EP3288712B1 - Dispositif servant à l'usinage de surface - Google Patents

Dispositif servant à l'usinage de surface Download PDFInfo

- Publication number

- EP3288712B1 EP3288712B1 EP16724583.6A EP16724583A EP3288712B1 EP 3288712 B1 EP3288712 B1 EP 3288712B1 EP 16724583 A EP16724583 A EP 16724583A EP 3288712 B1 EP3288712 B1 EP 3288712B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roller

- force

- actuator

- belt

- frame

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000003754 machining Methods 0.000 title claims description 12

- 238000000034 method Methods 0.000 claims description 10

- 238000005259 measurement Methods 0.000 claims description 4

- 230000000694 effects Effects 0.000 claims 1

- 238000000227 grinding Methods 0.000 description 57

- 238000012545 processing Methods 0.000 description 12

- 239000000463 material Substances 0.000 description 3

- 230000000903 blocking effect Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000005498 polishing Methods 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 230000006978 adaptation Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 230000001934 delay Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- 238000013178 mathematical model Methods 0.000 description 1

- 238000001000 micrograph Methods 0.000 description 1

- 210000003205 muscle Anatomy 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 230000001052 transient effect Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/04—Machines or devices using grinding or polishing belts; Accessories therefor for grinding plane surfaces

- B24B21/12—Machines or devices using grinding or polishing belts; Accessories therefor for grinding plane surfaces involving a contact wheel or roller pressing the belt against the work

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/18—Accessories

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/16—Machines or devices using grinding or polishing belts; Accessories therefor for grinding other surfaces of particular shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B21/00—Machines or devices using grinding or polishing belts; Accessories therefor

- B24B21/18—Accessories

- B24B21/20—Accessories for controlling or adjusting the tracking or the tension of the grinding belt

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B27/00—Other grinding machines or devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B27/00—Other grinding machines or devices

- B24B27/0069—Other grinding machines or devices with means for feeding the work-pieces to the grinding tool, e.g. turntables, transfer means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B41/00—Component parts such as frames, beds, carriages, headstocks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B41/00—Component parts such as frames, beds, carriages, headstocks

- B24B41/005—Feeding or manipulating devices specially adapted to grinding machines

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B47/00—Drives or gearings; Equipment therefor

- B24B47/10—Drives or gearings; Equipment therefor for rotating or reciprocating working-spindles carrying grinding wheels or workpieces

- B24B47/12—Drives or gearings; Equipment therefor for rotating or reciprocating working-spindles carrying grinding wheels or workpieces by mechanical gearing or electric power

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B49/00—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation

- B24B49/08—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation involving liquid or pneumatic means

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B49/00—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation

- B24B49/16—Measuring or gauging equipment for controlling the feed movement of the grinding tool or work; Arrangements of indicating or measuring equipment, e.g. for indicating the start of the grinding operation taking regard of the load

Definitions

- the invention relates to a device for the automated machining or smoothing of surfaces of workpieces, for example for grinding workpiece surfaces.

- the contact force is the force with which the sanding belt acts on the workpiece surface.

- JP S63-089263 A device is described that regulates the contact force through suitable storage.

- the above-mentioned phenomena inevitably occur due to the inertia.

- a belt sander which has a contact disk and several deflection rollers around which a sanding belt is guided.

- the contact disk is rotatably mounted on a holder, which can be moved by means of a linear drive, and can tension the belt in such a way that grinding is prevented Workpiece is possible at different angles.

- JP 2009 016759 A discloses an apparatus for grinding a semiconductor wafer, having three fixed deflection rollers around which a belt 31 is guided, and two tension rollers which can be displaced by a guide part in order to contact and tension the belt.

- JP 2002 301659 A and EP 0 477 737 A1 each disclose a belt grinding machine, whereby the entire machine moves when a workpiece is processed.

- DE 100 13 340 A1 on which the preamble of claims 1 and 11 is based, discloses a belt grinding machine with an arrangement of at least one mounted drive roller or deflection roller, an adjustable tension roller with a force element loading the tension roller, a contact element that can be moved in at least one direction with a contact element in in this direction relative to a pressure element loading the workpiece and a sanding belt guided around the contact element, the drive roller or deflection roller and the tension roller.

- the contact element and the force element of the tension roller are functionally coupled to one another in such a way that the force element changes the position of the tension roller depending on the respective changes in position of the contact element that serve as a guide variable in such a way that a predeterminable pressure force between the contact element and the workpiece changes independently of the respective changes in position of the contact element sets.

- the object on which the invention is based is therefore to provide a device which enables complex grinding or polishing tasks to be carried out partially or fully automatically with improved quality.

- the device comprises a frame and a roller carrier on which a first roller is rotatably mounted and which is mounted on the frame so as to be displaceable along a first direction.

- the device comprises at least a second roller, which is mounted on the frame, and a belt which is guided at least around the two rollers, and due to the tension of which a resulting belt force acts on the roller carrier, the first roller only serving as a deflection roller.

