EP1574455A1 - Dispositif de vidage pour un conteneur de produits en vrac et conteneur de produits en vrac - Google Patents

Dispositif de vidage pour un conteneur de produits en vrac et conteneur de produits en vrac Download PDFInfo

- Publication number

- EP1574455A1 EP1574455A1 EP04405150A EP04405150A EP1574455A1 EP 1574455 A1 EP1574455 A1 EP 1574455A1 EP 04405150 A EP04405150 A EP 04405150A EP 04405150 A EP04405150 A EP 04405150A EP 1574455 A1 EP1574455 A1 EP 1574455A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- bulk material

- container

- closure

- bulk

- emptying device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D90/00—Component parts, details or accessories for large containers

- B65D90/54—Gates or closures

- B65D90/62—Gates or closures having closure members movable out of the plane of the opening

- B65D90/626—Gates or closures having closure members movable out of the plane of the opening having a linear motion

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D88/00—Large containers

- B65D88/54—Large containers characterised by means facilitating filling or emptying

- B65D88/72—Fluidising devices

Definitions

- the invention relates to an emptying device for emptying bulk material from a Bulk container and a bulk material container and a closure for a bulk material container.

- the Bulk solids discharged through trained in the container walls outlet openings.

- the bulk containers are typically to an emptying device (also referred to as outlet or docking device or outlet or docking station) connected, which is provided with an inlet opening, which in a passageway opens, through which the bulk material flows (also called outflow) can.

- a bulk material emptying device which a provided with an inlet connection housing, which with a Passage channel is provided.

- a provided with an outlet bulk container is so tightly connected to the connection housing that the bulk material when opened Outlet opening out of the bulk material container through the passage channel can flow out.

- the bulk material container is indeed comparatively close to those in the document EP 0 915 032 described emptying device connected.

- problems arise during emptying, by the Clumping in the bulk material container hampers the emptying process or even completely block.

- the document US Pat. No. 5,474,111 describes a bulk material emptying device, which includes a pointed lance.

- a pointed lance To empty a sack-shaped bulk container is the hollow lance pierced through the container wall, whereupon the bulk material through a plurality of inlet openings into a passage formed in the lance and flows out of it through the bulk material container.

- the lance is further provided with a nozzle, through which compressed air in the bulk material container can be blown into it to support the flow of bulk material.

- the object of the invention is a belonging to the aforementioned technical field Specify emptying device and a bulk material container, which dense Connection of the bulk material container to the emptying device and a reliable Allow emptying and removal of bulk materials from the bulk material container.

- an emptying device for emptying bulk material from a bulk material container, a basic structure and one with an inlet opening provided connecting part on and a passage in which the inlet opening empties.

- the bulk material container has a closure with a connection flange and a closure member.

- the connection flange is provided with an outlet opening for the Bulk container provided bulk material, through which the Bulk material can flow out when the outlet opening is open.

- the closure member is for Closing and optionally opening the outlet opening formed and arranged.

- the connection flange of the bulk goods container is so close to the connection part of the Emptying device connectable, that - if the connection flange to the Connecting part is connected, d. H.

- the emptying device further has one on the base structure or on the connection part mounted on shutter actuating device, which for a Actuation of the closure of the bulk goods container is formed.

- the A shutter actuator is provided with a shutter actuator and a shutter actuator Adjustment provided.

- the adjusting device is designed and arranged in such a way in a state of the closure connected to the connection part, the Closure actuating element by means of the adjusting device optionally between a Closing position and at least one open position with respect to the connection section is displaceable.

- connection section is further provided with a pneumatic gas outlet, and on an outside the connecting flange of the bulk goods container is a pneumatic gas outlet corresponding pneumatic gas inlet of the bulk goods container arranged (here outside with respect to the bulk goods container and the outside of the Connecting flange forms part of the outside of the bulk goods container).

- the at the Outside of the bulk goods container or its connecting flange arranged pneumatic gas inlet is so to the pneumatic gas outlet of the connection part of the emptying device connectable that pneumatic gas from the emptying device through the pneumatic gas outlet of the connection section and the pneumatic gas inlet of the connection flange can flow through into the bulk material container to a loosening cause of the bulk material container received bulk material and thereby to support the outflow of the bulk material.

- pneumatic gas is any suitable for pneumatic applications gaseous fluid (gas medium) understood.

- Pneumatic gas can z. Air, in particular air, the one compared to the air pressure of the ambient air increased pressure has (usually referred to as compressed air).

- Pneumatic gas can as well Nitrogen, inert gas, or any other gas suitable for pneumatic applications or gas mixture.

- connection section of the emptying device connectable connection flange of the Bulk container that the connecting flange and the connecting part formed in such a way are that they can be connected together in bulk material conducting function or with each other are connectable.

- the bulk material container can be moved or moved and the Emptying station be stationary to allow the connection. But it can also the bulk material container stationary and the emptying station movable or displaceable be, or it may be both the bulk container and the emptying station be moved or displaced to allow the connection.

- the base structure can be used as a frame or as a housing of the emptying device be educated.

- the connection part can be formed as an integral part of the basic structure be.

- the passageway may also be formed as an integral part of the base structure be. But it can also be formed in an independent component that at the Basic structure of the emptying device is arranged.

- the bulk material container may have flexible container walls and z. B. as a sack or as Large container (also referred to as “big bag” or “bulk bag”) may be formed. Of the But bulk containers can also have solid container walls and z. B. as barrel or Container be formed.

- the outlet opening is open respectively. understood open closure. The closure is then in one Open position.

- the closure actuating device can directly on the connection part of the emptying device be stored.

- the shutter actuator can also on the base structure of the emptying device to be stored.

- the closure member may be a solid body (i.e., a closure body) and the shutter actuator can be used to selectively open and close the Closure be formed to a metered discharge of bulk material from the To allow bulk containers.

- a solid material e.g metal or plastic

- Made of a solid material (eg metal or plastic) manufactured closure body may be formed in particular cone-shaped, which has proven to be particularly advantageous for a metered emptying of bulk material.

- closure member may also only a perforable batch of the container wall, a perforable film or other perforable closure element.

- the closure is intended only for a single opening, d. h., it is a one-way closure.

- the closure member may substantially in a provided for receiving the bulk material Interior of the bulk goods container, it being in particular in form its closed position a lot of the container wall of the bulk material container can.

- pneumatic gas supply through the pneumatic gas outlet of the emptying device and the pneumatic gas inlet of the bulk goods container provided therethrough.

- the emptying device can use known pneumatic clutches be, with manually and / or automatically operable couplings are possible.

- the Pneumatic gas supply through the pneumatic gas outlet of the emptying device and the Pneumatic gas inlet of the bulk material container creates the possibility of any clumping Bulk goods in the bulk material container or bulk goods bridges, which are e.g. while have formed the storage or transport in bulk material, by means of pneumatic gas sockets loosen. Such a loosening process is also called fluidization of the Schüttguts called.

- the emptying device may further comprise a control unit for controlling the Pneumatic gas supply to the pneumatic gas outlet include, so that the pneumatic gas controlled by this control unit are injected into the bulk material container can.

- the control unit can be used to control the pneumatic gas supply depending the bulk material, the level in the bulk material container and / or the Evacuation of a device connected to the passage evacuation device be educated.

- the arrangement of the pneumatic gas inlet on an outside of the bulk goods container or its connection flange proves to be moreover advantageous because thereby contamination of the pneumatic gas outlet of the emptying device and the whole Connecting part of the emptying device by the bulk material largely can be avoided.

- This advantage is particularly true in the case of bulk materials of Importance for which increased purity requirements (for example in the case of pharmaceuticals) or safety (for toxic bulk materials).

- Emptying device is in the interior of the bulk goods container introduced lance tip of the emptying device described in the document US 5,474,111 exposed to heavy contamination by the bulk material. Thereby every time an elaborate cleaning of the emptying device is required when this is removed after emptying a first bulk container and even if this is to be used again for emptying another bulk goods container.

- the pneumatic gas outlet on the connection part of the emptying device can continue advantageously for additional cleaning of the connection part of the emptying device and / or the closure of the bulk goods container.

- To the completion of the emptying process and in particular even after a detachment namely the connection flange of the connection section can again pneumatic air are blown out through the pneumatic gas outlet so as to be generated by the thus generated Pneumatic gas flow possibly still on the connection section and / or on the connection flange Blow away existing bulk material. If the passageway a Evacuation device is connected, the blown bulk can equal by means of the evacuation device through the inlet opening and the passage channel therethrough be sucked off.

- a bulk goods container with flexible container walls eg a bulk goods container in the form of a bag

- the shutter actuating device another Advantage can be achieved.

- the ceiling of the bulk goods container can then at least in a late stage of the emptying process by means of the adjusting device upwardly (e.g., in an open position) displaced shutter actuator be supported to prevent - when the bulk container is almost empty - the flexible bulk material container cover on the bulk material container bottom and / or on the Outlet opening comes to rest and thus a complete emptying of the bulk material container with special needs.

- the closure actuating element can this closure body support.

- the ceiling of the nearly empty bulk container can then open rest on the closure body and be supported by this, which in turn is supported by the shutter actuator, so that the ceiling in turn indirectly is supported by the shutter actuator.

- the bulk container cover also be supported directly by the shutter actuator.

- Trained connecting section is provided with a pneumatic gas outlet

- a pneumatic gas outlet which corresponds to the basic structure of the Emptying device is attachable or grown.

- this kit is firmly attached to the base structure or with this connected.

- the one with the inlet opening and the pneumatic gas outlet port provided as the first, the emptying device side Construction unit of a common coupling device for the optionally detachable connection (ie the optionally detachable coupling) both the connection flange to the connection section and the pneumatic gas inlet formed on the pneumatic gas outlet.

- the coupling device comprises a second, bulk container-side construction unit, through the connecting flange is formed.

- the first and second construction units are in a single coupling operation can be coupled together or connected to one another to the connection flange of the bulk goods container to the connection part of the emptying device and the Pneumatic gas inlet of the bulk material container to the pneumatic gas outlet of the emptying device connect or couple.

- the coupling device be mechanically, pneumatically or hydraulically actuated to the coupling process perform.

- the coupling device is preferably for releasable again Connecting or coupling the two construction units formed together, wherein the coupling device z. B. be designed as a so-called bayonet coupling can.

- an evacuation or discharge path for emptying (also referred to as omission) of the bulk material from the Bulk container and on the other hand, a pneumatic gas line to supply the Bulk containers are created with pneumatic gas.

- the same construction unit thus serves both for coupling the pneumatic gas inlet of the bulk goods container the pneumatic gas outlet of the emptying device as well as for coupling the Connecting flange of the bulk goods container to the connecting section of the Emptying device such that bulk material through the outlet opening of the Bulk container out and through the inlet opening in the passage of the Emptying device flows into it.

- the pneumatic gas outlet is in an outer side of the connection part the emptying device formed as outwardly at least partially open channel, has at least one channel wall, which at the same time as a channel wall of the Passage channel is formed.

- the pneumatic gas outlet and the passage channel common channel wall may be on a wall side the channel-shaped pneumatic gas outlet and on the other wall side the passageway or limit its inlet opening.

- the pneumatic gas outlet and the bulk material inlet opening is formed and arranged such that the in the Outside the connecting section formed pneumatic gas outlet channel the bulk material inlet opening partially or even completely surrounds in this outside. It can the inlet opening circular and the pneumatic gas outlet as an annular channel (i.e., as an annular channel), the two being concentric with each other in the outside the connection part are arranged.

- An inventive Eritle fürsvortechnisch is advantageously further with a Provided with the shutter (i.e., the connecting flange and / or the closure member) of the bulk goods container can be coupled, that with the aid of Vibrators generated in the bulk material container bulk material Studttelioloen generated are to cause additional loosening of the bulk material.

- the shutter i.e., the connecting flange and / or the closure member

- the passage channel of an inventive emptying device on an evacuation device connected to the outflow of the bulk material from the To support bulk container out by creating a vacuum in the passageway.

- the passage channel extends substantially vertically in the region of the inlet opening and downstream the inlet opening has at least one change of direction, according to which the Passage passage in a direction different from the vertical (for example, in a horizontal Direction).

- the direction change can be made by an arcuate or an angular Part of the passage channel be realized.

- the bulk flow continues through an evacuation device and / or by pneumatic gas is supported, passing through a pneumatic gas inlet into the bulk material container into, through the outlet opening together with the bulk material again out of the bulk material container and then through the inlet opening into and through the passageway.

- the closure actuating element is in the region of the inlet opening in Passage channel arranged and by means of the adjusting device substantially vertically displaceable, wherein the adjusting device comprises an adjusting drive, at least is partially arranged outside the passage channel.

- the adjusting device comprises an adjusting drive, at least is partially arranged outside the passage channel.

- the pneumatic gas inlet of a bulk material container closed to the interior of the bulk material container from a check valve, which fluid flow through the pneumatic gas inlet in the direction of Bulk container interior allows in, but a fluid flow in reverse Direction out of the bulk material container interior through the pneumatic gas inlet prevented through.

- a check valve which fluid flow through the pneumatic gas inlet in the direction of Bulk container interior allows in, but a fluid flow in reverse Direction out of the bulk material container interior through the pneumatic gas inlet prevented through.

- an outflow of bulk material prevents the bulk material container through the pneumatic gas inlet.

- a check valve can also be a filter and / or a smaller Cross-section of the pneumatic gas inlet and / or provided a porous membrane

- the Pneumatic gas basically in both directions through the pneumatic gas inlet stream.

- a corresponding closure is thus not only for emptying the Bulk container usable, but it can also be used to fill the Bulk container can be used.

- for filling the bulk material together with pneumatic gas through the formed in the connection flange of the closure Feed the bulk material outlet opening into the bulk goods container.

- the pneumatic gas can then from the bulk material container through the pneumatic gas inlet back out of the Bulk containers flow out while the bulk material in the bulk container returns remains.

- the check valve made of a resilient material valve shut-off have, which also acts as a closing spring of the check valve. If the Pneumatikgaseinlass several opening into the interior of the bulk material container pneumatic gas inlet openings includes that of one of the number of pneumatic gas inlet ports appropriate number of check valves are completed, a be provided only one common valve shut-off of elastic material, the acts as a shut-off as well as a closing spring for all these check valves. This is a particularly simple and inexpensive construction of the bulk material container allows.

- the simultaneously acting as a closing valve shut-off valve is preferably such formed and arranged at least partially in the interior of the bulk goods container, that by pneumatic gas passing through the pneumatic gas inlet into the interior flows in the bulk goods container, can be excited to vibrate. The Vibrations are then transferred to the bulk material absorbed in the interior and cause a further loosening of the bulk material.

- a valve shut-off body may be formed in particular as a flat lip, which is attached to the connection flange is and opening into the bulk material container interior passage of the Pneumatic gas inlet completely spanned.

- the lip also referred to as kickback sealing lip

- an elastic tension force caused by the elastic material of the lip is taut against the muzzle, so that they are tightly closed by the lip becomes.

- pneumatic gas which is subjected to an overpressure, in the Passage of the pneumatic gas inlet is initiated, then the pneumatic gas due its overpressure the non-return sealing lip against the elasticity of the lip lift off the muzzle so that pneumatic gas can pass through the passageway Bulk container interior can flow.

- the kickback sealing lip is the Swinging (also called flapping) excited. The vibrations become on in the container interior transferred bulk material, which bears against the sealing lip. The vibrations loosen up the bulk material, which leads to a further improvement the emptying process leads.

- a bulk material container is characterized by the fact that a predominant proportion of the container wall of a flexible material is made, so that the bulk material container is essentially a sack or a so-called "big bag" is.

- the connection flange of the lock this baggy But the bulk material container is made of a solid material (for example metal or plastic) manufactured.

- the connection flange is at least a first passage for bulk material formed, as the outlet opening or as part of the outlet opening for in the bulk material container absorbed bulk material is used.

- the bulk material outlet can also have multiple passages formed in the connection flange.

- the Connecting flange formed at least one further passage for pneumatic gas

- the pneumatic gas inlet may also have a plurality of passages formed in the connection flange.

- the connection flange made of a solid material allows a simple and tight connection of the bulk material container to the emptying device itself in the case a bag formed bulk goods container.

- the container wall be clamped between two parts of the connection flange and only be fastened by means of the force caused by the clamping force on the flange.

- the container wall can also be glued by means of an adhesive to the connection flange, in particular in the case a container wall made of paper or cardboard.

- the container wall can but also be connected by welding to the connection flange, in the case of one out a plastic film manufactured container in particular by Ultrasonic welding.

- an emptying device for emptying bulk material from a bulk material container, a basic structure, a connection part provided with an inlet opening and a passageway into which the inlet opens.

- the bulk container has a closure with a Connection flange and a closure member.

- the connection flange is with a Provided outlet opening for bulk material received in the bulk material container, through which through which the bulk material can flow out at open outlet opening.

- the Closure member is for closing and optionally opening the outlet opening trained and arranged.

- the connecting flange of the bulk goods container is so tight connectable to the connection part of the emptying device that - in one of the Emptying device connected state of the bulk goods container or his Connecting flange - with the closure open, bulk material passes through the outlet opening out of the bulk material container, through the inlet opening into the Passage passage into and then through the passage channel through can.

- the emptying device further has one on the base structure or on the Connection part mounted on the shutter actuator, which is for actuation the closure of the bulk goods container is formed.

- the A shutter actuator is provided with a shutter actuator and a shutter actuator Adjustment provided.

- the adjusting device is designed and arranged that in a state connected to the connection part of the Closure the closure actuator by means of the adjustment either between a closed position and at least one open position with respect to Connecting party is displaced.

- the adjusting device comprises a piston-cylinder arrangement with a piston mounted on the base structure or on the connection part and at least one cylinder in which the piston is received such that the Cylinder with respect to the piston in the direction of the cylinder axis is displaceable.

- At least one cylinder is coupled to the shutter actuator, so that this is drivable by means of the piston-cylinder arrangement to substantially it to move in a straight line with respect to the connecting section.

- the shutter actuator in turn, in one of the connection part of the emptying device connected state of the bulk goods container so with the closure member coupled, that the closure member is driven by means of the piston-cylinder arrangement.

- the shutter actuating device of the emptying device is for selectively opening the closure in one of the emptying device connected state of the bulk goods container formed.

- the shutter actuator or the piston can directly at the provided with the inlet opening Be mounted connection part. But you can also s.der as a housing part or Frame part formed base structure of the emptying device to be stored.

- the piston-cylinder arrangement is pneumatically actuated.

- the danger of a Contamination of the bulk material during emptying is in the case of a pneumatically actuated Piston-cylinder arrangement smaller than in the case of a hydraulically actuated piston-cylinder arrangement.

- a pneumatically actuated Piston-cylinder arrangement smaller than in the case of a hydraulically actuated piston-cylinder arrangement.

- the inventive piston-cylinder arrangement can only a single respect Having the piston displaceable cylinder.

- the piston-cylinder arrangement but also a plurality of telescopically displaceable cylinder parts exhibit. This allows longer displacement paths.

- Such piston-cylinder arrangements with a piston and a plurality of telescopically into each other sliding cylinder parts are z. B. for lifting devices for dumping tipping containers known by construction machinery.

- an emptying device for emptying bulk material from a bulk material container, a basic structure, a connection part provided with an inlet opening and a passageway into which the inlet opens.

- the bulk container has a closure with a Connecting flange and a closure body made of a solid material (eg or plastic) is made.

- the connection flange is provided with an outlet opening for the Bulk container provided bulk material, through which the Bulk material can flow out when the outlet opening is open.

- the closure body is for Closing and optionally opening the outlet opening formed and arranged. He is essentially in an intended for receiving the bulk material interior of the Bulk container arranged, in particular in its closed position a Part of the container wall of the bulk material container can form.

- connection flange of the Bulk container is so close to the connection part of the emptying device connectable, that - in a state connected to the emptying device of the bulk material container or its connecting flange - with the closure open Bulk material through the outlet opening out of the bulk material container, through the inlet opening into the passageway and then through the Passage channel can flow through.

- the emptying device further has an on the base structure or on the connection part mounted shutter actuator on, which is designed for actuation of the closure of the bulk goods container.

- the shutter actuating device is also provided with a rotary drive which is such can be coupled with the closure body that the closure body by means of the rotary drive one stationary with respect to the connecting portion of the emptying device

- Rotary axis (hereinafter referred to as the first axis of rotation) is rotatable around.

- the closure body is designed and arranged such that it can be coupled to the rotary drive is.

- the closure body is with respect to the connection flange to a respect Stationary axis of rotation (hereinafter referred to as second axis of rotation) rotatable around.

- a coupled state i.e., when the rotary drive is connected to the Lock body is coupled

- a coupled state coincides the first axis of rotation and the second axis of rotation, so that then the closure body with respect to the connection part of the emptying device and with respect to the connection flange of the closure of the bulk goods container is rotatable about a single common axis of rotation.

- coupling means for coupling the closure body with the rotary drive can separate coupling means be provided, which mechanically and / or pneumatically and / or can be hydraulically actuated. But it can also be the closure body and the Rotary drive itself be designed such that they can be coupled together so that the rotary drive the closure body for rotation about the first and the second Rotary axis drives.

- the bulk material container is connected to the connection flange its closure connected to the connection section of the emptying device.

- the bulk material container is then substantially stationary with respect to the emptying device.

- the closure body by means of the shutter actuating device both with respect to the container and with respect to the emptying device slidable and rotatable about a stationary axis of rotation.

- the rotary drive can for a continuous, uniform rotation of the closure body be formed around the first and the second axis of rotation around.

- the rotary drive can also be designed in such a way that that he pulsating rotational movements or alternating rotational or pivotal movements effected in opposite directions of rotation of the closure body.

- the provided with the rotary actuator shutter actuator can further with a having the closure body couplable closure actuator and a elongate drive shaft fixedly connected to the shutter actuator, which is coaxial is arranged to the first axis of rotation.

- the drive shaft has a longitudinal axis has and is arranged such that its longitudinal axis coincides with the first axis of rotation, around which the closure body with respect to the connection part of the emptying device is rotatable.

- the shutter actuating device with a Adjustment which is designed and arranged such that by means of the adjusting device, the drive shaft together with the shutter actuating element optionally between a closed position and at least one open position substantially parallel (and thus rectilinear) is displaceable to the first axis of rotation.

- It is the Rotary drive coupled to the drive shaft such that the drive shaft by means of Rotary drive with respect to the connecting part is rotatable about the first axis of rotation.

- the shutter actuating element is then displaceable relative to the connection part and rotatable.

- the shutter actuating element with the closure body is such coupled, that it causes the displacement and rotation of the closure body.

- a vaporizer provided with a vibrator is further the vibrator advantageously arranged or attached to this shutter actuating element.

- one or more comminution elements e.g. Knives, blades, tines, spiral arms, lamellae, or the like

- the crushing elements can in Passage be arranged and substantially the entire cross section of the Capture passageway.

- these blades or blades provide for a mechanical Crushing of possible lumps or bridges in the bulk material. This will be another Loosening of the bulk material achieved, resulting in a further improvement of the Emptying process has the consequence.

- On the drive shaft can be complementary and / or as an alternative to the one or the several crushing elements additionally one or more bulk material conveying elements be mounted such that they rotate about the first upon rotation of the drive shaft Rotary axis around bulk material along the drive shaft in the manner of a screw conveyor or promote the nature of a turbine, the promotion of the bulk material in the direction of the Inlet opening and the passage channel through.

- these crushing elements additionally formed and arranged as conveying elements.

- one or more loosening elements are preferably on the closure body (e.g., blades, knives, tines, spiral arms, fins, or the like) which are at least partially in the space provided for receiving the bulk material of the Protrude bulk goods container into it.

- these loosening elements provide in the environment of the Closure body for mechanical comminution and loosening of any Lumps or bridges in the bulk material, which in turn improves the drainage process entails.

- On the closure body may be complementary and / or as an alternative to the one or the plurality of loosening elements additionally one or more bulk material conveying elements be mounted so rotatably that they upon rotation of the closure body Bulk material in the manner of a screw conveyor or according to Art a turbine in the direction of the interior of the bulk material container to the outlet opening promote.

- These Aufllock ceremoniess comprise additionally designed as conveying elements and be arranged.

- an emptying device for emptying bulk material from a bulk material container one with an inlet opening provided connecting part on and a passage in which the inlet opening empties.

- the draining device further includes a draining contact section at least partially made of an electrically conductive material is manufactured and grounded.

- the bulk material container has a closure with a connection flange and a Closure member.

- the connection flange is provided with an outlet opening for the Bulk container provided bulk material, through which the Bulk material can flow out when the outlet opening is open.

- the closure member is for Closing and optionally opening the outlet opening formed and arranged.

- the bulk goods container further has a bulk material container contact section, which at least partially made of an electrically conductive material.

- connection flange of the bulk goods container is so close to the connection part of the Emptying device connectable that - in one to the emptying device connected state of the bulk goods container or its connecting flange - at open closure bulk material through the outlet opening out of the Bulk container out, through the inlet opening into the passageway inside and then can flow through the passageway.

- the Connecting part connected state is the bulk material container contact section in Contact with the emptying machine contact section and the bulk goods container contact section is electrically conductive with the emptying device contact section connected by the electrically conductive material of the bulk material container contact section in direct, electrically conductive contact with the electrically conductive material of Emptying device contact section stands.

- An electrically conductive material may, for. B. be metallic material. But it can too a composite material or a composite material, which consists of both electrically conductive Material is composed as well as electrically insulating material. In this The meaning in the present context is also an electrostatically dissipative plastic or a plastic with an electrostatic dissipative coating as electrical conductive material understood. Next is in the present context under a Grounding as is common practice an electrically conductive connection with a mass or to understand an earth.

- the bulk material container may in particular have flexible container walls and z. B. as Sack or as a large container (also referred to as "big bag” or “bulk bag”) formed be.

- Sack or as a large container (also referred to as "big bag” or “bulk bag”) formed be.

- the bulk container contact section during the emptying process electrically conductively connected to the grounded emptying device contact section, is an electrostatic charge of the bulk material contact area and with prevents this connected bulk container during the bulk material discharge, without for this purpose the bulk material container during the emptying process must be grounded by means of additional electrical conductors.

- Draining devices and bulk containers with flexible container walls had to the bulk material container during the emptying process always by means of additional electrical conductors are grounded to allow electrostatic charging of the container prevent.

- this aspect of the invention is not necessarily related to the provision of a pneumatic gas supply for fluidization of the bulk material in Bulk container and / or with a piston-cylinder arrangement for driving a Closure actuating element and / or one with respect to the connection flange rotatable closure body must be used.

- connection part of the emptying device are simultaneously as Discharge device contact section and the connection flange of the bulk goods container at the same time formed as a bulk material container contact section.

- the Connecting part at least partially made of an electrically conductive material and grounded, and the connection flange is also at least partially made of an electric made of conductive material. The electrostatic discharge of the bulk goods container can then over the connecting flange of the bulk goods container and the connecting section of the Emptying device done.

- the emptying device can continue a basic structure and one mounted on the base structure or on the connecting section

- a shutter actuator associated with a shutter actuator and with an adjusting device is provided such that by means of the adjusting the Lock actuator optionally between a closed position and at least an open position is displaceable, wherein the shutter actuating element as Emptying device contact section is formed. That is, that Closure actuator at least partially made of an electrically conductive Material is made and grounded.

- connection flange of the bulk material container closure this closure is formed as a bulk material container contact part, that is, that the Closure body at least partially made of an electrically conductive material is.

- the closure body is then in contact with the (electrically conductive and earthed) shutter actuator, and the shutter body is then electrically conductively connected to the shutter actuator.

- the electrostatic discharge of the bulk material container can then on the closure body of the bulk material container and the closure actuating element of the emptying device take place.

- a bulk goods container has a Closure with a connection flange and a closure body, made of a solid Material (eg metal or plastic) is made.

- the connection flange is with a Provided outlet for bulk material in the bulk material container, through which through the bulk material can flow out at open outlet.

- the closure body is designed for closing and selectively opening the outlet opening and arranged. It is essentially in one intended for receiving the bulk material Interior of the bulk goods container, in particular in his Closing a batch of the container wall of the bulk material container can form.

- the closure body has a cavity open towards the outlet opening.

- the connecting flange of the bulk goods container is so close to one with an inlet opening provided connection part of an emptying device connectable that - in one connected to the emptying device state of the bulk material container or its connection flange - with the closure open, bulk material through the outlet opening through out of the bulk material container and through the inlet opening can flow through into the emptying device.

- the closure further has a covering member. This is not in one to the emptying device connected state of the bulk goods container so on the connection flange attachable that it is the outlet opening on the outside of the bulk goods container covers and thereby protects. If the connection flange with a Pneumatic gas inlet provided outside, the covering member can additionally also Cover and protect this exterior.

- the cover member is designed and at least partially through the outlet opening into the cavity of the Closing body arranged projecting into it, that in turn one outwards has open cavity, which is substantially within the cavity of the Closure body is arranged.

- the cavity of the Abdeckorgans is formed and measure that in him another closure body is partially receivable, the Part of another Veröes another bulk container is, with the other Bulk container with its closure and closure body identical to the first Bulk container is formed together with its closure and closure body.

- the Abdeckorgan is before emptying the bulk container by means of an emptying device, to which the bulk material container is connected, either perforated or removed from the connection flange to allow bulk material through the outlet opening of the bulk material container can flow through.

- the covering can a solid body (i.e., a cover body) and for optional mounting and again Removal-be or be formed from the connection flange to a multiple use to allow the Abdeckorgans.

- Made of a solid material (e.g., metal or metal) Plastic) manufactured cover body may in particular a cone shape corresponding to a be formed cone-shaped closure body.

- the covering can but also only a rupturable, tear-off or perforable film o. ⁇ . Be. In this Trap, the cover member is provided only for a one-time covering the closure.

- the cover member is preferably further formed such that it in his am Connection flange attached state mechanically secures the closure body and prevents the closure body from accidentally entering the bulk material container is moved and thereby the shutter is opened accidentally.

- the Abdeckorgan z. B. be provided with a screw thread and by means of this screw thread and a corresponding screw thread, the Closure body is formed with the closure body via an optionally detachable Be connected screw connection.

- the bulk material containers with closures which are provided with a covering element, may further comprise flexible container walls (eg container walls made of paper, Plastic film, textile fabric or similar foldable materials are made) and the cavities of the covering organs can be further designed and dimensioned in this way, that the closure body together with the them covering the container walls in the Cavities of covering organs be partially absorbable. This will ensure that a plurality of mutually identical bulk goods containers together their closures in an empty and not to the emptying device connected state of bulk containers can be stacked to save space.

- flexible container walls eg container walls made of paper, Plastic film, textile fabric or similar foldable materials are made

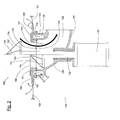

- Fig. 1 shows an emptying device 10, to which a bulk material container 50 is connected is.

- the illustration in Fig. 1 is divided vertically in the middle, wherein on the left Side the emptying device 10 and the bulk material container 50 in a closed Position are shown, while on the right side of the emptying device 10 and the bulk goods container 50 are shown in an open position.

- the emptying device 10 comprises a housing 20, in which a passage channel 22 is formed with a circular cross-section.

- the housing 20 has substantially the shape of a rectangular curved pipe section, wherein the passage channel 22nd is formed by the interior of this pipe section.

- the housing 20 has an im Essentially flat, horizontally arranged circular top, in which a circular Opening 26 is formed, which as an inlet opening 26 for inflowing into the passage 22 Bulk material (not shown) is used.

- the inlet opening 26 takes the largest Part of the surface of the housing top and opens into a first (upper) end of Passage channel 22.

- the uppermost part of the housing 20, which also provided with the inlet opening 26 Housing top comprises, is as a connection part 24 of the emptying device 10th educated.

- the connection part 24 is made of an electrically conductive material and grounded.

- an annular collar 25th formed in a horizontal plane from the inside and below Housing party projecting radially outward and for coupling the bulk goods container 50 to the emptying device 10 is used.

- the passage 22 In the connecting part 24 formed as the upper part of the passage passage 22 runs in the vertical direction. Below this, the passage 22 has a curved Part, by a rectangular bent lower portion of the tubular housing 20th is formed. After the right-angled bend or bend, the passage opens 22 in an outlet opening 23, in a vertical outer side of the housing 20th is trained. Overall, the passageway 22 extends from that in the housing top trained entrance opening 26 up to that in a vertical outside of the Housing 20 formed outlet opening 23, wherein it is in the region of the inlet opening 26 initially runs vertically downwards, in the lower region of the housing 20 at right angles turns and in the region of the outlet opening 23 extends approximately horizontally.

- a bulk material suction line (not shown) can be connected, which is connected to an evacuation device (not shown) to prevent the outflow of Bulk material out of the bulk material container 50 and through the passageway 22 therethrough by creating a vacuum in the bulk material suction line and in the passageway 22 to support.

- annular channel 28 In the top of the connecting section 24 is an upwardly open annular channel 28th (Also referred to as annular channel 28), which as compressed air outlet 28 of the emptying device 10 serves.

- the annular channel 28 extends substantially in a horizontal Plane (i.e., parallel to the top of the connecting section 24) the outer circumference of Along inlet opening 26 and surrounds them completely.

- the annular channel 28 is below and bounded on two sides by channel walls, which as parts of walls of the housing 20th are formed.

- the radially inward side wall 29 of the annular channel 28 simultaneously formed as a channel wall 29 of the passage channel 22, which this is limited to the outside in its uppermost area.

- the channel inner wall 29th the annular channel 28 is simultaneously formed as an outer wall 29 of the passage channel 22.

- the radially outer side wall of the annular channel 28 forms at the same time an outer wall of the housing 20 and its connection part 24th

- the annular channel 28 is further provided with a compressed air connection 30, which is one of includes obliquely down into the annular channel 28 opening passage through which Compressed air in the annular channel 28 can be supplied.

- a Druck Kunststoffzu111 Gustav (not shown) can be connected, which with a compressed air source (not shown) is connected to supply the annular channel 28 with compressed air.

- the thin arrows 80 in FIG. 1 show the compressed air flow 80 or its flow direction at.

- the emptying device 10 is further provided with a shutter actuating device for optionally opening and closing a closure of the bulk goods container 50 provided.

- the shutter actuating device comprises an elongate drive shaft 32, a Shutter actuating element 34 and an adjusting device 36.

- the drive shaft 32 has a circular cylindrical shape and one through the axis of the circular cylinder defined shaft axis.

- the drive shaft 32 is in one pass of a guide bushing 38 received and through the guide bush 38 in the direction of the shaft axis slidably and rotatably guided around the shaft axis.

- the passage of the Guide bushing 38 leads from below through a wall of the housing 20 in the Passage passage 22 into, wherein this wall is a part of the boundary wall of the passage channel 22 forms in the lower arcuate lot.

- the guide bushing 38 is firmly attached to this wall.

- the drive shaft 32 is in through the passage of the guide bush 38 leading arrangement arranged such that the shaft axis or their extension in the vertical direction through the center of the inlet opening 26th passes through, wherein an upper portion of the drive shaft 32 in the passageway 22 is arranged is while a lower portion of the drive shaft 32 below and outside the passageway 22 is arranged.

- the shutter actuator 34 is attached. This is essentially a cone-shaped body made of a solid material, the so mounted with its base at the top end of the drive shaft 32 is that the axis of the cone-shaped shutter actuating element 34 coaxial with Axle of the drive shaft 32 is arranged, wherein the tip of the cone, the topmost lot and the circular base of the cone is the lowest part of the shutter actuator 34 form.

- the shutter actuator 34 is made of an electric conductive material made and grounded.

- a driver ring 45 is on the outer peripheral surface of Shutter actuator 34 attached.

- the driving ring 45 is one of a made of elastic material with a comparatively large adhesion coefficient. He serves for a frictional connection between the shutter actuating element 34 and a resting on the shutter actuating element 34 closure body 60 and to take the latter by means of frictional force when the shutter actuator 34 or around its axis (that is, the axis of its cone) is moved longitudinally to this axis.

- the drive shaft 32 is coupled to the adjustment device 36 such that it by means of the adjusting device 36 either in the direction of the shaft axis with respect to the Housing 20 is vertically displaceable or adjustable up and down.

- the position with maximally downwardly shifted drive shaft 32 is used as a closed position (in Fig. 1 on the left side) and the position shifted upwards Drive shaft 32 as a fully open position (shown in Fig. 1 on the right side) the emptying device 10 and its drive shaft 32 denotes. Is the drive shaft 32 between its closed position and its fully open position arranged, this is as a partially open position of the emptying device 10th or their drive shaft 32 referred to.

- the adjusting device 36 is further formed simultaneously as a rotary drive 36, by means the drive shaft 32 with respect to the housing 20 optionally about the shaft axis is pivotable about 360 degrees back and forth.

- the adjustment device 36 is mounted on the housing 20 and completely outside the passageway 22 and below arranged by this.

- the bulk material container 50 shown in FIG. 1 is a bag 50 with a flexible container wall 53 or bag wall 53, which is made of paper and has the shape of a shell, which is closed on all sides except for the closure described below. By doing bottom, the bottom of the bag 50 forming portion of the bag wall 53 is a closure used.

- the closure has a connection flange 51, 52 a closure body 60 and a shut-off seal 65 designed as a check-seal lip.

- connection flange is made of an inner flange part 51 and an outer flange part 52 composed, both of which are annular and in the illustration of Fig. 1 are arranged such that their ring axes coincide and substantially run vertically.

- the two flange parts 51, 52 are made of an electrically conductive Material made.

- the inner flange part 51 has a circular cylinder shell-shaped part 59, which identifies the shape of a pipe section and a substantially vertical extending circular cylindrical passage 54 bounded laterally, as the outlet opening 54 for in the bag 50 recorded bulk material (not shown) is used.

- the end of the inner flange 51 is radially (i.e., horizontally) outwardly projecting Part 55 formed, which has the shape of a flat annular disc and at right angles to cylinder jacket-shaped portion 59 of the inner flange 51 is arranged.

- the outer Flange portion 52 has the shape of a thick annular disc with a central passage, the Diameter is slightly smaller than the outer diameter of the cylinder jacket-shaped Lot 59 of the inner flange portion 51 so that this cylinder jacket-shaped lot 59 under interference fit in the central passage in the annular outer flange portion 52 is plugged into it.

- annular collar 56 integrally formed in a horizontal plane from the inside and above Part of the outer flange 52 protrudes radially outward and for coupling the flange portion 52 and the bag 50 to the connection part 24 of the emptying device 10 serves.

- the bottom of the connection flange 51, 52 integrally formed collar 56 has the same outer circumference as the uppermost at the connection part 24 of the emptying device 10 molded collar 25th

- a plurality of circular compressed air passages 57, 58 are formed, which each have a diameter which is the maximum Channel width of the formed in the top of the connecting section 24 annular channel 28th equivalent.

- the compressed air passages 57, 58 lead in the vertical direction through the outer flange 52 through. They are the entire circumference of the annular outer flange portion 52 along a circular line having a diameter of the Annular channel 28 corresponding diameter (i.e., eccentric with respect to the annular outer flange portion 52) and serve as compressed air inlet 57, 58, through which compressed air can flow into the bag 50.

- the shut-off body 65 is made of a flexible, elastic plastic material and has the shape of a flat, circular disk with a central passage, the diameter of the outer diameter of the cylinder jacket-shaped portion 59 of the inner flange 51 corresponds.

- the outer diameter of the shut-off body 65 is much larger than the outer diameter of the ring-shaped portion 55 of the inner flange 51 and the outer diameter of the outer flange 52nd

- the envelope-like bag wall 53 has in its lowest area (also as the bottom of the bag 50 denotes) a circular opening whose diameter is also the outer diameter the cylinder jacket-shaped portion 59 of the inner flange 51 corresponds.

- the shut-off body 65 and the bottom of the bag 50 are superimposed Passages or openings arranged such that the cylinder jacket-shaped portion 59 of the inner flange portion 51 from top to bottom successively through the passage in the Shut-off 65, the opening in the bottom of the bag and into the central passage in the outer flange 52 are inserted.

- the bag wall 53 is in the area of Sack opening at the top of the outer flange 52 glued.

- shut-off 65 serves as shut-off and closing spring at the same time of check valves, which the compressed air passages 57, 58 to the interior of the bag 50 close and allow a compressed air flow 80 in the bag 50 in, a Compressed air and / or bulk flow in reverse direction out of the bag however, prevent.

- the radially outer region of the annular disk-shaped shut-off body 65 protrudes the outer edges of the inner flange 51 and the outer flange 52 before and protrudes into the interior of the bag 50.

- This is projecting Area of the shut-off 65 brought to vibrate (also as flutter designated). The vibrations are then applied to the interior of the bag 50 transferred bulk material and cause a loosening of the bulk material.

- the closure body 60 is for selectively closing and opening the outlet opening 54 formed and arranged. He is made of a solid, electrostatically dissipative Made of plastic and designed as a hollow, thin-walled cone, the cone shape the likewise conical interior of the closure body 60 substantially the Outer shape of the cone-shaped shutter actuating element of Emptying device 10 corresponds.

- the Closure body 60 arranged such that the axis of symmetry of the cone-shaped Closure body is vertical and is arranged coaxially to the axis of the drive shaft, the top of the cone being the topmost part and the circular one open at the bottom Base surface of the cone form the bottom part of the closure body 60.

- the maximum Diameter of the cone 60 in the area of its base is slightly smaller than that Inner diameter of the inner flange 51 formed in the outlet opening 54, see that the lowermost portion of the closure body 60 with clearance fit in the Outlet opening 54 can be arranged to close them tight, as shown in Fig. 1 is shown on the left side.

- the closure body 60 is in the vertical direction with respect to the connection flange 51, 52 can be moved downwards and upwards as well as lifted upwards from the connecting flange to To close or release the outlet opening 54 and thereby the closure to open, as shown in Fig. 1 on the right side.

- the position with maximum downwardly displaced closure body 60 is used as a closed position of the closure body 60 and the closure referred to.

- Position is the base of the closure body 60 within the outlet opening 54 arranged and closes this tight.

- the position with maximum after above shifted closure body 60 is the fully open position of the closure or of the closure body 60. Is this in Fig. 1 on the right Side shown position is the entire closure body 60 above the outlet opening 54 arranged.

- Next is the closure body 60 with respect to the connection flange 51, 52 freely rotatable about the vertical axis of symmetry of the cone.

- the connecting section 24 On the top of the connecting section 24 are further three of an elastic sealing material manufactured sealing rings 41, 42, 43 arranged so that they are in one unloaded state (i.e., when no bulk container to the emptying device 10th is coupled) at least partially from the surface plane of the top to protrude above. If - as shown in the illustration of Fig.

- connection flange 51, 52 of the bulk goods container 50 to the connection part 24 of the emptying device 10 is coupled, the sealing rings 41, 42, 43 between the abutting Surfaces of the connection flange 51, 52 and the connection part 24th compressed and then seal passages passing through these surfaces lead and through which bulk material and / or air from the bulk material container 50 into the emptying device 10 and compressed air from the emptying device 10 in the bulk material container 50 can flow into it.

- a first sealing ring 41 is arranged along the outer circumference of the annular channel 28 and seals the annular channel 28 to the outside.

- a second sealing ring 42 is the inner periphery of the annular channel 28 arranged along and seals the annular channel 28 from the inside.

- a third Sealing ring 43 is disposed along the outer circumference of the inlet opening 26 and seals the inlet opening and the passageway 22 in the top of the connection section 24 off.

- a sack 50 shown in FIG. 1 is emptied at the connecting flange 51. 52 of the bag 50 arranged cover member from the connection flange 51, 52 away. Of the Closure of the bag 50 and the shutter actuating device of the emptying device 10 are in their closed positions. Thereafter, the bag 50 together with the connecting flange 51, 52 via the housing 20 of the emptying device 10 transported. Subsequently, the coupling process for coupling the bag 50th introduced to the emptying device 10 by the bag 50 to the housing 20 down becomes.

- the closure body which is open at the bottom becomes 60 over the top over the top of the connecting portion 24 of the housing 20 protruding shutter actuator 34 is slipped, whereby the Connection flange 51, 52 together with the bag 50 with respect to the connecting section 24 and the Housing 20 centered and aligned exactly on this.

- the bag 50 is so far lowered until the connecting flange 51, 52 with its underside on top of the Housing 20 and its connection part 24 rests.

- the lowest at the connection flange 51, 52 molded collar 56 is now directly on the top of the connecting section 24 molded collar 25 on.

