JP4612783B2 - トナーの製造方法 - Google Patents

トナーの製造方法 Download PDFInfo

- Publication number

- JP4612783B2 JP4612783B2 JP2001298917A JP2001298917A JP4612783B2 JP 4612783 B2 JP4612783 B2 JP 4612783B2 JP 2001298917 A JP2001298917 A JP 2001298917A JP 2001298917 A JP2001298917 A JP 2001298917A JP 4612783 B2 JP4612783 B2 JP 4612783B2

- Authority

- JP

- Japan

- Prior art keywords

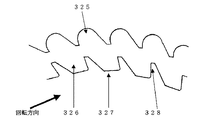

- rotor

- stator

- toner

- flat surface

- slope

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C2/00—Crushing or disintegrating by gyratory or cone crushers

- B02C2/10—Crushing or disintegrating by gyratory or cone crushers concentrically moved; Bell crushers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C13/00—Disintegrating by mills having rotary beater elements ; Hammer mills

- B02C13/10—Disintegrating by mills having rotary beater elements ; Hammer mills with horizontal rotor shaft and axial flow

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C17/00—Disintegrating by tumbling mills, i.e. mills having a container charged with the material to be disintegrated with or without special disintegrating members such as pebbles or balls

- B02C17/16—Mills in which a fixed container houses stirring means tumbling the charge

- B02C17/166—Mills in which a fixed container houses stirring means tumbling the charge of the annular gap type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C17/00—Disintegrating by tumbling mills, i.e. mills having a container charged with the material to be disintegrated with or without special disintegrating members such as pebbles or balls

- B02C17/18—Details

- B02C17/1815—Cooling or heating devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C17/00—Disintegrating by tumbling mills, i.e. mills having a container charged with the material to be disintegrated with or without special disintegrating members such as pebbles or balls

- B02C17/18—Details

- B02C17/183—Feeding or discharging devices

- B02C17/186—Adding fluid, other than for crushing by fluid energy

- B02C17/1875—Adding fluid, other than for crushing by fluid energy passing gas through crushing zone

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G9/00—Developers

- G03G9/08—Developers with toner particles

- G03G9/0802—Preparation methods

- G03G9/0808—Preparation methods by dry mixing the toner components in solid or softened state

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G9/00—Developers

- G03G9/08—Developers with toner particles

- G03G9/0802—Preparation methods

- G03G9/0815—Post-treatment

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G9/00—Developers

- G03G9/08—Developers with toner particles

- G03G9/0802—Preparation methods

- G03G9/0817—Separation; Classifying

-

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03G—ELECTROGRAPHY; ELECTROPHOTOGRAPHY; MAGNETOGRAPHY

- G03G9/00—Developers

- G03G9/08—Developers with toner particles

- G03G9/0819—Developers with toner particles characterised by the dimensions of the particles

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Developing Agents For Electrophotography (AREA)

- Crushing And Pulverization Processes (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001298917A JP4612783B2 (ja) | 2000-11-15 | 2001-09-28 | トナーの製造方法 |

| EP01127018A EP1207432B1 (en) | 2000-11-15 | 2001-11-14 | Toner production process |

| US09/987,506 US6630277B2 (en) | 2000-11-15 | 2001-11-15 | Toner production system |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000347410 | 2000-11-15 | ||

| JP2000-354000 | 2000-11-21 | ||

| JP2000-347410 | 2000-11-21 | ||

| JP2000354000 | 2000-11-21 | ||

| JP2001298917A JP4612783B2 (ja) | 2000-11-15 | 2001-09-28 | トナーの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2002221828A JP2002221828A (ja) | 2002-08-09 |

| JP2002221828A5 JP2002221828A5 (enExample) | 2008-11-06 |

| JP4612783B2 true JP4612783B2 (ja) | 2011-01-12 |

Family

ID=27345190

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001298917A Expired - Fee Related JP4612783B2 (ja) | 2000-11-15 | 2001-09-28 | トナーの製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US6630277B2 (enExample) |

| EP (1) | EP1207432B1 (enExample) |

| JP (1) | JP4612783B2 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101803441B1 (ko) * | 2011-12-18 | 2017-11-30 | 가부시키가이샤 츠카사 | 밀 |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2162410C1 (ru) * | 2000-07-13 | 2001-01-27 | Харина Рита Адамовна | Устройство для обработки и переработки материалов |

