EP2319793B1 - Actuator for a speed restrictor of a lift system - Google Patents

Actuator for a speed restrictor of a lift system Download PDFInfo

- Publication number

- EP2319793B1 EP2319793B1 EP09175529A EP09175529A EP2319793B1 EP 2319793 B1 EP2319793 B1 EP 2319793B1 EP 09175529 A EP09175529 A EP 09175529A EP 09175529 A EP09175529 A EP 09175529A EP 2319793 B1 EP2319793 B1 EP 2319793B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- actuator

- wheel

- governor

- speed

- coupling means

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/04—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions for detecting excessive speed

- B66B5/044—Mechanical overspeed governors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/04—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions for detecting excessive speed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/16—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B5/00—Applications of checking, fault-correcting, or safety devices in elevators

- B66B5/02—Applications of checking, fault-correcting, or safety devices in elevators responsive to abnormal operating conditions

- B66B5/16—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well

- B66B5/18—Braking or catch devices operating between cars, cages, or skips and fixed guide elements or surfaces in hoistway or well and applying frictional retarding forces

Definitions

- the present invention relates to a tripping device for a speed limiter of an elevator installation and to a speed limiter equipped with such a tripping device.

- the prior art discloses (prescribed) speed limiters for elevator installations which, when a triggering speed is exceeded, provide emergency measures, e.g. activate the safety gear.

- the DE 34 46 337 A1 shows a speed limiter for an elevator system that triggers the safety gear of the car when a tripping speed is exceeded.

- the speed limiter has a pulley which is connected to the car by means of a cable loop and is set in rotation of the car in rotation.

- the pulley carries flyweights, which are connected to rotatably mounted eccentric cams. As the pulley rotates, the centrifugal weights move outwardly, causing the eccentric cams to rotate or deflect so that they overshoot a braking wheel when the firing speed is exceeded to press. As a result, the sheave and by means of the driving ability of its rope groove, the rope wrapped around it is braked, whereby the safety gear is triggered.

- a comparable speed limiter is in the DE 18 00 270 A1 discloses in which a pulley is driven by two pivotally mounted on journal flyweights of a control cable.

- the flyweight are each equipped at their outwardly pivoting ends with a leaf spring, which in turn has a brake shoe. This arrangement rotates within a stationary brake wheel. Exceeds the rotational speed of the sheave a predetermined threshold, the flyweights pivot about the pins that the respective brake shoe moves outward and presses against the brake wheel, so that the pulley is braked so that the control cable of the car can not follow and a safety gear triggers.

- speed limiters are known in which instead of a brake wheel, a trigger wheel is provided, which is acted upon by the coupling means when the release speed is exceeded and taken in the direction of rotation. By the rotation of the trigger wheel then a rope brake for the cable pulley looping around rope is triggered, which in turn a safety gear is triggered on the car.

- a speed limiter is marketed for example under the name OL 100 by Wittur or is in the DE 2007 052 280 A1 disclosed.

- the speed limiters known in the prior art have the disadvantage that the interaction of pulley, flyweight, coupling means and tripping or braking a variety of individual components conditionally, which are all subject to certain tolerance requirements.

- the previous solutions require high manufacturing accuracy, since they are constructively overdetermined. This over-determination of the construction can lead to disturbances and high wear.

- the overall system is relatively expensive as a result, since certain minimum tolerances must be maintained for the individual elements during manufacture. This is also due to the symmetrical structure, ie some elements such as flyweights and coupling means are usually provided at least twice, so that both the tolerances of an element and element-overlapping tolerances play a role.

- the present invention therefore proposes a release device for a speed limiter of an elevator installation according to claim 1.

- Advantageous embodiments are the subject of the dependent claims and the following description.

- the invention teaches to provide an elastic material between the coupling means and the trigger wheel. Due to the elasticity of size deviations of components can be compensated among each other and tolerance overruns. As a result, the tolerance requirements on the individual components decrease, so that the manufacturing costs can be reduced.

- the release wheel can be divided across its width into two functional areas. A clamping area, which comes into contact with the coupling means, and a triggering area, which abuts the release lever.

- a (rubber) elastic material in particular as a covering, is now provided.

- the rigidity is reduced and also increases the static friction, whereby even smaller normal forces are sufficient for triggering.

- the material is a spring component, which softens with increasing lining thickness.

- the material expediently has a high stiction in contact with the coupling means and a high elastic deformability.

- the shear strength and the quality of the connection to the body should be sufficient to transmit the release torque.

- a high time stability should also be present under the given environmental influences.

- the rubber-like properties also create a damping effect when triggered, which contributes to material protection, especially at high speeds.

- the response can be improved and the reliability of the response can be increased.

- the elasticity and the friction of the material can be selected so that a rotation of the trigger wheel takes place safely as soon as a predetermined loading of the trigger wheel takes place by the coupling means.

- the ratio of elasticity and friction can be specified so that a tolerance compensation of component sizes and a safe triggering of the trigger wheel are possible.

- the tripping wheel in turn can actuate a release lever for triggering a cable brake and / or a switch for de-energized switching of the elevator drive.

- the trigger wheel on a tire or covering of the elastic material.

- the material can be easily provided between the trigger wheel and coupling means and, for example, in the case of wear also replaced.

- the coupling means may be provided with the elastic material.

- the flyweight simultaneously represent the coupling means.

- at least two additional components and their connection means can be saved with each other.

- the design of the tripping device becomes simpler and cheaper.

- the design is kinematically and statically determined, which increases the tolerance ranges to be complied with.

- the coupling agents acting as flyweight compounds expediently have a coupling region for loading or contacting the trigger wheel and a weight range.

- the weight range is expediently designed so that it does not come into contact with the trigger wheel and that it is suitable for receiving separate additional weights. These separate additional weights are used to set the release speed of the release device.

- edge of the coupling means at least partially in the form of an Archimedean spiral, gently applying the trigger wheel without jerk occurs with moderate increase in force.

- the correspondingly shaped edge of the coupling means is expediently in the area designated above as a coupling region.

- the provision of an elastic material can develop particular advantages, since the acting as flyweight coupling means depending on the release speed may possibly have different shapes, so that the distance of the edge of the coupling means from the trigger wheel, if necessary, depends on the design of the limiter , These different distances can be compensated for while maintaining all other structural sizes by the elastic material.

- the coupling means have a nose which defines an end stop, an excessive loading of the trigger wheel by the coupling means can be avoided.

- the tripping wheel is at rest.

- the coupling means rotate around the trigger wheel at the speed of the governor wheel, being deflected about its own axis depending on the speed of rotation of the governor wheel.

- the coupling means are expediently so arranged that the rotation or deflection about its own axis when applied to the trigger wheel leads to a self-boosting of the admission. This self-energizing continues until the trigger wheel has reached the rotational speed of the governor wheel.

- these are expediently equipped with an end stop. If this strikes against the trigger wheel, no further screwing can take place.

- the flyweights are coupled to each other by means of a cable connection and tensioned spring loaded, so that there is a linear relationship between the spring load and the deflection of the flyweight.

- the flyweights are arranged in pairs on the governor wheel and connected by a cable connection to compensate for gravitational effects. Furthermore, they are biased against the centrifugal force so that sufficient for an actuation of the trigger wheel deflection of the flyweight takes place only when reaching the triggering speed.

- the flyweight and the spring are dimensioned so that below the release speed no deflection of the flyweight takes place. In this way, the components mentioned during normal operation remain at rest, so that no wear takes place.

- the flyweights are arranged on the governor wheel so that the center of gravity of the flyweights has a smaller distance from the axis of rotation of the governor wheel than the distance of the axis of rotation of the flyweights from the axis of rotation of the Baskyrrads.

- the center of gravity of the flyweights is closer to the axis of rotation of the governor than its own axis of rotation.

- the governor wheel is provided with a central co-rotating shaft, this can serve, for example, as a mounting space for other units.

- encoders u.ä. simply be placed in an elevator system.

