JP2011527830A - 導体間隙が縮小された超小型電子相互接続素子 - Google Patents

導体間隙が縮小された超小型電子相互接続素子 Download PDFInfo

- Publication number

- JP2011527830A JP2011527830A JP2011517428A JP2011517428A JP2011527830A JP 2011527830 A JP2011527830 A JP 2011527830A JP 2011517428 A JP2011517428 A JP 2011517428A JP 2011517428 A JP2011517428 A JP 2011517428A JP 2011527830 A JP2011527830 A JP 2011527830A

- Authority

- JP

- Japan

- Prior art keywords

- metal

- metal line

- layer

- lines

- line

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B81—MICROSTRUCTURAL TECHNOLOGY

- B81B—MICROSTRUCTURAL DEVICES OR SYSTEMS, e.g. MICROMECHANICAL DEVICES

- B81B7/00—Microstructural systems; Auxiliary parts of microstructural devices or systems

- B81B7/0006—Interconnects

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/52—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B81—MICROSTRUCTURAL TECHNOLOGY

- B81C—PROCESSES OR APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OR TREATMENT OF MICROSTRUCTURAL DEVICES OR SYSTEMS

- B81C1/00—Manufacture or treatment of devices or systems in or on a substrate

- B81C1/00436—Shaping materials, i.e. techniques for structuring the substrate or the layers on the substrate

- B81C1/00523—Etching material

- B81C1/00539—Wet etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/48—Manufacture or treatment of parts, e.g. containers, prior to assembly of the devices, using processes not provided for in a single one of the groups H01L21/18 - H01L21/326 or H10D48/04 - H10D48/07

- H01L21/4814—Conductive parts

- H01L21/4846—Leads on or in insulating or insulated substrates, e.g. metallisation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/48—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor

- H01L23/488—Arrangements for conducting electric current to or from the solid state body in operation, e.g. leads, terminal arrangements ; Selection of materials therefor consisting of soldered or bonded constructions

- H01L23/498—Leads, i.e. metallisations or lead-frames on insulating substrates, e.g. chip carriers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/52—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames

- H01L23/538—Arrangements for conducting electric current within the device in operation from one component to another, i.e. interconnections, e.g. wires, lead frames the interconnection structure between a plurality of semiconductor chips being formed on, or in, insulating substrates

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

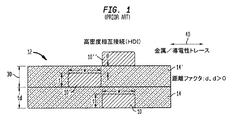

- H01L24/18—High density interconnect [HDI] connectors; Manufacturing methods related thereto

- H01L24/19—Manufacturing methods of high density interconnect preforms

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/18—High density interconnect [HDI] connectors; Manufacturing methods related thereto

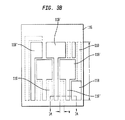

- H01L24/23—Structure, shape, material or disposition of the high density interconnect connectors after the connecting process

- H01L24/24—Structure, shape, material or disposition of the high density interconnect connectors after the connecting process of an individual high density interconnect connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/18—High density interconnect [HDI] connectors; Manufacturing methods related thereto

- H01L2224/23—Structure, shape, material or disposition of the high density interconnect connectors after the connecting process

- H01L2224/24—Structure, shape, material or disposition of the high density interconnect connectors after the connecting process of an individual high density interconnect connector

- H01L2224/244—Connecting portions

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/0001—Technical content checked by a classifier

- H01L2924/0002—Not covered by any one of groups H01L24/00, H01L24/00 and H01L2224/00

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1204—Optical Diode

- H01L2924/12042—LASER

Landscapes

- Engineering & Computer Science (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Ceramic Engineering (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Manufacturing Of Printed Circuit Boards (AREA)

- Manufacturing Of Printed Wiring (AREA)

- Production Of Multi-Layered Print Wiring Board (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13445708P | 2008-07-09 | 2008-07-09 | |

| US61/134,457 | 2008-07-09 | ||

| PCT/US2009/004033 WO2010005592A2 (en) | 2008-07-09 | 2009-07-08 | Microelectronic interconnect element with decreased conductor spacing |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2011527830A true JP2011527830A (ja) | 2011-11-04 |

| JP2011527830A5 JP2011527830A5 (enExample) | 2012-09-13 |

Family

ID=41396280

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2011517428A Pending JP2011527830A (ja) | 2008-07-09 | 2009-07-08 | 導体間隙が縮小された超小型電子相互接続素子 |