| JP3979589B2 (ja) | 2002-08-12 | 2007-09-19 | 株式会社リコー | 電子写真用トナーの製造方法 |

| JP4290107B2 (ja) * | 2003-10-20 | 2009-07-01 | キヤノン株式会社 | トナーの製造方法 |

| CN100339957C (zh) * | 2003-10-24 | 2007-09-26 | 上海宏力半导体制造有限公司 | 在金属层蚀刻后移除光阻的方法 |

| JP2008225317A (ja) * | 2007-03-15 | 2008-09-25 | Ricoh Co Ltd | 静電荷像現像用トナー |

| JP5261002B2 (ja) * | 2008-03-31 | 2013-08-14 | アシザワ・ファインテック株式会社 | メディア混合式ミル |

| JP5527942B2 (ja) * | 2008-04-22 | 2014-06-25 | キヤノン株式会社 | 粉砕機及びトナー製造装置 |

| US9421549B2 (en) * | 2010-04-22 | 2016-08-23 | A New Way Of Living Pty Ltd | Material treatment and apparatus |

| WO2012125834A2 (en) * | 2011-03-15 | 2012-09-20 | Nordell Lawrence K | Conjugate anvil hammer mill |

| JP2013215666A (ja) * | 2012-04-06 | 2013-10-24 | Ricoh Co Ltd | メディア攪拌型ミル及び分散体の製造方法 |

| HK1177381A2 (en) * | 2012-12-21 | 2013-08-23 | Ltg Green-Tech R&D Company Limited | A system and method for processing objects having contaminating particles |

| JP2014176829A (ja) * | 2013-03-15 | 2014-09-25 | Ricoh Co Ltd | 機械式粉砕機、トナー製造装置及びトナー製造方法 |

| TWI602037B (zh) | 2013-07-31 | 2017-10-11 | 佳能股份有限公司 | 調色劑 |

| US9588450B2 (en) | 2013-07-31 | 2017-03-07 | Canon Kabushiki Kaisha | Magnetic toner |

| CN105363535A (zh) * | 2015-09-10 | 2016-03-02 | 江阴碳谷科技有限公司 | 一种石墨烯干态剥离装置、生产系统及生产干态石墨烯的方法 |

| US9897932B2 (en) | 2016-02-04 | 2018-02-20 | Canon Kabushiki Kaisha | Toner |

| JP6900279B2 (ja) | 2016-09-13 | 2021-07-07 | キヤノン株式会社 | トナー及びトナーの製造方法 |

| CN106475210B (zh) * | 2016-10-21 | 2018-05-22 | 江中药业股份有限公司 | 一种超低湿低温进风粉碎设备 |

| CN110402417B (zh) * | 2017-03-13 | 2023-03-28 | 株式会社理光 | 调色剂、成像方法、成像设备和处理卡盒 |

| CN112638539A (zh) | 2018-08-28 | 2021-04-09 | 加拿大矿业创新委员会 | 单辊研磨机 |

| JP7512162B2 (ja) * | 2020-10-13 | 2024-07-08 | キヤノン株式会社 | トナー用粉砕装置及びトナーの製造方法 |

| CN113082966A (zh) * | 2021-03-02 | 2021-07-09 | 王洪 | 一种应用于大气治理装置中的脱硫脱硝剂的连续供给装置 |

| EP4059607A1 (de) * | 2021-03-18 | 2022-09-21 | Bühler AG | Kolloidmühle |

| JP2022166401A (ja) * | 2021-04-21 | 2022-11-02 | キヤノン株式会社 | トナー製造用機械式粉砕機及びトナーを製造する粉砕工程システム |

| CN114130485B (zh) * | 2021-11-25 | 2022-06-14 | 东莞市华汇精密机械有限公司 | 双凸钉棒销式纳米砂磨机 |

| JP7075163B1 (ja) | 2022-01-05 | 2022-05-25 | 株式会社辰巳エヤーエンジニアリング | 衝撃ブロア装置 |

| CN117866709A (zh) * | 2024-01-12 | 2024-04-12 | 江苏卫生健康职业学院 | 一种超临界二氧化碳萃取设备 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH359596A (de) * | 1957-01-18 | 1962-01-15 | Voith Gmbh J M | Entstipper |

| US3464636A (en) * | 1966-12-14 | 1969-09-02 | Robert C Byers | Grinding and mixing apparatus and method |

| JPS5442141A (en) | 1977-09-10 | 1979-04-03 | Canon Inc | Developing method |

| GB2006055B (en) | 1977-09-10 | 1982-07-07 | Canon Kk | Method and apparatus for image development |

