EP1566539B1 - Brennstoffeinspritzdüse - Google Patents

Brennstoffeinspritzdüse Download PDFInfo

- Publication number

- EP1566539B1 EP1566539B1 EP05405036A EP05405036A EP1566539B1 EP 1566539 B1 EP1566539 B1 EP 1566539B1 EP 05405036 A EP05405036 A EP 05405036A EP 05405036 A EP05405036 A EP 05405036A EP 1566539 B1 EP1566539 B1 EP 1566539B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzle

- longitudinal bore

- fuel

- fuel injection

- valve seat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 239000000446 fuel Substances 0.000 title claims abstract description 73

- 238000002347 injection Methods 0.000 claims abstract description 32

- 239000007924 injection Substances 0.000 claims abstract description 32

- 238000002485 combustion reaction Methods 0.000 claims abstract description 25

- 230000007704 transition Effects 0.000 claims description 3

- 238000000034 method Methods 0.000 description 7

- 230000000694 effects Effects 0.000 description 5

- 238000004519 manufacturing process Methods 0.000 description 4

- 230000035882 stress Effects 0.000 description 4

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000005553 drilling Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000010248 power generation Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 230000002000 scavenging effect Effects 0.000 description 1

- 239000000779 smoke Substances 0.000 description 1

- -1 that is Substances 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/18—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for

- F02M61/1806—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for characterised by the arrangement of discharge orifices, e.g. orientation or size

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/14—Arrangements of injectors with respect to engines; Mounting of injectors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M61/00—Fuel-injectors not provided for in groups F02M39/00 - F02M57/00 or F02M67/00

- F02M61/16—Details not provided for in, or of interest apart from, the apparatus of groups F02M61/02 - F02M61/14

- F02M61/18—Injection nozzles, e.g. having valve seats; Details of valve member seated ends, not otherwise provided for

Definitions

- the invention relates to a fuel injector for an internal combustion engine, in particular a large diesel engine, according to the preamble of the independent claim of the respective category.

- the nozzle head is a wear part, which is subject to a high thermal, mechanical and chemical stress collective.

- the mechanical loads are based on the high injection pressure, which can amount to more than 100 MPa (thousand bar).

- the thermal stresses are caused by the high temperatures in the combustion chamber and the enormous temperature changes between combustion temperature and temperature of the freshly supplied scavenging air, while the chemical stress are mainly due to high-temperature or hot corrosion.

- valve seat is usually arranged slightly away from the nozzle holes, so that an excessive exposure to heat of combustion is avoided, such as in the US 5,398,875 or the EP 0 569 655 shown.

- valve seat and nozzle holes brings with it the following problem.

- the nozzle needle is pressed into the valve seat, so that the fuel, which is located downstream of the valve seat - ie between valve seat and nozzle holes - is no longer supplied with the feed pressure.

- This remaining fuel in the nozzle head can to some extent after completion of the injection through the nozzle holes poorly atomized get into the combustion chamber, where it burns little or not at all. This leads to an additional pollution of the exhaust gas especially smoke, that is, particles, and possibly to deposits of unburned fuel to all parts of the combustion chamber and the exhaust gas-carrying components.

- a fuel injector for an internal combustion engine, in particular for a large diesel engine, having a nozzle body and a nozzle head connected to the nozzle body, with a nozzle needle arranged in the interior of the nozzle body whose end interacts with a valve seat such that the nozzle needle engages in an open position Opens passage for the fuel at the valve seat and closes the passage in a closed position, with a longitudinal bore extending from the valve seat through the nozzle head and having a flow diameter, and with at least one nozzle hole, which emanates from the longitudinal bore and through which the fuel is introduced into a combustion chamber of the internal combustion engine.

- the ratio of the length of the longitudinal bore and the flow diameter of the longitudinal bore is at least 17, preferably at least 20, and more preferably more than 22.

- This configuration of the fuel injection nozzle and the nozzle head, the volume between the valve seat and the nozzle holes - the blind hole - can be drastically reduced compared to known nozzle heads.

- the significantly reduced ratio of length and flow diameter of the longitudinal bore of the nozzle head makes it possible to reduce this volume by 50% or more. Consequently, after completion of the injection process downstream of the valve seat only a considerably smaller amount of fuel in the nozzle head is present, so that the negative effects caused by this fuel - especially the harmful emissions - are significantly reduced.

- all the nozzle holes together form a total flow diameter for the fuel, wherein the flow diameter of the longitudinal bore is at most 2 times, preferably at least 0.5 times and at most 1.5 times, the total flow diameter of all the nozzle holes.

- the longitudinal bore in the region of the nozzle holes on an extension is an extension.

- This local extension has two advantages. Given a given number of nozzle holes, the distance between the individual junctions of the nozzle holes in the longitudinal bore can be selected larger, whereby the pressure caused by the internal pressure mechanical stress peaks in the material of the nozzle head are reduced. In addition, local expansion facilitates redirecting the fuel flow from the longitudinal bore into the nozzle holes, thereby reducing the hydraulic friction losses as it flows into the nozzle holes.

- the extension may be advantageous to form the extension asymmetrically with respect to the longitudinal axis of the longitudinal bore. This is easier to realize in terms of manufacturing technology.

- the wall thickness of the nozzle head in the area where the nozzle holes are provided can be made thinner than in the area having no nozzle holes. This has the advantage that the nozzle holes do not become too long, thereby avoiding excessive bundling of the fuel jet.

- the advantageous asymmetry can also or additionally be generated by the fact that the longitudinal bore extends obliquely to the longitudinal axis of the nozzle head.

- each nozzle hole opens at an angle of more than 90 ° in the longitudinal bore, that is, in the installed state, the nozzle holes extend from the longitudinal bore obliquely downwards. This measure facilitates the deflection of the fuel flow and thus serves to reduce the hydraulic friction losses.

- Another advantageous measure for reducing the friction losses is to design the transition region between the longitudinal bore and the nozzle hole in each case rounded.

- the passage on the valve seat in the open position of the nozzle needle has a surface which is at least as large as the flow cross-section of the longitudinal bore.

- the nozzle head is usually a Verschleissteil, such embodiments of the fuel injector are preferred in which the nozzle head is detachably connected to the nozzle body.

- the inventive fuel injector is particularly suitable for diesel engines, especially for two-stroke large diesel engines.

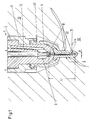

- Fig. 1 shows in a longitudinal section for the understanding of the invention essential parts of an embodiment of a fuel injection nozzle according to the invention, which is provided throughout with the reference numeral 1.

- the fuel injection nozzle 1 is in Fig. 1 installed in the cylinder head 10 of a two-stroke large diesel engine, such as a marine engine shown. In the mounted state protrudes the lower end of the fuel injector 1 as shown in a combustion chamber 20 of a cylinder of the diesel engine.

- the fuel injection nozzle 1 comprises a nozzle body 2 and an embodiment of a nozzle head 3 which is connected to the nozzle body 2.

- the Connection by means of a holding sleeve 4, which tapers at its lower end to the longitudinal axis A of the fuel injector 1 out.

- the longitudinal axis A is also the longitudinal axis A of the nozzle head 3.

- the holding sleeve 4 is fixed by means of a union nut 5 and an elastic member 45, for example a snap ring on the nozzle body 2.

- the nozzle head 3 is supported in the tapered part of the retaining sleeve 4.

- the nozzle head 3 has a longitudinal bore 32 and in the region of its lower end at least one nozzle hole 31, typically z. B. five nozzle holes 31, which emanate from the longitudinal bore 32 and through which the fuel can escape into the combustion chamber 20.

- Fig. 2 shows a view of the lower part of the nozzle head 3, in which the arrangement of the five nozzle holes 31 can be seen.

- the nozzle holes 31 extend from the longitudinal bore 32 downwardly inclined towards the combustion chamber 20, that is, each nozzle hole 31 opens at an angle ⁇ ( Fig. 1 ) of more than 90 ° in the longitudinal bore 32 a.

- a pressure chamber 6 In the interior of the nozzle body 2, a pressure chamber 6 is provided, in which a feed line 12 opens for the fuel.

- the pressure chamber 6 is bounded in the axial direction by a valve seat 8.

- a nozzle needle 7 is arranged in the interior of the nozzle body 2, which extends substantially in the direction of the longitudinal axis A and which cooperates with the valve seat 8.

- the lower tip of the nozzle needle 7 In the in Fig. 1 shown closed position, the lower tip of the nozzle needle 7 is pressed into the valve seat 8, so that the passage from the pressure chamber 6 is closed in the downstream of the longitudinal bore 32.

- the nozzle needle 7 is spring-loaded in a conventional manner by means of a compression spring, not shown, and biased against the valve seat 8. In the open position of the nozzle needle 7, this is lifted up out of the valve seat 8, so that between the lower end of the nozzle needle 7 and the valve seat 8, a passage is open, through which the fuel from the pressure chamber 6 can get into the longitudinal bore 32.

- Fig. 1 Like this in Fig. 1 is shown, with the length L of the longitudinal bore 32, the distance meant between the representation according to the lower end that surface of the valve seat 8, on which the nozzle needle 7 rests in the closed position and the lower, that is, the combustion chamber end of the longitudinal bore L.

