of manufacturing ferroelectric film, ferroelectric capacitor, and ferroelectric memory |

| CNB2004100841060A CN100364065C (zh) | 2003-10-15 | 2004-10-15 | 强电介质膜的制造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2003355046A JP4632018B2 (ja) | 2003-10-15 | 2003-10-15 | 強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005123310A JP2005123310A (ja) | 2005-05-12 |

| JP2005123310A5 JP2005123310A5 (ja) | 2006-11-24 |

| JP4632018B2 true JP4632018B2 (ja) | 2011-02-16 |

Family

ID=34612779

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003355046A Expired - Fee Related JP4632018B2 (ja) | 2003-10-15 | 2003-10-15 | 強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US7056750B2 (ja) |

| JP (1) | JP4632018B2 (ja) |

| CN (1) | CN100364065C (ja) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3937174B2 (ja) | 2004-03-22 | 2007-06-27 | セイコーエプソン株式会社 | 強誘電体膜、強誘電体膜の製造方法、強誘電体キャパシタ、強誘電体メモリおよび圧電素子 |

| JP4983633B2 (ja) * | 2008-02-07 | 2012-07-25 | セイコーエプソン株式会社 | 誘電体膜の成膜方法および誘電体デバイスの製造方法 |

| KR101928438B1 (ko) * | 2012-08-08 | 2019-02-26 | 삼성전자주식회사 | 대전 입자의 진동을 이용한 전자기파 발생기 및 비트 생성기 |

| CN106683882B (zh) * | 2017-01-19 | 2018-07-06 | 广州天极电子科技有限公司 | 一种制备薄膜电容器的方法 |

| US10497774B2 (en) | 2017-10-23 | 2019-12-03 | Blackberry Limited | Small-gap coplanar tunable capacitors and methods for manufacturing thereof |

| US10332687B2 (en) | 2017-10-23 | 2019-06-25 | Blackberry Limited | Tunable coplanar capacitor with vertical tuning and lateral RF path and methods for manufacturing thereof |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000328223A (ja) * | 1999-05-25 | 2000-11-28 | Agency Of Ind Science & Technol | 積層構造体及びその原料粉、及び、圧電アクチュエータ |

| JP2001358031A (ja) * | 2000-06-13 | 2001-12-26 | Ube Ind Ltd | Pzt系結晶膜素子の実装方法 |

| JP2002208271A (ja) * | 2000-12-05 | 2002-07-26 | Sony Internatl Europ Gmbh | 強誘電体メモリの製造方法、情報格納方法及び記憶素子 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5818916A (ja) * | 1981-07-27 | 1983-02-03 | ソニー株式会社 | 焦電体の製造方法 |

| JP3254750B2 (ja) * | 1992-09-28 | 2002-02-12 | セイコーエプソン株式会社 | 強誘電体薄膜素子、インクジェット記録装置および強誘電体薄膜素子の製造方法 |

| JP3206454B2 (ja) * | 1996-10-21 | 2001-09-10 | 東海ゴム工業株式会社 | 複合酸化物薄膜及びその製造方法 |

| US6120846A (en) * | 1997-12-23 | 2000-09-19 | Advanced Technology Materials, Inc. | Method for the selective deposition of bismuth based ferroelectric thin films by chemical vapor deposition |

| JP2000150295A (ja) * | 1998-11-17 | 2000-05-30 | Hokuriku Electric Ind Co Ltd | コンデンサ及びその製造方法 |

| DE60120315T2 (de) * | 2000-10-04 | 2007-05-16 | Seiko Epson Corp. | Elektroforetische Vorrichtung und deren Herstellungsverfahren |

| KR20030025671A (ko) * | 2001-09-22 | 2003-03-29 | 주식회사 하이닉스반도체 | 커패시터의 제조방법 |

| JP2003218102A (ja) * | 2002-01-23 | 2003-07-31 | Komatsu Ltd | 誘電体膜の処理装置及び誘電体膜の処理方法 |

