EP2319793B1 - Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage - Google Patents

Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage Download PDFInfo

- Publication number

- EP2319793B1 EP2319793B1 EP09175529A EP09175529A EP2319793B1 EP 2319793 B1 EP2319793 B1 EP 2319793B1 EP 09175529 A EP09175529 A EP 09175529A EP 09175529 A EP09175529 A EP 09175529A EP 2319793 B1 EP2319793 B1 EP 2319793B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- actuator

- wheel

- governor

- speed

- coupling means

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/04—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions for detecting excessive speed

- B66B5/044—Mechanical overspeed governors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/04—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions for detecting excessive speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/16—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/16—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well

- B66B5/18—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well and applying frictional retarding forces

Definitions

- the present invention relates to a tripping device for a speed limiter of an elevator installation and to a speed limiter equipped with such a tripping device.

- the prior art discloses (prescribed) speed limiters for elevator installations which, when a triggering speed is exceeded, provide emergency measures, e.g. activate the safety gear.

- the DE 34 46 337 A1 shows a speed limiter for an elevator system that triggers the safety gear of the car when a tripping speed is exceeded.

- the speed limiter has a pulley which is connected to the car by means of a cable loop and is set in rotation of the car in rotation.

- the pulley carries flyweights, which are connected to rotatably mounted eccentric cams. As the pulley rotates, the centrifugal weights move outwardly, causing the eccentric cams to rotate or deflect so that they overshoot a braking wheel when the firing speed is exceeded to press. As a result, the sheave and by means of the driving ability of its rope groove, the rope wrapped around it is braked, whereby the safety gear is triggered.

- a comparable speed limiter is in the DE 18 00 270 A1 discloses in which a pulley is driven by two pivotally mounted on journal flyweights of a control cable.

- the flyweight are each equipped at their outwardly pivoting ends with a leaf spring, which in turn has a brake shoe. This arrangement rotates within a stationary brake wheel. Exceeds the rotational speed of the sheave a predetermined threshold, the flyweights pivot about the pins that the respective brake shoe moves outward and presses against the brake wheel, so that the pulley is braked so that the control cable of the car can not follow and a safety gear triggers.

- speed limiters are known in which instead of a brake wheel, a trigger wheel is provided, which is acted upon by the coupling means when the release speed is exceeded and taken in the direction of rotation. By the rotation of the trigger wheel then a rope brake for the cable pulley looping around rope is triggered, which in turn a safety gear is triggered on the car.

- a speed limiter is marketed for example under the name OL 100 by Wittur or is in the DE 2007 052 280 A1 disclosed.

- the speed limiters known in the prior art have the disadvantage that the interaction of pulley, flyweight, coupling means and tripping or braking a variety of individual components conditionally, which are all subject to certain tolerance requirements.

- the previous solutions require high manufacturing accuracy, since they are constructively overdetermined. This over-determination of the construction can lead to disturbances and high wear.

- the overall system is relatively expensive as a result, since certain minimum tolerances must be maintained for the individual elements during manufacture. This is also due to the symmetrical structure, ie some elements such as flyweights and coupling means are usually provided at least twice, so that both the tolerances of an element and element-overlapping tolerances play a role.

- the present invention therefore proposes a release device for a speed limiter of an elevator installation according to claim 1.

- Advantageous embodiments are the subject of the dependent claims and the following description.

- the invention teaches to provide an elastic material between the coupling means and the trigger wheel. Due to the elasticity of size deviations of components can be compensated among each other and tolerance overruns. As a result, the tolerance requirements on the individual components decrease, so that the manufacturing costs can be reduced.

- the release wheel can be divided across its width into two functional areas. A clamping area, which comes into contact with the coupling means, and a triggering area, which abuts the release lever.

- a (rubber) elastic material in particular as a covering, is now provided.

- the rigidity is reduced and also increases the static friction, whereby even smaller normal forces are sufficient for triggering.

- the material is a spring component, which softens with increasing lining thickness.

- the material expediently has a high stiction in contact with the coupling means and a high elastic deformability.

- the shear strength and the quality of the connection to the body should be sufficient to transmit the release torque.

- a high time stability should also be present under the given environmental influences.

- the rubber-like properties also create a damping effect when triggered, which contributes to material protection, especially at high speeds.

- the response can be improved and the reliability of the response can be increased.

- the elasticity and the friction of the material can be selected so that a rotation of the trigger wheel takes place safely as soon as a predetermined loading of the trigger wheel takes place by the coupling means.

- the ratio of elasticity and friction can be specified so that a tolerance compensation of component sizes and a safe triggering of the trigger wheel are possible.

- the tripping wheel in turn can actuate a release lever for triggering a cable brake and / or a switch for de-energized switching of the elevator drive.

- the trigger wheel on a tire or covering of the elastic material.

- the material can be easily provided between the trigger wheel and coupling means and, for example, in the case of wear also replaced.

- the coupling means may be provided with the elastic material.

- the flyweight simultaneously represent the coupling means.

- at least two additional components and their connection means can be saved with each other.

- the design of the tripping device becomes simpler and cheaper.

- the design is kinematically and statically determined, which increases the tolerance ranges to be complied with.

- the coupling agents acting as flyweight compounds expediently have a coupling region for loading or contacting the trigger wheel and a weight range.

- the weight range is expediently designed so that it does not come into contact with the trigger wheel and that it is suitable for receiving separate additional weights. These separate additional weights are used to set the release speed of the release device.

- edge of the coupling means at least partially in the form of an Archimedean spiral, gently applying the trigger wheel without jerk occurs with moderate increase in force.

- the correspondingly shaped edge of the coupling means is expediently in the area designated above as a coupling region.

- the provision of an elastic material can develop particular advantages, since the acting as flyweight coupling means depending on the release speed may possibly have different shapes, so that the distance of the edge of the coupling means from the trigger wheel, if necessary, depends on the design of the limiter , These different distances can be compensated for while maintaining all other structural sizes by the elastic material.

- the coupling means have a nose which defines an end stop, an excessive loading of the trigger wheel by the coupling means can be avoided.

- the tripping wheel is at rest.

- the coupling means rotate around the trigger wheel at the speed of the governor wheel, being deflected about its own axis depending on the speed of rotation of the governor wheel.

- the coupling means are expediently so arranged that the rotation or deflection about its own axis when applied to the trigger wheel leads to a self-boosting of the admission. This self-energizing continues until the trigger wheel has reached the rotational speed of the governor wheel.

- these are expediently equipped with an end stop. If this strikes against the trigger wheel, no further screwing can take place.

- the flyweights are coupled to each other by means of a cable connection and tensioned spring loaded, so that there is a linear relationship between the spring load and the deflection of the flyweight.

- the flyweights are arranged in pairs on the governor wheel and connected by a cable connection to compensate for gravitational effects. Furthermore, they are biased against the centrifugal force so that sufficient for an actuation of the trigger wheel deflection of the flyweight takes place only when reaching the triggering speed.

- the flyweight and the spring are dimensioned so that below the release speed no deflection of the flyweight takes place. In this way, the components mentioned during normal operation remain at rest, so that no wear takes place.

- the flyweights are arranged on the governor wheel so that the center of gravity of the flyweights has a smaller distance from the axis of rotation of the governor wheel than the distance of the axis of rotation of the flyweights from the axis of rotation of the Baskyrrads.

- the center of gravity of the flyweights is closer to the axis of rotation of the governor than its own axis of rotation.

- the governor wheel is provided with a central co-rotating shaft, this can serve, for example, as a mounting space for other units.

- encoders u.ä. simply be placed in an elevator system.

- An inventive speed limiter for an elevator is equipped with a tripping device according to the invention for triggering a cable brake and / or for actuating a switch for stopping an elevator drive.

- An advantageous cable brake comprises a four-link coupling gear, in particular a sliding crank.

- a large leverage can be generated, so that a large braking force, which, for example, from a cocked Spring can be provided, can be held by a small release force. This small release force is absorbed by the trigger wheel.

- the rope brake comprises an eccentric crank, in particular, the eccentricity is greater than the crank length.

- the joint connecting the crank and the connecting rod presses on the trigger wheel via a release lever.

- the trigger is held in a metastable state on the trigger wheel.

- the joint is thereby pushed through, so that the rope brake is released.

- Triggers the triggering device the trigger wheel is set in rotation, thereby pushing the release lever away.

- the joint can move, so that the connecting rod can move up and the rope brake closes.

- a screw arrangement may be provided, in which, for example, by means of a screw or nut to be screwed, a transmission element located behind it, such as, for example, a washer, clamps the spring (plate spring, spiral spring, etc.).

- the Beipporrad be equipped on both sides. Flywheels with a trigger wheel for releasing the rope brake are seated on one side, whereas flywheels and a trigger wheel for actuating an electrical switch are arranged on the other side.

- the two-sided design can be different Triggering speeds for the rope brake and the electrical switch are provided and adjusted.

- the parameters required by standard elevator standards "release speed” (mechanical emergency stop) and "pre-switch-off speed” (electrical emergency stop) can thereby be set independently of one another.

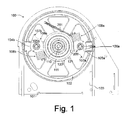

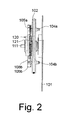

- FIGS. 1 to 3 the same elements are provided with the same reference numerals.

- the FIGS. 1 and 2 are described in a coherent and comprehensive way.

- FIG. 1 are components of a preferred embodiment of a tripping device 100 according to the invention in a plan view and in FIG. 2 shown schematically in a side view.

- the triggering device 100 has a carrier 101 on which in particular the elements to be triggered, such as. As a rope brake or an electrical switch can be attached.

- a Beskyrrad 102 is rotatably mounted, which is offset by a limiter cable 103 in operation in rotation.

- the Beskyrrad 102 is rotatably mounted on a bearing 110.

- the Beskyrrad 102 has two axes 104a, 104b rotatably mounted flyweights 105a, 105b, which act simultaneously as a coupling agent.

- the flyweights 105a, 105b each have a coupling region 106a, 106b and a nose 107a, 107b defining a stop. Furthermore, the fly weights 105a, 105b have attachable and removable additional weights 108a, 108b to set the release speed of the triggering device 100.

- the flyweight / coupling means 105a, 105b are connected by means of a cable connection 200, which is biased by a spring 201.

- a predetermined centrifugal force must be achieved to overcome the spring biasing force.

- the spring biasing force is expediently predetermined so that the flyweights / coupling means 105a, 105b remain at rest during normal operation and are not deflected. This wear and disturbing noises, especially rattles can be avoided.

- the cable connection 200 is used in particular for gravity compensation.

- the Beipporrad 102 is rotatably connected to a central shaft 111 which rotates synchronously with the Beipporrad and can be used for example for receiving a rotary encoder.

- the rotational speed of the governor wheel can be scanned electronically, for example.

- a trigger wheel 120 is also rotatably mounted, which is at rest during operation in the untripped condition.

- the trigger wheel 120 has a ring 121 made of elastic material, which serves in particular to compensate for tolerances and for friction mediation.

- the flyweights / coupling means 105a, 105b are not deflected and therefore are not in contact with the trigger wheel 120. However, if the rotational speed of the governor wheel 102 exceeds the predetermined release speed, the flyweights / coupling means 105a, 105b are counteracted deflected the force of the spring 201 and approach the trigger wheel to the touch. Depending on Distance is necessary for a swivel angle of up to 30 °. Finally, the coupling regions 106a, 106b come into contact with the elastic material 121 of the Begrenzerrads 120.

- the flyweight / coupling means 105a, 105b roll through the static friction automatically on until the release torque is reached.

- the rotational movement of the Beipporrads 102 is transmitted to the trigger wheel 120, which is set in the sequence in a rotational movement. From a swivel angle of about 70 ° further rolling is prevented by the impact of specially shaped noses. Due to this limitation of the maximum pivot angle, the flyweights / coupling means are prevented from penetrating and at the same time the system is protected against overloading.

- the impact of the formed on each flyweight / coupling agent nose 107a and 107b on the trigger wheel 120 causes a significant shift of the force application point.

- the ratio between the normal force and the static friction force required for further agitation changes so much that slippage occurs.