- An inventive speed limiter for an elevator is equipped with a tripping device according to the invention for triggering a cable brake and / or for actuating a switch for stopping an elevator drive.

- An advantageous cable brake comprises a four-link coupling gear, in particular a sliding crank.

- a large leverage can be generated, so that a large braking force, which, for example, from a cocked Spring can be provided, can be held by a small release force. This small release force is absorbed by the trigger wheel.

- the rope brake comprises an eccentric crank, in particular, the eccentricity is greater than the crank length.

- the joint connecting the crank and the connecting rod presses on the trigger wheel via a release lever.

- the trigger is held in a metastable state on the trigger wheel.

- the joint is thereby pushed through, so that the rope brake is released.

- Triggers the triggering device the trigger wheel is set in rotation, thereby pushing the release lever away.

- the joint can move, so that the connecting rod can move up and the rope brake closes.

- a screw arrangement may be provided, in which, for example, by means of a screw or nut to be screwed, a transmission element located behind it, such as, for example, a washer, clamps the spring (plate spring, spiral spring, etc.).

- the Beipporrad be equipped on both sides. Flywheels with a trigger wheel for releasing the rope brake are seated on one side, whereas flywheels and a trigger wheel for actuating an electrical switch are arranged on the other side.

- the two-sided design can be different Triggering speeds for the rope brake and the electrical switch are provided and adjusted.

- the parameters required by standard elevator standards "release speed” (mechanical emergency stop) and "pre-switch-off speed” (electrical emergency stop) can thereby be set independently of one another.

- FIGS. 1 to 3 the same elements are provided with the same reference numerals.

- the FIGS. 1 and 2 are described in a coherent and comprehensive way.

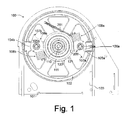

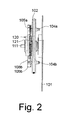

- FIG. 1 are components of a preferred embodiment of a tripping device 100 according to the invention in a plan view and in FIG. 2 shown schematically in a side view.

- the triggering device 100 has a carrier 101 on which in particular the elements to be triggered, such as. As a rope brake or an electrical switch can be attached.

- a Beskyrrad 102 is rotatably mounted, which is offset by a limiter cable 103 in operation in rotation.

- the Beskyrrad 102 is rotatably mounted on a bearing 110.

- the Beskyrrad 102 has two axes 104a, 104b rotatably mounted flyweights 105a, 105b, which act simultaneously as a coupling agent.

- the flyweights 105a, 105b each have a coupling region 106a, 106b and a nose 107a, 107b defining a stop. Furthermore, the fly weights 105a, 105b have attachable and removable additional weights 108a, 108b to set the release speed of the triggering device 100.

- the flyweight / coupling means 105a, 105b are connected by means of a cable connection 200, which is biased by a spring 201.

- a predetermined centrifugal force must be achieved to overcome the spring biasing force.

- the spring biasing force is expediently predetermined so that the flyweights / coupling means 105a, 105b remain at rest during normal operation and are not deflected. This wear and disturbing noises, especially rattles can be avoided.

- the cable connection 200 is used in particular for gravity compensation.

- the Beipporrad 102 is rotatably connected to a central shaft 111 which rotates synchronously with the Beipporrad and can be used for example for receiving a rotary encoder.

- the rotational speed of the governor wheel can be scanned electronically, for example.

- a trigger wheel 120 is also rotatably mounted, which is at rest during operation in the untripped condition.

- the trigger wheel 120 has a ring 121 made of elastic material, which serves in particular to compensate for tolerances and for friction mediation.

- the flyweights / coupling means 105a, 105b are not deflected and therefore are not in contact with the trigger wheel 120. However, if the rotational speed of the governor wheel 102 exceeds the predetermined release speed, the flyweights / coupling means 105a, 105b are counteracted deflected the force of the spring 201 and approach the trigger wheel to the touch. Depending on Distance is necessary for a swivel angle of up to 30 °. Finally, the coupling regions 106a, 106b come into contact with the elastic material 121 of the Begrenzerrads 120.

- the flyweight / coupling means 105a, 105b roll through the static friction automatically on until the release torque is reached.

- the rotational movement of the Beipporrads 102 is transmitted to the trigger wheel 120, which is set in the sequence in a rotational movement. From a swivel angle of about 70 ° further rolling is prevented by the impact of specially shaped noses. Due to this limitation of the maximum pivot angle, the flyweights / coupling means are prevented from penetrating and at the same time the system is protected against overloading.

- the impact of the formed on each flyweight / coupling agent nose 107a and 107b on the trigger wheel 120 causes a significant shift of the force application point.

- the ratio between the normal force and the static friction force required for further agitation changes so much that slippage occurs.

- the system is designed so that the release torque has already been safely exceeded at this point.

- the further increase of the moment due to the inertia of the trigger wheel 120 is already greatly reduced by the damping effect of the elastic lining 121 and limited by the sliding upwards.

- a rotational movement of the trigger wheel 120 in turn can be used to trigger a variety of functions, such as an electric switch or a rope brake, as described below FIG. 3 will be used.

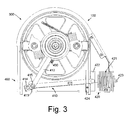

- FIG. 3 a preferred embodiment of a speed limiter 300 according to the invention is shown in a plan view, which has the triggering device 100 and a particularly preferred embodiment 400 of a rope brake.

- the cable brake 400 comprises a four-link coupling mechanism configured as a sliding crank 410 and a clamping brake 420 prestressed by means of a disk spring arrangement 421.

- the clamping brake 420 has a rigid brake shoe 424 and a movable brake shoe 422 which is connected by a connecting rod 411 of the crank 410 against the force of the disk spring 421 is held.

- a trip lever 412 is in a metastable position on a pin 430 and the trigger wheel 120 at.

- the crank 413 is rotatably mounted on an axle 414 and connected at a joint 415 with the connecting rod 411 and the release lever 412.

- the trip lever 412 pushes down the hinge 415 in the view shown so that the connecting rod 411 pushes the brake shoes 422 to the right.

- the trigger lever 412 on the trigger wheel is pushed to the left in the drawing, thereby releasing the hinge 415 and allowing it to move up to the left.

- the plate spring 421 pushes the brake shoes 422 against the brake shoe 424 and clamps the rope 103 running therebetween.

- the plate spring package 421 with a threaded assembly 423 provided by the operation of the plate spring package 421 can be biased.

- the force acting on the brake shoes 422 force is released, so that the connecting rod 411 and the release lever 412 can be brought back into the position shown.

- the threaded arrangement 423 is released again in order to pretension the brake shoes 422.

- a trigger device for a speed limiter of an elevator installation can be provided which has a number of advantages.

- the special design leads to a robustness, which allows usual manufacturing tolerances without adverse effect. It is kinematically and statically determined and places less demands on the manufacturing accuracy. The process capability is given. Smaller and lighter parts can be used, simplifying manufacturing and reducing costs. Compared to known limiters, the device is small, light, durable and low in noise.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Maintenance And Inspection Apparatuses For Elevators (AREA)

- Braking Arrangements (AREA)

- High-Pressure Fuel Injection Pump Control (AREA)

Abstract

Description

Die vorliegende Erfindung betrifft eine Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage sowie einen mit einer solchen Auslösevorrichtung ausgestatteten Geschwindigkeitsbegrenzer.The present invention relates to a tripping device for a speed limiter of an elevator installation and to a speed limiter equipped with such a tripping device.

Aus dem Stand der Technik sind (vorgeschriebene) Geschwindigkeitsbegrenzer für Aufzugsanlagen bekannt, welche bei Überschreiten einer Auslösegeschwindigkeit Notfallmaßnahmen, z.B. das Aktivieren der Fangvorrichtung, einleiten.The prior art discloses (prescribed) speed limiters for elevator installations which, when a triggering speed is exceeded, provide emergency measures, e.g. activate the safety gear.

