EP2072681B1 - Console pour rails installés temporairement - Google Patents

Console pour rails installés temporairement Download PDFInfo

- Publication number

- EP2072681B1 EP2072681B1 EP20080019474 EP08019474A EP2072681B1 EP 2072681 B1 EP2072681 B1 EP 2072681B1 EP 20080019474 EP20080019474 EP 20080019474 EP 08019474 A EP08019474 A EP 08019474A EP 2072681 B1 EP2072681 B1 EP 2072681B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- arms

- rail

- bracket

- console

- bracket according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 241001669679 Eleotris Species 0.000 claims description 11

- 239000000853 adhesive Substances 0.000 claims description 5

- 230000001070 adhesive effect Effects 0.000 claims description 5

- 239000004033 plastic Substances 0.000 claims description 5

- 230000006978 adaptation Effects 0.000 description 5

- 238000010276 construction Methods 0.000 description 5

- 238000009434 installation Methods 0.000 description 5

- 239000000463 material Substances 0.000 description 5

- 230000007704 transition Effects 0.000 description 4

- 229910000831 Steel Inorganic materials 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000013016 damping Methods 0.000 description 3

- 239000010959 steel Substances 0.000 description 3

- 238000003466 welding Methods 0.000 description 3

- 239000012790 adhesive layer Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000003137 locomotive effect Effects 0.000 description 2

- 230000009467 reduction Effects 0.000 description 2

- 230000000284 resting effect Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000009418 renovation Methods 0.000 description 1

- 239000012858 resilient material Substances 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 230000035939 shock Effects 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- 230000005641 tunneling Effects 0.000 description 1

- 239000002023 wood Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B26/00—Tracks or track components not covered by any one of the preceding groups

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B2/00—General structure of permanent way

- E01B2/003—Arrangement of tracks on bridges or in tunnels

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B23/00—Easily dismountable or movable tracks, e.g. temporary railways; Details specially adapted therefor

-

- E—FIXED CONSTRUCTIONS

- E01—CONSTRUCTION OF ROADS, RAILWAYS, OR BRIDGES

- E01B—PERMANENT WAY; PERMANENT-WAY TOOLS; MACHINES FOR MAKING RAILWAYS OF ALL KINDS

- E01B9/00—Fastening rails on sleepers, or the like

- E01B9/68—Pads or the like, e.g. of wood, rubber, placed under the rail, tie-plate, or chair

- E01B9/685—Pads or the like, e.g. of wood, rubber, placed under the rail, tie-plate, or chair characterised by their shape

Definitions

- the invention relates to a serving as a base of temporarily installed in the context of tunnel construction measures rails console.

- the present invention has the object to provide a serving as a support of temporarily installed rails for rail transport console, which is adapted to overcome the aforementioned disadvantages.

- console rests with its underside on the tunnel sole and has a below the rail to be positioned plateau with uneven thickness and pairwise oppositely arranged arms.

- the console is positioned below the rails as part of the installation, where it forms a particularly suitable support for the rails.

- the console has pairs of oppositely arranged arms.

- the console according to the invention adapts on the one hand rail or threshold and on the other hand, the tunnel sole.

- the plateau has an uneven thickness.

- the underside of the console can be arranged linearly inclined or even running around.

- the console if made of a resilient material, can also adapt well to local conditions.

- the arms comprise the foot of the rail and / or the rail sleeper.

- the module consisting of bracket or rail and / or threshold is given an additional degree of stability by the console serves not only as a support, but beyond also to stabilize rail and / or threshold from above and to create contact surfaces.

- a preferred variant of the invention provides that the console has at least two arms arranged in pairs. Total at least four arms so that the console or the plateau evenly and on both sides of rail or threshold.

- the proposal is to be understood, according to which the arms are provided on the outside of the plateau. Preferably, they are positioned in the four corners of the plateau or console and extend upwardly out of the plane of the plateau.