- the system is designed so that the release torque has already been safely exceeded at this point.

- the further increase of the moment due to the inertia of the trigger wheel 120 is already greatly reduced by the damping effect of the elastic lining 121 and limited by the sliding upwards.

- a rotational movement of the trigger wheel 120 in turn can be used to trigger a variety of functions, such as an electric switch or a rope brake, as described below FIG. 3 will be used.

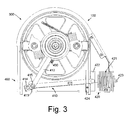

- FIG. 3 a preferred embodiment of a speed limiter 300 according to the invention is shown in a plan view, which has the triggering device 100 and a particularly preferred embodiment 400 of a rope brake.

- the cable brake 400 comprises a four-link coupling mechanism configured as a sliding crank 410 and a clamping brake 420 prestressed by means of a disk spring arrangement 421.

- the clamping brake 420 has a rigid brake shoe 424 and a movable brake shoe 422 which is connected by a connecting rod 411 of the crank 410 against the force of the disk spring 421 is held.

- a trip lever 412 is in a metastable position on a pin 430 and the trigger wheel 120 at.

- the crank 413 is rotatably mounted on an axle 414 and connected at a joint 415 with the connecting rod 411 and the release lever 412.

- the trip lever 412 pushes down the hinge 415 in the view shown so that the connecting rod 411 pushes the brake shoes 422 to the right.

- the trigger lever 412 on the trigger wheel is pushed to the left in the drawing, thereby releasing the hinge 415 and allowing it to move up to the left.

- the plate spring 421 pushes the brake shoes 422 against the brake shoe 424 and clamps the rope 103 running therebetween.

- the plate spring package 421 with a threaded assembly 423 provided by the operation of the plate spring package 421 can be biased.

- the force acting on the brake shoes 422 force is released, so that the connecting rod 411 and the release lever 412 can be brought back into the position shown.

- the threaded arrangement 423 is released again in order to pretension the brake shoes 422.

- a trigger device for a speed limiter of an elevator installation can be provided which has a number of advantages.

- the special design leads to a robustness, which allows usual manufacturing tolerances without adverse effect. It is kinematically and statically determined and places less demands on the manufacturing accuracy. The process capability is given. Smaller and lighter parts can be used, simplifying manufacturing and reducing costs. Compared to known limiters, the device is small, light, durable and low in noise.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Maintenance And Inspection Apparatuses For Elevators (AREA)

- Braking Arrangements (AREA)

- High-Pressure Fuel Injection Pump Control (AREA)

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES09175529T ES2381966T3 (es) | 2009-11-10 | 2009-11-10 | Dispositivo de liberación para un limitador de velocidad de una instalación de ascensor |

| EP09175529A EP2319793B1 (de) | 2009-11-10 | 2009-11-10 | Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage |

| AT09175529T ATE542767T1 (de) | 2009-11-10 | 2009-11-10 | Auslösevorrichtung für einen geschwindigkeitsbegrenzer einer aufzugsanlage |

| JP2012538274A JP5385464B2 (ja) | 2009-11-10 | 2010-10-29 | エレベータ・システムの調速機のためのアクチュエータ |

| CN201080051141.6A CN102695665B (zh) | 2009-11-10 | 2010-10-29 | 用于升降机系统的调速器的致动器 |

| BR112012010492A BR112012010492A2 (pt) | 2009-11-10 | 2010-10-29 | acionador para um regulador de velocidade de um sistema e regulador de velocidade para um elevador com acionador |

| PCT/EP2010/066547 WO2011057907A1 (de) | 2009-11-10 | 2010-10-29 | Auslösevorrichtung für einen geschwindigkeitsbegrenzer einer aufzugsanlage |

| KR1020127012581A KR101833382B1 (ko) | 2009-11-10 | 2010-10-29 | 엘리베이터 시스템의 조속기용 트리거 디바이스 |

| US13/468,762 US8453799B2 (en) | 2009-11-10 | 2012-05-10 | Actuator for a speed governor of an elevator system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09175529A EP2319793B1 (de) | 2009-11-10 | 2009-11-10 | Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2319793A1 EP2319793A1 (de) | 2011-05-11 |