- the device further comprises a tension roller for adjusting a pretensioning force in the band.

- the device further includes an actuator mechanically coupled to the frame and the roller carrier such that an adjustable actuator force acts between the frame and the first roller along the first direction.

- the band is guided with the help of the second roller - or with the help of the second roller and further rollers - in such a way that the resulting band force acting on the roller carrier acts approximately in a second direction, which is orthogonal to the first direction, when the actuator is deflected to a desired extent is.

- the actuator works purely force-controlled.

- a device for this purpose which has a frame, a roller carrier on which a first roller is rotatably mounted and which is mounted on the frame so as to be displaceable along a first direction, an actuator which is mechanically connected to the frame and the roller carrier is coupled, a second roller which is mounted on the frame, and a belt which is guided around the first and the second roller and which exerts a resulting belt force on the roller carrier, the first roller serving only as a deflection roller.

- the device further comprises a tension roller for adjusting a pretensioning force in the band.

- the method includes positioning the workpiece on the first roller, measuring a contact force between the first roller and the workpiece, and adjusting a contact force between the first roller and the workpiece by adjusting a force acting between the frame and the actuator.

- positioning the workpiece it is positioned relative to the device in such a way that the deflection of the actuator corresponds to its target deflection.

- the resulting belt force acting on the roller carrier acts approximately in one second direction that is orthogonal to the first direction.

- the reaction of the belt force on the actuator can therefore theoretically be reduced to zero.

- the actuator works purely force-controlled.

- the system comprises a processing device and a manipulator for positioning the workpiece relative to the processing device.

- This has a frame and a roller carrier on which a first roller is rotatably mounted and which is mounted on the frame so as to be displaceable along a first direction.

- the processing device comprises at least a second roller, which is mounted on the frame, and a belt which is guided at least around the two rollers, and due to the tension of which a resulting belt force acts on the roller carrier, the first roller only serving as a deflection roller.

- the system further includes a tension roller for adjusting a pre-tension force in the belt.

- the processing device further comprises an actuator that is mechanically coupled to the frame and the roller carrier such that an adjustable actuator force acts between the frame and the first roller along the first direction.

- the band is guided with the help of the second roller - or with the help of the second roller and further rollers - in such a way that the resulting band force acting on the roller carrier acts approximately in a second direction, which is orthogonal to the first direction, when the actuator is deflected to a desired extent is.

- the actuator works purely in a force-controlled manner and a position of the workpiece relative to the processing device is only determined by the manipulator.

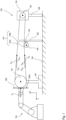

- FIG. 1 An example of a grinding device 100 known per se is shown in Figure 1 shown.

- the grinding device 100 is stationary and has a rotating grinding belt 102, which is guided over at least two rollers 101, 103. In this example it is assumed that the belt rotates clockwise.

- the sanding belt 102 is tensioned by a tensioning element 105 (tensioning roller), which is mounted in a linearly displaceable manner by a suitable bearing 130 (for example by means of a plain bearing).

- the components (rollers 101 and 103, clamping element 105) are connected to a frame 160 (eg a machine bed or a housing part) using one or more supports 401, 402, 403.

- the surface 200a of a workpiece 200 to be processed is pressed against the sanding belt 102 in the area of the first roller 101 while the sanding belt 102 is running.

- the contact force F K (grinding force) required for this can be set, for example, manually or with the help of a manipulator 150, which holds the workpiece.

- the manipulator 150 can be, for example, a standard industrial robot (with six degrees of freedom). Alternatively, however, another manually or mechanically operated clamping and/or pressing device can also be used as a manipulator.

- the contact force F K creates friction between the workpiece surface 200a and the Grinding belt 102 and material removal occurs.

- the main influencing factors for the machining result are the contact force F K per surface (support surface on which the sanding belt 102 and the surface of the workpiece 200a touch), hereinafter also referred to as contact pressure, and the rotational speed of the sanding belt 102. Since the contact surface is between the workpiece and grinding belt 102 generally does not change significantly during a grinding process, contact pressure and contact force F K are de facto proportional. In the area of corners and edges, the contact force (ie its target value) can be reduced accordingly due to the smaller contact surface.

- a correct setting (ie regulation) of the contact force F K is desirable throughout the entire machining process.

- Force control by the generally "rigid" manipulator proves to be difficult in known automated grinding devices, especially when placing the workpiece 200 on the grinding belt.

- transient disturbances (force peaks) in the contact force F K are very difficult to compensate for through control using conventional means. This is usually a result of the inertia of the moving parts of the manipulator 150 and limitations in the actuators (minimum dead time, maximum force or torque, etc.).

- Insufficient force control results in inhomogeneous micrographs with chatter marks. Chatter marks are surface irregularities caused by inadequate control of the contact force F K.

- the workpiece 200 is held and positioned by a manipulator 150.

- the manipulator 150 only requires a simple position control; the contact force control is implemented in the grinding machine 100 - as described below.

- Relatively inexpensive manipulators e.g. industrial robots

- the actuator 302 used for force control can be a simple linear actuator, for example an actuator with low static friction and passive compliance.