Die

Ein vergleichbarer Geschwindigkeitsbegrenzer ist in der

Weiterhin sind Geschwindigkeitsbegrenzer bekannt, bei denen statt einem Bremsrad ein Auslöserad vorgesehen ist, das bei Überschreiten der Auslösegeschwindigkeit von den Koppelmitteln beaufschlagt und in Drehrichtung mitgenommen wird. Durch die Drehung des Auslöserads wird dann eine Seilbremse für das die Seilscheibe umschlingende Seil ausgelöst, wodurch wiederum eine Fangvorrichtung am Fahrkorb ausgelöst wird. Ein solcher Geschwindigkeitsbegrenzer wird beispielsweise unter der Bezeichnung OL 100 von der Firma Wittur vertrieben oder ist in der

Die im Stand der Technik bekannten Geschwindigkeitsbegrenzer weisen den Nachteil auf, dass das Zusammenwirken von Seilscheibe, Fliehmassen, Koppelmitteln und Auslöse- bzw. Bremsrad eine Vielzahl von Einzelkomponenten bedingt, welche alle bestimmten Toleranzanforderungen unterliegen. Die bisherigen Lösungen setzen hohe Fertigungsgenauigkeiten voraus, da sie konstruktiv überbestimmt sind. Diese Überbestimmtheit der Konstruktion kann zu Störungen und hohem Verschleiß führen. Das Gesamtsystem ist in der Folge relativ teuer, da bei der Herstellung gewisse Mindesttoleranzen für die Einzelelemente eingehalten werden müssen. Dies liegt auch am symmetrischen Aufbau, d.h. einige Elemente wie z.B. Fliehmassen und Koppelmittel sind in der Regel mindestens doppelt vorgesehen, so dass sowohl die Toleranzen eines Elements als auch elementübergreifende Toleranzen eine Rolle spielen. In der Folge gestaltet sich insbesondere die Herstellung und Wartung schwierig, da nicht nur Bauteile ausgesucht werden müssen, die innerhalb der vorgeschriebenen Toleranzgrenzen liegen, sondern deren Abmessungen auch untereinander zusammenpassen. Da bei einem Aufzug üblicherweise große Kräfte und Geschwindigkeiten auftreten, sind die einzelnen Elemente aus steifen und festen Materialien, wie z.B. Stahl, gefertigt, welche eine sehr große Federkonstante haben, so dass die zulässigen Toleranzen relativ klein ausfallen. Durch die großen Federkonstanten wirken große Kräfte, so dass die Elemente, Lager und Bolzen massiv ausgebildet sind..The speed limiters known in the prior art have the disadvantage that the interaction of pulley, flyweight, coupling means and tripping or braking a variety of individual components conditionally, which are all subject to certain tolerance requirements. The previous solutions require high manufacturing accuracy, since they are constructively overdetermined. This over-determination of the construction can lead to disturbances and high wear. The overall system is relatively expensive as a result, since certain minimum tolerances must be maintained for the individual elements during manufacture. This is also due to the symmetrical structure, ie some elements such as flyweights and coupling means are usually provided at least twice, so that both the tolerances of an element and element-overlapping tolerances play a role. As a result, in particular the production and maintenance is difficult because not only components must be selected within the prescribed tolerance limits, but their dimensions also fit together. Since large forces and speeds usually occur in an elevator, the individual elements are made of rigid and solid materials, such as steel, which have a very large spring constant, so that the permissible tolerances are relatively small. Due to the large spring constants act large forces, so that the elements, bearings and bolts are solid ..

Es ist somit wünschenswert, eine Auslösevorrichtung für einen Geschwindigkeitsbegrenzer anzugeben, die einfacher und damit kostengünstiger herzustellen ist, wobei das Auslöseverhalten jedoch nicht verschlechtert sein darf.It is thus desirable to provide a trigger device for a speed limiter, which is simpler and thus cheaper to produce, but the tripping behavior must not be deteriorated.

Ausgehend von diesem Stand der Technik schlägt die vorliegende Erfindung daher eine Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage gemäß dem Patentanspruch 1 vor. Vorteilhafte Ausgestaltungen sind Gegenstand der Unteransprüche sowie der nachfolgenden Beschreibung.Based on this prior art, the present invention therefore proposes a release device for a speed limiter of an elevator installation according to claim 1. Advantageous embodiments are the subject of the dependent claims and the following description.

Die Erfindung lehrt insbesondere, ein elastisches Material zwischen den Koppelmitteln und dem Auslöserad vorzusehen. Durch die Elastizität können Größenabweichungen von Bauteilen untereinander sowie Toleranzüberschreitungen ausgeglichen werden. In der Folge sinken die Toleranzanforderungen an die einzelnen Bauteile, so dass die Herstellungskosten reduziert werden können.In particular, the invention teaches to provide an elastic material between the coupling means and the trigger wheel. Due to the elasticity of size deviations of components can be compensated among each other and tolerance overruns. As a result, the tolerance requirements on the individual components decrease, so that the manufacturing costs can be reduced.

Auch die im Stand der Technik vorhandene hohe Steifigkeit des Klemmmechanismus, welche zu großen Normalkräften sowie zu engen Toleranzfeldern führt, wird vermindert. Das Auslöserad kann über seine Breite in zwei Funktionsbereiche unterteilt werden. Einen Klemmbereich, der in Kontakt mit den Koppelmitteln tritt, und einen Auslösebereich, an dem der Auslösehebel anliegt. Zumindest im Klemmbereich wird nun ein (gummi-)elastisches Material, insbesondere als Belag, vorgesehen. Dadurch wird die Steifigkeit vermindert und auch die Haftreibung erhöht, wodurch bereits kleinere Normalkräfte zur Auslösung ausreichend sind. Gleichzeitig stellt das Material eine Federkomponente dar, die mit zunehmender Belagdicke weicher wird.The existing in the prior art high rigidity of the clamping mechanism, which leads to large normal forces and tight tolerance fields is reduced. The release wheel can be divided across its width into two functional areas. A clamping area, which comes into contact with the coupling means, and a triggering area, which abuts the release lever. At least in the clamping area, a (rubber) elastic material, in particular as a covering, is now provided. As a result, the rigidity is reduced and also increases the static friction, whereby even smaller normal forces are sufficient for triggering. At the same time, the material is a spring component, which softens with increasing lining thickness.

Der Werkstoff weist zweckmäßigerweise eine hohe Haftreibung im Kontakt mit den Koppelmitteln sowie eine hohe elastische Verformbarkeit auf. Gleichzeitig sollte die Scherfestigkeit und die Qualität der Verbindung zum Grundkörper ausreichend sein, um das Auslösemoment zu übertragen. Außerdem sollte eine hohe Zeitfestigkeit auch unter den gegebenen Umwelteinflüssen vorhanden sein. Durch die gummiähnlichen Eigenschaften entsteht zusätzlich bei der Auslösung ein Dämpfungseffekt, der vor allem bei hohen Geschwindigkeiten zur Materialschonung beiträgt.The material expediently has a high stiction in contact with the coupling means and a high elastic deformability. At the same time, the shear strength and the quality of the connection to the body should be sufficient to transmit the release torque. In addition, a high time stability should also be present under the given environmental influences. The rubber-like properties also create a damping effect when triggered, which contributes to material protection, especially at high speeds.

Wird ein elastisches Material eingesetzt, welches zugleich eine reibungsvermittelnde Wirkung zeigt, kann das Ansprechverhalten verbessert und die Zuverlässigkeit des Ansprechens erhöht werden. Die Elastizität sowie die Reibung des Materials können so gewählt werden, dass eine Rotation des Auslöserads sicher erfolgt, sobald eine vorgegebene Beaufschlagung des Auslöserads durch die Koppelmittel stattfindet. Das Verhältnis von Elastizität und Reibung kann so vorgegeben werden, dass ein Toleranzausgleich von Bauteilgrößen und ein sicheres Auslösen des Auslöserads möglich sind. Das Auslöserad wiederum kann einen Auslösehebel zum Auslösen einer Seilbremse und/oder einen Schalter zum stromlos Schalten des Aufzugantriebs betätigen.If an elastic material is used, which also has a friction-promoting effect, the response can be improved and the reliability of the response can be increased. The elasticity and the friction of the material can be selected so that a rotation of the trigger wheel takes place safely as soon as a predetermined loading of the trigger wheel takes place by the coupling means. The ratio of elasticity and friction can be specified so that a tolerance compensation of component sizes and a safe triggering of the trigger wheel are possible. The tripping wheel in turn can actuate a release lever for triggering a cable brake and / or a switch for de-energized switching of the elevator drive.

Es wurde erkannt, dass wider Erwarten auch im Aufzugsbau, wo raue Umgebungsbedingungen im Schacht vorliegen und große Kräfte wirken, elastisches Material bewusst eingesetzt werden kann, um bestimmte Vorteile zu erreichen. Als elastisches Material mit geeigneten Eigenschaften kann beispielsweise Vulkollan eingesetzt werden. Ebenso können andere Kunststoffe auf Elastomerbasis verwendet werden.It has been recognized that contrary to expectations, even in elevator construction, where harsh environmental conditions prevail in the shaft and large forces act, elastic material can be deliberately used to achieve certain advantages. As an elastic material with suitable properties Vulkollan can be used for example. Likewise, other elastomers based plastics can be used.

Vorteilhafterweise weist das Auslöserad einen Reifen bzw. Belag aus dem elastischen Material auf. Auf diese Weise kann das Material einfach zwischen Auslöserad und Koppelmittel bereitgestellt und beispielsweise im Falle von Verschleiß auch ausgetauscht werden. Alternativ oder zusätzlich können auch die Koppelmittel mit dem elastischen Material versehen sein.Advantageously, the trigger wheel on a tire or covering of the elastic material. In this way, the material can be easily provided between the trigger wheel and coupling means and, for example, in the case of wear also replaced. Alternatively or additionally, the coupling means may be provided with the elastic material.

Gemäß einer besonders bevorzugten Ausgestaltung stellen die Fliehmassen gleichzeitig die Koppelmittel dar. Bei dieser bevorzugten Lösung können somit wenigstens zwei zusätzliche Bauteile sowie deren Verbindungsmittel untereinander eingespart werden. Die Konstruktion der Auslösevorrichtung wird einfacher und preiswerter. Die Konstruktion ist kinematisch und statisch bestimmt, was die einzuhaltenden Toleranzbereiche vergrößert. Die als Fliehmassen wirkenden Koppelmittel (bzw. die als Koppelmittel wirkenden Fliehmassen) weisen zweckmäßigerweise einen Koppelbereich zur Beaufschlagung bzw. Kontaktierung des Auslöserads sowie einen Gewichtsbereich auf. Der Gewichtsbereich ist zweckmäßigerweise so ausgebildet, dass er nicht in Kontakt mit dem Auslöserad kommt und dass er zur Aufnahme von separaten Zusatzgewichten geeignet ist. Diese separaten Zusatzgewichte dienen dazu, die Auslösegeschwindigkeit der Auslösevorrichtung einzustellen.According to a particularly preferred embodiment, the flyweight simultaneously represent the coupling means. In this preferred solution, at least two additional components and their connection means can be saved with each other. The design of the tripping device becomes simpler and cheaper. The design is kinematically and statically determined, which increases the tolerance ranges to be complied with. The coupling agents acting as flyweight compounds (or the flyweights acting as coupling agents) expediently have a coupling region for loading or contacting the trigger wheel and a weight range. The weight range is expediently designed so that it does not come into contact with the trigger wheel and that it is suitable for receiving separate additional weights. These separate additional weights are used to set the release speed of the release device.

Wenn der Rand der Koppelmittel zumindest teilweise die Form einer archimedischen Spirale hat, erfolgt ein sanftes Beaufschlagen des Auslöserads ohne Ruck mit gemäßigtem Kraftanstieg. Der entsprechend geformte Rand der Koppelmittel liegt zweckmäßigerweise in dem weiter oben als Koppelbereich bezeichneten Bereich. Insbesondere bei dieser Ausgestaltung kann das Bereitstellen eines elastischen Materials besondere Vorteile entfalten, da die als Fliehmassen wirkenden Koppelmittel in Abhängigkeit von der Auslösegeschwindigkeit ggf. unterschiedliche Formen haben können, so dass der Abstand des Rands des Koppelmittels vom Auslöserad ggf. von der Auslegung des Begrenzers abhängt. Diese unterschiedlichen Abstände können bei Beibehaltung aller anderen konstruktiven Größen durch das elastische Material ausgeglichen werden.If the edge of the coupling means at least partially in the form of an Archimedean spiral, gently applying the trigger wheel without jerk occurs with moderate increase in force. The correspondingly shaped edge of the coupling means is expediently in the area designated above as a coupling region. In particular, in this embodiment, the provision of an elastic material can develop particular advantages, since the acting as flyweight coupling means depending on the release speed may possibly have different shapes, so that the distance of the edge of the coupling means from the trigger wheel, if necessary, depends on the design of the limiter , These different distances can be compensated for while maintaining all other structural sizes by the elastic material.

Wenn die Koppelmittel eine Nase aufweisen, welche einen Endanschlag definiert, kann ein übermäßiges Beaufschlagen des Auslöserads durch die Koppelmittel vermieden werden. Zu Beginn des Auslösevorgangs befindet sich das Auslöserad in Ruhe. Die Koppelmittel rotieren jedoch mit der Geschwindigkeit des Begrenzerrads um das Auslöserad herum und werden dabei - in Abhängigkeit von der Rotationsgeschwindigkeit des Begrenzerrads - um ihre eigene Achse ausgelenkt. Die Koppelmittel sind dabei zweckmäßigerweise so angeordnet, dass die Rotation bzw. Auslenkung um ihre eigene Achse bei Beaufschlagung des Auslöserads zu einer Selbstverstärkung der Beaufschlagung führt. Diese Selbstverstärkung hält solange an, bis das Auslöserad die Rotationsgeschwindigkeit des Begrenzerrads erreicht hat. Um dabei jedoch kein übermäßiges Eindrehen der Koppelmittel zu riskieren, sind diese zweckmäßigerweise mit einem Endanschlag ausgestattet. Schlägt dieser an das Auslöserad an, kann kein weiteres Eindrehen stattfinden.If the coupling means have a nose which defines an end stop, an excessive loading of the trigger wheel by the coupling means can be avoided. At the beginning of the tripping process, the tripping wheel is at rest. However, the coupling means rotate around the trigger wheel at the speed of the governor wheel, being deflected about its own axis depending on the speed of rotation of the governor wheel. The coupling means are expediently so arranged that the rotation or deflection about its own axis when applied to the trigger wheel leads to a self-boosting of the admission. This self-energizing continues until the trigger wheel has reached the rotational speed of the governor wheel. However, in order to avoid excessive screwing the coupling agent, these are expediently equipped with an end stop. If this strikes against the trigger wheel, no further screwing can take place.

Zweckmäßigerweise sind die Fliehmassen miteinander mittels einer Seilverbindung gekoppelt und zugbelastet federvorgespannt, so dass ein linearer Zusammenhang zwischen der Federbelastung und der Auslenkung der Fliehmassen besteht. Die Fliehmassen sind paarweise auf dem Begrenzerrad angeordnet und mittels einer Seilverbindung verbunden, um Gravitationseffekte zu kompensieren. Weiterhin sind sie gegen die Fliehkraftwirkung so vorgespannt, dass eine für eine Beaufschlagung des Auslöserads ausreichende Auslenkung der Fliehmassen erst bei Erreichen der Auslösegeschwindigkeit stattfindet. Zweckmäßigerweise sind dabei die Fliehmassen und die Feder so bemessen, dass unterhalb der Auslösegeschwindigkeit keine Auslenkung der Fliehmassen stattfindet. Auf diese Weise bleiben die genannten Bauteile während des Normalbetriebs in Ruhe, so dass keine Abnutzung stattfindet. Durch die federvorgespannte Seilverbindung kann ein linearer Zusammenhang zwischen Federbelastung und Auslenkung der Fliehmassen bereitgestellt werden, so dass die erwünschte Auslösegeschwindigkeit auf sehr einfache Weise einzustellen ist.Conveniently, the flyweights are coupled to each other by means of a cable connection and tensioned spring loaded, so that there is a linear relationship between the spring load and the deflection of the flyweight. The flyweights are arranged in pairs on the governor wheel and connected by a cable connection to compensate for gravitational effects. Furthermore, they are biased against the centrifugal force so that sufficient for an actuation of the trigger wheel deflection of the flyweight takes place only when reaching the triggering speed. Conveniently, the flyweight and the spring are dimensioned so that below the release speed no deflection of the flyweight takes place. In this way, the components mentioned during normal operation remain at rest, so that no wear takes place. By the spring-biased cable connection, a linear relationship between the spring load and deflection of the flyweight can be provided so that the desired release speed is set in a very simple manner.

Vorteilhafterweise sind die Fliehmassen so auf dem Begrenzerrad angeordnet, dass der Schwerpunkt der Fliehmassen einen kleineren Abstand von der Drehachse des Begrenzerrads aufweist als den Abstand der Drehachse der Fliehmassen von der Drehachse des Bagrenzerrads. Mit anderen Worten liegt der Schwerpunkt der Fliehmassen näher an der Drehachse des Begrenzerrads als ihre eigene Drehachse. Diese Anordnung führt dazu, dass die Ansprechgeschwindigkeit der Auslösevorrichtung von der Rotationsbeschleunigung des Drehrades insofern abhängt, als eine Beschleunigung des Begrenzerrads zu einem schnelleren Ansprechen der Auslösevorrichtung führt. Dieses Verhalten ist insbesondere für Seilbruchfälle besonders vorteilhaft, da dort eine große Beschleunigung des Fahrkorbs nach unten stattfindet und so ein möglicht frühes Auslösen wünschenswert ist.Advantageously, the flyweights are arranged on the governor wheel so that the center of gravity of the flyweights has a smaller distance from the axis of rotation of the governor wheel than the distance of the axis of rotation of the flyweights from the axis of rotation of the Bagrenzerrads. In other words, the center of gravity of the flyweights is closer to the axis of rotation of the governor than its own axis of rotation. This arrangement results in that the response speed of the triggering device depends on the rotational acceleration of the rotary wheel in so far as an acceleration of the governor wheel leads to a faster response of the triggering device. This behavior is particularly advantageous for rope breakage, since there is a large acceleration of the car down and so a possible early release is desirable.

Wenn das Begrenzerrad mit einer zentralen mitrotierenden Welle versehen ist, kann diese beispielsweise als Montageplatz für andere Einheiten dienen. Insbesondere können so Drehgeber u.ä. einfach in einer Aufzugsanlage platziert werden.If the governor wheel is provided with a central co-rotating shaft, this can serve, for example, as a mounting space for other units. In particular, so encoders u.ä. simply be placed in an elevator system.

Ein erfindungsgemäßer Geschwindigkeitsbegrenzer für einen Aufzug ist mit einer erfindungsgemäßen Auslösevorrichtung zum Auslösen einer Seilbremse und/oder zum Betätigen eines Schalters zum Stillsetzen eines Aufzugantriebs ausgestattet.An inventive speed limiter for an elevator is equipped with a tripping device according to the invention for triggering a cable brake and / or for actuating a switch for stopping an elevator drive.

Eine vorteilhafte Seilbremse umfasst ein viergliedriges Koppelgetriebe, insbesondere eine Schubkurbel. Damit kann eine große Hebelwirkung erzeugt werden, so dass eine große Bremskraft, welche beispielsweise von einer gespannten Feder bereitgestellt werden kann, durch eine kleine Auslösekraft gehalten werden kann. Diese kleine Auslösekraft wird vom Auslöserad aufgenommen.An advantageous cable brake comprises a four-link coupling gear, in particular a sliding crank. Thus, a large leverage can be generated, so that a large braking force, which, for example, from a cocked Spring can be provided, can be held by a small release force. This small release force is absorbed by the trigger wheel.

Zweckmäßigerweise umfasst die Seilbremse eine exzentrische Schubkurbel, bei der insbesondere die Exzentrizität größer als die Kurbellänge ist.Conveniently, the rope brake comprises an eccentric crank, in particular, the eccentricity is greater than the crank length.

Vorteilhafterweise drückt dabei das die Kurbel und das Pleuel verbindende Gelenk über einen Auslösehebel auf das Auslöserad. Der Auslösehebel ist in einem metastabilen Zustand am Auslöserad gehaltert. Das Gelenk wird dadurch durchgedrückt, so dass die Seilbremse gelüftet ist. Löst die Auslösevorrichtung aus, wird das Auslöserad in Rotation versetzt und drückt dadurch den Auslösehebel weg. Damit kann sich das Gelenk bewegen, so dass das Pleuel nachrücken kann und die Seilbremse schließt.Advantageously, the joint connecting the crank and the connecting rod presses on the trigger wheel via a release lever. The trigger is held in a metastable state on the trigger wheel. The joint is thereby pushed through, so that the rope brake is released. Triggers the triggering device, the trigger wheel is set in rotation, thereby pushing the release lever away. Thus, the joint can move, so that the connecting rod can move up and the rope brake closes.

Zur Platzersparnis bietet es sich an, die Seilbremse mittels wenigstens einer Tellerfeder vorzuspannen. Zur einfachen Lüftung der Seilbremse kann eine Schraubanordnung vorgesehen sein, bei der bspw. mittels einer einzuschraubenden Schraube oder Mutter ein dahinter befindliches Übertragungselement, wie bspw. eine Beilagscheibe, die Feder (Tellerfeder, Spiralfeder u.ä.) spannt.To save space, it is advisable to bias the rope brake by means of at least one plate spring. For easy ventilation of the rope brake, a screw arrangement may be provided, in which, for example, by means of a screw or nut to be screwed, a transmission element located behind it, such as, for example, a washer, clamps the spring (plate spring, spiral spring, etc.).

Vorteilhafterweise kann das Begrenzerrad beidseitig bestückt sein. Auf einer Seite sitzen Fliehmassen mit einem Auslöserad zum Auslösen der Seilbremse, wohingegen auf der anderen Seite Fliehmassen und ein Auslöserad zum Betätigen eines elektrischen Schalters angeordnet sind. Durch die zweiseitige Ausführung können unterschiedliche Auslösegeschwindigkeiten für die Seilbremse und den elektrischen Schalter bereitgestellt und eingestellt werden. Insbesondere können dadurch die von gängigen Aufzugnormen geforderten Parameter "Auslösegeschwindigkeit" (mechanischer Nothalt) und "Vorabschaltgeschwindigkeit" (elektrischer Nothalt) unabhängig voneinander eingestellt werden.Advantageously, the Begrenzerrad be equipped on both sides. Flywheels with a trigger wheel for releasing the rope brake are seated on one side, whereas flywheels and a trigger wheel for actuating an electrical switch are arranged on the other side. The two-sided design can be different Triggering speeds for the rope brake and the electrical switch are provided and adjusted. In particular, the parameters required by standard elevator standards "release speed" (mechanical emergency stop) and "pre-switch-off speed" (electrical emergency stop) can thereby be set independently of one another.

Weitere Vorteile und Ausgestaltungen der Erfindung ergeben sich aus der Beschreibung und der beiliegenden Zeichnung.Further advantages and embodiments of the invention will become apparent from the description and the accompanying drawings.

Es versteht sich, daß die vorstehend genannten und die nachstehend noch zu erläuternden Merkmale nicht nur in der jeweils angegebenen Kombination, sondern auch in anderen Kombinationen oder in Alleinstellung verwendbar sind, ohne den Rahmen der vorliegenden Erfindung zu verlassen.It is understood that the features mentioned above and those yet to be explained not only in the particular combination given, but also in other combinations or alone, without departing from the scope of the present invention.

Die Erfindung ist anhand eines Ausführungsbeispieles in der Zeichnung schematisch dargestellt und wird im Folgenden unter Bezugnahme auf die Zeichnung ausführlich beschrieben.The invention is illustrated schematically with reference to an embodiment in the drawing and will be described in detail below with reference to the drawing.

Es zeigt

- Figur 1

- eine bevorzugte Ausführungsform einer erfindungs- gemäßen Auslösevorrichtung in einer schematischen Draufsicht.

- Figur 2

- die Auslösevorrichtung gemäß

Figur 1 in einer schematischen Seitenansicht. - Figur 3

- eine bevorzugte Ausführungsform eines erfin- dungsgemäßen Geschwindigkeitsbegrenzers mit einer Auslösevorrichtung und einer Seilbremse.

- FIG. 1

- a preferred embodiment of a tripping device according to the invention in a schematic plan view.

- FIG. 2

- the triggering device according to

FIG. 1 in a schematic side view. - FIG. 3

- A preferred embodiment of an inventive speed limiter with a tripping device and a rope brake.

In den

Die Auslösevorrichtung 100 weist einen Träger 101 auf, an dem insbesondere auch die auszulösenden Elemente, wie z. B. eine Seilbremse oder ein elektrischer Schalter, angebracht werden können. An der Halterung 101 ist ein Begrenzerrad 102 drehbar gelagert, das von einem Begrenzerseil 103 bei Betrieb in Drehung versetzt wird. Das Begrenzerrad 102 ist an einem Lager 110 drehbar gelagert. Das Begrenzerrad 102 weist zwei an Achsen 104a, 104b drehbar gelagerte Fliehmassen 105a, 105b auf, welche gleichzeitig als Koppelmittel wirken.The triggering

In der dargestellten Grundstellung sind die Fliehmassen nicht ausgelenkt und beaufschlagen das Auslöserad nicht. Die Fliehmassen 105a, 105b weisen jeweils einen Koppelbereich 106a, 106b sowie eine einen Anschlag definierende Nase 107a, 107b auf. Weiterhin weisen die Fliehmassen 105a, 105b anbringbare und entfernbare Zusatzgewichte 108a, 108b auf, um die Auslösegeschwindigkeit der Auslösevorrichtung 100 einzustellen bzw. vorzugeben.In the illustrated basic position, the flyweights are not deflected and do not act on the trigger wheel. The

Die Fliehmassen/Koppelmittel 105a, 105b sind mittels einer Seilzugverbindung 200 verbunden, welche über eine Feder 201 vorgespannt ist. Somit muss eine vorgegebene Fliehkraft erreicht werden, um die Federvorspannkraft zu überwinden. Die Federvorspannkraft ist zweckmäßigerweise so vorgegeben, dass die Fliehmassen/Koppelmittel 105a, 105b während des Normalbetriebs in Ruhe bleiben und nicht ausgelenkt werden. Damit können Verschleiß sowie störende Geräusche, insbesondere Klappern, vermieden werden. Die Seilverbindung 200 dient insbesondere zum Gravitationsausgleich.The flyweight / coupling means 105a, 105b are connected by means of a

Das Begrenzerrad 102 ist drehfest mit einer zentralen Welle 111 verbunden, die sich synchron zum Begrenzerrad dreht und beispielsweise zur Aufnahme eines Drehgebers verwendet werden kann. So kann auf einfache Weise die Drehgeschwindigkeit des Begrenzerrades beispielsweise elektronisch abgetastet werden.The

An dem Lager 110 ist weiterhin ein Auslöserad 120 drehbar gelagert, welches sich während des Betriebs im nicht ausgelösten Zustand in Ruhe befindet. Das Auslöserad 120 weist einen Ring 121 aus elastischem Material auf, welcher insbesondere zum Ausgleich von Toleranzen sowie zur Reibungsvermittlung dient.On the

Im dargestellten, nicht ausgelösten Zustand (Grundstellung) sind die Fliehmassen/Koppelmittel 105a, 105b nicht ausgelenkt und stehen deshalb nicht in Kontakt mit dem Auslöserad 120. Überschreitet die Drehgeschwindigkeit des Begrenzerrades 102 jedoch die vorgegebene Auslösegeschwindigkeit, werden die Fliehmassen/Koppelmittel 105a, 105b gegen die Kraft der Feder 201 ausgelenkt und nähern sich dem Auslöserad bis zur Berührung an. Je nach Abstand ist dafür ein Schwenkwinkel von bis zu 30° nötig. Schließlich kommen die Koppelbereiche 106a, 106b in Kontakt mit dem elastischen Material 121 des Begrenzerrads 120. Im weiteren Verlauf wälzen die Fliehmassen/Koppelmittel 105a, 105b durch die Haftreibung selbsttätig weiter ein, bis das Auslösemoment erreicht ist. Auf diese Weise wird die Drehbewegung des Begrenzerrads 102 an das Auslöserad 120 übertragen, welches in der Folge in eine Drehbewegung versetzt wird. Ab einem Schwenkwinkel von etwa 70° wird ein weiteres Einwälzen durch das Auftreffen der speziell geformten Nasen verhindert. Durch diese Begrenzung des maximalen Schwenkwinkels werden die Fliehmassen/Koppelmittel am Durchschlagen gehindert und gleichzeitig wird das System vor Überlastung geschützt. Das Auftreffen der an jeder Fliehmasse/Koppelmittel ausgeformten Nase 107a bzw. 107b am Auslöserad 120 bewirkt eine deutliche Verschiebung des Kraftangriffspunktes. In der Folge ändert sich das Verhältnis zwischen der Normalkraft und der zum weiteren Einwälzen nötigen Haftreibungskraft so stark, dass es zum Rutschen kommt. Das System ist so ausgelegt, dass das Auslösemoment an diesem Punkt bereits sicher überschritten ist. Das weitere Anwachsen des Moments durch die Trägheit des Auslöserades 120 wird bereits durch die Dämpfungswirkung des elastischen Belags 121 stark gemindert und durch das Rutschen nach oben begrenzt.In the illustrated, untripped condition (basic position), the flyweights / coupling means 105a, 105b are not deflected and therefore are not in contact with the

Eine Drehbewegung des Auslöserads 120 wiederum kann zum Auslösen unterschiedlichster Funktionen, beispielsweise eines elektrischen Schalters oder einer Seilbremse, wie es nachfolgend anhand

In

Ein Auslösehebel 412 liegt in einer metastabilen Stellung an einem Zapfen 430 sowie an dem Auslöserad 120 an. Die Kurbel 413 ist an einer Achse 414 drehbar gelagert und an einem Gelenk 415 mit dem Pleuel 411 und dem Auslösehebel 412 verbunden. In der gelüfteten Stellung der Bremse 400 drückt der Auslösehebel 412 das Gelenk 415 in der gezeigten Ansicht nach unten, so dass das Pleuel 411 den Bremsbacken 422 nach rechts drückt.A

Wird das Auslöserad 120 jedoch durch Beaufschlagung mit den Koppelmitteln 105a, 105b in Drehung (im Uhrzeigersinn) versetzt, wird der am Auslöserad anstehende Auslösehebel 412 in der Zeichnung nach links weggedrückt, wodurch das Gelenk 415 freigegeben wird und sich nach links oben bewegen kann. In der Folge drückt die Tellerfeder 421 den Bremsbacken 422 gegen den Bremsbacken 424 und klemmt das dazwischen laufende Seil 103 ein.However, when the

Um einen einmal ausgelösten Begrenzer auf einfache Weise wieder in die Grundstellung zurückzuführen, ist das Tellerfederpaket 421 mit einer Gewindeanordnung 423 versehen, durch deren Betätigung das Tellerfederpaket 421 vorgespannt werden kann. Damit wird die auf den Bremsbacken 422 wirkende Kraft gelöst, so dass das Pleuel 411 und der Auslösehebel 412 wieder in die gezeigte Stellung gebracht werden können. Aus Sicherheitsgründen muss anschließend sichergestellt werden, dass die Gewindeanordnung 423 wieder gelöst wird, um den Bremsbacken 422 vorzuspannen.To return a once triggered limiter in a simple way back to the normal position, the

Erfindungsgemäß kann eine Auslösevorrichtung für einen Geschwindigkeitsbegrenzer einer Aufzugsanlage bereitgestellt werden, die eine Reihe von Vorteilen aufweist. Die besondere Konstruktion führt zu einer Robustheit, welche übliche Fertigungstoleranzen ohne nachteilige Wirkung zulässt. Sie ist kinematisch und statisch bestimmt und stellt geringere Anforderungen an die Fertigungsgenauigkeit. Die Prozessfähigkeit ist gegeben. Es können kleinere und leichtere Teile verwendet werden, was die Fertigung vereinfacht und die Kosten verringert. Im Vergleich zu bekannten Begrenzern baut die Vorrichtung klein, ist leicht, langlebig und zeigt nur eine geringe Geräuschentwicklung.According to the invention, a trigger device for a speed limiter of an elevator installation can be provided which has a number of advantages. The special design leads to a robustness, which allows usual manufacturing tolerances without adverse effect. It is kinematically and statically determined and places less demands on the manufacturing accuracy. The process capability is given. Smaller and lighter parts can be used, simplifying manufacturing and reducing costs. Compared to known limiters, the device is small, light, durable and low in noise.

Claims (13)

- Actuator (100) for a speed governor (300) of a lift system, comprising

a governor wheel (102) equipped with at least two inertia masses (105a, 105b) which can be driven by an encircling governor cable (103),

an actuator wheel (120) that is stationary in a basic position,

coupling means (105a, 105b) that act on the actuator wheel (120) when the governor wheel (102) reaches an actuating speed and thus couple to the governor wheel (102) in such a way that the actuator wheel (120) is set in rotation,

an elastic material that preferably imparts high friction being provided between the coupling means (105a, 105b) and the actuator wheel (120),

characterised in that

the actuator wheel (120) has a lining or rim (121) composed of the elastic material, and/or the coupling means (105a, 105b) are equipped with the elastic material. - Actuator (100) according to claim 1, wherein the inertia masses (105a, 105b) are simultaneously the coupling means (105a, 105b).

- Actuator (100) according to one of the preceding claims, wherein at least one coupling region (106a, 106b) of the edge of the coupling means (105a, 105b) is in the form of an Archimedean screw.

- Actuator (100) according to one of the preceding claims, wherein the coupling means (105a, 105b) each comprise a lug (107a, 107b) which defines an end stop.

- Actuator (100) according to one of the preceding claims, wherein the inertia masses (105a, 105b) are coupled to one another by a cable connection (200) and are springloaded under tension, so that there is a linear correlation between the spring loading (102) and the deflection of the inertia masses (105a, 105b).

- Actuator (100) according to claim 5, wherein the inertia masses (105a, 105b) and the spring (201) are of such dimensions that there is no deflection of the inertia masses below the actuation speed.

- Actuator (100) according to one of the preceding claims, wherein the centre of gravity of an inertia mass (105a, 105b) is at a spacing from the rotation axis (111) of the governor wheel (102) that is less than the spacing of the rotation axis (104a, 104b) of the inertia mass from the rotation axis (111) of the governor wheel (102).

- Actuator (100) according to one of the preceding claims, wherein the governor wheel (102) is provided with a central co-rotating shaft (111).

- Speed governor (300) for a lift having an actuator (100) according to one of the preceding claims, for actuating a cable brake (400) and/or for actuating a switch for stopping a lift drive.

- Speed governor (300) according to claim 9, wherein the cable brake (400) comprises a four-member linkage, particularly a thrust crank (410).

- Speed governor (300) according to claim 10, wherein the cable brake (400) comprises an eccentric thrust crank (410), the eccentricity being, in particular, greater than the length of the crank.

- Speed governor (300) according to claim 10 or 11, wherein the joint (415) that connects the crank (413) and the connecting rod (411) presses on the actuator wheel (12) via an actuator lever (412).

- Speed governor (300) according to one of claims 10 to 12, wherein the cable brake (400) can be released by a thread arrangement (423).

Priority Applications (9)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09175529A EP2319793B1 (en) | 2009-11-10 | 2009-11-10 | Actuator for a speed restrictor of a lift system |

| ES09175529T ES2381966T3 (en) | 2009-11-10 | 2009-11-10 | Release device for a speed limiter of an elevator installation |

| AT09175529T ATE542767T1 (en) | 2009-11-10 | 2009-11-10 | TRIGGER DEVICE FOR A SPEED LIMITER OF AN ELEVATOR SYSTEM |

| CN201080051141.6A CN102695665B (en) | 2009-11-10 | 2010-10-29 | Trigger device for a speed governor of an elevator system |

| KR1020127012581A KR101833382B1 (en) | 2009-11-10 | 2010-10-29 | Trigger Device for a Speed Governor of an Elevator System |

| JP2012538274A JP5385464B2 (en) | 2009-11-10 | 2010-10-29 | Actuator for governor of elevator system |

| PCT/EP2010/066547 WO2011057907A1 (en) | 2009-11-10 | 2010-10-29 | Trigger device for a speed governor of an elevator system |

| BR112012010492A BR112012010492A2 (en) | 2009-11-10 | 2010-10-29 | drive for one system speed governor and drive speed governor with actuator |

| US13/468,762 US8453799B2 (en) | 2009-11-10 | 2012-05-10 | Actuator for a speed governor of an elevator system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09175529A EP2319793B1 (en) | 2009-11-10 | 2009-11-10 | Actuator for a speed restrictor of a lift system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2319793A1 EP2319793A1 (en) | 2011-05-11 |

| EP2319793B1 true EP2319793B1 (en) | 2012-01-25 |

Family

ID=41647106

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09175529A Not-in-force EP2319793B1 (en) | 2009-11-10 | 2009-11-10 | Actuator for a speed restrictor of a lift system |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US8453799B2 (en) |

| EP (1) | EP2319793B1 (en) |

| JP (1) | JP5385464B2 (en) |

| KR (1) | KR101833382B1 (en) |

| CN (1) | CN102695665B (en) |

| AT (1) | ATE542767T1 (en) |

| BR (1) | BR112012010492A2 (en) |

| ES (1) | ES2381966T3 (en) |

| WO (1) | WO2011057907A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016208403A1 (en) | 2016-05-17 | 2017-11-23 | Thyssenkrupp Ag | Speed limiter for a lift |

| CN108529411A (en) * | 2017-12-29 | 2018-09-14 | 迅达(中国)电梯有限公司 | The installation of hawser for speed restrictor |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2913287B1 (en) | 2014-02-26 | 2018-01-03 | Otis Elevator Company | Governor for controlling the speed of a hoisted object relative to a guide member |

| EP3363759B1 (en) * | 2015-10-13 | 2020-05-06 | Hitachi, Ltd. | Elevator device |

| CN105293247B (en) * | 2015-11-26 | 2017-11-17 | 上海乐天电梯部件有限公司 | A kind of limiter of speed and its application method |

| CN107021395B (en) * | 2016-01-04 | 2020-11-10 | 奥的斯电梯公司 | Elevator overspeed governor with automatic reset |

| CN107673159B (en) * | 2016-08-01 | 2020-09-08 | 奥的斯电梯公司 | Speed limiter of elevator |

| CN108002168B (en) | 2016-10-27 | 2021-04-02 | 奥的斯电梯公司 | Remote triggering device, speed limiter assembly and elevator |

| CN108298398B (en) | 2017-01-13 | 2020-09-01 | 奥的斯电梯公司 | Core ring assembly for elevator governor, governor and elevator system |

| CN109720961B (en) * | 2017-10-30 | 2021-08-17 | 奥的斯电梯公司 | Speed limiter assembly and elevator system |

| CN108639894B (en) * | 2018-04-02 | 2019-10-22 | 浙江工贸职业技术学院 | A kind of elevator stopping device with trigger mechanism |

| US11034546B2 (en) * | 2018-06-28 | 2021-06-15 | Otis Elevator Company | Elevator governor |

