JP3692437B2 - ヒートシンクの製造方法 - Google Patents

ヒートシンクの製造方法 Download PDFInfo

- Publication number

- JP3692437B2 JP3692437B2 JP13059897A JP13059897A JP3692437B2 JP 3692437 B2 JP3692437 B2 JP 3692437B2 JP 13059897 A JP13059897 A JP 13059897A JP 13059897 A JP13059897 A JP 13059897A JP 3692437 B2 JP3692437 B2 JP 3692437B2

- Authority

- JP

- Japan

- Prior art keywords

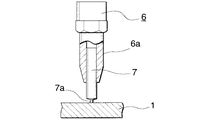

- pin

- substrate material

- shaped

- heat sink

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 27

- 239000000758 substrate Substances 0.000 claims description 67

- 239000000463 material Substances 0.000 claims description 61

- 238000000034 method Methods 0.000 description 9

- 238000003466 welding Methods 0.000 description 7

- 238000005520 cutting process Methods 0.000 description 6

- 238000010438 heat treatment Methods 0.000 description 5

- 238000005242 forging Methods 0.000 description 4

- 238000004080 punching Methods 0.000 description 4

- 230000000694 effects Effects 0.000 description 3

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- 238000001816 cooling Methods 0.000 description 2

- 230000007423 decrease Effects 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 230000004927 fusion Effects 0.000 description 1

- 230000017525 heat dissipation Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Landscapes

- Cooling Or The Like Of Semiconductors Or Solid State Devices (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP13059897A JP3692437B2 (ja) | 1997-05-21 | 1997-05-21 | ヒートシンクの製造方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP13059897A JP3692437B2 (ja) | 1997-05-21 | 1997-05-21 | ヒートシンクの製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JPH10321774A JPH10321774A (ja) | 1998-12-04 |

| JPH10321774A5 JPH10321774A5 (enExample) | 2005-04-07 |

| JP3692437B2 true JP3692437B2 (ja) | 2005-09-07 |

Family

ID=15038048

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP13059897A Expired - Fee Related JP3692437B2 (ja) | 1997-05-21 | 1997-05-21 | ヒートシンクの製造方法 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3692437B2 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6591897B1 (en) * | 2002-02-20 | 2003-07-15 | Delphi Technologies, Inc. | High performance pin fin heat sink for electronics cooling |

| JP5028147B2 (ja) * | 2007-05-29 | 2012-09-19 | 株式会社アライドマテリアル | 半導体装置用ヒートスプレッダとその製造方法 |

| KR100877400B1 (ko) | 2007-08-17 | 2009-01-07 | 최동철 | 히트싱크 조립장치 |

| KR100888646B1 (ko) | 2007-08-17 | 2009-03-17 | 최동철 | 히트싱크 조립장치 |

| CN102183161A (zh) * | 2011-01-25 | 2011-09-14 | 国研高能(北京)稳态传热传质技术研究院有限公司 | 一种均热板 |

| JP6064191B2 (ja) * | 2012-08-30 | 2017-01-25 | 太陽工業株式会社 | ヒートシンク及びヒートシンクの製造方法 |

| CN104124331A (zh) * | 2014-07-04 | 2014-10-29 | 张逸兴 | 一种led的散热装置 |

| JP6775374B2 (ja) | 2016-10-07 | 2020-10-28 | 昭和電工株式会社 | 放熱ユニットの製造方法 |

| JP7243262B2 (ja) | 2019-02-15 | 2023-03-22 | 富士電機株式会社 | 半導体モジュール、車両および製造方法 |

| WO2021045211A1 (ja) * | 2019-09-06 | 2021-03-11 | 大日本印刷株式会社 | ベーパーチャンバ、電子機器、ベーパーチャンバ用シート、ベーパーチャンバ用の中間体が多面付けされたシート、ベーパーチャンバ用の中間体が多面付けされたシートが巻かれたロール、ベーパーチャンバ用の中間体 |

-

1997

- 1997-05-21 JP JP13059897A patent/JP3692437B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPH10321774A (ja) | 1998-12-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3692437B2 (ja) | ヒートシンクの製造方法 | |

| CA1059396A (en) | Method of sizing heat exchange panels | |

| MXPA04000495A (es) | MeTODO PARA HACER UNA ALETA ALANCEADA Y DESFASADA. | |

| US9073143B2 (en) | Automation of reaction metallurgical joining for copper conductors | |

| JPS61198508A (ja) | 電線識別用スリーブ及びその形成方法 | |

| JPH10321774A5 (enExample) | ||

| JPS63264218A (ja) | 熱交換器用チユ−ブの製造方法およびその装置 | |

| JP2002071286A (ja) | 熱交換器用偏平チューブおよびその製造方法 | |

| ITMI980924A1 (it) | Macchina con serie di stampi e metodo di fabbricazione di alette scambiatrici di calore | |

| JP7021648B2 (ja) | グランドバー付はんだ及び同軸ケーブルアレイ製造方法 | |

| JPH0880013A (ja) | 突起部を有した鉄心板からなる鉄心およびその製造方法とその鉄心板のプレス抜き型とその鉄心板の製造装置およびその鉄心板の製造方法 | |

| US7256364B2 (en) | Method for simultaneous resistance brazing of adjacent conductor joints | |

| JPH02268966A (ja) | 熱交換器の製造方法 | |

| US6511406B1 (en) | Method and apparatus for producing a compression preservation bag | |

| JPS63185627A (ja) | ハニカム構造体の製造方法 | |

| JP3575671B2 (ja) | 対導線列の端部接合方法 | |

| JP2542553B2 (ja) | 合成樹脂製装飾片の製造方法 | |

| CA2563604C (en) | Stranded bar to solidified bar braze method and series loop connection | |

| JP3793409B2 (ja) | 温熱発生体及びその製造方法 | |

| JPH0356808B2 (enExample) | ||

| JP2000323367A (ja) | 電極箔帯の巻取り装置 | |

| EP0191601A2 (en) | Wire marker sleeve and assembly and method of forming a wire marker sleeve and assembly thereof | |

| JPH0147256B2 (enExample) | ||

| JPH04184822A (ja) | 電気接点付き端子の製造方法 | |

| JP2732739B2 (ja) | 導体箔の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20040518 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20040518 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20050201 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050208 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050307 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050408 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20050510 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20050606 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| LAPS | Cancellation because of no payment of annual fees |