- the connecting flange 51, 52 by means of an annular retaining clip 47 on the connection part 24 of the emptying device 10 clamped.

- the coupling process is completed, and the bag 50 is located Now in the one shown in Fig. 1, coupled to the emptying device 10 Status.

- connecting portion 24 forms a first, the emptying device side Construction unit and provided with the collar 56 Connecting flange 51, 52 a second, bag-side construction unit of a coupling device, for the optional detachable connection of the connection flange 51, 52 is formed on the connection part 24.

- the first and second Construction unit can be coupled together in a single coupling operation or connectable to one another with the outlet opening 54 and the compressed air inlet 57, 58 provided connecting flange 51, 52 of the bag 50 to the with the inlet opening 26 and the compressed air outlet 28 provided connection part 24 of Connect emptying device 10 or couple.

- the drive shaft 32 is shifted upward. This will make it top of the drive shaft 32 mounted closure actuator 34, already in the interior the closure body 60 is arranged, from below against the closure body 60th pressed and raises this to the closure body 60 of the outlet opening 54th lift and thereby the from the connection flange 51, 52 and the closure body 60 formed closure of the bag 50 to open.

- the driving ring 45 is between the closure actuator 34 and the closure body 60 compressed and thereby ensures a non-rotatable connection acting by means of adhesion between the shutter actuator 34 and the shutter body 60.

- the shutter body 60 is by means of the shutter actuating device 32, 34, 36 to a the desired dosage of the bulk material flow corresponding height raised.

- the closure body 60 in its maximum height via the outlet opening shown. This open position of the closure has a maximum Flow of bulk material out of the sack 50 results.

- the air flow indicated by the arrows 80 is generated in the bag 50, which leads to a further loosening of the bulk material received in the bag 50 leads and also the bulk material through the outlet opening 54 through from the bag 50th

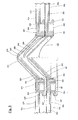

- FIG. 2 shows an emptying device 110, to which a bulk material container 150 is connected is.

- the illustration in Fig. 2 is divided vertically in the middle, wherein on the left Side the emptying device 110 and the bulk material container 150 in a closed Position are shown, while on the right side of the emptying device 110 and the bulk goods container 150 are shown in an open position.

- the bulk material container 150 or bag 150 shown in FIG. 2 differs from FIG the bulk material container 50 or bag 50 shown in FIG. 1 essentially only in FIG Reference to the formation of the closure member 160 for closing the outlet opening 154. Otherwise, the bag 150 shown in Fig. 2 is formed substantially the same as shown in Fig. 1 bag 50.

- the bag 150 shown in Fig. 2 has turn a flexible bag wall 153 and a closure provided with a two-piece connection flange 151, 152, a closure body 160 and a shut-off 165 provided is.

- the two flange parts 151, 152 are made of an electrically conductive material manufactured.

- the closure member 160 shown in FIG. 2 for closing the outlet opening 154 is a perforable sheet 160 made of a flexible sheet material, which is shown in FIG closed state on the inner flange 151 of the connecting flange 151, 152 such is welded, that they formed in the inner flange 151 Completely closes outlet opening 154.

- the through the film 160 and the Connection flange 151, 152 formed closure is only for a single opening of the Closure provided, that is, it is a one-way closure.

- the emptying device 110 shown in FIG. 2 differs from that in FIG. 1 shown emptying device 10 essentially only with respect to the training the closure actuator 132, 134, 136 for closing and optional Opening the closure of the bag 150. Otherwise, the shown in Fig. 2 Emptying device 110 substantially the same design as that shown in Fig. 1 Emptying device 10.

- the emptying device 110 shown in FIG in turn has a housing 122 provided with a passage 122, the uppermost Lot designed as a connecting portion 124 and opening into the passageway 122 with a Inlet opening 126 and a compressed air outlet 128 is provided.

- the Terminal part 124 is made of an electrically conductive material and grounded.

- the shutter actuating device 132, 134, 136 shown in FIG. 2 again comprises an elongated drive shaft 132, a shutter actuator 134 and a Adjusting device 136 for adjusting the drive shaft 132 in the direction of its longitudinal axis.

- the shutter actuator 134 is mounted on top of the drive shaft 132 and in turn formed as a cone-shaped body, wherein the tip of the cone the uppermost part and the circular base of the cone are the lowest part of the shutter actuating element 134 form.

- Closure actuating element 34 is the cone-shaped outer surface of the in FIG. 2 shown shutter actuator 134 with a plurality of sharp Cutting edges 131, 133, 135, 137 provided, which for perforating and blending serve the foil 160 of the closure of the bag 150.

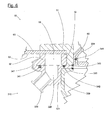

- FIG. 3 shows an emptying device 210 to which a bulk material container 250 is connected is.

- the illustration in Fig. 3 is divided vertically in the middle, with the left Side the emptying device 210 and the bulk material container 250 in a closed Position are shown, while on the right side of the emptying device 210 and the bulk goods container 250 are shown in an open position.

- the bulk goods container 250 shown in FIG. 3 is a bag-shaped bulk container 250 (also referred to as "big bag” or “bulk bag”).

- this large container 250 is in Stand alone. 5 shows the large container 250 together with another, to this identical bulk container 350 in a stacked arrangement.

- the large container 250 shown in FIGS. 3-5 differs from that in FIG Fig. 1 illustrated bag 50 in terms of its dimensions and with respect to several Hang tabs 285, 286 mounted on top of the flexible container wall 253 and allow the bulk container 250 to be hung on a hanger (e.g. Crane). Otherwise, the large container 250 shown in FIGS.

- 3-5 is essentially the same design as the bag 50 shown in FIG Large container 250 in turn has a flexible container wall 253 and a closure, the is identical to the closure of the bag 50 shown in Fig. 1 and with a two-part Connection flange 251, 252, a conical closure body 260 and a shut-off 265 is provided of a flexible material.

- the two flange parts 251, 252 are made of an electrically conductive material.

- the closure body 260 is made of a solid, electrostatic dissipative plastic.

- the emptying device 210 shown in FIG. 3 comprises a funnel-shaped housing 220, in which a passageway 222 formed with a circular cross-section is.

- the housing 220 has a substantially flat, horizontally disposed circular Top in which a circular opening 226 is formed, which serves as an inlet opening 226 for in the passage 222 incoming bulk material (not shown) is used.

- the inlet opening 226 occupies most of the surface of the housing top and opens into the upper end of the passageway 222.

- the passage channel 222 extends in the vertical direction down to an exit opening 223, wherein the diameter of the passageway 222 decreases smaller due to the funnel shape of the housing 220 downwards.

- the uppermost part of the housing 220 which also provided with the inlet opening 226 Housing top is, as a connecting portion 224 of the emptying device 210 formed.

- the connection part 224 is made of an electrically conductive material manufactured and grounded.

- an annular Collar 225 integrally formed, which projects radially outward and for coupling the Bulk container 250 to the emptying device 210 is used.

- a compressed air connection 230 to which a Druck Kunststoffzucel (not shown) connected to a compressed air source (not shown) is connected to supply the annular channel 228 with compressed air.

- the thin arrows 280 in Fig. 3 indicate the compressed air flow 280 and their flow direction.

- the emptying device 210 is further provided with a shutter actuating device for optionally opening and closing a closure of the bulk goods container 250 provided.

- the shutter actuating device comprises a shutter actuating element 234 and an adjusting device 236 provided with a piston-cylinder arrangement 270, 277, 278, a guide rod 267 and a rotary drive 237 is provided.

