EP1574151A2 - Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem Möbelkorpus verfahrbaren Schublade - Google Patents

Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem Möbelkorpus verfahrbaren Schublade Download PDFInfo

- Publication number

- EP1574151A2 EP1574151A2 EP05012879A EP05012879A EP1574151A2 EP 1574151 A2 EP1574151 A2 EP 1574151A2 EP 05012879 A EP05012879 A EP 05012879A EP 05012879 A EP05012879 A EP 05012879A EP 1574151 A2 EP1574151 A2 EP 1574151A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rack

- tooth

- drawer

- gear

- teeth

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 230000003019 stabilising effect Effects 0.000 title 1

- 230000000087 stabilizing effect Effects 0.000 claims description 4

- 239000000463 material Substances 0.000 claims description 3

- 238000006073 displacement reaction Methods 0.000 claims description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 210000003128 head Anatomy 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 210000001331 nose Anatomy 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B88/00—Drawers for tables, cabinets or like furniture; Guides for drawers

- A47B88/40—Sliding drawers; Slides or guides therefor

- A47B88/44—Sequencing or synchronisation of drawer slides or functional units

- A47B88/45—Synchronisation of cooperating drawer slides, i.e. with a coordination of the rail movement of different drawer slides

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47B—TABLES; DESKS; OFFICE FURNITURE; CABINETS; DRAWERS; GENERAL DETAILS OF FURNITURE

- A47B2210/00—General construction of drawers, guides and guide devices

- A47B2210/0002—Guide construction for drawers

- A47B2210/0064—Guide sequencing or synchronisation

- A47B2210/0078—Drawers with parallel guidance or synchronization by pinion-shaft linkages

Definitions

- the invention relates to a device for stabilizing the running behavior a movable in a furniture body drawer, wherein on both sides of the Drawer is a gear stored and the two gears that are non-rotatable with each other Comb, mesh with body-side racks.

- the object of the invention is a device of the type mentioned to improve that the hanging of the drawer is facilitated.

- the lateral orientation of a slightly oblique in the furniture body to correct the introduced drawer.

- the object of the invention is achieved in that on each rack at least one subsequent to the rear end of the row of teeth through the gear is provided relative to the rack movable tooth.

- the movable tooth allows a "skipping" of teeth on the gear and rack and thus one Correction of the position of a possibly obliquely introduced drawer.

- At least one rack made of elastic compliant material, such as plastic is made and that the rearmost Mounting point of the rack on the furniture body so far in front of the rear end the rack is that the rack is deflectable in the correction area, wherein the rearmost attachment point of the rack on the furniture body in front of the Correction range is.

- a secure meshing of the gears with the To ensure racks is in one embodiment of the invention provided that in the bearing bodies horizontally and transversely to the direction of the Drawer sliding slide lagem, which is in the movement position of the drawer engage under horizontal guide rails of the racks.

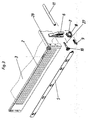

- a drawer 3 is by means of a conventional Auszieh Operationssgarnitur 4 between the side walls 1 of a furniture body movable.

- Auszieh Equipmentsgarnitur 4 may be both a single extension with a body-side mounting rail and a loading-side drawer on both sides the drawer or to act a full statement, in which between the Body-side mounting rail and the loading-side pull-out rail a middle rail is stored.

- the gears 10 store by means of their stub axles 27 in bearing bodies 7, which in turn are mounted vertically adjustable in brackets 6.

- the bearing body 7 are in the Holding bodies 6, for example, by means of a dovetail guide 26.

- the brackets 6 are on the drawer 3, preferably on the drawer 2 attached.

- the drawer 2 are with a rear provided angled web 28 on which the brackets 6 are pushed.

- the stub axles 27 of the gears 10 protrude through the bearing body 7 and in a sleeve-shaped rod 11, which at least in its two end regions with an internal toothing is provided. As a result, the two gears 10 to the both sides of the drawer 3 rotatably connected.

- a slider 9 is mounted below the gear 10, the is displaceable perpendicular to the direction of travel of the drawer 3.

- the slider 9 is acted upon by a spring 8 and pressed to the rack 5.