| CN111377326A (en) * | 2018-12-29 | 2020-07-07 | 上海龙钰电梯配件有限公司 | Mechanical trigger mechanism of speed limiter |

| KR102348331B1 (en) | 2019-12-30 | 2022-01-11 | 현대엘리베이터주식회사 | Apparatus for governor trip of temporary elevator car |

| CN113266142B (en) * | 2021-04-30 | 2022-04-19 | 中交第四公路工程局有限公司 | Rapid lifting platform for elevator shaft construction |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH480258A (en) | 1967-10-04 | 1969-10-31 | Aufzuege Ag Schaffhausen | Speed limiter for elevators |

| US4134482A (en) * | 1976-08-20 | 1979-01-16 | Tsentralny Nauchno-Issledovatelsky Avtomobilny I Avtomotorny Institut | Device to effect control over the friction clutch of a transport vehicle |

| JPS54108339A (en) * | 1978-02-14 | 1979-08-24 | Mitsubishi Electric Corp | Driving device for elevators |

| AT382848B (en) | 1983-12-16 | 1987-04-10 | Kone Sowitsch Aktiengesellscha | SPEED LIMITER FOR ELEVATOR EQUIPPED |

| JPH0475985A (en) * | 1990-07-18 | 1992-03-10 | Fujitsu Ltd | Elevator device |

| FI95021C (en) * | 1993-06-08 | 1995-12-11 | Kone Oy | Method and apparatus for triggering an elevator gripping device |

| JPH07315732A (en) * | 1994-05-24 | 1995-12-05 | Hitachi Building Syst Eng & Service Co Ltd | Repairing tool for electromagnetic braking machine of elevator |

| JP2006046633A (en) * | 2004-07-02 | 2006-02-16 | Yamaha Motor Co Ltd | Vehicle |

| EP1852383A4 (en) * | 2005-02-24 | 2012-11-14 | Mitsubishi Electric Corp | Governor for elevator |

| FI120303B (en) * | 2005-06-23 | 2009-09-15 | Kone Corp | Method and apparatus for triggering a captive device in an elevator |

| JP4985649B2 (en) * | 2006-10-18 | 2012-07-25 | 三菱電機株式会社 | Elevator speed control device and elevator device |

| EP2144835B1 (en) * | 2007-04-13 | 2014-07-16 | Otis Elevator Company | Governor sheave with an overlapping flyweight system |

| CN101679000B (en) * | 2007-06-21 | 2012-07-18 | 三菱电机株式会社 | Safety device for elevator and rope slip detection method |

| DE102007052280B4 (en) | 2007-11-02 | 2015-04-02 | Wittur Holding Gmbh | Independently responsive speed limiter |

| WO2010023745A1 (en) * | 2008-08-28 | 2010-03-04 | 三菱電機株式会社 | Elevator speed governor |

| JP5360201B2 (en) * | 2009-04-09 | 2013-12-04 | 三菱電機株式会社 | Elevator governor |

| KR20120069780A (en) * | 2010-01-07 | 2012-06-28 | 미쓰비시덴키 가부시키가이샤 | Elevator device |

-

2009

- 2009-11-10 EP EP09175529A patent/EP2319793B1/en not_active Not-in-force

- 2009-11-10 ES ES09175529T patent/ES2381966T3/en active Active

- 2009-11-10 AT AT09175529T patent/ATE542767T1/en active

-

2010

- 2010-10-29 CN CN201080051141.6A patent/CN102695665B/en not_active Expired - Fee Related

- 2010-10-29 BR BR112012010492A patent/BR112012010492A2/en not_active Application Discontinuation

- 2010-10-29 JP JP2012538274A patent/JP5385464B2/en not_active Expired - Fee Related

- 2010-10-29 KR KR1020127012581A patent/KR101833382B1/en active IP Right Grant

- 2010-10-29 WO PCT/EP2010/066547 patent/WO2011057907A1/en active Application Filing

-

2012

- 2012-05-10 US US13/468,762 patent/US8453799B2/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102016208403A1 (en) | 2016-05-17 | 2017-11-23 | Thyssenkrupp Ag | Speed limiter for a lift |

| CN108529411A (en) * | 2017-12-29 | 2018-09-14 | 迅达(中国)电梯有限公司 | The installation of hawser for speed restrictor |

| CN108529411B (en) * | 2017-12-29 | 2020-05-08 | 迅达(中国)电梯有限公司 | Installation of a cable for a speed limiter |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2319793A1 (en) | 2011-05-11 |

| KR20120104546A (en) | 2012-09-21 |

| CN102695665A (en) | 2012-09-26 |

| US20120312638A1 (en) | 2012-12-13 |

| JP2013510059A (en) | 2013-03-21 |

| WO2011057907A1 (en) | 2011-05-19 |

| JP5385464B2 (en) | 2014-01-08 |

| US8453799B2 (en) | 2013-06-04 |

| ES2381966T3 (en) | 2012-06-04 |

| CN102695665B (en) | 2015-06-10 |

| KR101833382B1 (en) | 2018-02-28 |

| BR112012010492A2 (en) | 2016-03-15 |

| ATE542767T1 (en) | 2012-02-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2319793B1 (en) | Actuator for a speed restrictor of a lift system | |

| DE69509265T2 (en) | Device in an elevator overspeed governor | |

| DE3111583C2 (en) | ||

| EP2006563B1 (en) | Automatic spring brake for industrial trucks | |

| EP3402999B1 (en) | Vibration absorber having an electromagnetic brake for wind turbines | |

| EP2751005B1 (en) | Friction brake having an actuator unit that acts perpendicularly to the brake application direction | |

| DE102005001344B4 (en) | Wind turbine | |

| EP1995203B1 (en) | Velocity and acceleration monitoring device with electronically actuated servo-start for use in conveyor devices | |

| WO2010091895A2 (en) | Brake system for a wind turbine | |

| DE102005039434A1 (en) | Wind power plant to produce energy has thread-form connection with wedge-shaped grooves as contact surface to transmit drive torque between tower and head | |

| DE2337397A1 (en) | LOAD-DEPENDENT BRAKING DEVICE FOR CONVEYOR DEVICES | |

| EP3883875A1 (en) | Speed limiter for a lifting gear having brake actuated by centrifugal force | |

| DE19851668A1 (en) | Wheel brake arrangement for motor vehicle has electric motor, spring storage device acting upon non-linear gear set containing cam drive in direction of brake application | |

| EP2534390A2 (en) | Electric brake | |

| EP2989344B1 (en) | Disc brake having a bidirectional wear adjustment device and bidirectional wear adjustment device | |

| EP1952043B1 (en) | Electromechanical zero backlash brake | |

| DE102004023123A1 (en) | Safety brake for load carrying rotor in hoist has centrifugal brake elements with plastic deformation in enclosed mountings and with blocking elements | |

| DE69511589T2 (en) | Method and device for triggering an elevator safety mechanism | |

| DE102012006097A1 (en) | Clamping device for a lever-operated disc brake | |

| EP4077190B1 (en) | Safety brake device for a lift | |

| DE2913574B2 (en) | Drive mechanism | |

| DE102020120313B4 (en) | caliper brake | |

| DE102007052280B4 (en) | Independently responsive speed limiter | |

| DE2649629C2 (en) | Drive with accident prevention device for gates or the like | |

| DD214582A1 (en) | DEVICE FOR CONTROLLING A PACKAGE BRAKE |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20100730 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: THYSSENKRUPP ELEVATOR AG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: B66B 5/04 20060101AFI20110701BHEP |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 542767 Country of ref document: AT Kind code of ref document: T Effective date: 20120215 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009002550 Country of ref document: DE Effective date: 20120322 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOHEST AG |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2381966 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120604 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120425 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120525 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120426 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20121026 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009002550 Country of ref document: DE Effective date: 20121026 |

|

| BERE | Be: lapsed |

Owner name: THYSSENKRUPP ELEVATOR A.G. Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121110 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: HOLBEINSTRASSE 36-38, 4051 BASEL (CH) |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20091110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120125 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|