- the arms are resilient and / or stored, so that there is a kind of snap or click connection between the console and rail and / or Threshold can come.

- a very simple mounting of console and rail is possible by the arms, so to speak automatically after installation rail foot or threshold enclose and virtually position themselves.

- the arms are formed and arranged at its upper end corresponding to the rail foot and / or the rail sleeper. This ensures that the arms may also partially include rail foot or threshold so that it comes to the intended, particularly suitable connection. This is also advantageous in that a noise-damping device is realized by the close contact between the console and rail. In addition to the narrow and large-area contact between rail and console, this is also ensured by the choice of a correspondingly resilient and noise-damping material for the console.

- a variant of the invention provides that the console has on one side a pair of arms and on the opposite side a corresponding to the rail formed and upwardly extending end strip.

- This variant proves to be in addition to the four arms in the corners of the plateau to the effect that the surface pressure is lower.

- two arms on one side of the console are complemented or replaced by the corresponding trained to the rail and positioned on the opposite side of the console end bar for better distribution of the forces occurring.

- the end strip at its ends in transversely to its longitudinal axis arranged, arranged on the outside of the plateau webs merges.

- a kind of ramp-like transition extends to this end of the end strip in its transverse direction to the webs, which in turn form a kind of connection to the oppositely positioned arms.

- the end bar can also serve the function of a partial enclosure for rail or rail sleeper. It serves to the sides, as well as partly upwards by their corresponding training as their additional guidance.

- pairs of oppositely arranged arms or arms and end strip can be connected to each other with a tension belt.

- this tension belt it is achieved that corresponding contact surfaces exist between the console on the one hand and the rail or the threshold, on the other hand.

- each such arms are positioned with straps in the region of the ends of the console.

- the plateau has a frame formed corresponding to a rail tie.

- This frame is preferably formed by webs arranged on two longitudinal sides and one end face and can thus serve as a border of a rail sleeper.

- the plateau has at least one step on its upper side.

- the plateau has at least one step on its upper side.

- the opposite sides of the plateau such, extending on the inside of the click arms grading is provided so that there forms a kind of well-sleeper bed.

- the primary purpose of these gradations is to absorb the dynamic forces associated with driving the trains, in particular the braking forces.

- the console be made in one piece, which is advantageous in several aspects.

- the assembly of the consoles below the tracks or sleepers is particularly easy, especially since no tools are necessary for this purpose.

- separate fasteners are unnecessary.

- this one-piece design of the console proves to be advantageous in terms of noise reduction, the possibility of disassembly or replacement or low wear.

- console is made of plastic or rubber, in particular the Shore hardness 80 A for plastic or the Shore hardness 40 D for rubber.

- the console has an adhesive surface on its upper side.

- the adhesive layer on the top of the console additionally fixes it on the tunnel sole. Due to the above-described frame-like design of the contact surface between the console and rail sleeper forming plateau, this adhesive surface is additionally only relatively low mechanical load, so that they can develop their full effect.

- the invention is characterized in particular by the fact that a serving as a base of temporarily installed rails for rail transport console is created, their use is useful in the context of tunnel construction measures.

- the compactness of the consisting of a plateau and the pairs arranged opposite two, four or more arms console and their connection to rail and / or threshold gives the system special advantages such as noise reduction, exact adaptation to the tunnel radius, the absence of surface damage to the tubbing stone or the concrete base, longer life of the rolling stock in the form of locomotives and wagons by damping the shocks and vibrations and associated lower maintenance costs, easy and quick installation in the factory or on the tunnel construction site, reusability, protection of the track material, easy dismantling at track dismantling or simple change derailment of individual sleepers or track bumps as well as a full-surface discharge of the resulting braking forces through the grooved sleeper bed of the console and a flexible material with regard to flammability or the avoidance of En formation of soot particles.

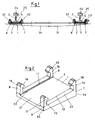

- a track 31 is shown in section. This consists of the two rails 3 and 3 'together with the console 1, 1' positioned underneath.