- Each rack is at its free edge with a horizontal guide rail 14th provided at the rear end of the rack 5 at a distance in front of a Guide block 29 ends.

- the guide block 29 is at its front end of a sloping guide 15 limited.

- Above the guide rail 14 is a vertical guide wall 30.

- the teeth 17, 18 are each arranged in a groove 31 of the rack 5 and are bounded by lateral guide walls.

- Each rack 15 is at its rear end with a correction area 24 provided in which the height of the teeth 18 is approximately half the height of the Teeth 17 in the remaining running area 25 of the rack.

- the height of the teeth 18 is at most 3/4 of the height of the teeth 17 and is preferably in a range between 2/3 and half the height of the teeth 17th

- the racks 5, which are made of a plastic material, are by means of Screwed screws 16 on the body side wall 1, wherein the rearmost screw 16, d. H. the rearmost attachment point of the rack 5 on the side wall 1 of the Furniture carcass is located at a distance a in front of the rear end of the rack 5.

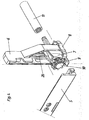

- the gears are 10, as shown in Fig. 6, above the teeth 17, 18 of the racks 5 and the Noses of the slide 9 above the guide rails 14 of the racks 5.

- the Slide 9 abuts with its tip on the vertical guide wall 30 of the Rack 5 and is against the pressure of the spring 8 in the direction of Drawer center pressed.

- a stop 13 is provided to limit the slide path. So that the bearing body 7 is not too far up is pressed, the holders 6 stops 12, which the displacement of the Limit bearing body 7 vertically upwards.

- the drawer 3 is inserted so far into the furniture body until the slide 9 at the oblique guides 15 of the racks 5 abut. Due to the Slanted guides, the slide 9 are pressed down and snap below the Edge 32 of the blocks 29, wherein they from the springs 8 under the racks. 5 be pushed.

- the gear 10 rotates on the upper end surfaces of the teeth 18, wherein the rear end of the rack 5 pressed by the dimension 21 down and the axis of the gear 10 is pushed by the dimension 20 upwards.

- the Gear 10 can thus be rotated away over the teeth 18 until it in the rear end position in turn is brought into engagement with the teeth 18 (see FIG. 13a).

- the Tooth width 33 of the teeth 18 larger than the tooth head width 34 of the teeth 17th

- a movable tooth 18 is either As shown in FIGS. 17 to 22, mounted on an axis 23 tiltable or rotatable or, as shown in the embodiment of FIGS. 23 to 24, linearly displaceable.

- Fig. 25 shows a variant of the tiltable mounting, wherein the tooth 18 of the Gear 10 can escape laterally.

- the distance between the tooth 18 and the next rigid tooth 17 of the rack 5 in approximately twice as large as the distance between two adjacent rigid teeth 17.

- the movable tooth 18 only in one Dodge direction i. in the embodiment of FIGS. 17 to 24 can the tooth 18 only in the direction of the rearmost fixed tooth 17 of the rack 5 are moved.

- the lever 35, at the free end of the tooth 18 is formed, only in the direction of the arrow swing.

- the gear 10 on the left side can rotate until the gear 10th on the right side of the drawer 3 has reached the rearmost position. now is the Drawer 3 is straight and can be straight out of the furniture body be pulled out.

- the tiltably mounted on the axis 23 tooth 18 is vertically laterally with a side projecting arm 36 provided on which a spring 37 presses.

- the movable tooth 18 is on a slidable block 38 formed in a recess 42 of the rack. 5 is movable.

- the pad 38 is linearly displaceable in the direction of the rack 5 and is by a spring 37, this time a helical compression spring, to the rear pressed.

- the tooth 18 is on an arm 35 formed, which is rotatable about an axis 39.

- the tooth 18 is provided with a vertical inclined surface 40.

Landscapes

- Drawers Of Furniture (AREA)

Abstract

Description

Claims (23)

- Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem Möbelkorpus verfahrbaren Schublade, wobei an beiden Seiten der Schublade ein Zahnrad gelagert ist und die beiden Zahnräder, die drehfest miteinander verbunden sind, mit korpusseitigen Zahnstangen kämmen, dadurch gekennzeichnet, dass an jeder Zahnstange (5) mindestens ein an das hintere Ende der Zahnreihe anschließender durch das Zahnrad (10) relativ zur Zahnstange (5) bewegbarer Zahn (18) vorgesehen ist.

- Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, dass der Abstand des bewegbaren Zahnes (18) vom hintersten festen Zahn (17) der Zahnstange (5) in etwa doppelt so groß ist wie der Abstand zwischen zwei benachbarten festen Zähnen (17) der Zahnstange (5).

- Vorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass der bewegbare Zahn (18) um eine horizontale Achse (23) kippbar ist.

- Vorrichtung nach Anspruch 3, dadurch gekennzeichnet, dass der bewegbare Zahn (18) auf einer Achse (23) lagert, die in der Zahnstange (5) verankert ist.

- Vorrichtung nach Anspruch 4, dadurch gekennzeichnet, dass der Zahn (18) auf der Achse (23) klemmend gehalten ist.

- Vorrichtung nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass der bewegbare Zahn (18) von einer Feder (37) beaufschlagt wird, der ihn in die aufrechte Stellung drückt.

- Vorrichtung nach Anspruch 6, dadurch gekennzeichnet, dass der bewegbare Zahn (18) mit einem Arm (36) verbunden ist, an dem die Feder (37) angreift.

- Vorrichtung nach einem der Ansprüche 3 bis 7, dadurch gekennzeichnet, dass der bewegbare Zahn (18) nur in einer Richtung kippbar ist.

- Vorrichtung nach Anspruch 8, dadurch gekennzeichnet, dass der bewegbare Zahn (18) in der Richtung zu den festen Zähnen (17) der Zahnstange (5) kippbar ist.

- Vorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass der bewegbare Zahn (18) in der Längsrichtung der Zahnstange (5) linear verschiebbar ist.

- Vorrichtung nach Anspruch 10, dadurch gekennzeichnet, dass der verschiebbare Zahn (18) von einer Feder (37) zur Möbelrückwand gedrückt wird.

- Vorrichtung nach Anspruch 10 oder 11, dadurch gekennzeichnet, dass der linear verschiebbare Zahn (18) auf einem Klotz (38) angeordnet ist, der in eine Aussparung (42) am hinteren Ende der Zahnstange (5) eingesetzt ist.

- Vorrichtung nach einem der Ansprüche 10 bis 12, dadurch gekennzeichnet, dass der linear verschiebbare Zahn (18) durch das Zahnrad (10) nur in der Richtung zur Möbelfront bewegbar ist.

- Vorrichtung nach Anspruch 1 oder 2,- dadurch gekennzeichnet, dass der bewegbare Zahn (18) eine vertikale Schägfläche (40) aufweist, über die der Zahn (18) vom Zahnrad (10) zur Seite, aus der Spur des Zahnrades (10) hinaus, drückbar ist.

- Vorrichtung nach einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, dass bei mindestens einer der Zahnstangen (5) ein an das hintere Ende der Zahnstangen (5) anschließender Korrekturbereich (24) vorgesehen ist, in dem die Höhe der Zähne geringer ist als die Höhe der Zähne (17) der restlichen Zahnstangen (5).

- Vorrichtung nach einem der Ansprüche 1 bis 15, dadurch gekennzeichnet, dass die mindestens eine Zahnstange (5) aus elastisch nachgiebigem Material, beispielsweise Kunststoff gefertigt ist und dass der hinterste Befestigungspunkt der Zahnstange (5) am Möbelkorpus so weit vor dem hinteren Ende der Zahnstange (5) liegt, dass die Zahnstange (5) im Korrekturbereich (24) durchbiegbar ist.

- Vorrichtung nach einem der Ansprüche 1 bis 16, dadurch gekennzeichnet, dass die Zahnräder (10) in Lagerkörpern (7) lagern, die in an der Schublade (3) befestigten Halterungen (6) in der Höhe verschiebbar gelagert sind.

- Vorrichtung nach Anspruch 17, dadurch gekennzeichnet, dass die Halterungen (6) Anschläge (12) aufweisen, die den Verschiebeweg der Lagerkörper (7) begrenzen.