| US4292387A (en) | 1978-07-28 | 1981-09-29 | Canon Kabushiki Kaisha | Magnetic developing method under A.C. electrical bias and apparatus therefor |

| JPS5832375B2 (ja) | 1978-07-28 | 1983-07-12 | キヤノン株式会社 | 現像方法 |

| US4562972A (en) * | 1983-04-13 | 1986-01-07 | Kawasaki Jukogyo Kabushiki Kaisha | Micropulverizer |

| US4839255A (en) * | 1987-03-31 | 1989-06-13 | Canon Kabushiki Kaisha | Process for producing toner for developing electrostatic images |

| JP3273394B2 (ja) * | 1993-11-30 | 2002-04-08 | 株式会社リコー | 機械式粉砕装置 |

| JPH07301950A (ja) * | 1994-04-28 | 1995-11-14 | Canon Inc | 現像剤及び画像形成方法 |

| JPH0871439A (ja) * | 1994-09-05 | 1996-03-19 | Dainippon Ink & Chem Inc | 粉砕機 |

| EP0775526B1 (en) | 1995-11-24 | 2002-01-09 | Nisshin Seifun Group Inc. | Mechanical grinding apparatus |

| JP3900311B2 (ja) * | 1995-11-24 | 2007-04-04 | 株式会社日清製粉グループ本社 | 機械式粉砕装置 |

| JP3884826B2 (ja) | 1996-07-30 | 2007-02-21 | キヤノン株式会社 | 固体粒子の表面の処理装置、固体粒子の表面の処理方法及びトナーの製造方法 |

| JPH10211438A (ja) * | 1997-01-29 | 1998-08-11 | Minolta Co Ltd | 機械式粉砕機およびこれを用いた電子写真用トナーの製造方法 |

-

2001

- 2001-09-28 JP JP2001298917A patent/JP4612783B2/ja not_active Expired - Fee Related

- 2001-11-14 EP EP01127018A patent/EP1207432B1/en not_active Expired - Lifetime

- 2001-11-15 US US09/987,506 patent/US6630277B2/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101803441B1 (ko) * | 2011-12-18 | 2017-11-30 | 가부시키가이샤 츠카사 | 밀 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1207432B1 (en) | 2012-10-31 |

| US20020086231A1 (en) | 2002-07-04 |

| EP1207432A2 (en) | 2002-05-22 |

| EP1207432A3 (en) | 2004-05-26 |

| US6630277B2 (en) | 2003-10-07 |

| JP2002221828A (ja) | 2002-08-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4612783B2 (ja) | トナーの製造方法 | |

| US6586151B1 (en) | Toner, process for producing toner image forming method and apparatus unit | |

| US7506830B2 (en) | Apparatus for modifying surfaces of toner particles | |

| JP4545897B2 (ja) | トナー | |

| JP4235567B2 (ja) | トナーの製造方法 | |

| JP2003173046A (ja) | トナーの製造方法 | |

| JP4422889B2 (ja) | トナーの製造方法 | |

| JP4448019B2 (ja) | トナーの製造方法およびトナー粒子の表面を改質するための装置 | |

| JP2003262981A (ja) | トナーの製造方法 | |

| JP3943793B2 (ja) | トナーの製造方法 | |

| JP4065494B2 (ja) | トナーの製造方法 | |

| JP2002229266A (ja) | トナーの製造方法 | |

| JP4497712B2 (ja) | 機械式粉砕機及びトナーの製造方法 | |

| JP3870032B2 (ja) | トナーの製造方法 | |

| JP4208693B2 (ja) | トナーの製造方法及びトナー粒子表面改質装置 | |

| JP2008122754A (ja) | トナー表面改質装置及びトナーの製造方法 | |

| JP2003103187A (ja) | トナーの製造方法 | |

| JP3817432B2 (ja) | トナー及び画像形成方法 | |

| JP4474036B2 (ja) | トナー及びトナーの製造方法 | |

| JP2002189314A (ja) | トナーの製造方法 | |

| JP2002186869A (ja) | 機械式粉砕機及びトナーの製造方法 | |

| JP2002040702A (ja) | トナー | |

| JP2002365854A (ja) | トナー,画像形成方法及びプロセスカートリッジ | |

| JP2002278151A (ja) | トナーの製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080924 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080924 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100527 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100601 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100802 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20100802 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20101012 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20101016 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131022 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4612783 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |