EP1593641B1 - Dispositif pour le montage d' un treuil d'ascenseur - Google Patents

Dispositif pour le montage d' un treuil d'ascenseur Download PDFInfo

- Publication number

- EP1593641B1 EP1593641B1 EP20050103705 EP05103705A EP1593641B1 EP 1593641 B1 EP1593641 B1 EP 1593641B1 EP 20050103705 EP20050103705 EP 20050103705 EP 05103705 A EP05103705 A EP 05103705A EP 1593641 B1 EP1593641 B1 EP 1593641B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lift

- hoist

- shaft

- cage

- mounting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000009434 installation Methods 0.000 title description 5

- 238000000034 method Methods 0.000 claims description 7

- 239000000872 buffer Substances 0.000 claims description 2

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 238000011900 installation process Methods 0.000 description 1

- 239000003380 propellant Substances 0.000 description 1

- 239000000725 suspension Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B66—HOISTING; LIFTING; HAULING

- B66B—ELEVATORS; ESCALATORS OR MOVING WALKWAYS

- B66B19/00—Mining-hoist operation

- B66B19/005—Mining-hoist operation installing or exchanging the elevator drive

Definitions

- the invention relates to a device for mounting an elevator drive, which can be mounted by means of assembly tool and hoist just below a shaft ceiling.

- the device consists of a counterweight frame movable along guide rails, a boom arranged on the counterweight frame and a hoist.

- the boom is loaded on a lower floor with the elevator drive and then lifted by means of the counterweight frame attacking hoist up to the shaft head area.

- a disadvantage of the known device is that the boom takes up a lot of space in the shaft cross-section. As a result, the transfer of the elevator drive from the boom to the engine console is made more difficult.

- the invention aims to remedy this situation.

- the invention as characterized in claim 1 solves the problem of avoiding the disadvantages of the known device and to provide a mounting device by means of an elevator drive under the shaft ceiling is easy to install.

- the advantages achieved by the invention are in essential to see that for mounting the elevator drive by means of a simple assembly tool can be lifted up below the shaft ceiling and then attachable to the motor console.

- the assembly tool is simple and inexpensive to produce. With the assembly tool a safe and quick installation process is feasible. In addition, the existing load hook on the manhole cover can be used. Since the elevator drive is always fastened to at least one console (assembly tool or motor console) during installation, the safety for the installation personnel is guaranteed.

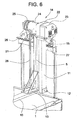

- Fig. 1 shows an arranged on an elevator car 1 assembly tool 2.

- the elevator car 1 is by means of a hoist 3 along in a hoistway 4th arranged guide rails 5 can be raised and lowered.

- the elevator car 1 is guided by guide shoes 1.1 to the guide rails 5.

- the hoist 3 is suspended on a load hook 6 a shaft ceiling 7, wherein a support means 8, for example, a chain or straps with a clevis 9 of a cab yoke 10 is connected.

- the assembly tool 2 consists of a pivot support 11 which is pivotally mounted on an axis 12 of a tool foot 13.

- the tool foot 13 is supported by the cab yoke 10.

- a lift carrier 14 carrying load carrier 15 is provided at the free end of the pivot support 11 .

- standing installation personnel 16 operates the hoist 3 and the mounting tool 2, wherein a first stop 17 and a second stop 18 limits the pivoting movement of the mounting tool 3.

- Fig. 2 to Fig. 5 show the assembly of the elevator drive 14 by means of the elevator car 1 and the assembly tool 2 and the hoist 3.

- the elevator car 1 is located on buffers 19 of a shaft pit 20.

- the elevator car 1 can also be held in the elevator shaft 4 by means of a catching device or by means of clamps or bolts acting on the guide rails 5 or by means of supports supported in the shaft pit 20.

- the pivot support 11 of the assembly tool 2 extends to the next higher floor 4.1, from which the elevator drive 14 is transferred by means of the hoist 3 on the load carrier 15 of the pivot support 11.

- the transfer process is symbolized by arrow P1.

- the elevator drive 14 is festgegurtet on the load carrier 15 and the support means 8 of the hoist 3 attached to the clevis 9 of the cabin yoke 10.

- Fig. 3 is the Elevator car 1 has been lifted by hoist 3 so far that the load carrier 15 is pivotable via a motor console designated 21.

- Fig. 4 the elevator drive 14 is transferred from the load carrier 15 to the motor console 21.

- the transfer process is symbolized by arrow P2.

- the elevator car 1 is lowered until the elevator drive 14 rests on the motor console 21. Thereafter, the elevator drive 14 is bolted firmly to the engine bracket 21.

- the assembly tool 2, together with the hoist 3 allows a mounting of the elevator drive 14 scarce (a few centimeters) below the shaft ceiling. 7

- Fig. 6 shows details of the elevator drive 14 and the assembly tool 2.

- the elevator drive 14 consists of a motor 22 with motor plate 23, a traction sheave with housing 24 and arranged on the traction sheave housing 24 brake unit 25.

- a housing foot 26 of the traction sheave housing 24 is supported by the motor bracket 21, the is supported on a arranged on the guide rails 5 console support 27.

- the engine plate 23 is supported on the bracket 27.

- an opening in the traction sheave housing 24 is provided, through which a flat belt 28 serving as a support and propellant is guided over the traction sheave.

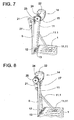

- FIGS. 7 and 8 show a variant of the assembly tool 2.

- the pivot support 11 instead of the stops 17,18 a support leg 11.1, which is as in Fig. 7 shown supported on the cabin roof.

- the support leg 11.11 loads the cabin roof no more than a standing on the cab roof fitter.

- the Swivel support 11 pivoted about the engine console 21, wherein the support leg 11.11 is raised.

- the elevator car 1 is suspended at the corners on suspension means, wherein the support means are merged below the load carrier 15 on the diagonal intersection of the cabin roof and are connected to the support means 8 of the hoist 3.

Landscapes

- Cage And Drive Apparatuses For Elevators (AREA)

- Lift-Guide Devices, And Elevator Ropes And Cables (AREA)

Claims (4)

- Dispositif pour le montage d'un entraînement d'ascenseur (14) apte à être monté juste au-dessous d'un plafond de gaine (7) à l'aide d'un outil de montage (2) et d'un engin de levage (3),

caractérisé en ce que l'outil de montage (2) qui porte l'entraînement d'ascenseur (14) est disposé sur une cabine d'ascenseur (1) apte à se déplacer dans une gaine d'ascenseur (4), et ladite cabine d'ascenseur (1) est apte à monter et descendre grâce à un engin de levage (3). - Dispositif selon la revendication 1, caractérisé en ce que l'outil de montage (2) comporte un pied d'outil (13) qui est disposé sur la traverse (10) de la cabine d'ascenseur (1) et qui présente un axe (12), étant précisé qu'il est prévu, monté pivotant sur l'axe (12), un montant pivotant (11) qui comporte un récepteur de charge (15) destiné à recevoir l'entraînement d'ascenseur (14).

- Procédé pour le montage d'un entraînement d'ascenseur (14) à l'aide d'un dispositif pour le montage de l'entraînement d'ascenseur (14) selon la revendication 1 ou 2, étant précisé que l'entraînement d'ascenseur (14) est apte à être monté juste au-dessous d'un plafond de gaine (7) à l'aide d'un outil de montage (2) et d'un engin de levage (3),

caractérisé en ce que lors d'une première étape, une cabine d'ascenseur (1) est arrêtée dans une gaine d'ascenseur (4), étant précisé que l'outil de montage (2) disposé sur la cabine (1) va jusqu'à l'étage supérieur suivant, à partir duquel l'entraînement d'ascenseur (14) est apte à être transféré sur ledit outil de montage (2) à l'aide de l'engin de levage (3),

en ce que lors d'une étape suivante, la cabine d'ascenseur (1) est soulevée à l'aide de l'engin de levage (3) jusqu'à ce que l'entraînement d'ascenseur (14) soit apte à pivoter et à être transféré sur une console de moteur (21), et

en ce que lors d'une étape suivante, après l'opération de transfert la cabine d'ascenseur (1) est abaissée à l'aide de l'outil de levage (3) jusqu'à ce que l'entraînement d'ascenseur (14) soit posé sur la console de moteur (21). - Procédé selon la revendication 3, caractérisé en ce que la cabine d'ascenseur (1) est arrêtée sur des tampons (19) d'une cuvette (20) de la gaine d'ascenseur (4).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20050103705 EP1593641B1 (fr) | 2004-05-07 | 2005-05-03 | Dispositif pour le montage d' un treuil d'ascenseur |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04405289 | 2004-05-07 | ||

| EP04405289 | 2004-05-07 | ||

| EP20050103705 EP1593641B1 (fr) | 2004-05-07 | 2005-05-03 | Dispositif pour le montage d' un treuil d'ascenseur |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1593641A1 EP1593641A1 (fr) | 2005-11-09 |

| EP1593641B1 true EP1593641B1 (fr) | 2014-12-10 |

Family

ID=35445887

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20050103705 Active EP1593641B1 (fr) | 2004-05-07 | 2005-05-03 | Dispositif pour le montage d' un treuil d'ascenseur |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP1593641B1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11198595B2 (en) | 2019-03-07 | 2021-12-14 | Tk Elevator Innovation And Operations Gmbh | Methods and apparatuses for installing elevator machines |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101139062A (zh) | 2006-09-06 | 2008-03-12 | 因温特奥股份公司 | 引导装置、具有这种引导装置的电梯及其操作方法 |