- Vorrichtung nach Anspruch 17 oder 18, dadurch gekennzeichnet, dass in den Lagerkörpern (7) horizontal und quer zur Verfahrrichtung der Schublade (3) verschiebbare Schieber (9) lagern, die in der Verfahrstellung der Schublade (3) horizontale Führungsleisten (14) der Zahnstangen (4) untergreifen.

- Vorrichtung nach einem der Ansprüche 17 bis 19, dadurch gekennzeichnet, dass die Schieber (9) von einer Feder (8) beaufschlagt sind.

- Vorrichtung nach einem der Ansprüche 17 bis 20, dadurch gekennzeichnet, dass Lagerkörper (7) über Schwalbenschwanzführungen (26) an den Halterungen (6) geführt sind.

- Vorrichtung nach einem der Ansprüche 1 bis 21, dadurch gekennzeichnet, dass die Zahnräder (10) mit Steckachsen (27) versehen sind, die in eine Verbindungsstange (11) ragen, die zumindestens an ihren beiden Endbereichen hülsenförmig ausgeführt ist und dort eine Innenverzahnung aufweist.

- Vorrichtung nach einem der Ansprüche 1 bis 22, dadurch gekennzeichnet, dass die Zähne (17, 18) jeder Zahnstange (5) in einer Nut (31) mit seitlichen Führungsflanken für das Zahnrad (10) angeordnet sind.

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT47399 | 1999-03-17 | ||

| AT0047399A AT410162B (de) | 1999-03-17 | 1999-03-17 | Vorrichtung zur stabilisierung des laufverhaltens einer in einem möbelkorpus verfahrbaren schublade |

| AT0152399A AT410163B (de) | 1999-09-06 | 1999-09-06 | Vorrichtung zur stabilisierung des laufverhaltens einer in einem möbelkorpus verfahrbaren schublade |

| AT152399 | 1999-09-06 | ||

| EP00104058A EP1036526B1 (de) | 1999-03-17 | 2000-02-28 | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem M-belkorpus verfahrbaren Schublade |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00104058A Division EP1036526B1 (de) | 1999-03-17 | 2000-02-28 | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem M-belkorpus verfahrbaren Schublade |

| EP00104058.3 Division | 2000-02-28 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1574151A2 true EP1574151A2 (de) | 2005-09-14 |

| EP1574151A3 EP1574151A3 (de) | 2006-08-16 |

| EP1574151B1 EP1574151B1 (de) | 2013-11-06 |

Family

ID=25592852

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00104058A Expired - Lifetime EP1036526B1 (de) | 1999-03-17 | 2000-02-28 | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem M-belkorpus verfahrbaren Schublade |

| EP05012879.2A Expired - Lifetime EP1574151B1 (de) | 1999-03-17 | 2000-02-28 | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem Möbelkorpus verfahrbaren Schublade |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00104058A Expired - Lifetime EP1036526B1 (de) | 1999-03-17 | 2000-02-28 | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem M-belkorpus verfahrbaren Schublade |

Country Status (4)

| Country | Link |

|---|---|

| EP (2) | EP1036526B1 (de) |

| AT (2) | ATE302558T1 (de) |

| DE (1) | DE50011002D1 (de) |

| ES (2) | ES2244369T3 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1913842A1 (de) * | 2006-08-04 | 2008-04-23 | Miguel Angel Rioja Calvo | Möbelschubladenführung |

| DE202008012077U1 (de) * | 2008-09-11 | 2010-02-25 | Paul Hettich Gmbh & Co. Kg | Synchronführung eines Schubelementes |

| DE202009016105U1 (de) * | 2009-07-06 | 2010-12-02 | Paul Hettich Gmbh & Co. Kg | Synchronführung eine Schubelements und Möbel |

| US20130270989A1 (en) * | 2012-04-12 | 2013-10-17 | Samsung Electronics Co., L To | Sliding apparatus and refrigerator having the same |

| EP3378354A1 (de) * | 2017-03-20 | 2018-09-26 | King Slide Works Co., Ltd. | Ganganordnung für möbelsystem |

| CN108652284A (zh) * | 2017-03-28 | 2018-10-16 | 川湖科技股份有限公司 | 齿轮装置 |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10228470A1 (de) | 2002-06-26 | 2004-01-15 | Grass Gmbh | Schubladenführung |

| DE202004016393U1 (de) * | 2004-10-21 | 2005-12-29 | Grass Gmbh | Vorrichtung zur Stabilisierung des Laufverhaltens eines in einem Möbelkorpus fahrbaren Möbelteiles |

| AT8111U1 (de) * | 2004-10-22 | 2006-02-15 | Fulterer Gmbh | Ausziehführung |

| DE202006000711U1 (de) * | 2006-01-18 | 2006-04-06 | Anton Schneider Gmbh & Co Kg | Differentialauszug für Schubladen o.dgl. |

| KR100790543B1 (ko) * | 2006-10-25 | 2008-01-02 | 엘지전자 주식회사 | 바스켓출납용 레일어셈블리 |

| US7594707B2 (en) | 2007-08-15 | 2009-09-29 | Whirlpool Corporation | Snap-in bearing rack and pinion system |

| TW201039777A (en) * | 2009-05-05 | 2010-11-16 | Zong-Yao Chen | Drawing stabilization structure of cupboard-drawing bearing member |

| CN102090800B (zh) * | 2009-12-15 | 2015-04-08 | 陈崇尧 | 橱柜抽拉承载件的抽拉平稳结构 |

| CN101716032B (zh) * | 2009-12-17 | 2012-01-18 | 伍志勇 | 抽屉平衡机构 |

| AT509256B1 (de) * | 2009-12-23 | 2013-06-15 | Blum Gmbh Julius | Schienensystem für schubladen |

| AT509257B1 (de) * | 2009-12-23 | 2013-09-15 | Blum Gmbh Julius | Schienensystem für schubladen |

| TW201225884A (en) * | 2010-12-30 | 2012-07-01 | Chong-Yao Chen | Drawing synchronization device of side-travelling type slide rail and support unit and slide rail unit thereof |

| AT511045A1 (de) * | 2011-01-28 | 2012-08-15 | Blum Gmbh Julius | Möbelteil mit einer drehmomentübertragenden welle |

| AT511511B1 (de) | 2011-05-20 | 2015-05-15 | Blum Gmbh Julius | Synchronisationsvorrichtung für ein bewegbar gelagertes möbelteil |

| TW201320927A (zh) * | 2011-11-21 | 2013-06-01 | 陳崇堯 | 抽拉同步裝置及其軸裝單元 |

| AT512382B1 (de) | 2011-12-27 | 2016-05-15 | Blum Gmbh Julius | Synchronisationsvorrichtung für eine schublade |

| DE202012002127U1 (de) * | 2012-02-29 | 2013-06-06 | Grass Gmbh | Vorrichtung zur Stabilisierung des Laufverhaltens eines in einem Möbelkorpus verfahrbaren Möbelteils |

| US20130270987A1 (en) * | 2012-04-17 | 2013-10-17 | Electrolux Home Products, Inc. | Freezer slide rack alignment |

| DE102012111977B4 (de) | 2012-12-07 | 2024-01-11 | Paul Hettich Gmbh & Co. Kg | Schubelement |

| CN103960890B (zh) * | 2014-05-14 | 2016-08-31 | 伍志勇 | 一种抽屉滑轨同步装置的辅助稳定机构 |

| AT520817B1 (de) | 2018-02-01 | 2019-08-15 | Blum Gmbh Julius | Anordnung aus Ausziehführung, Schienen-Synchronisierungsvorrichtung und Mitnehmer |

| CN108741784A (zh) * | 2018-06-04 | 2018-11-06 | 安徽知之信息科技有限公司 | 一种用于杂物收纳的机器人 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2214291A (en) | 1937-10-13 | 1940-09-10 | Wyckoff William Le Roy | Cabinet |

| EP0875178A2 (de) | 1997-04-29 | 1998-11-04 | Schock Metallwerk GmbH | Parallelauszugführung |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB436082A (en) * | 1934-03-28 | 1935-09-30 | William Mackey Stavers | Improvements in rack and pinion mechanism |

| US2410643A (en) * | 1944-10-17 | 1946-11-05 | Fielding Charles Stuart | Rack and pinion mechanism |

| US2620253A (en) * | 1948-05-20 | 1952-12-02 | Robert C Read | Glide control means for drawers |

| US3323853A (en) * | 1965-12-06 | 1967-06-06 | Art Metal Inc | Filing cabinet drawer motion control means |

| DE2609977A1 (de) * | 1976-03-10 | 1977-09-15 | Siemens Ag | Einlaufzahnstange fuer angetriebene foerderwagen |

| US4226490A (en) | 1978-08-04 | 1980-10-07 | General Electric Company | Stabilizing arrangement for movably mounted drawer or rack |

| DD217293A1 (de) * | 1983-07-18 | 1985-01-09 | Groeditz Stahl Walzwerk Veb | Zahnstangentrieb |

| DE8905197U1 (de) * | 1989-04-25 | 1989-06-08 | Paul Hettich GmbH & Co, 4983 Kirchlengern | Vorrichtung zur Gewährleistung des Parallellaufes eines Möbelauszuges |

| NL9100758A (nl) * | 1991-05-02 | 1992-12-01 | Regout Nv Thomas | Anti-schranksysteem voor een schuiflade. |

| US5409309A (en) | 1993-04-19 | 1995-04-25 | Whirlpool Corporation | Dishrack motion control arrangement for a dishwasher |

| GB9416305D0 (en) * | 1994-08-12 | 1994-10-05 | Alliedsignal Ltd | Driving arrangement |

| EP0718574A1 (de) * | 1994-12-19 | 1996-06-26 | Bosch-Siemens HausgerÀ¤te GmbH | Kältegerät |

-

2000

- 2000-02-28 AT AT00104058T patent/ATE302558T1/de active

- 2000-02-28 ES ES00104058T patent/ES2244369T3/es not_active Expired - Lifetime

- 2000-02-28 EP EP00104058A patent/EP1036526B1/de not_active Expired - Lifetime

- 2000-02-28 DE DE50011002T patent/DE50011002D1/de not_active Expired - Lifetime

- 2000-02-28 ES ES05012879.2T patent/ES2445162T3/es not_active Expired - Lifetime

- 2000-02-28 EP EP05012879.2A patent/EP1574151B1/de not_active Expired - Lifetime

-

2003

- 2003-11-03 AT AT0075703U patent/AT6674U3/de not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2214291A (en) | 1937-10-13 | 1940-09-10 | Wyckoff William Le Roy | Cabinet |

| EP0875178A2 (de) | 1997-04-29 | 1998-11-04 | Schock Metallwerk GmbH | Parallelauszugführung |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1913842A1 (de) * | 2006-08-04 | 2008-04-23 | Miguel Angel Rioja Calvo | Möbelschubladenführung |

| DE202008012077U1 (de) * | 2008-09-11 | 2010-02-25 | Paul Hettich Gmbh & Co. Kg | Synchronführung eines Schubelementes |

| DE202009016105U1 (de) * | 2009-07-06 | 2010-12-02 | Paul Hettich Gmbh & Co. Kg | Synchronführung eine Schubelements und Möbel |

| US20130270989A1 (en) * | 2012-04-12 | 2013-10-17 | Samsung Electronics Co., L To | Sliding apparatus and refrigerator having the same |

| EP3378354A1 (de) * | 2017-03-20 | 2018-09-26 | King Slide Works Co., Ltd. | Ganganordnung für möbelsystem |

| US10352412B2 (en) | 2017-03-20 | 2019-07-16 | King Slide Works Co., Ltd. | Gear arrangement |

| CN108652284A (zh) * | 2017-03-28 | 2018-10-16 | 川湖科技股份有限公司 | 齿轮装置 |

| CN108652284B (zh) * | 2017-03-28 | 2023-08-08 | 川湖科技股份有限公司 | 齿轮装置 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1574151A3 (de) | 2006-08-16 |

