JP3992463B2 - タイヤ加硫装置 - Google Patents

タイヤ加硫装置 Download PDFInfo

- Publication number

- JP3992463B2 JP3992463B2 JP2001258389A JP2001258389A JP3992463B2 JP 3992463 B2 JP3992463 B2 JP 3992463B2 JP 2001258389 A JP2001258389 A JP 2001258389A JP 2001258389 A JP2001258389 A JP 2001258389A JP 3992463 B2 JP3992463 B2 JP 3992463B2

- Authority

- JP

- Japan

- Prior art keywords

- mold

- base plate

- bladder

- tire

- slide block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000007246 mechanism Effects 0.000 claims description 25

- 238000004073 vulcanization Methods 0.000 claims description 24

- 238000010438 heat treatment Methods 0.000 claims description 15

- 239000012530 fluid Substances 0.000 claims description 11

- 238000007789 sealing Methods 0.000 claims description 5

- 230000003028 elevating effect Effects 0.000 claims description 3

- 230000009956 central mechanism Effects 0.000 description 6

- 238000000034 method Methods 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 1

- 241001122767 Theaceae Species 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000013022 venting Methods 0.000 description 1

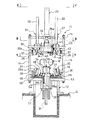

Images

Landscapes

- Heating, Cooling, Or Curing Plastics Or The Like In General (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001258389A JP3992463B2 (ja) | 2001-08-28 | 2001-08-28 | タイヤ加硫装置 |

| US10/250,552 US20040046286A1 (en) | 2001-08-28 | 2002-08-27 | Method and device for vulcanizing tire |

| EP02760756A EP1422036A4 (en) | 2001-08-28 | 2002-08-27 | METHOD AND DEVICE FOR VULCANIZING PNEUMATIC |

| PCT/JP2002/008595 WO2003020487A1 (fr) | 2001-08-28 | 2002-08-27 | Procede et dispositif de vulcanisation de pneumatique |

| KR10-2003-7011395A KR20040028723A (ko) | 2001-08-28 | 2002-08-27 | 타이어 가황 방법 및 장치 |

| CNA028054679A CN1492796A (zh) | 2001-08-28 | 2002-08-27 | 轮胎硫化方法及装置 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001258389A JP3992463B2 (ja) | 2001-08-28 | 2001-08-28 | タイヤ加硫装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003062832A JP2003062832A (ja) | 2003-03-05 |

| JP2003062832A5 JP2003062832A5 (enExample) | 2004-10-28 |

| JP3992463B2 true JP3992463B2 (ja) | 2007-10-17 |

Family

ID=19085924

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001258389A Expired - Fee Related JP3992463B2 (ja) | 2001-08-28 | 2001-08-28 | タイヤ加硫装置 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3992463B2 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005009713A1 (ja) * | 2003-07-25 | 2005-02-03 | Fuji Shoji Co., Ltd. | タイヤの加硫方法及び同方法を実施するための加硫機 |

| JP5694932B2 (ja) * | 2009-06-23 | 2015-04-01 | 株式会社ブリヂストン | 加硫タイヤの製造方法、及び、加硫装置 |

| JP5336272B2 (ja) * | 2009-06-23 | 2013-11-06 | 株式会社ブリヂストン | 加硫タイヤの製造方法、及び、加硫装置 |

| CN102700035B (zh) * | 2011-01-17 | 2014-09-24 | 潍坊跃龙橡胶有限公司 | 一种间歇式热水循环稳压保温轮胎硫化工艺 |

| CN107718442A (zh) * | 2017-10-23 | 2018-02-23 | 昆山众异特机械工业有限公司 | 一种模具 |

| CN110239125A (zh) * | 2018-03-09 | 2019-09-17 | 四川轮胎橡胶(集团)股份有限公司 | B型轮胎定型硫化机的胶囊夹具 |

| CN108621343B (zh) * | 2018-04-27 | 2024-09-27 | 宫达 | 轮胎活络模具限位机构及轮胎活络模具 |

| CN108481768A (zh) * | 2018-05-23 | 2018-09-04 | 青岛万龙智控科技有限公司 | 机模一体硫化机及其方法 |

| CN116653331B (zh) * | 2023-07-31 | 2023-09-29 | 山东力创模具股份有限公司 | 一种轮胎硫化机及其使用方法 |

| CN119408020B (zh) * | 2024-09-09 | 2025-04-11 | 南京固瑞橡胶有限公司 | 一种橡胶板加工用硫化装置及其控制方法 |

-

2001

- 2001-08-28 JP JP2001258389A patent/JP3992463B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003062832A (ja) | 2003-03-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3992463B2 (ja) | タイヤ加硫装置 | |

| US20040046286A1 (en) | Method and device for vulcanizing tire | |

| US12459222B2 (en) | Tire vulcanization device and method | |

| KR0138108B1 (ko) | 자동차 공기타이어 경화를 위한 방법 및 장치 | |

| JP3701087B2 (ja) | タイヤ加硫方法および装置 | |

| JP7469603B2 (ja) | タイヤ加硫方法 | |

| US4606714A (en) | Tire press mechanism | |

| US4444715A (en) | Method of making tires | |

| JP3865503B2 (ja) | タイヤ加硫装置およびタイヤ加硫装置の金型交換方法並びにタイヤ加硫方法 | |

| JPS5830138B2 (ja) | 生タイヤの上方ビ−ドを加硫プレスの金型の上方部分内に心決めしかつ位置決めする方法および装置 | |

| KR20080034018A (ko) | 타이어 가류 방법 및 타이어 가류 장치 | |

| US5026515A (en) | Crude tire setting method in tire vulcanizing press | |

| US8097201B2 (en) | Bisplit mold for tire forming and process for manufacturing tire therewith | |

| US3816217A (en) | Method and apparatus for retreading tires | |

| JP4027638B2 (ja) | タイヤ加硫コンテナーにおけるセグメント摺動装置 | |

| JP3865500B2 (ja) | タイヤ加硫装置およびタイヤ加硫装置のモールド交換方法並びにタイヤ加硫方法 | |

| KR100888279B1 (ko) | 타이어 가류몰드의 센터포스트장치 | |

| JP2001322132A (ja) | タイヤ加硫用コンテナ | |

| JP2709505B2 (ja) | 自動車用タイヤの加硫装置 | |

| JPH02200405A (ja) | タイヤ加硫機のグリーンタイヤ挿入方法及び装置 | |

| JP2004009313A (ja) | タイヤ加硫装置 | |

| JP2018058251A (ja) | タイヤ加硫装置、及びタイヤ加硫方法 | |

| JP7469594B2 (ja) | タイヤ加硫方法 | |

| JP2003136532A (ja) | タイヤ加硫装置における型締め固定装置 | |

| JP2003236842A (ja) | タイヤ加硫機における真空装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060704 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060901 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20070123 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070322 |

|

| A911 | Transfer of reconsideration by examiner before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20070405 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20070717 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20070724 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100803 Year of fee payment: 3 |

|

| LAPS | Cancellation because of no payment of annual fees |