- Possible examples include pneumatic cylinders, air muscles, bellows cylinders, and electric direct drives (without gearboxes).

- a pneumatic cylinder is used as actuator 302.

- the actuator 302 does not act on the grinding machine 100 as a whole, but only on that roller of the grinding machine 100 that presses against the workpiece during operation (ie on the roller 101).

- the roller 101 is mounted on the frame 160 in a linearly displaceable manner (linear guide 140) (via the roller carrier 401).

- the actuator 302 acts between the roller carrier 401 and the frame 160.

- the actuator is mounted on the roller carrier 401 and on a further carrier 404, which is rigidly connected to the frame 160.

- the Roller 101 exerts an actuator force F A , which acts along the direction of movement (x-direction) of the linear guide 140. Due to the comparatively low mass of the first roller 101 (and the roller carrier 401), only small inertia forces occur on the actuator 302.

- the grinding device is in accordance with Fig. 2 constructed in the same way as the grinding device in the previous example Fig. 1 .

- the second role 103 is mounted immovably on the frame 160 via the (roller) carrier 403.

- immovable does not mean that the position of the roller 103 cannot be changed, for example to set a suitable tension in the sanding belt.

- the position of the roller 103 does not change during operation of the device (for example, during a grinding process).

- the roller 103 is driven (motor 104), whereas the roller 101 only serves as a deflection roller.

- the sanding belt 102 is guided around both rollers 101 and 103.

- a tensioning device can be provided for adjusting a pretension of the sanding belt.

- the tensioning device can, for example, have one or more tension rollers 105 which rest on the belt 102 and which can be moved approximately at right angles to the grinding belt 102 in order to tension the grinding belt 102.

- the tension rollers 105 are mounted on the roller carrier 402 with the aid of a linear guide 130, which in turn is rigidly connected to the frame 160.

- the pretension can be generated, for example, with the help of a spring which acts between the roller carrier 402 and the tension roller (or tension rollers) 105.

- the forces acting in the sanding belt 102 are in Fig. 2 shown as band forces F B1 (force in the upper part 102a of the band 102) and F B2 (force in the lower part 102b of the band 102), whereby both forces F B1 and F B2 each have a force component in the x direction (F B1,x or . F B2,x ) and have a force component in the y direction (F B1,y or F B1,y ).

- the resulting belt force F B,x acting on the roller 101 in the x direction also acts on the actuator 302 and thus against the actuator force F A.

- the band force F B, x must be known. This can either be measured (e.g. using a force sensor in the clamping device and the drive torque of the motor) or estimated using a mathematical model.

- actuator force F A and the resulting belt force F B,x in the effective direction (x direction) of actuator 302 are decoupled.

- An example of a suitable deflection of the sanding belt 102 is shown in Fig. 3 shown.

- FIG. 3 The example shown essentially corresponds to the previous example Fig. 2 , whereby two further deflection rollers 101a and 101b are arranged on the roller carrier 401 in addition to the deflection roller 101. Furthermore, two further deflection rollers 121a, 121b are provided, which are mounted immovably on the frame 160.

- the roller carrier 401 with the rollers 101, 101a and 101b is mounted on the frame 160 by means of the linear guide 140, the linear guide enabling the roller carrier 401 to be displaced in the horizontal direction (x direction) and blocking other degrees of freedom.

- the deflection rollers 101a and 101b as well as the deflection rollers 121a and 121b are arranged so that - at a nominal deflection x 0 (target deflection) of the actuator 302 - the resulting belt force F B 'acting on the roller carrier 401 is the actuator force F A (at least approximately) is at a right angle.

- the x component F B,x 'of the resulting belt force F B' is approximately zero, with the linear guide 140 allowing force transmission from the actuator 302 to the roller carrier 401 only in the x direction.

- Figure 4 shows the on a roll carrier 401 (e.g. from Fig. 3 ) acting forces in detail.

- Fig. 4c is a variant of Fig. 4a , in which the actuator force F A attacks exactly in the center of the roller carrier 401, so that all forces cancel out at the operating point and no torque acts on the roller carrier 4.

- Fig. 4a and Fig. 4b the relevant forces on the rollers 101, 101a, 101b mounted on the roller carrier 401 are shown again in detail.

- the rollers 101, 101a and 101b which are mounted displaceably in the x direction, as well as the sanding belt 102 and the workpiece 200 are shown.

- the position of the axes of rotation of the rollers 101, 101a and 101b relative to one another is fixed and does not change during operation.

- the actuator force F A and the contact force F K act on the rollers in the x direction (actuator and contact forces in other directions would be absorbed by the linear guide 140).

- Fig. 4a and Fig. 4b the relevant forces on the rollers 101, 101a, 101b mounted on the roller carrier 401 are shown again in detail.

- the actuator force F A and the contact force F K act on the rollers in the x direction (actuator and contact forces in other directions would be absorbed by the linear guide 140).

- the actuator 302 only acts on the roller carrier 401, which carries the deflection rollers 101, 101a, 101b, and not on the entire grinding device.