| CN101821189B (zh) † | 2007-10-05 | 2014-01-29 | 三菱电机株式会社 | 电梯的提升装置、电梯的轿厢架以及电梯的提升方法 |

| JP5778581B2 (ja) * | 2008-12-05 | 2015-09-16 | オーチス エレベータ カンパニーOtis Elevator Company | エレベータシステムおよび据付方法 |

| EP3838828B1 (fr) * | 2019-12-19 | 2023-02-08 | KONE Corporation | Agencement d'ascenseur et procédé |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1102908C (zh) * | 1997-03-07 | 2003-03-12 | 通力股份公司 | 用于装设电梯的竖井设备的方法和设备 |

| JP2000034072A (ja) * | 1998-07-17 | 2000-02-02 | Hitachi Building Systems Co Ltd | エレベータ巻上機の据付装置 |

| JP2000226169A (ja) * | 1999-02-08 | 2000-08-15 | Hitachi Building Systems Co Ltd | エレベータの据付方法 |

| JP2003292263A (ja) * | 2002-04-05 | 2003-10-15 | Fujitec Co Ltd | エレベータ機器の吊り上げ装置及び方法 |

-

2005

- 2005-05-03 EP EP20050103705 patent/EP1593641B1/fr active Active

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11198595B2 (en) | 2019-03-07 | 2021-12-14 | Tk Elevator Innovation And Operations Gmbh | Methods and apparatuses for installing elevator machines |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1593641A1 (fr) | 2005-11-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2935075B1 (fr) | Procédé d'installation pour un ascenseur | |

| EP0501140B1 (fr) | Echafaudage de montage déplaçable dans une cage d'ascenseur pour monter l'équipement de cage | |

| DE69107509T2 (de) | Arbeitsbühne eines Aufzugsschachts. | |

| DE69805257T2 (de) | Verfahren und apparatus zum einbau eines aufzugs | |

| CN1962387B (zh) | 建造电梯设备的方法及用于该目的的电梯设备 | |

| EP1593641B1 (fr) | Dispositif pour le montage d' un treuil d'ascenseur | |

| EP3548413A1 (fr) | Installation d'ascenseur et procédé de fonctionnement d'une telle installation d'ascenseur | |

| US20070090074A1 (en) | Mobile crane with ballasting | |

| AU2006201735A1 (en) | Method and device for installation of guide rails in a lift shaft | |

| DE112014006899T5 (de) | Aufzughubmaschinen-Befestigungsvorrichtung | |

| EP2014603B1 (fr) | Grue de véhicule | |

| EP2423147B1 (fr) | Agencement destiné à retourner une charge | |

| US2674378A (en) | Removable counter weight for truck cranes | |

| CN211770148U (zh) | 一种用于铁路腕臂安装机器人的升降操作平台 | |

| CN219823333U (zh) | 一种井道施工升降机的提升机构 | |

| JP2007210703A (ja) | マシンルームレスエレベータの巻上機据付装置および据付工法 | |

| DE602004005796T2 (de) | Aufzug mit reduziertem Schachtkopf und Schachtgrube, sogar ohne Maschinenraum | |

| EP2935076A1 (fr) | Procédé de maintenance d'ascenseur | |

| EP1245522B1 (fr) | Procédé de montage pour la machinerie dans une cage d'ascenseur | |

| CN211761507U (zh) | 一种铁路腕臂安装机器人 | |

| US11059701B2 (en) | Methods and apparatuses for lifting elevator cars during installation | |

| DE102008046867B4 (de) | Elektrokettenzug mit Lastausleger | |

| CN211283463U (zh) | 一种滑移调整提升装置 | |

| DE102020121344A1 (de) | Mobilkran mit Anhänger | |

| DE112015006414T5 (de) | Aufzugsvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060418 |

|

| AKX | Designation fees paid |

Designated state(s): AT CH DE FR GB LI |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20131010 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140626 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140909 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502005014616 Country of ref document: DE Effective date: 20150115 Ref country code: AT Ref legal event code: REF Ref document number: 700543 Country of ref document: AT Kind code of ref document: T Effective date: 20150115 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502005014616 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20150911 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 502005014616 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20220524 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R084 Ref document number: 502005014616 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20220518 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 700543 Country of ref document: AT Kind code of ref document: T Effective date: 20230503 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230503 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230503 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240529 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20240602 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20240527 Year of fee payment: 20 |