- the rails 3, 3 ' have a head 24, 24', a web 25, 25 'and a foot 4, 4'.

- the latter is comprised of the console 1, 1 'positioned under the rail 3, 3' on its upper side.

- Fasteners 32, 32 ', 33, 33' serve to fix the rails 3, 3 '.

- the reference numeral 34 denotes the tunnel radius, the z. B. is specified by the tubbing and must be compensated by the consoles 1, 1 '. For this reason, the brackets 1, 1 'have an uneven thickness in the area of the plateaus 2, 2' serving as the actual base.

- the thickness of the plateau 2, 2 'increases from the outside 35 to the outside 36 in order to achieve a corresponding adaptation to the tunnel construction.

- each extend arms 6, 7, 8, 9. These have at their upper ends 13, 14, 15, 16 projections 17, 18, 19, 20, which inward, ie where, rail foot and / or threshold to include extend.

- the resilient design of these arms 6, 7, 8, 9 and their corresponding training on the rail and / or threshold so that a kind locking or click connection is realized.

- the plateau 2 On the upper side 21 and there on the outer sides 11, 12, the plateau 2 has gradations 22, 23. This is a full-scale discharge of the resulting braking forces can be achieved by this sown threshold bed.

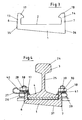

- FIG. 4 the console according to the invention 1.

- This rests with its underside 37 on the tunnel sole not shown here and comprises by means of the arms 6, 7, more precisely, the projections 17, 18 of the foot 4 of the rail 3 in a kind of click connection.

- the reference numerals 40, 41 are springs, with the reference numeral 27 is provided the net hook.

- FIG. 5 In plan view shows rail 3 and console 1 FIG. 5 , The rail 3 rests on the rail sleeper 5 and is connected via welding bolts 38, 39 and nuts 28, respectively. 30 fixed with the rail chairs 29. Before and behind the threshold 5, the four arms 6, 7, 8, 9 of the console 1 can be seen.

- FIG. 6 shows the ensemble of rail 3 and console 1 in side view.

- the foot 4 of the rail 3 is encompassed by the here recognizable arms 6 and 8.

- About the rail chair 29 and bolt 39 and nut 30 rail 3 and 5 threshold are fixed together.

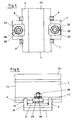

- FIG. 7 shows a console 1 in side view, the thickness of which increases greatly from page 35 to page 36. With the bottom 37 it rests on the tunnel sole, not shown here. It is in the representation according to FIG. 7 to the variant of the invention with only a pair of opposing arms, of which here the arm provided with the reference numeral 7 conceals the underlying.

- this console is 1 in FIG. 8 shown.

- the steel sleeper not shown here is additionally fixed and framed by the webs 24, 49 and 50.

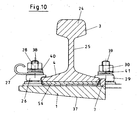

- FIG. 10 The variant of the console 1 with only a pair of oppositely positioned arms shows FIG. 10 , Only the arm 7 or by this hidden arm is present and serves to surround the foot 4 of the rail 3. This is otherwise fixed by the clamping plates 26, 29 with the welding studs 38, 39 and the nuts 28, 30. A Liner 54 off Plastic is still below the foot 4 of the rail 3 and thus between rail 4 and console. 1

- the arms are located laterally on the console 1.

- the arms 7 and 8 on the outer side 43 of the console 1 can be seen. They are perpendicular to the ground from the outside 43.

- FIG. 12 This is also in FIG. 12 shown.

- the arms 7 and 8 on the outside 43 and the arms 6 and 9 on the outside 42 are positioned so that the tension belt can be fastened between them.

- Well recognizable here is again the frame 46, consisting of the webs 48, 49 and 50.

- FIG. 13 shows the tension belt 44 installed on the arms 6 and 7. To better fix the tension belt 44 on the arms 6, 7, these have a chamfer 55, 56 and a thickening 57, 58, behind which the tension belt 44 can engage.