- the actuator force acts exactly at the center point C, so that the clamping forces F B1 ', F B2 ' and the friction force F R cancel each other out. In the same way, contact force F K and actuator force F A cancel each other out.

- Fig. 5 shows an alternative embodiment of the grinding device 100, which is also suitable for decoupling the actuator force F A and the belt forces F B1 , F B2 .

- the grinding device 100 is constructed in the same way as that in the previous example Fig. 4 .

- the linear guide 140 of the roller carrier 401 and the actuator 302 are compared to the example Fig. 4 rotated by 90 degrees.

- the frame 160 includes an arm 402 on which the roller carrier 401 is mounted (with the help of the linear guide 140).

- the actuator 302 acts in the vertical direction (x direction) between the arm 402 of the frame 160 and the roller carrier 401.

- the coordinate system is also rotated by 90 degrees compared to the previous example, so that the effective direction of the actuator 302 is the x- direction is. Additional deflection rollers are not essential in this exemplary embodiment necessary.

- the sanding belt 102 is only guided around the deflection roller 101 and the roller 103 (driven by the motor 104).

- a tensioning device with a tension roller 105 ensures the necessary pretension of the sanding belt 102.

- the belt forces acting on the displaceably mounted deflection roller are designated F B1 (force in the upper belt part) and F B2 (force in the lower belt part).

- the force components F B1,x and F B2,x in the x direction at least partially compensate each other (F B1,x >0 and F B2,x ⁇ 0), so that the resulting force component in the x direction F B1,x +F B2,x is negligibly small.

- the resulting force F B1,x +F B2,x is equal to zero and there is no reaction of the belt forces F B1 and F B2 on the actuator 302.

- Fig. 6a corresponds to the situation in Fig.

- the resulting belt force disappears in the x-direction

- ⁇ sin( ⁇ 2 ) and there is no reaction on the actuator 302 (for example because ⁇ 1 ⁇ 2 and

- Two deflection rollers 121a and 121b, which are firmly mounted on the frame 160, ensure that the angles ⁇ 1 and ⁇ 2 are equal to zero, so that the belt runs horizontally back and forth to the roller 101. Consequently, in this case, the resulting belt forces in the x direction are zero, provided that the factory return and thus the actuator 302 are at the operating point (x x 0 ).

- the previous example Fig. 3

- FIG. 7a shows devices which are not covered by the claims.

- Two rollers 101a and 101b are arranged on the roller carrier 401, on which the actuator 302 also acts.

- the belt 102 runs over the two rollers 101a, 101b essentially at right angles to the direction of action of the actuator 302.

- the workpiece 200 can be processed (eg ground or polished) between the rollers 101a, 101b; the tape can follow the contour of the workpiece 200 adjust.

- Fig. 7a constructed in the same way as the example Fig. 3 .

- Fig. 7b essentially corresponds to the previous example Fig.

- the carrier 401' (sliding carriage) instead has a sliding surface 101c along which the belt can slide essentially at right angles to the effective direction of the actuator 302.

- the band 102 runs essentially perpendicular to the effective direction of the actuator 302 at the operating point.

- the example according to Fig. 8 It is not the workpiece that is guided by the manipulator 150, but rather the grinding machine.

- the frame 160 (see e.g Fig. 3 ) is therefore part of the manipulator 150 or rigidly connected to it (its tool center point TCP).

- the workpiece 200 can be arranged on a fixed support (not shown).

- Two further deflection rollers 101a and 101b are arranged on a roller carrier 401 in addition to the deflection roller 101.

- two further deflection rollers 105 and 103 are provided, which are mounted on the manipulator 150 (a, frame 160) by means of the roller carriers 402 and 403, respectively.

- the roller 4 can be driven with the help of a motor.

- the motor (not explicitly shown) can also be mounted on the carrier 402.

- the roller 105 on the roller carrier 402 is designed as a tension roller.

- the roller carrier 401 with the rollers 101, 101a and 101b is similar to the example according to Fig. 3 slidably mounted on the manipulator, allowing the roller carrier 401 to be displaced in the x direction and blocking other degrees of freedom.

- the carrier 404 is also mounted on the manipulator 150.

- the actuator 302, which acts on the roller carrier 401, is arranged on the carrier 404.

- the tool with the frontmost roller 101 is a grinding wheel 101 '(or a other rotating tool).

- the belt runs essentially at right angles to the direction of action of the actuator, so that the belt forces F B1 ', F B2 ' are decoupled from the actuator force and there is no reaction from the belt forces F B1 '. ', F B2 ' takes place on the actuator 302.

- Figure 9 shows an example not covered by the claims, in which two rollers 101, 101a are arranged on an elongated roller carrier 401 at opposite ends of the roller carrier 401.

- the roller carrier is on the frame 160 (cf. Fig. 3 , in Fig. 9 not shown) stored slidably.