- the piston-cylinder arrangement 270, 277, 278 comprises a piston 270 with a circular cylindrical outer shape, by means of connecting struts 268, 269 fixed to the Housing 220 is connected and stored at this stationary.

- the piston 270 is in one circular cylindrical cavity of a first downwardly open hollow cylinder 277 such received that the first hollow cylinder 277 in the vertical direction with respect to the Piston 270 is displaceable.

- the outer shape of the piston 270 substantially corresponds the shape of the cavity of the first hollow cylinder 277.

- a first sealing ring 271 is on the circular cylinder jacket-shaped outer surface of the piston 270 along the arranged upper edge and seals the between the piston 270 and the first Hollow cylinder 277 formed gap airtight against the outside.

- a second Sealing ring 272 and a first scraper ring 273 are on the inner surface of the first Hollow cylinder 277 arranged along its lower edge. They write that between the piston 270 and the first hollow cylinder 277 formed gap below the first sealing ring 271 in addition to the outside and prevent the Ingress of bulk material or other dirt particles in this space.

- the first hollow cylinder 277 in turn has a kresizylindharide outer shape and is in a circular cylindrical cavity of a second downwardly open hollow cylinder 278 received such that the second hollow cylinder 278 in the vertical direction with respect the first hollow cylinder 277 is displaceable.

- a third sealing ring 274 is on the circular cylinder jacket-shaped outer surface of the first hollow cylinder 277 along the arranged upper edge and seals the between the first hollow cylinder 277 and the second hollow cylinder 278 formed gap airtight from the outside.

- One fourth seal ring 275 and a second scraper ring 276 are on the inner surface of the second hollow cylinder 278 along the lower edge thereof. They write that between the first hollow cylinder 277 and the second hollow cylinder 278 formed gap below the third seal ring 274 in addition to the outside and prevent The penetration of bulk material or other dirt particles in this space.

- the shutter actuator 234 is mounted, which is similar to the closure actuator shown in Fig. 1 34.

- the shutter actuating element 234 is made of an electrically conductive Material made and grounded.

- a compressed air line fed by compressed air from an external source of compressed air (not shown) (not shown) passes through the piston 270 into the space between the piston 270 and the first hollow cylinder 277. From this gap a compressed air passage leads to the space between the first hollow cylinder 277th and the second hollow cylinder 278.

- the piston 270, the first Hollow cylinder 277 and the second hollow cylinder 278 a piston-cylinder arrangement with a piston 270 mounted on the housing 220 and two with respect to the piston 270 and telescopically telescoping hollow cylinders 277, 278 created, wherein the Piston-cylinder arrangement 270, 277, 278 pneumatically by means of the compressed air source is operable to the second hollow cylinder 278 and attached to this Shutter actuator 234 in the vertical direction with respect to the housing 220 or the piston 270 to move.

- the guide rod 267 has a circular cylindrical shape and a rod axis defined by the axis of the circular cylinder which is in vertical Direction runs.

- the guide rod 267 is mounted in a fixed to the housing 220 Guide bushing 266 slidable in the vertical direction and around the rod axis rotatably guided, wherein the guide rod 267 further displaced in the vertical direction passed through passages in the piston 270 and the first hollow cylinder 277th are formed.

- the linear guide unit 266, 267 ensures that the sealing or Wiper rings 271-276 between the hollow cylinders 277, 278 and between the first Hollow cylinder 277 and the piston 270 must exert no management forces and therefore not be overburdened.

- a rotary drive 237 is further supported, by means of which the guide rod 267 and associated with this second hollow cylinder 278 with respect to the piston 270th or the housing 220, optionally about 360 degrees back and forth about the rod axis is pivotable or rotatable.

- the guide rod 267 is thus simultaneously as Drive shaft 267 is formed, by means of which the shutter actuating element 234 for Rotation about the rod axis is driven around.

- the shutter actuating element 234 shown in FIGS. 3-5 is one of one solid material produced conical hollow body, the top with its base is mounted on the second hollow cylinder 278 of the adjusting device 236 and means the adjusting device 236 displaceable in the vertical direction and about the axis of the Guide rod 267 is pivotable around back and forth.

- a pneumatic operable vibrator 239 is arranged, which the shutter actuating element 234 to vibrate or vibrate can stimulate.

- the closure body 260 sits directly on the closure actuating element 234. The vibrations generated by the vibrator are then removed by the vibrator Closure actuator 234 on the closure body 260 and from there to the transferring surrounding bulk material, thereby providing additional loosening of the bulk material is effected.

- the entire emptying device 210 shown in FIG. 3 together with the connected thereto Connecting flange 251, 252 of the large container 250 is in the vertical direction with respect to a suspension device (not shown) to which the large container 250 is suspended, movable. This will give the opportunity for continuous stretching of the large container 250 created during the emptying process to always the entire flexible bottom of the large container 250 in the direction of the outlet opening 254 out inclined to keep.

- the suspension device with respect to the emptying device 210 to be moved in the vertical direction.

- Fig. 4 shows the large container 250 of FIG. 3 in isolation.

- the illustration in FIG. 4 is divided vertically in the middle.

- On the right side is the connection flange 251, 252 the closure of the large container 250 with a cover member 282 according to a second Variant of the invention covered.

- the cover member 281 shown in Fig. 4 on the left side is one of a fixed Material manufactured conical hollow body 281 with a bottom surface open at the bottom.

- the cone shape of the cover body 281 substantially corresponds to the cone shape At the bottom is on the cover body 281 a radially from the base the conical shape formed outwardly projecting annular disc 263, the outer circumference essentially the outer circumference of the outer flange part 252 of the connection flange 251, 252 corresponds.

- the annular disc has in the area of its outer circumference an identical outer shape as the collar 225 of the connecting portion 224 of in 3 emptying device 210.

- the cover body 281 In the state clamped to the connection flange 251, 252, the cover body 281 is partially from below through the outlet opening 254 into the cavity of the closure body 260 projecting into it, wherein the downwardly open cavity of the Cover body 281 substantially within the cavity of the closure body 260th is arranged. In this state, the cover body 281 covers the entire connection flange 251, 252 on its underside.

- the Abdeckorgan in this state 281 optionally releasably connected to the closure body 260 so that it the Closure body 260 secures mechanically and prevents the closure body 260th accidentally moved into the large container 250 and thereby the shutter unintentionally opened.

- the cover member 281 shown in Fig. 4 on the right side is one of a flexible Foil material produced covering film 282. It is the outer circumference of the connection flange along the underside of the outer flange 252 and covers the entire connecting flange 251, 252 on the underside from. In the area inside of the inner flange part 251, the cover film protrudes from below through the outlet opening 254 passes into the cavity of the closure body 260 and in turn forms a downwardly open cavity substantially within the cavity the closure body 260 is arranged.

- Fig. 5 shows the large container 250 of Figures 3 and 4 together with another identical large container 350 in a stacked arrangement, the closures the two large containers 250, 350 each with identical Abdeckorganen 281, 282; 381, 382 are covered.

- the illustration in Fig. 5 is divided vertically in the middle.

- On the left side are the connecting flanges 251, 252; 351, 352 of the closures of large containers 250; 350 with cover bodies 281, 381 according to the illustrations on the left Side of Fig. 4 covered.

- On the right side are the connecting flanges 251, 252; 351, 352 of the closures of the large containers 250; 350 with cover sheets 282, 382 according to covered on the right side of Fig. 4.

- the closure body 360 of FIG Closure of the further bulk container 350 partially in the cavity of the cover body 281 of the large container 250, wherein the ceiling part of the flexible container wall 353 of the further large container 350 resting on its closure body 360 between this closure body 360 and the covering body 281 of the other Large container 250 is arranged.