- FIG. 14 this variant of the console 1 in a perspective view.

- the arms 8 and 9 are of the tension belt 45, the arms 6 and 7 spanned by the tension belt 44, so that resting on the plateau 2, but not shown here threshold between the webs 48, 49, 50 positioned and in addition of the tension straps 44th and 45 is included safely.

- FIG. 15 a variant of the invention is shown, which is characterized in particular by the end strip 10, which replaces as a variant two arranged in the respective corners of the plateau arms.

- This solution is considered to be advantageous in that the surface pressure can be reduced by the compact design of the end strip 10.

- the end strip 10 is positioned opposite the arms 7 and 9 and extends here over the complete outer side 35 of the console 2. Transverse to one of its longitudinal axes 63 are located at the ends 61, 62 of the end strip 10th ramp-like transitions 64, 65 in the webs 48, 49, which in turn form a kind of connection to the oppositely positioned arms 7 and 9.

- the end strip 10 is arranged by the ramp-like transitions 64, 65 and / or by the receptacle 66, which forms them for the rail or rail tie, not shown here, corresponding to the latter.

- FIG. 16 the console 1 is shown with the end strip 10 in side view.

- the end strip 10 is in the frame 48 in the context of the ramp-like transition 64.

- the end strip 10 forms with the opposite arms 18 together the receptacle for the rail or railroad tie, not shown here.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Railway Tracks (AREA)

- Vehicle Step Arrangements And Article Storage (AREA)

Claims (17)

- Console servant d'embase de rails installés temporairement dans le cadre de travaux de construction de tunnel,

caractérisée

en ce que la console (1) repose avec sa face inférieure sur le fond du tunnel et présente un plateau (2) d'épaisseur non uniforme à positionner au-dessous du rail (3) avec des bras (6, 7, 8, 9) disposés en paires l'un en face de l'autre. - Console selon la revendication 1,

caractérisée

en ce que les bras (6, 7, 8, 9) comprennent le pied (4) du rail (3) et/ou la traverse de rail (5). - Console selon la revendication 1,

caractérisée

en ce que la console (1) présente au moins deux bras disposés en paires (6, 7, 8, 9). - Console selon la revendication 1,

caractérisée

en ce que les bras (6, 7, 8, 9) sont prévus sur la face extérieure (11, 12) du plateau (2). - Console selon la revendication 1,

caractérisée

en ce que les bras (6, 7, 8, 9) sont élastiques et/ou sur paliers élastiques. - Console selon la revendication 1,

caractérisée

en ce que les bras (6, 7, 8, 9) sont, à leur extrémité supérieure (13, 14, 15, 16) formés et disposés de manière à correspondre au pied de rail (4) et/ou à la traverse de rail (5). - Console selon la revendication 6,

caractérisée

en ce que les bras (6, 7, 8, 9) présentent à leur face supérieure (13, 14, 15, 16) une projection (17, 18, 19, 20) vers l'intérieur. - Console selon la revendication 1,

caractérisée

en ce que les bras (6, 7, 8, 9) sont prévus sur la face extérieure (42, 43) de la console (1). - Console selon la revendication 1,

caractérisée

en ce que la console (1) présente sur un côté (36) une paire de bras (7, 9) et sur le côté opposé (35) une baguette de bord (10) formée de manière à correspondre au rail (3) et s'étendant vers le haut. - Console selon la revendication 9,

caractérisée

en ce que la baguette de bord (10) se transforme à ses extrémités (61, 62) en arêtes (59, 60) disposées transversalement par rapport à leur axe longitudinal (63) et disposées sur la face extérieure (11, 12) du plateau (2). - Console selon la revendication 1,

caractérisée

en ce que les bras disposés en paires l'un en face de l'autre (6, 7, 8, 9) sont reliés l'un avec l'autre par une sangle (44, 45). - Console selon la revendication 1,

