EP1581069B1 - Sportschuh - Google Patents

Sportschuh Download PDFInfo

- Publication number

- EP1581069B1 EP1581069B1 EP03810328.9A EP03810328A EP1581069B1 EP 1581069 B1 EP1581069 B1 EP 1581069B1 EP 03810328 A EP03810328 A EP 03810328A EP 1581069 B1 EP1581069 B1 EP 1581069B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- wedge

- insole

- sports footwear

- heel

- cap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 210000004744 fore-foot Anatomy 0.000 claims description 9

- 238000004026 adhesive bonding Methods 0.000 claims description 6

- 210000002683 foot Anatomy 0.000 claims description 5

- 239000002991 molded plastic Substances 0.000 claims 2

- 238000010276 construction Methods 0.000 description 9

- 239000000463 material Substances 0.000 description 8

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 210000004013 groin Anatomy 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 239000010985 leather Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B7/00—Footwear with health or hygienic arrangements

- A43B7/14—Footwear with health or hygienic arrangements with foot-supporting parts

- A43B7/1405—Footwear with health or hygienic arrangements with foot-supporting parts with pads or holes on one or more locations, or having an anatomical or curved form

- A43B7/141—Footwear with health or hygienic arrangements with foot-supporting parts with pads or holes on one or more locations, or having an anatomical or curved form having an anatomical or curved form

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B13/00—Soles; Sole-and-heel integral units

- A43B13/38—Built-in insoles joined to uppers during the manufacturing process, e.g. structural insoles; Insoles glued to shoes during the manufacturing process

- A43B13/383—Built-in insoles joined to uppers during the manufacturing process, e.g. structural insoles; Insoles glued to shoes during the manufacturing process pieced

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B13/00—Soles; Sole-and-heel integral units

- A43B13/38—Built-in insoles joined to uppers during the manufacturing process, e.g. structural insoles; Insoles glued to shoes during the manufacturing process

- A43B13/41—Built-in insoles joined to uppers during the manufacturing process, e.g. structural insoles; Insoles glued to shoes during the manufacturing process combined with heel stiffener, toe stiffener, or shank stiffener

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B23/00—Uppers; Boot legs; Stiffeners; Other single parts of footwear

- A43B23/02—Uppers; Boot legs

- A43B23/0245—Uppers; Boot legs characterised by the constructive form

- A43B23/0295—Pieced uppers

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B23/00—Uppers; Boot legs; Stiffeners; Other single parts of footwear

- A43B23/08—Heel stiffeners; Toe stiffeners

- A43B23/081—Toe stiffeners

- A43B23/086—Toe stiffeners made of impregnated fabrics, plastics or the like

- A43B23/087—Toe stiffeners made of impregnated fabrics, plastics or the like made of plastics

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B23/00—Uppers; Boot legs; Stiffeners; Other single parts of footwear

- A43B23/08—Heel stiffeners; Toe stiffeners

- A43B23/16—Heel stiffeners; Toe stiffeners made of impregnated fabrics, plastics or the like

- A43B23/17—Heel stiffeners; Toe stiffeners made of impregnated fabrics, plastics or the like made of plastics

-

- A—HUMAN NECESSITIES

- A43—FOOTWEAR

- A43B—CHARACTERISTIC FEATURES OF FOOTWEAR; PARTS OF FOOTWEAR

- A43B9/00—Footwear characterised by the assembling of the individual parts

Definitions

- the invention relates to a sports shoe, such as ski boot, cross country boot, hiking shoe od. Like., Which is assembled from several individual parts and a shaft, a tip or front and a heel or rear cap and a sole member having a wedge with having preformed footbed, wherein the items are interconnected, preferably glued, are.

- Conventional shoes are constructed so that the upper, e.g. Leather or other material is tweaked over a last, whereupon a more or less flat sole is glued.

- an insole must be placed in the shoe to realize the natural foot shape in its three-dimensionality.

- the shoe upper is usually stamped from sheet material, which is brought by appropriate dart, but mainly by a forming process during the Zwickvorgang in the three-dimensional shape of the last. It works with more or less force. Due to the resilience of shank and lining materials, the final internal volume of the shoe is difficult to control, as the material may shrink if the shank fits too close to the groin or the volume may be too wide in case the shank does not overly strong Strips are tweaked. Different volumes between left and right shoe and from pair to pair are not uncommon.

- a sports shoe which has a sole part with an anatomically preformed footbed.

- this shoe is also in the forefoot and heel area of conventional sheet material, in which the above-mentioned disadvantages may occur.

- Constructions are also known in which textile insoles are sewn to the shaft (Strobl-style). As a result, a certain three-dimensionality of the heel (ball heel) and the joint can be achieved. Such insoles are usually soft and cuddly and therefore lack sufficient torsional rigidity.

- the heel height is appropriate for all constructions in the form of an intermediate or outsole outside the insole.

- an anatomically shaped footbed is desired, this is usually inserted later in the shoe in the form of a more or less shaped insole.

- the anatomical value of such insoles can be disputed, as they often for reasons of price made of unstable materials, such as. EVA, are made.

- Object of the present invention is to provide a shoe of the type mentioned above while avoiding the stated disadvantages of the known shoes, in which an anatomically shaped shape is achieved.

- tip or front and the heel and rear cap are each formed as a three-dimensional preformed plastic injection molded part, wherein the wedge of the sole part is connected to an at least provided in the forefoot area insole and the rear cap with the wedge and the toe cap is connected to the insole.

- the shoe construction thus has three parts, namely a front cap, a rear cap and a wedge, with an insole, which parts are adapted to a last and are mutually connected preferably by gluing.

- This shoe construction has the advantage that a conversion of shoe parts from a two-dimensional to a three-dimensional shape, as was previously the case, is no longer required, so that a force or distortion is no longer necessary.

- gluing especially if no waterproof shoe is required, any seam can be used.

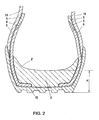

- Fig. 1 1 denotes a last and 2 a wedge, which is anatomically shaped and located in the heel area.

- the wedge 2 replaces an insole and extends to the bale.

- the heel is integrated, the height of which corresponds to the usual shoes and ensures the necessary torsional rigidity.

- such wedges may preferably be molded or molded from hard foam or similar materials.

- the upper contour corresponds to the anatomical shape of the foot and is equipped for this purpose with a heel bed and a longitudinal arch. This creates a relatively high edge on the side.

- the bottom surface of the wedge 2 may be flat or contoured.

- the lateral edge forms a relatively smooth surface which has an edge at the transition to the bottom surface.

- a step as a positioning edge for a shaft 5, which may consist of a sheet material and in the heel area to the bale, ie in the area where it is not sewn or glued with an insole, with the side surface of the wedge 2 is glued.

- a step as a positioning edge for a shaft 5, which may consist of a sheet material and in the heel area to the bale, ie in the area where it is not sewn or glued with an insole, with the side surface of the wedge 2 is glued.

- the top part of the shoe construction is formed by a front cap 4 and the heel part by a rear cap 6, which caps are three-dimensionally shaped, for example injection-molded and connected to the shaft 5 along the surfaces 7 and 8, respectively, preferably glued, are.

- both the wedge 2 and the front and rear cap 4 and 6 are made of molded parts, these parts fit together exactly and eliminate any deformation.

- the wedge 2 is connected to the toe cap 4 by an insole 3, which is connected either by a stitching seam 9 or by gluing or the like.

- the volume of the shoe is precisely specified and controllable.

- outsole serves a shell sole, not shown, which constructed just after the preformed parts, glued in the forefoot with the sewn or bonded insole 3 and the shaft 5, in the rear area with the underside of the wedge 2 and on the sides with the shaft 5 is ,

- the flex zone can be optimally positioned and the torsional stiffness can be precisely defined and controlled by the combination of a stripped or pinched forefoot and wedge in the joint and heel area.

- the inventive design a high torsional stiffness of the shoe can be achieved.

- the flexibility of the shoe in the ball area is controllable.

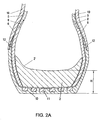

- Fig. 2 an embodiment with an outer shaft 19 and an outsole 10, wherein the heel height of the wedge 2 is adapted to the anatomical shape of theticianferse and has a height H.

- the wedge bottom 2 ' is contoured, and the outsole 10 bonded to the outer shaft 19 of the rear cap 6 and the wedge 2.

- the outsole 10 which is provided with a Ausgitt für 11, with the outer shaft 19 by a Seam 12 connected.

- the connection through a seam is preferably provided on both sides of the shoe.

- the wedge 2 is provided with a recessed heel 11 for lateral positioning of the shaft 5.

- the Fig. 4 shows an embodiment in which the toe cap 4 with the shaft 5 and the insole 3 by an overlapped paragraph 7 'and 3' is glued.

- the toe cap 4 is only glued to the shaft 5 by an overlapped shoulder 7, while the connection with the insole 3 is effected by a Strobelnaht 9.

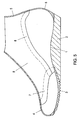

- Fig. 5 and 6 show a variant with the wedge 2 inside applied rear cap 6 and a front cap 4.

- the insole 3 on the underside is additionally grooved transversely to the longitudinal axis of the foot.

- Fig. 7 shows a continuous, patched on the wedge 2 insole. 3

- the wedge 2 and the insole 3 are not vertically, but horizontally separated.

- the advantage of this construction lies in the patency of the insole 3.

- the function of the footbed and forefoot flex is thus with only one part, the insole 3, controllable.

- the wedge 2 assumes the function of high torsional stiffness.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT16632002 | 2002-11-05 | ||

| AT0166302A AT413626B (de) | 2002-11-05 | 2002-11-05 | Sportschuh |

| PCT/AT2003/000260 WO2004041015A1 (de) | 2002-11-05 | 2003-09-08 | Schuh, insbesondere sportschuh |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1581069A1 EP1581069A1 (de) | 2005-10-05 |

| EP1581069B1 true EP1581069B1 (de) | 2015-04-08 |

Family

ID=32303948

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03810328.9A Expired - Lifetime EP1581069B1 (de) | 2002-11-05 | 2003-09-08 | Sportschuh |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20060021258A1 (ru) |

| EP (1) | EP1581069B1 (ru) |

| CN (1) | CN1694629A (ru) |

| AT (1) | AT413626B (ru) |

| AU (1) | AU2003264152A1 (ru) |

| CA (1) | CA2503379A1 (ru) |

| NO (1) | NO20052664L (ru) |

| RU (1) | RU2005117167A (ru) |

| WO (1) | WO2004041015A1 (ru) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2865616A1 (fr) * | 2004-01-30 | 2005-08-05 | Salomon Sa | Chaussure dont la tige comporte au moins une piece collee |

| JP2012504025A (ja) * | 2008-09-26 | 2012-02-16 | ナイキ インターナショナル リミテッド | ヒールサポート付きミッドソールを有する靴 |

| CN102469844B (zh) * | 2009-08-11 | 2015-01-21 | 沈相玉 | 鞋类用鞋跟辅助件 |

| DE102012206062B4 (de) | 2012-04-13 | 2019-09-12 | Adidas Ag | Schuhoberteil |

| DE102013207163B4 (de) | 2013-04-19 | 2022-09-22 | Adidas Ag | Schuhoberteil |

| US11666113B2 (en) | 2013-04-19 | 2023-06-06 | Adidas Ag | Shoe with knitted outer sole |

| DE102013207156A1 (de) | 2013-04-19 | 2014-10-23 | Adidas Ag | Schuh, insbesondere ein Sportschuh |

| DE102013207155B4 (de) | 2013-04-19 | 2020-04-23 | Adidas Ag | Schuhoberteil |

| EP3056106B1 (en) * | 2013-10-09 | 2018-05-30 | ASICS Corporation | Exercise shoe |

| DE102014202432B4 (de) | 2014-02-11 | 2017-07-27 | Adidas Ag | Verbesserter Fußballschuh |

| DE102014220087B4 (de) | 2014-10-02 | 2016-05-12 | Adidas Ag | Flachgestricktes Schuhoberteil für Sportschuhe |

| TWI749878B (zh) * | 2017-05-31 | 2021-12-11 | 荷蘭商耐克創新有限合夥公司 | 製造鞋類物品的方法 |

| EP3632251B1 (en) * | 2018-10-04 | 2023-03-29 | Calzaturificio dal Bello S.R.L. | Sports shoe and method of construction thereof |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2125272A (en) * | 1982-08-16 | 1984-03-07 | John Hall | Shoe construction |

Family Cites Families (34)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2200333A (en) * | 1937-10-13 | 1940-05-14 | Mishawaka Rubber & Woolen Mfg | Article of footwear |

| US2306306A (en) * | 1941-05-19 | 1942-12-22 | Mishawaka Rubber & Woolen Mfg | Leather topped rubber footwear |

| US3365821A (en) * | 1963-08-28 | 1968-01-30 | C I C Engineering Ltd | Footwear and method of making same |

| US4133118A (en) * | 1977-05-06 | 1979-01-09 | Khalsa Gurujot S | Footwear construction |

| GB2034170B (en) * | 1978-11-17 | 1982-12-22 | Clarks Ltd | Manufacture of articles of footwear |

| US4322895B1 (en) * | 1979-12-10 | 1995-08-08 | Stan Hockerson | Stabilized athletic shoe |

| US4455767A (en) * | 1981-04-29 | 1984-06-26 | Clarks Of England, Inc. | Shoe construction |

| US4590123A (en) * | 1982-04-13 | 1986-05-20 | Bridgestone Tire Co., Ltd. | Low-resilience rubber compositions and foams |

| US4505055A (en) * | 1982-09-29 | 1985-03-19 | Clarks Of England, Inc. | Shoe having an improved attachment of the upper to the sole |

| US4580359A (en) * | 1983-10-24 | 1986-04-08 | Pro-Shu Company | Golf shoes |

| FR2554690B1 (fr) * | 1983-11-14 | 1986-09-12 | Technisynthese Sarl | Contrefort pour chaussures de sport |

| FR2563089A1 (fr) * | 1984-04-19 | 1985-10-25 | Carrillo Pierre | Procede de fabrication d'une chaussure et nouveau type de chaussure obtenu par la mise en oeuvre de ce procede |

| IT1185504B (it) * | 1985-01-22 | 1987-11-12 | Falc Spa | Calzatura e procedimento per fabbricarla |

| US4662088A (en) * | 1985-04-29 | 1987-05-05 | Autry Industries, Inc. | Achilles tendon protection and support pad |

| DE8530136U1 (de) * | 1985-10-24 | 1988-02-25 | Solidschuhwerk Gmbh, 7200 Tuttlingen | Sohlenelement, insbesondere für orthopädisches Schuhwerk |

| US4707874A (en) * | 1986-03-13 | 1987-11-24 | Genfoot, Inc. | Method of waterproofing an article of footwear and the waterproofed article produced therefrom |

| US4852275A (en) * | 1986-09-25 | 1989-08-01 | Highland Import Corporation | Shoe having a rigid back part |

| FI76479C (fi) * | 1987-07-01 | 1988-11-10 | Karhu Titan Oy | Skodon, i synnerhet ett bollspelsskodon, foerfarande foer framstaellning av skodonet och sulaaemne foer skodonet avsett foer foerverkligande av foerfarandet. |

| FR2631790B1 (fr) * | 1988-05-24 | 1991-04-26 | Jallatte Sa | Procede et dispositif de fabrication de chaussures avec forme rigide, forme d'emboitage, matrice d'emboutissage et lames de placage laterales, et chaussures obtenues |

| DE19616027A1 (de) * | 1996-04-23 | 1997-10-30 | Alsa Gmbh | Sicherheitsschuh und Verfahren zu seiner Herstellung |

| US6205683B1 (en) * | 1997-05-30 | 2001-03-27 | The Timberland Company | Shock diffusing, performance-oriented shoes |

| US6038790A (en) * | 1998-02-26 | 2000-03-21 | Nine West Group, Inc. | Flexible sole with cushioned ball and/or heel regions |

| US6519876B1 (en) * | 1998-05-06 | 2003-02-18 | Kenton Geer Design Associates, Inc. | Footwear structure and method of forming the same |

| US6092305A (en) * | 1998-05-06 | 2000-07-25 | Footwear Concept Center, Inc. | Footwear structure and method of forming the same |

| DE29910684U1 (de) * | 1999-06-18 | 1999-08-12 | Müller, Oliver, 66994 Dahn | Business-Schuh |

| US6625906B2 (en) * | 2000-03-28 | 2003-09-30 | Helmut Mayer | Insole and use of the same for producing a shoe |

| US6474002B2 (en) * | 2000-06-09 | 2002-11-05 | Eddie Chen | Waterproof shoe having a waterproof but vapor-permeable lining sleeve |

| US20040123492A1 (en) * | 2000-08-01 | 2004-07-01 | Dewks, Llc | Shoe construction |

| US20030051375A1 (en) * | 2001-01-22 | 2003-03-20 | Lu Chun-Ming | Shoe body of waterproof boot |

| DE20106350U1 (de) * | 2001-04-11 | 2002-08-14 | Uvex Arbeitsschutz GmbH, 90766 Fürth | Schutzschuh, Sicherheitsschuh bzw. -stiefel |

| US6684532B2 (en) * | 2001-11-21 | 2004-02-03 | Nike, Inc. | Footwear with removable foot-supporting member |

| US6662473B2 (en) * | 2002-03-26 | 2003-12-16 | Eddie Chen | Shoe with ergonomic insole unit |

| US6718657B2 (en) * | 2002-05-09 | 2004-04-13 | Eddie Chen | Shoe with ergonomic foot pad |

| US20060117608A1 (en) * | 2004-12-03 | 2006-06-08 | Eddie Chen | Shoe with shell portions |

-

2002

- 2002-11-05 AT AT0166302A patent/AT413626B/de not_active IP Right Cessation

-

2003

- 2003-09-08 WO PCT/AT2003/000260 patent/WO2004041015A1/de not_active Application Discontinuation

- 2003-09-08 US US10/533,638 patent/US20060021258A1/en not_active Abandoned

- 2003-09-08 CN CN03824807.7A patent/CN1694629A/zh active Pending

- 2003-09-08 AU AU2003264152A patent/AU2003264152A1/en not_active Abandoned

- 2003-09-08 CA CA002503379A patent/CA2503379A1/en not_active Abandoned

- 2003-09-08 EP EP03810328.9A patent/EP1581069B1/de not_active Expired - Lifetime

- 2003-09-08 RU RU2005117167/12A patent/RU2005117167A/ru not_active Application Discontinuation

-

2005

- 2005-06-03 NO NO20052664A patent/NO20052664L/no not_active Application Discontinuation