-

2003

- 2003-10-15 JP JP2003355046A patent/JP4632018B2/ja not_active Expired - Fee Related

-

2004

- 2004-10-08 US US10/960,001 patent/US7056750B2/en not_active Expired - Lifetime

- 2004-10-15 CN CNB2004100841060A patent/CN100364065C/zh not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000328223A (ja) * | 1999-05-25 | 2000-11-28 | Agency Of Ind Science & Technol | 積層構造体及びその原料粉、及び、圧電アクチュエータ |

| JP2001358031A (ja) * | 2000-06-13 | 2001-12-26 | Ube Ind Ltd | Pzt系結晶膜素子の実装方法 |

| JP2002208271A (ja) * | 2000-12-05 | 2002-07-26 | Sony Internatl Europ Gmbh | 強誘電体メモリの製造方法、情報格納方法及び記憶素子 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1607650A (zh) | 2005-04-20 |

| US7056750B2 (en) | 2006-06-06 |

| US20050117439A1 (en) | 2005-06-02 |

| CN100364065C (zh) | 2008-01-23 |

| JP2005123310A (ja) | 2005-05-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10192972B2 (en) | Semiconductor ferroelectric storage transistor and method for manufacturing same | |

| JP3258899B2 (ja) | 強誘電体薄膜素子、それを用いた半導体装置、及び強誘電体薄膜素子の製造方法 | |

| TW571432B (en) | Ferroelectric composite material, method of making same, and memory utilizing same | |

| KR100737636B1 (ko) | 금속 박막 및 그 형성 방법, 유전체 캐패시터 및 그 제조방법과 반도체 장치 | |

| JPH07502150A (ja) | 集積回路メモリー | |

| JPH1050960A (ja) | 強誘電体キャパシタ及び強誘電体メモリ装置と、これらの製造方法 | |

| CN108281544B (zh) | 基于铁电共存畴的多阻态铁电量子隧道结及制备方法 | |

| JP4632018B2 (ja) | 強誘電体膜、強誘電体膜の製造方法、および強誘電体キャパシタ、ならびに強誘電体メモリ | |

| JP2007318018A (ja) | 強誘電体メモリセル及び強誘電体メモリセルの製造方法 | |

| JPH1012832A (ja) | 強誘電体キャパシタの作製方法及び強誘電体メモリ装置の製造方法 | |

| JP4811551B2 (ja) | 強誘電体膜の製造方法および強誘電体キャパシタの製造方法 | |

| JP4596117B2 (ja) | 強誘電体膜の製造方法 | |

| JPH02154389A (ja) | 強誘電体メモリ | |

| CN1319256A (zh) | 减少四方性的铁电薄膜 | |

| JPH11243179A (ja) | 強誘電体メモリおよびそのパッケージング方法 | |

| JPH104181A (ja) | 強誘電体素子及び半導体装置 | |

| US7419579B2 (en) | Method for manufacturing a ferroelectric film | |

| KR20010109957A (ko) | 엘비티 용액, 엘비티 용액의 제조방법 및 이를 이용한엘비티 박막과 전자 소자의 제조방법 | |

| JP3924928B2 (ja) | 強誘電体材料及び強誘電体メモリ | |

| JP2004319995A (ja) | 強誘電体膜およびその製造方法ならびに半導体装置 | |

| JPH10270646A (ja) | 強誘電体薄膜素子の製造方法及び半導体装置 | |

| JP4349293B2 (ja) | 強誘電体薄膜の製造方法、圧電素子、強誘電体メモリ | |

| TW569461B (en) | A fabrication method for a ferroelectric capacitor applied in a low driving voltage | |

| JP3764650B2 (ja) | 強誘電体キャパシタとその製造方法およびその強誘電体キャパシタを備えた半導体装置 | |

| JPH08249876A (ja) | 強誘電体デバイス |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20060112 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061005 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061005 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100723 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100728 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100922 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101020 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101102 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131126 Year of fee payment: 3 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313532 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| LAPS | Cancellation because of no payment of annual fees |