- Two further rollers 103 and 105 are also mounted on the frame (carriers 403 and 402), whereby the roller 105 can be driven by a motor (cf. Fig. 3 , in Fig. 9 not shown) and the other roller 103 can be part of a tensioning unit to tension the rotating belt 102.

- the tensioning unit can also be integrated in the drive (roller 105).

- the movable roller carrier 401 (slide) is arranged between the rollers 103 and 105;

- the belt running around the rollers 101, 103, 101a, 105 approximately forms a convex square in the cross-sectional view.

- the illustration makes it clear that the belt forces acting on the roller carrier 401 cancel each other out in the direction of action of the actuator 302, and no belt forces act back on the actuator 302, which acts on the roller carrier 401.

- the actuator presses the roller carrier 401 with a force F A and thus the roller 101 onto the workpiece.

- the contact force F K reaction force

- corresponds to the actuator force F A (F K -F A ).

- the workpiece is guided by a manipulator 150 and positioned so that the deflection x of the actuator 302 lies at a defined working point x 0 .

- the actuator 302 works purely in a force-controlled manner; the position is determined by the (position-controlled) manipulator 150. Small deviations from the operating point (e.g. due to shape and positional tolerances of the workpiece or due to limited positioning accuracy of the manipulator 150) do not lead to any significant change in the geometry of the device and the belt forces, so that the grinding force can always be specified by the force-controlled actuator 302.

- Fig. 10 shows an example of a control loop for regulating the contact force F K between the workpiece 200 and the grinding belt 102 on the deflection roller 101.

- the force measurement can take place directly via a force sensor integrated in the actuator 302 or coupled to it. In the case of a pneumatic actuator, however, the force measurement can also take place indirectly via the pressure p in the pneumatic actuator, taking into account the deflection x of the actuator 302.

- the actuator force F A (p, x) is a function of the pressure p in the actuator (e.g. in the pneumatic piston) and the deflection x of the actuator.

- an estimate or a separate measurement of the resulting belt force can be taken into account when measuring the contact force.

- F K,m -F A (p, x)-F B,x .

- the controller 301 can be, for example, a P controller, a PI controller, or a PID controller. However, other types of controllers can also be used.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Constituent Portions Of Griding Lathes, Driving, Sensing And Control (AREA)

Claims (12)

- Dispositif (100) servant à l'usinage d'une surface d'une pièce (200a), comportant :un châssis (160) ;un support de rouleau (401) sur lequel un premier rouleau (101) est monté en rotation, et qui est monté de manière coulissante sur le châssis (160) le long d'une première direction (x) ;un second rouleau (103) monté sur le châssis (160) ;une courroie (102) qui est guidée autour des deux rouleaux (101, 103) et par la tension de laquelle une force de courroie résultante (FB, FB') agit sur le support de rouleau, dans lequel le premier rouleau (101) sert uniquement de rouleau de renvoi ; etun galet tendeur (105) pour régler une force de sollicitation dans la courroie (102) ;caractérisé parun actionneur (302) qui est couplé mécaniquement au châssis (160) et au support de rouleau (401) de sorte qu'une force d'actionneur réglable (FA) entre le châssis (160) et le premier rouleau (101) agit le long de la première direction (x) ;dans lequel la courroie est guidée à l'aide du second rouleau (103) ou à l'aide du second rouleau (103) et d'autres rouleaux de sorte que la force de courroie résultante (FB, FB') agissant sur le support de rouleau (401) agit, lors d'une déviation de consigne de l'actionneur (302), approximativement dans une seconde direction (y), qui est orthogonale à la première direction (x), dans lequel l'actionneur (302) fonctionne uniquement sous contrôle de force.

- Dispositif selon la revendication 1, comportant en outre :un dispositif de mesure de force pour mesurer directement ou indirectement une force de contact (FK) entre le premier rouleau (101) et une pièce (200), ou entre un outil rotatif (101') relié au premier rouleau (101) et la pièce (200) etune unité de commande conçue pour régler la force d'actionnement (FA) de sorte que la force de contact (FK) correspond à une valeur de consigne prédéfinie (FK,S).

- Dispositif selon la revendication 2,dans lequel l'actionneur (302) est un actionneur linéaire pneumatique, etdans lequel le dispositif de mesure de force comporte un capteur de pression conçu pour mesurer la pression de l'air (p) dans l'actionneur linéaire pneumatique.

- Dispositif selon l'une des revendications 1 à 3,

dans lequel le premier rouleau (101) est monté en rotation sur le support de rouleau (401) autour d'un axe de rotation, et le support de rouleau (401) peut être déplacé le long de la première direction (x) par rapport au châssis (160) à l'aide d'un guide linéaire (140). - Dispositif selon l'une des revendications 1 à 4,

dans lequel - lors d'une déviation de consigne de l'actionneur (302) - la courroie (102) se dirige vers le support de rouleau (401) et s'éloigne du support de rouleau (401) approximativement à angle droit par rapport à la première direction. - Dispositif selon l'une des revendications 1 à 5, dans lequelle premier rouleau (101) est monté sur une première extrémité du support de rouleau (401) et un autre rouleau (101a) est monté sur une seconde extrémité du support de rouleau (401) opposée à la première extrémité, etla courroie (102) est guidée symétriquement autour du premier rouleau (101) et d'autres rouleaux lors d'une déviation nominale (x0) de l'actionneur (302), de sorte que la force de courroie résultante sur le support de rouleau (401) dans la première direction est nulle ou négligeable.