| EP2319793B1 true EP2319793B1 (de) | 2012-01-25 |

Family

ID=41647106

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09175529A Not-in-force EP2319793B1 (de) | 2009-11-10 | 2009-11-10 | Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US8453799B2 (pt) |

| EP (1) | EP2319793B1 (pt) |

| JP (1) | JP5385464B2 (pt) |

| KR (1) | KR101833382B1 (pt) |

| CN (1) | CN102695665B (pt) |

| AT (1) | ATE542767T1 (pt) |

| BR (1) | BR112012010492A2 (pt) |

| ES (1) | ES2381966T3 (pt) |

| WO (1) | WO2011057907A1 (pt) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016208403A1 (de) | 2016-05-17 | 2017-11-23 | Thyssenkrupp Ag | Geschwindigkeitsbegrenzer für einen Aufzug |

| CN108529411A (zh) * | 2017-12-29 | 2018-09-14 | 迅达(中国)电梯有限公司 | 用于速度限制器的缆绳的安装 |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2913287B1 (en) | 2014-02-26 | 2018-01-03 | Otis Elevator Company | Governor for controlling the speed of a hoisted object relative to a guide member |

| EP3363759B1 (en) * | 2015-10-13 | 2020-05-06 | Hitachi, Ltd. | Elevator device |

| CN105293247B (zh) * | 2015-11-26 | 2017-11-17 | 上海乐天电梯部件有限公司 | 一种限速器及其使用方法 |

| CN107021395B (zh) * | 2016-01-04 | 2020-11-10 | 奥的斯电梯公司 | 具有自动复位的电梯超速调节器 |

| CN107673159B (zh) * | 2016-08-01 | 2020-09-08 | 奥的斯电梯公司 | 升降机的限速器 |

| CN108002168B (zh) | 2016-10-27 | 2021-04-02 | 奥的斯电梯公司 | 远程触发装置,限速器组件以及电梯 |

| CN108298398B (zh) | 2017-01-13 | 2020-09-01 | 奥的斯电梯公司 | 用于电梯限速器的芯环组件,限速器和电梯系统 |

| CN109720961B (zh) * | 2017-10-30 | 2021-08-17 | 奥的斯电梯公司 | 限速器组件以及电梯系统 |

| CN108639894B (zh) * | 2018-04-02 | 2019-10-22 | 浙江工贸职业技术学院 | 一种带触发机构的电梯制停装置 |

| US11034546B2 (en) * | 2018-06-28 | 2021-06-15 | Otis Elevator Company | Elevator governor |

| CN111377326A (zh) * | 2018-12-29 | 2020-07-07 | 上海龙钰电梯配件有限公司 | 一种限速器机械触发机构 |

| KR102348331B1 (ko) | 2019-12-30 | 2022-01-11 | 현대엘리베이터주식회사 | 임시 엘리베이터 카의 조속기 작동 장치 |

| CN113266142B (zh) * | 2021-04-30 | 2022-04-19 | 中交第四公路工程局有限公司 | 一种电梯井施工用快速升降平台 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH480258A (de) | 1967-10-04 | 1969-10-31 | Aufzuege Ag Schaffhausen | Geschwindigkeitsbegrenzer für Aufzüge |

| US4134482A (en) * | 1976-08-20 | 1979-01-16 | Tsentralny Nauchno-Issledovatelsky Avtomobilny I Avtomotorny Institut | Device to effect control over the friction clutch of a transport vehicle |

| JPS54108339A (en) * | 1978-02-14 | 1979-08-24 | Mitsubishi Electric Corp | Driving device for elevators |

| AT382848B (de) | 1983-12-16 | 1987-04-10 | Kone Sowitsch Aktiengesellscha | Geschwindigkeitsbegrenzer fuer mit einer fangvorrichtung versehene aufzuege |

| JPH0475985A (ja) * | 1990-07-18 | 1992-03-10 | Fujitsu Ltd | 昇降装置 |

| FI95021C (fi) * | 1993-06-08 | 1995-12-11 | Kone Oy | Menetelmä ja laitteisto hissin tarrauslaitteen laukaisemiseksi |