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2125272A (en) * | 1982-08-16 | 1984-03-07 | John Hall | Shoe construction |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1694629A (zh) | 2005-11-09 |

| ATA16632002A (de) | 2005-09-15 |

| RU2005117167A (ru) | 2006-11-20 |

| EP1581069A1 (de) | 2005-10-05 |

| NO20052664L (no) | 2005-06-03 |

| AT413626B (de) | 2006-04-15 |

| US20060021258A1 (en) | 2006-02-02 |

| WO2004041015A1 (de) | 2004-05-21 |

| AU2003264152A1 (en) | 2004-06-07 |

| CA2503379A1 (en) | 2004-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69909957T2 (de) | Verfahren zur Herstellung von Schuhwerk | |

| DE10222897B4 (de) | Schuh | |

| EP1581069B1 (de) | Sportschuh | |

| DE29903764U1 (de) | Schuh | |

| DE2458674C2 (ru) | ||

| DE3406504C2 (ru) | ||

| DE4229039C2 (de) | Sportschuh, insbesondere Langlaufskischuh mit Torsionsversteifungs- und Biegegeschmeidigmachungseinrichtungen | |

| EP3815562B1 (de) | Sohle geeignet für den einsatz in einem sicherheitsschuh | |

| AT398157B (de) | Schuh mit einer mehrschichtigen brandsohle, brandsohle für einen solchen schuh und verfahren zur herstellung einer brandsohle | |

| DE2914309A1 (de) | Naturformschuh | |

| EP0331780B1 (de) | Oberschuh und Verfahren zu seiner Herstellung | |

| EP0080456B1 (de) | Schuhsohle, sowie Form und Verfahren zur Herstellung derselben | |

| EP0466895B1 (de) | Schuh | |

| CH580400A5 (en) | Moulded shoe inner sole giving correct support - has shaped toe region and differential resilience between toe and heel | |

| DE2409907A1 (de) | Sportschuh | |

| DE2630389A1 (de) | Verfahren zum herstellen von verleisteten, mit verstaerkungseinlagen versehenen sicherheitsschuhen sowie ein erzeugnis zur verwendung bei der herstellung solcher schuhe | |

| DE102024105642A1 (de) | Verfahren und Bausatz zur Fertigung von Fußoberbekleidungsstücken sowie solchermaßen gefertigtes Fußoberbekleidungsstück | |

| AT517450B1 (de) | Brandsohle für Schuhe mit Absatz | |

| DE102016102571B4 (de) | Anatomisch geformte Rohling und Fußbettung | |

| DE9212852U1 (de) | Mehrteilige Fußbettsohle | |

| EP0398869A2 (de) | Schuh | |

| DE3733411C2 (ru) | ||

| DE2328824A1 (de) | Schuh der mokassin-art und verfahren zu dessen herstellung | |

| DE555661C (de) | Schuhwerk mit im hinteren Schuhteil angeordnetem unnachgiebigem Bodenteil | |

| DE10043459A1 (de) | Verfahren zur Herstellung von Schuhen, insbesondere Maßschuhen sowie Probeschuh zur Verwendung mit dem Verfahren |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050427 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20080701 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 50315241 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: A43B0013380000 Ipc: A43B0023020000 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A43B 7/14 20060101ALI20140918BHEP Ipc: A43B 13/41 20060101ALI20140918BHEP Ipc: A43B 9/00 20060101ALI20140918BHEP Ipc: A43B 23/02 20060101AFI20140918BHEP Ipc: A43B 23/17 20060101ALI20140918BHEP Ipc: A43B 23/08 20060101ALI20140918BHEP Ipc: A43B 13/38 20060101ALI20140918BHEP |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20141031 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50315241 Country of ref document: DE Effective date: 20150513 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 719821 Country of ref document: AT Kind code of ref document: T Effective date: 20150515 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150810 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150709 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 50315241 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150408 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| 26N | No opposition filed |

Effective date: 20160111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150908 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20150908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150908 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150908 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 719821 Country of ref document: AT Kind code of ref document: T Effective date: 20150908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150908 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20030908 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20150408 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50315241 Country of ref document: DE Representative=s name: WUNDERLICH & HEIM PATENTANWAELTE PARTNERSCHAFT, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20220920 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20220920 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20220930 Year of fee payment: 20 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230519 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50315241 Country of ref document: DE |