- Dispositif selon l'une des revendications 1 à 6,dans lequel le support de châssis comporte des rouleaux de renvoi (101a, 101b) pour dévier la courroie (102).dans lequel les rouleaux de renvoi (101a, 101b) sont disposés de sorte que, lors d'une déviation nominale (x0) de l'actionneur (302), la courroie se dirige vers le support de rouleau (401) et s'éloigne du support de rouleau (401) dans une seconde direction (y), qui est orthogonale à la première direction.

- Procédé servant à l'usinage de surface d'une pièce (200) à l'aide d'un dispositif (100), comportant :un châssis (160),un support de rouleau (401) sur lequel un premier rouleau (101) est monté en rotation, et qui est monté de manière coulissante sur le châssis (160) le long d'une première direction (x),un second rouleau (103) monté sur le châssis (160),un actionneur (302) qui est couplé mécaniquement au châssis (160) et au support de rouleau (401),une courroie (102) qui est guidée au moins autour des deux rouleaux (101, 103) et qui exerce une force de courroie résultante (FB, FB') sur le support de rouleau (401), dans lequel le premier rouleau (101) sert uniquement de rouleau de renvoi, etun galet tendeur (105) pour régler une force de sollicitation dans la courroie (102),dans lequel le procédé comprend :le positionnement de la pièce (200) sur le premier rouleau (101),la mesure d'une force de contact (FK) entre le premier rouleau (191) et la pièce (200) ;le réglage d'une force de contact (FK) entre le premier rouleau (101) et la pièce (200) en réglant une force agissant entre le châssis (160) et l'actionneur (302), dans lequel, lors du positionnement de la pièce (200), celle-ci est positionnée par rapport au dispositif (100) de sorte que la déviation de l'actionneur (302) correspond à sa déviation de consigne, dans laquelle la force de courroie résultante (FB, FB') agissant sur le support de rouleau (401) agit approximativement dans une seconde direction (y), qui est orthogonale à la première direction (x), dans lequel l'actionneur (302) fonctionne uniquement sous contrôle de force.

- Procédé selon la revendication 8, dans lequel la réaction de la force de courroie résultante (FB, FB') sur l'actionneur est approximativement nulle lors de la déviation de consigne.

- Procédé selon la revendication 8 ou 9, dans lequel l'actionneur est un actionneur linéaire pneumatique et la mesure d'une force de contact (FK) comprend la mesure de la pression (p) dans l'actionneur linéaire pneumatique.

- Système servant à l'usinage robotisé de surface de pièces, comportant :un dispositif d'usinage (100), etun manipulateur (150) pour positionner la pièce par rapport au dispositif d'usinage (100),dans lequel le dispositif d'usinage (100) comporte :un châssis (160) ;un support de rouleau (401) sur lequel un premier rouleau (101) est monté en rotation, et qui est monté de manière coulissante sur le châssis (160) le long d'une première direction (x) ;au moins un second rouleau (103) monté sur le châssis (160) ;une courroie (102) qui est guidée au moins autour des deux rouleaux (101, 103) et par la tension de laquelle une force de courroie résultante (FB, FB') agit sur le support de rouleau, dans lequel le premier rouleau (101) sert uniquement de rouleau de renvoi ; etun galet tendeur (105) pour régler une force de sollicitation dans la courroie (102),caractérisé parun actionneur (302) qui est couplé mécaniquement au châssis (160) et au support de rouleau (401) de sorte qu'une force d'actionneur réglable (FA) entre le châssis (160) et le premier rouleau (101) agit le long de la première direction (x) ;dans lequel la courroie est guidée à l'aide du second rouleau (103) ou à l'aide du second rouleau (103) et d'autres rouleaux de sorte que la force de courroie résultante (FB, FB') agissant sur le support de rouleau (401) agit, lors d'une déviation de consigne de l'actionneur (302), approximativement dans une seconde direction (y), qui est orthogonale à la première direction (x), dans lequel l'actionneur (302) fonctionne uniquement sous contrôle de force, et une position de la pièce par rapport au dispositif d'usinage (100) est déterminée uniquement par le manipulateur (150).