| DE50011002D1 (de) | 2005-09-29 |

| ES2244369T3 (es) | 2005-12-16 |

| EP1036526A1 (de) | 2000-09-20 |

| EP1036526B1 (de) | 2005-08-24 |

| EP1574151B1 (de) | 2013-11-06 |

| ATE302558T1 (de) | 2005-09-15 |

| ES2445162T3 (es) | 2014-02-28 |

| AT6674U2 (de) | 2004-02-25 |

| AT6674U3 (de) | 2004-12-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1036526B1 (de) | Vorrichtung zur Stabilisierung des Laufverhaltens einer in einem M-belkorpus verfahrbaren Schublade | |

| EP1978842B1 (de) | Antriebsmechanismus für ein an einem möbel bewegbar gelagertes möbelteil | |

| EP2012619B1 (de) | Unterflur-führungsanordnung für möbelteile, insbesondere schubladen im korpus von möbelstücken | |

| EP0700649B2 (de) | Einzugsvorrichtung für Schubladen | |

| EP3603449B1 (de) | Ausziehführung für eine schublade | |

| AT395095B (de) | Schliessvorrichtung fuer schubladen | |

| EP1440632A1 (de) | Stuhl mit schnell verstellbarem Kraftspeicher | |

| DE69203929T2 (de) | System um das Verkanten von Schubladen zu verhindern. | |

| AT17935U1 (de) | Schubladenausziehführung | |

| EP0780071A2 (de) | Schublade mit Rollen-Ausziehführung | |

| DE2659741C3 (de) | Lamellenfenster | |

| DE4308195A1 (de) | Führungsschienensystem für herausnehmbare Schränke | |

| AT413473B (de) | Selbsteinzugvorrichtung | |

| DE69503828T2 (de) | Blokiervorrichtung für eine Verlängerung Bezüglich eines Möbelstückes, und Möbelstück damit Ausgestattet | |

| EP0806163B1 (de) | Vorrichtung zur Lagerung eines in einem Schrankelement verschiebbaren und schwenkbaren Einbauteils | |

| AT410162B (de) | Vorrichtung zur stabilisierung des laufverhaltens einer in einem möbelkorpus verfahrbaren schublade | |

| EP2633780B1 (de) | Vorrichtung zur Stabilisierung des Laufverhaltens eines in einem Möbelkorpus verfahrbaren Möbelteils | |

| AT410163B (de) | Vorrichtung zur stabilisierung des laufverhaltens einer in einem möbelkorpus verfahrbaren schublade | |

| DE3505614C2 (de) | ||

| EP3745916B1 (de) | Anordnung aus ausziehführung, schienen-synchronisierungsvorrichtung und mitnehmer | |

| EP0528218B1 (de) | Mit einer Dreh-Schiebetür verschliessbares Möbelstück, insbesondere Schrank | |

| DE19737034B4 (de) | Lenkmodul eines Kraftfahrzeugs mit sowohl in ihrer Neigung als auch in der Länge verstellbarer Lenksäule | |

| EP0199270A2 (de) | Feststellvorrichtung für einen Fenster- oder Türflügel in wenigstens einer Spaltlüftungsstellung | |

| DE20220861U1 (de) | Anordnung für eine auf einem Ski positionierbare Skibindung | |

| EP1319426A1 (de) | Anordnung für eine auf einem Ski positionierbare Skibindung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1036526 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT DE ES IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT DE ES IT |

|

| 17P | Request for examination filed |

Effective date: 20060920 |

|

| AKX | Designation fees paid |

Designated state(s): AT DE ES IT |

|

| 17Q | First examination report despatched |

Effective date: 20120515 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130805 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1036526 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE ES IT |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 638830 Country of ref document: AT Kind code of ref document: T Effective date: 20131215 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50016337 Country of ref document: DE Effective date: 20140102 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2445162 Country of ref document: ES Kind code of ref document: T3 Effective date: 20140228 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 50016337 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140807 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 50016337 Country of ref document: DE Effective date: 20140807 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R079 Ref document number: 50016337 Country of ref document: DE Free format text: PREVIOUS MAIN CLASS: A47B0088040000 Ipc: A47B0088400000 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20170221 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170428 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20170331 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180228 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50016337 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180901 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20190801 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 638830 Country of ref document: AT Kind code of ref document: T Effective date: 20190228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190228 |