| JPH07315732A (ja) * | 1994-05-24 | 1995-12-05 | Hitachi Building Syst Eng & Service Co Ltd | エレベータ用電磁制動機の補修用具 |

| JP2006046633A (ja) * | 2004-07-02 | 2006-02-16 | Yamaha Motor Co Ltd | 車両 |

| WO2006090453A1 (ja) * | 2005-02-24 | 2006-08-31 | Mitsubishi Denki Kabushiki Kaisha | エレベータ用調速機 |

| FI120303B (fi) * | 2005-06-23 | 2009-09-15 | Kone Corp | Menetelmä ja laitteisto hissin tarrauslaitteen laukaisemiseksi |

| CN101522554B (zh) * | 2006-10-18 | 2011-11-23 | 三菱电机株式会社 | 电梯限速装置以及电梯装置 |

| JP5153863B2 (ja) * | 2007-04-13 | 2013-02-27 | オーチス エレベータ カンパニー | オーバラップ式フライウエイトシステムを備えたガバナシーブ |

| CN101679000B (zh) * | 2007-06-21 | 2012-07-18 | 三菱电机株式会社 | 电梯的安全装置及绳索打滑检测方法 |

| DE102007052280B4 (de) | 2007-11-02 | 2015-04-02 | Wittur Holding Gmbh | Richtungsunabhängig ansprechender Geschwindigkeitsbegrenzer |

| EP2316775A4 (en) * | 2008-08-28 | 2014-09-03 | Mitsubishi Electric Corp | ELEVATOR SPEED LIMITER |

| WO2010116503A1 (ja) * | 2009-04-09 | 2010-10-14 | 三菱電機株式会社 | エレベータ用調速機 |

| WO2011083574A1 (ja) * | 2010-01-07 | 2011-07-14 | 三菱電機株式会社 | エレベータ装置 |

-

2009

- 2009-11-10 ES ES09175529T patent/ES2381966T3/es active Active

- 2009-11-10 AT AT09175529T patent/ATE542767T1/de active

- 2009-11-10 EP EP09175529A patent/EP2319793B1/de not_active Not-in-force

-

2010

- 2010-10-29 KR KR1020127012581A patent/KR101833382B1/ko active IP Right Grant

- 2010-10-29 BR BR112012010492A patent/BR112012010492A2/pt not_active Application Discontinuation

- 2010-10-29 JP JP2012538274A patent/JP5385464B2/ja not_active Expired - Fee Related

- 2010-10-29 WO PCT/EP2010/066547 patent/WO2011057907A1/de active Application Filing

- 2010-10-29 CN CN201080051141.6A patent/CN102695665B/zh not_active Expired - Fee Related

-

2012

- 2012-05-10 US US13/468,762 patent/US8453799B2/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016208403A1 (de) | 2016-05-17 | 2017-11-23 | Thyssenkrupp Ag | Geschwindigkeitsbegrenzer für einen Aufzug |

| CN108529411A (zh) * | 2017-12-29 | 2018-09-14 | 迅达(中国)电梯有限公司 | 用于速度限制器的缆绳的安装 |

| CN108529411B (zh) * | 2017-12-29 | 2020-05-08 | 迅达(中国)电梯有限公司 | 用于速度限制器的缆绳的安装 |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE542767T1 (de) | 2012-02-15 |

| US20120312638A1 (en) | 2012-12-13 |

| EP2319793A1 (de) | 2011-05-11 |

| CN102695665A (zh) | 2012-09-26 |

| CN102695665B (zh) | 2015-06-10 |

| KR101833382B1 (ko) | 2018-02-28 |

| KR20120104546A (ko) | 2012-09-21 |

| JP2013510059A (ja) | 2013-03-21 |

| ES2381966T3 (es) | 2012-06-04 |

| JP5385464B2 (ja) | 2014-01-08 |

| BR112012010492A2 (pt) | 2016-03-15 |

| WO2011057907A1 (de) | 2011-05-19 |

| US8453799B2 (en) | 2013-06-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2319793B1 (de) | Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage | |

| DE69509265T2 (de) | Vorrichtung in einem Aufzugsübergeschwindigkeitsbegrenzer | |