- Système selon la revendication 11,

dans lequel le manipulateur (150) positionne la pièce par rapport au dispositif d'usinage (100) de sorte que la déviation de l'actionneur (302) correspond à sa déviation de consigne.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102015106480.4A DE102015106480A1 (de) | 2015-04-27 | 2015-04-27 | Vorrichtung zur Oberflächenbearbeitung |

| PCT/AT2016/050111 WO2016172751A1 (fr) | 2015-04-27 | 2016-04-25 | Dispositif servant à l'usinage de surface |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP3288712A1 EP3288712A1 (fr) | 2018-03-07 |

| EP3288712B1 true EP3288712B1 (fr) | 2023-10-11 |

| EP3288712C0 EP3288712C0 (fr) | 2023-10-11 |

Family

ID=56072142

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16724583.6A Active EP3288712B1 (fr) | 2015-04-27 | 2016-04-25 | Dispositif servant à l'usinage de surface |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US10974362B2 (fr) |

| EP (1) | EP3288712B1 (fr) |

| JP (2) | JP7017934B2 (fr) |

| KR (1) | KR102480548B1 (fr) |

| CN (1) | CN107666985A (fr) |

| DE (1) | DE102015106480A1 (fr) |

| WO (1) | WO2016172751A1 (fr) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101944958B1 (ko) * | 2017-06-07 | 2019-02-07 | 주식회사 제이로보텍 | 그라인더 장치 |

| DE102020111292A1 (de) | 2020-04-24 | 2021-10-28 | Ferrobotics Compliant Robot Technology Gmbh | Schnellspannsystem zur verbindung von werkzeugmaschinen mit einem roboter |

| CN112077674A (zh) * | 2020-09-08 | 2020-12-15 | 合肥江丰电子材料有限公司 | 一种靶材组件中背板的抛光工艺 |

| CN112720188B (zh) * | 2020-12-25 | 2022-12-06 | 邵武市泽诚机械有限公司 | 一种打磨机 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10013340A1 (de) * | 2000-03-17 | 2001-09-27 | Carat Robotic Innovation Gmbh | Bandschleifmaschine mit Andruckregelung |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6389263A (ja) | 1986-10-02 | 1988-04-20 | Toshiba Corp | ベルトグラインダ−装置 |

| US4841683A (en) * | 1987-12-23 | 1989-06-27 | Williams Clarence W | Roll grinding system |

| DE4030158A1 (de) * | 1990-09-24 | 1992-03-26 | Hau Simex Gmbh | Bandschleifmaschine |

| CA2092995C (fr) * | 1991-07-31 | 2003-10-14 | Urs Maier | Rectifieuse pour les surfaces cylindriques ou spheriques d'un tambour, notamment un tambour de machine a papier |

| CH686350A5 (de) | 1992-02-07 | 1996-03-15 | Sig Schweiz Industrieges | Bandschleifmaschine. |

| JPH08108359A (ja) * | 1994-10-07 | 1996-04-30 | Fuji Photo Film Co Ltd | 研磨装置 |

| JPH10549A (ja) * | 1996-06-12 | 1998-01-06 | Nisshinbo Ind Inc | 研磨加工装置 |

| WO1999036616A1 (fr) * | 1998-01-20 | 1999-07-22 | Valmet Corporation | Procede et dispositif de conditionnement d'un cylindre, notamment d'un cylindre d'une machine a papier ou d'un dispositif de finissage du papier |

| DE19825698B4 (de) * | 1998-06-09 | 2005-07-21 | SHL Seelmann, Häring und Lehr Automatisierungstechnik GmbH | Bandschleifmaschine |

| KR20020034408A (ko) * | 2000-11-01 | 2002-05-09 | 이구택 | 스트립 연마 벨트의 위치 교정장치 |

| US6561870B2 (en) * | 2001-03-30 | 2003-05-13 | Lam Research Corporation | Adjustable force applying air platen and spindle system, and methods for using the same |

| JP2002301659A (ja) * | 2001-04-03 | 2002-10-15 | Kawasaki Heavy Ind Ltd | 自動仕上げ方法および装置 |

| JP2003220546A (ja) | 2002-01-24 | 2003-08-05 | Soken Kogyo Kk | ベルト式研磨装置 |

| JP2009016759A (ja) * | 2007-07-09 | 2009-01-22 | Nihon Micro Coating Co Ltd | 半導体ウェーハ端面研磨装置およびこれに用いる研磨ヘッド |

| DE102012005439A1 (de) * | 2012-03-20 | 2013-09-26 | Texmag Gmbh Vertriebsgesellschaft | Vorrichtung zum Beeinflussen einer laufenden Warenbahn |

| CN203779279U (zh) * | 2013-12-07 | 2014-08-20 | 泸州职业技术学院 | 自适应压力机械手打磨装置 |

| CN103692317B (zh) * | 2013-12-10 | 2017-01-25 | 深圳先进技术研究院 | 带力反馈的砂带机 |

| ES2616797T3 (es) | 2014-07-17 | 2017-06-14 | Franke Water Systems Ag | Procedimiento para el accionamiento de un dispositivo de rectificado con cinta |

-

2015

- 2015-04-27 DE DE102015106480.4A patent/DE102015106480A1/de active Pending

-

2016

- 2016-04-25 CN CN201680030814.7A patent/CN107666985A/zh active Pending

- 2016-04-25 US US15/569,704 patent/US10974362B2/en active Active

- 2016-04-25 KR KR1020177032399A patent/KR102480548B1/ko active IP Right Grant

- 2016-04-25 WO PCT/AT2016/050111 patent/WO2016172751A1/fr active Application Filing