caractérisée

en ce que le plateau (2) présente un cadre (46) formé de manière à correspondre à une traverse de rail (5). - Console selon la revendication 1,

caractérisée

en ce que le plateau (2) présente sur sa face supérieure (21) au moins un gradin (22, 23). - Console selon la revendication 1,

caractérisée

en ce que la console (1) est fabriquée en une seule pièce. - Console selon la revendication 1,

caractérisée

en ce que la console (1) est fabriquée en matière plastique ou en caoutchouc. - Console selon la revendication 15,

caractérisée

en ce que la console (1) est fabriquée en une matière plastique de dureté Shore 80 A ou en caoutchouc de dureté Shore 40 D. - Console selon la revendication 1,

caractérisée

en ce que la console (1) présente sur sa face supérieure (21) une surface adhésive (47).

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE200710061008 DE102007061008A1 (de) | 2007-12-18 | 2007-12-18 | Konsole für temporär installierte Schienen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP2072681A2 EP2072681A2 (fr) | 2009-06-24 |

| EP2072681A3 EP2072681A3 (fr) | 2011-03-23 |

| EP2072681B1 true EP2072681B1 (fr) | 2013-01-09 |

Family

ID=40460004

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20080019474 Active EP2072681B1 (fr) | 2007-12-18 | 2008-11-07 | Console pour rails installés temporairement |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2072681B1 (fr) |

| DE (1) | DE102007061008A1 (fr) |

| ES (1) | ES2402228T3 (fr) |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE105110C (fr) * | ||||

| US1431296A (en) * | 1921-05-16 | 1922-10-10 | Elmer E Fox | Tie plate |

| US1577830A (en) * | 1924-08-26 | 1926-03-23 | Minna Kruttschnitt E | Railway tie plate |

| DE816705C (de) * | 1950-06-01 | 1951-10-11 | Wilhelm Wichmann | Schienenhalter |

| GB2086966A (en) * | 1980-11-01 | 1982-05-19 | Serni Ltd | Railway sleepers with rail clamping devices |

| DE3408597C2 (de) * | 1984-03-09 | 1986-03-13 | Hoesch Ag, 4600 Dortmund | Betonschwelle mit Schienenbefestigungen |

| DE19801584A1 (de) * | 1998-01-19 | 1999-07-29 | Schreck Mieves Gmbh | Rillenschiene |

-

2007

- 2007-12-18 DE DE200710061008 patent/DE102007061008A1/de not_active Withdrawn

-

2008

- 2008-11-07 ES ES08019474T patent/ES2402228T3/es active Active

- 2008-11-07 EP EP20080019474 patent/EP2072681B1/fr active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP2072681A2 (fr) | 2009-06-24 |

| ES2402228T3 (es) | 2013-04-29 |

| EP2072681A3 (fr) | 2011-03-23 |

| DE102007061008A1 (de) | 2009-06-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE202006020567U1 (de) | System zur Befestigung einer Schiene | |

| EP1866481A2 (fr) | Assiette de rail | |

| DE102009005439A1 (de) | Minischutzwand für Schwellengleise | |

| CH620004A5 (en) | Railway sleeper | |

| EP3744893A1 (fr) | Système de fixation de rail | |

| EP0542782B1 (fr) | Passage a niveau | |

| AT409641B (de) | Schotterloser oberbau mit vorgefertigten betontragplatten sowie verfahren zum ersatz derselben | |

| DE19931048A1 (de) | Gleis für schienengebundene Fahrzeuge sowie Schallschutzelement hierfür | |

| DE1964039A1 (de) | Elastisches Element zur Lagerung von Schienen oder Gleisschwellen | |

| AT404266B (de) | Schienengleicher bahnübergang | |

| EP2072681B1 (fr) | Console pour rails installés temporairement | |

| DE2718665A1 (de) | Stahlschwelle fuer den gleisbau | |

| EP1767696B1 (fr) | Traverse pour des chemins de fer | |

| CH641861A5 (en) | Arrangement for re-constructing a boundary path next to the ballast bed of a railway embankment | |