| DE3111583C2 (pt) | ||

| EP2006563B1 (de) | Automatische Federspeicherbremse für Flurförderzeug | |

| EP3402999B1 (de) | Schwingungstilger mit elektromagnetischer bremse für windkraftanlagen | |

| EP2751005B1 (de) | Reibungsbremse mit einer senkrecht zur zuspannrichtung wirkenden aktoreinheit | |

| DE102005001344B4 (de) | Windenergieanlage | |

| EP1995203B1 (de) | Geschwindigkeits- und Beschleunigungsüberwachungseinheit mit elektronisch angesteuerter Servoauslösung zum Einsatz für Fördermittel | |

| WO2010091895A2 (de) | Bremssystem für eine windturbine | |

| DE102005039434A1 (de) | Windenergieanlage | |

| DE2337397A1 (de) | Lastabhaengige bremsvorrichtung fuer foerdereinrichtungen | |

| WO2020104428A1 (de) | Geschwindigkeitsbegrenzer für ein hebezeug mit fliehkraftbetätigter bremse | |

| DE19851668A1 (de) | Radbremsvorrichtung | |

| EP2534390A2 (de) | Elektrische bremse | |

| EP2989344B1 (de) | Scheibenbremse mit einer bidirektionalen verschleissnachstellvorrichtung, und bidirektionale verschleissnachstellvorrichtung | |

| EP1952043B1 (de) | Elektromechanische bremse mit spielfreier betätigung | |

| DE102004023123A1 (de) | Absturzsicherung | |

| DE69511589T2 (de) | Verfahren und Vorrichtung zum Auslösen eines Aufzugssicherheitsmechanismus | |

| DE102012006097A1 (de) | Zuspannvorrichtung für eine drehhebelbetätigte Scheibenbremse | |

| EP4077190B1 (de) | Fangvorrichtung für einen aufzug | |

| DE2913574B2 (de) | Antriebsmechanismus | |

| DE102020120313B4 (de) | Sattelbremse | |

| DE102007052280B4 (de) | Richtungsunabhängig ansprechender Geschwindigkeitsbegrenzer | |

| DE2649629C2 (de) | Antrieb mit Unfallverhütungseinrichtung für Tore oder dergleichen | |

| DD214582A1 (de) | Vorrichtung zum steuern einer packmittelbremse |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20100730 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: THYSSENKRUPP ELEVATOR AG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B66B 5/04 20060101AFI20110701BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 542767 Country of ref document: AT Kind code of ref document: T Effective date: 20120215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009002550 Country of ref document: DE Effective date: 20120322 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOHEST AG |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2381966 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120604 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120525 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120426 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20121026 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009002550 Country of ref document: DE Effective date: 20121026 |

|

| BERE | Be: lapsed |

Owner name: THYSSENKRUPP ELEVATOR A.G. Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121110 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: HOLBEINSTRASSE 36-38, 4051 BASEL (CH) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20151118 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20151118 Year of fee payment: 7 Ref country code: AT Payment date: 20151119 Year of fee payment: 7 Ref country code: FR Payment date: 20151119 Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20161201 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 542767 Country of ref document: AT Kind code of ref document: T Effective date: 20161110 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20161110 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161110 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009002550 Country of ref document: DE Representative=s name: DEHNSGERMANY PARTNERSCHAFT VON PATENTANWAELTEN, DE Ref country code: DE Ref legal event code: R082 Ref document number: 502009002550 Country of ref document: DE Representative=s name: KUDLEK GRUNERT & PARTNER PATENTANWAELTE MBB, DE Ref country code: DE Ref legal event code: R081 Ref document number: 502009002550 Country of ref document: DE Owner name: THYSSENKRUPP ELEVATOR AG, DE Free format text: FORMER OWNER: THYSSENKRUPP ELEVATOR AG, 45143 ESSEN, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20191121 Year of fee payment: 11 Ref country code: FI Payment date: 20191121 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20191220 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20191121 Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009002550 Country of ref document: DE Representative=s name: DEHNSGERMANY PARTNERSCHAFT VON PATENTANWAELTEN, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502009002550 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MAE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210601 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20220201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20201111 |