- 2016-04-25 JP JP2017556218A patent/JP7017934B2/ja active Active

- 2016-04-25 EP EP16724583.6A patent/EP3288712B1/fr active Active

-

2021

- 2021-10-28 JP JP2021176697A patent/JP2022017427A/ja active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10013340A1 (de) * | 2000-03-17 | 2001-09-27 | Carat Robotic Innovation Gmbh | Bandschleifmaschine mit Andruckregelung |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3288712A1 (fr) | 2018-03-07 |

| WO2016172751A1 (fr) | 2016-11-03 |

| CN107666985A (zh) | 2018-02-06 |

| KR102480548B1 (ko) | 2022-12-22 |

| KR20170140261A (ko) | 2017-12-20 |

| JP7017934B2 (ja) | 2022-02-09 |

| US10974362B2 (en) | 2021-04-13 |

| JP2018516764A (ja) | 2018-06-28 |

| DE102015106480A1 (de) | 2016-10-27 |

| US20180126512A1 (en) | 2018-05-10 |

| JP2022017427A (ja) | 2022-01-25 |

| EP3288712C0 (fr) | 2023-10-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3439836B1 (fr) | Dispositif de ponçage robotisé | |

| EP3325214B1 (fr) | Machine-outil assistée par un robot pour le traitement de surfaces | |

| EP3288712B1 (fr) | Dispositif servant à l'usinage de surface | |

| DE102016106141A1 (de) | Wechselstation zum automatischen Wechseln von Schleifmittel | |

| DE102015104164B4 (de) | Verfahren und Vorrichtung zur robotergestützten Oberflächenbearbeitung | |

| DE102015007132B4 (de) | Motorsteuervorrichtung | |

| EP3765239B1 (fr) | Régulation de vitesse avec rectification assistée par robot | |

| DE102012222586A1 (de) | Werkzeugmaschine | |

| DE102015119589B4 (de) | Vorrichtung und Verfahren zum robotergestützen Rollfalzen | |

| WO2013149894A1 (fr) | Outil de formage guidé par robot et procédé de formage | |

| EP2919081B1 (fr) | Machine d'usinage avec prise en compte des erreurs de position lors du contrôle de collision | |

| EP3159103A1 (fr) | Procede de fonctionnement du dispositif de ponçage et dispositif de ponçage | |

| DE102020113098A1 (de) | Werkstück-drehvorrichtung und robotersystem | |

| DE102013202332B4 (de) | Vorrichtung zur automatischen zerspanenden Bearbeitung von Werkstücken | |

| EP3999277B1 (fr) | Dispositif et procédé de retrait automatique de disques de meulage | |

| DE102017213717A1 (de) | Bearbeitungsvorrichtung für ein Luftfahrzeug | |

| DE102020110492A1 (de) | Vorrichtung zum robotergestützten bearbeiten von oberflächen | |

| EP2623257B1 (fr) | machine-outil avec un dispositif d'équilibrage de position | |

| DE102015113890A1 (de) | Werkzeugmaschine mit Werkstückpositions- und gewichtsabhängiger Einfederungskompensation | |

| DE102019101579A1 (de) | Robotergestützte schleifvorrichtung mit integrierter wartungseinheit | |

| DE102022125510A1 (de) | Bearbeitungsvorrichtung sowie Verfahren zum Bearbeiten von Werkstücken | |

| DE10239570B3 (de) | Verfahren zum Kalibrieren eines Regelventils mit Nullschnitt-Kolben für eine Maschine mit einem Hydraulikantrieb, insbesondere für Manipulatoren | |

| DE102006020681A1 (de) | Vorrichtung und Verfahren zum lagegenauen Positionieren eines Werkstücks | |

| EP0178254A1 (fr) | Rectifieuse à commande numérique | |

| DD292165A5 (de) | Verfahren zur vermeidung des ueberschwingens von werkzeugen oder werkstuecken bei der zustellung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE INTERNATIONAL PUBLICATION HAS BEEN MADE |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: REQUEST FOR EXAMINATION WAS MADE |

|

| 17P | Request for examination filed |

Effective date: 20171122 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| DAV | Request for validation of the european patent (deleted) | ||

| DAX | Request for extension of the european patent (deleted) | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| 17Q | First examination report despatched |

Effective date: 20210531 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: EXAMINATION IS IN PROGRESS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: GRANT OF PATENT IS INTENDED |

|

| INTG | Intention to grant announced |

Effective date: 20230726 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502016016149 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| U01 | Request for unitary effect filed |

Effective date: 20231011 |

|

| U07 | Unitary effect registered |

Designated state(s): AT BE BG DE DK EE FI FR IT LT LU LV MT NL PT SE SI Effective date: 20231026 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240112 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240211 |

|

| U20 | Renewal fee paid [unitary effect] |

Year of fee payment: 9 Effective date: 20240319 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231011 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240211 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20240112 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20231011 |