| DE1534108A1 (de) | Gleiskonstruktion | |

| WO2018215033A2 (fr) | Ensemble rail pour véhicules ferroviaires à roues à boudin | |

| DE202007017646U1 (de) | Konsole für temporär installierte Schienen | |

| EP1830002B1 (fr) | Système de support de rails pour voie ferrée | |

| DE815047C (de) | Eisenbahngleis mit laengs der Aussenseite einer jeden Gleisschiene angeordneter Beischiene zur Ermoeglichung des Befahrens des Gleises auch mit gummibereiften Fahrzeugen | |

| DE4236191A1 (de) | Bahnkörper | |

| DE19501696A1 (de) | Geräuscharmer Gleiskörper | |

| DE10333838B4 (de) | Vorrichtung zum Justieren eines Gleisrostes | |

| DE4325869C2 (de) | Feste Fahrbahn für schienengebundenen Verkehr | |

| DE4430881A1 (de) | Gleitlager für Schienen mit kontinuierlicher elastischer oder nur elastischer Auflagerung | |

| DE565544C (de) | Eisenbahnschwelle mit einer in den Schwellenkoerper eingebetteten Stuhlplatte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA MK RS |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: E01B 23/00 20060101ALI20110217BHEP Ipc: E01B 26/00 20060101ALI20110217BHEP Ipc: E01B 9/68 20060101ALI20110217BHEP Ipc: E01B 2/00 20060101AFI20090331BHEP |

|

| 17P | Request for examination filed |

Effective date: 20110923 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: AT Ref legal event code: REF Ref document number: 592843 Country of ref document: AT Kind code of ref document: T Effective date: 20130115 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502008009050 Country of ref document: DE Effective date: 20130307 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ALDO ROEMPLER PATENTANWALT, CH |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2402228 Country of ref document: ES Kind code of ref document: T3 Effective date: 20130429 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130409 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130509 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130409 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130410 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130509 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| 26N | No opposition filed |

Effective date: 20131010 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502008009050 Country of ref document: DE Effective date: 20131010 |

|

| BERE | Be: lapsed |

Owner name: VOESTALPINE KLOCKNER BAHNTECHNIK G.M.B.H. Effective date: 20131130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20131107 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20081107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130109 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20151124 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20151221 Year of fee payment: 8 Ref country code: FR Payment date: 20151130 Year of fee payment: 8 Ref country code: NL Payment date: 20151125 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MM Effective date: 20161201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20170731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161130 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20161108 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20181121 |

|

| REG | Reference to a national code |

Representative=s name: PATENTANWAELTE SCHULTE & SCHULTE, DE Ref country code: DE Ref legal event code: R082 Ref document number: 502008009050 Country of ref document: DE Ref country code: DE Ref legal event code: R081 Ref document number: 502008009050 Country of ref document: DE Owner name: VOESTALPINE VAE GMBH, AT Free format text: FORMER OWNER: VOESTALPINE KLOECKNER BAHNTECHNIK GMBH, 47057 DUISBURG, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502008009050 Country of ref document: DE Representative=s name: PATENTANWAELTE SCHULTE & SCHULTE, DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: VOESTALPINE VAE GMBH, AT Free format text: FORMER OWNER: VOESTALPINE KLOECKNER BAHNTECHNIK GMBH, DE |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20190314 AND 20190320 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: PC Ref document number: 592843 Country of ref document: AT Kind code of ref document: T Owner name: VOESTALPINE VAE GMBH, AT Effective date: 20190328 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20231123 Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20231121 Year of fee payment: 16 Ref country code: CH Payment date: 20231202 Year of fee payment: 16 Ref country code: AT Payment date: 20231121 Year of fee payment: 16 |