Country Status (4)

| Country | Link |

|---|---|

| US (4) | US8461460B2 (enExample) |

| JP (1) | JP2011527830A (enExample) |

| KR (1) | KR101654820B1 (enExample) |

| WO (1) | WO2010005592A2 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7914296B1 (en) * | 2010-01-05 | 2011-03-29 | Exatron, Inc. | Interconnecting assembly with conductive lever portions on a support film |

| US9761489B2 (en) | 2013-08-20 | 2017-09-12 | Applied Materials, Inc. | Self-aligned interconnects formed using substractive techniques |

| US9159670B2 (en) * | 2013-08-29 | 2015-10-13 | Qualcomm Incorporated | Ultra fine pitch and spacing interconnects for substrate |

| US9263349B2 (en) * | 2013-11-08 | 2016-02-16 | Globalfoundries Inc. | Printing minimum width semiconductor features at non-minimum pitch and resulting device |

| US9609751B2 (en) * | 2014-04-11 | 2017-03-28 | Qualcomm Incorporated | Package substrate comprising surface interconnect and cavity comprising electroless fill |

| CN105097758B (zh) * | 2014-05-05 | 2018-10-26 | 日月光半导体制造股份有限公司 | 衬底、其半导体封装及其制造方法 |

| ITUB20155408A1 (it) * | 2015-11-10 | 2017-05-10 | St Microelectronics Srl | Substrato di packaging per dispositivi a semiconduttore, dispositivo e procedimento corrispondenti |

| US11063758B1 (en) | 2016-11-01 | 2021-07-13 | F5 Networks, Inc. | Methods for facilitating cipher selection and devices thereof |

| US10636758B2 (en) * | 2017-10-05 | 2020-04-28 | Texas Instruments Incorporated | Expanded head pillar for bump bonds |

| CN109673112B (zh) * | 2017-10-13 | 2021-08-20 | 鹏鼎控股(深圳)股份有限公司 | 柔性电路板以及柔性电路板的制作方法 |

| US11018024B2 (en) * | 2018-08-02 | 2021-05-25 | Nxp Usa, Inc. | Method of fabricating embedded traces |

| US11251117B2 (en) * | 2019-09-05 | 2022-02-15 | Intel Corporation | Self aligned gratings for tight pitch interconnects and methods of fabrication |

| US11791320B2 (en) | 2021-11-22 | 2023-10-17 | Qualcomm Incorporated | Integrated circuit (IC) packages employing a package substrate with a double side embedded trace substrate (ETS), and related fabrication methods |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03110849A (ja) * | 1989-09-25 | 1991-05-10 | Nec Corp | 半導体装置 |

| JPH08330473A (ja) * | 1995-05-31 | 1996-12-13 | Samsung Electron Co Ltd | ソルダーボールの装着溝を有する印刷回路基板とこれを使用したボールグリッドアレイパッケージ |

| US5846876A (en) * | 1996-06-05 | 1998-12-08 | Advanced Micro Devices, Inc. | Integrated circuit which uses a damascene process for producing staggered interconnect lines |

| US5854128A (en) * | 1996-04-29 | 1998-12-29 | Micron Technology, Inc. | Method for reducing capacitive coupling between conductive lines |

| JP2000031280A (ja) * | 1998-06-17 | 2000-01-28 | Siemens Ag | 集積回路のためのメタライゼ―ション装置 |

| JP2002198422A (ja) * | 2000-12-26 | 2002-07-12 | Toshiba Corp | 半導体装置およびその製造方法 |

| JP2002246466A (ja) * | 2001-02-08 | 2002-08-30 | Samsung Electronics Co Ltd | 多層配線構造を有する半導体素子及びその製造方法 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5072075A (en) * | 1989-06-28 | 1991-12-10 | Digital Equipment Corporation | Double-sided hybrid high density circuit board and method of making same |

| US5287619A (en) * | 1992-03-09 | 1994-02-22 | Rogers Corporation | Method of manufacture multichip module substrate |

| US5440805A (en) * | 1992-03-09 | 1995-08-15 | Rogers Corporation | Method of manufacturing a multilayer circuit |

| US5509553A (en) * | 1994-04-22 | 1996-04-23 | Litel Instruments | Direct etch processes for the manufacture of high density multichip modules |

| US5995328A (en) * | 1996-10-03 | 1999-11-30 | Quantum Corporation | Multi-layered integrated conductor trace array interconnect structure having optimized electrical parameters |

| US6222136B1 (en) * | 1997-11-12 | 2001-04-24 | International Business Machines Corporation | Printed circuit board with continuous connective bumps |

| US6849923B2 (en) | 1999-03-12 | 2005-02-01 | Kabushiki Kaisha Toshiba | Semiconductor device and manufacturing method of the same |

| JP3384995B2 (ja) * | 2000-05-18 | 2003-03-10 | 株式会社ダイワ工業 | 多層配線基板及びその製造方法 |

| US7670962B2 (en) * | 2002-05-01 | 2010-03-02 | Amkor Technology, Inc. | Substrate having stiffener fabrication method |

| US20040011555A1 (en) * | 2002-07-22 | 2004-01-22 | Chiu Tsung Chin | Method for manufacturing printed circuit board with stacked wires and printed circuit board manufacturing according to the mehtod |

| JP4133560B2 (ja) * | 2003-05-07 | 2008-08-13 | インターナショナル・ビジネス・マシーンズ・コーポレーション | プリント配線基板の製造方法およびプリント配線基板 |

| TWI286916B (en) * | 2004-10-18 | 2007-09-11 | Via Tech Inc | Circuit structure |

| US20080001297A1 (en) * | 2006-06-30 | 2008-01-03 | Stefanie Lotz | Laser patterning and conductive interconnect/materials forming techniques for fine line and space features |

-

2009

- 2009-07-08 US US12/459,864 patent/US8461460B2/en active Active

- 2009-07-08 KR KR1020117003020A patent/KR101654820B1/ko not_active Expired - Fee Related

- 2009-07-08 WO PCT/US2009/004033 patent/WO2010005592A2/en not_active Ceased

- 2009-07-08 JP JP2011517428A patent/JP2011527830A/ja active Pending

-

2013

- 2013-06-10 US US13/914,616 patent/US8900464B2/en active Active

-

2014

- 2014-12-01 US US14/557,120 patent/US9524947B2/en active Active

-

2016

- 2016-12-15 US US15/380,391 patent/US9856135B2/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH03110849A (ja) * | 1989-09-25 | 1991-05-10 | Nec Corp | 半導体装置 |

| JPH08330473A (ja) * | 1995-05-31 | 1996-12-13 | Samsung Electron Co Ltd | ソルダーボールの装着溝を有する印刷回路基板とこれを使用したボールグリッドアレイパッケージ |

| US5854128A (en) * | 1996-04-29 | 1998-12-29 | Micron Technology, Inc. | Method for reducing capacitive coupling between conductive lines |

| US5846876A (en) * | 1996-06-05 | 1998-12-08 | Advanced Micro Devices, Inc. | Integrated circuit which uses a damascene process for producing staggered interconnect lines |

| JP2000031280A (ja) * | 1998-06-17 | 2000-01-28 | Siemens Ag | 集積回路のためのメタライゼ―ション装置 |

| JP2002198422A (ja) * | 2000-12-26 | 2002-07-12 | Toshiba Corp | 半導体装置およびその製造方法 |

| JP2002246466A (ja) * | 2001-02-08 | 2002-08-30 | Samsung Electronics Co Ltd | 多層配線構造を有する半導体素子及びその製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20110039337A (ko) | 2011-04-15 |

| WO2010005592A3 (en) | 2010-10-07 |

| US20150087146A1 (en) | 2015-03-26 |

| US8900464B2 (en) | 2014-12-02 |

| WO2010005592A8 (en) | 2011-02-10 |

| US8461460B2 (en) | 2013-06-11 |

| US20100009554A1 (en) | 2010-01-14 |

| US20130341299A1 (en) | 2013-12-26 |

| US9856135B2 (en) | 2018-01-02 |

| US20170096329A1 (en) | 2017-04-06 |

| US9524947B2 (en) | 2016-12-20 |

| KR101654820B1 (ko) | 2016-09-06 |

| WO2010005592A2 (en) | 2010-01-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9856135B2 (en) | Microelectronic interconnect element with decreased conductor spacing | |

| US7911805B2 (en) | Multilayer wiring element having pin interface | |

| KR101376265B1 (ko) | 배선 기판 및 그 제조 방법 | |

| JP5010737B2 (ja) | プリント配線板 | |

| US8610268B2 (en) | Semiconductor element, semiconductor element mounted board, and method of manufacturing semiconductor element | |

| JP2007311688A (ja) | 電子装置用基板およびその製造方法、並びに電子装置およびその製造方法 | |

| JP2015144157A (ja) | 回路基板、電子装置及び電子装置の製造方法 | |

| JP2014229689A (ja) | モジュールおよびその製造方法 | |

| JP4170266B2 (ja) | 配線基板の製造方法 | |

| CN101488487B (zh) | 元件搭载用基板、半导体组件及其制造方法及便携式设备 | |

| KR100934107B1 (ko) | 미세 피치의 금속 범프를 제공하는 인쇄회로기판 제조 방법 | |

| KR100908986B1 (ko) | 코어리스 패키지 기판 및 제조 방법 | |

| JP5295211B2 (ja) | 半導体モジュールの製造方法 | |

| JP2011035296A (ja) | 半導体パッケージ及びその製造方法、並びに電子装置 | |

| KR100925669B1 (ko) | 코어리스 패키지 기판 제조 공법에 의한 솔더 온 패드 제조방법 | |

| TWI420989B (zh) | 印刷電路板及其製造方法 | |

| JP2004207262A (ja) | 薄膜多層回路基板及びその製造方法 | |

| JP5511922B2 (ja) | 配線基板とその製造方法 | |

| KR20200105031A (ko) | 미세 피치 회로구조를 갖는 인쇄회로기판 및 그 제조 방법 | |

| JP2001358173A (ja) | 半導体装置及びその製造方法、回路基板並びに電子機器 | |

| KR20100104244A (ko) | 인쇄회로기판 및 그 제조 방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A712 Effective date: 20120516 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120629 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120709 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20120709 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130903 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20131203 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20131210 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20140303 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20140430 |