- the volume between the valve seat 8 and the nozzle holes 31 is commonly referred to as a blind hole.

- the longitudinal bore 32 is configured in the embodiment described here as a substantially cylindrical bore which extends in the direction of the longitudinal axis A.

- the diameter D of the longitudinal bore 32 determines a flow diameter and thus a flow cross-section, which means the available for the flow of the fuel cross-sectional area in the longitudinal bore 32 is meant. If the longitudinal bore is not cylindrical but with a changing diameter, for example conical, then the flow cross-section or diameter of the longitudinal bore means its minimum flow cross-section or diameter.

- the individual nozzle holes 31 are also designed as a respective cylindrical bore. Their diameter b ( Fig. 2 ) defines in each case a flow cross-section for the respective nozzle hole 31.

- the diameters b of the individual nozzle holes 31 may be different from nozzle hole to nozzle hole, or the diameter b may be the same for some or all of the nozzle holes 31.

- the respective flow cross sections defined by the individual nozzle holes 31 add up to form an overall flow cross section of the nozzle holes.

- the total flow cross section of the nozzle holes 31 thus means the sum of the flow cross sections of all the nozzle holes-here five-that is to say the entire flow cross-section which is available to the fuel for the exit from the longitudinal bore 32 into the combustion chamber 20. The same applies to the total flow diameter of the nozzle holes 31

- the fuel injection nozzle 1 or the nozzle head 3 is designed so that the ratio of the length L of the longitudinal bore 32 and the flow diameter of the longitudinal bore is at least 17, preferably at least 20 and more preferably more than 22.

- the blind hole that is to say the volume downstream of the valve seat 8 and upstream of the nozzle holes 31, can be reduced by more than 50%, for example, in comparison to known designs.

- the specified ratios length L to flow diameter of the longitudinal bore 32 of at least 17, preferably at least 20 and more preferably more than 22 lead to a favorable reduction in the volume of the blind hole without the other hand, the hydrodynamic properties significantly deteriorated or the pressure drop across the nozzle head 3 too large becomes.

- the length L of the longitudinal bore is for example about 48.1 mm with a diameter of about 2.1 mm or about 70.7 mm with a diameter of about 2.9 mm.

- the nozzle head 3 is designed such that the flow diameter of the longitudinal bore 32 is at most twice the total flow diameter of the nozzle holes 31. In practice, it has proven particularly useful if the flow diameter of the longitudinal bore 32 is at least 0.5 times and at most 1.5 times the total flow diameter of the nozzle holes 31.

- the fuel injector 1 operates as follows.

- the fuel is introduced through the supply line 12 into the pressure chamber 6.

- the connection between a common rail pressure accumulator for the fuel and the pressure chamber 6 is opened, for example via a valve or the fuel is conveyed by an injection pump into the pressure chamber 6.

- the fuel acts on the nozzle needle 7 and does not raise it against the bias of the illustrated compression spring from the valve seat 8, so that the passage is opened in the nozzle head 3.

- the fuel flows through the longitudinal bore 32 and is injected through the nozzle holes 31 into the combustion chamber 20.

- the pressure in the pressure chamber 6 is reduced by stopping the fuel delivery or by closing the connection with the common rail pressure accumulator, so that the nozzle needle 7 is pressed by the compression spring back into the valve seat 8 and closes the passage for the fuel.

- the greatly reduced volume of the blind hole substantially less fuel then enters the combustion chamber 20 after closing the passage at the valve seat.

- the friction between the fuel and the wall of the bore is increased. This is equivalent to a greater pressure drop or pressure loss caused by the nozzle head 3.

- the conditional by the friction pressure drop in the inventive nozzle head 3 may well be 50 - 100 bar. In modern large diesel engines, which operate on the common rail principle and are completely electronically controlled, this frictional pressure drop can be easily compensated by the fuel pressure in the common rail pressure accumulator is increased accordingly.

- this frictional pressure drop can be easily compensated by the fuel pressure in the common rail pressure accumulator is increased accordingly.

- the lower speed range ensures that for the actual injection of the fuel through the nozzle holes 31 still sufficient pressure - for example, 500-700 bar - is present to ensure proper injection into the combustion chamber 20.

- the cross section of the nozzle holes 31 can be increased. Furthermore, it is advantageous to design the transition region between the longitudinal bore 32 and the nozzle hole 31 each rounded, wherein a lighter rounding of a lighter inflow of the fuel from the longitudinal bore 32 into the nozzle hole 31 and thus a reduction of the flow resistance can be achieved.

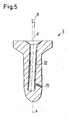

- FIG. 3 shows a section through the second embodiment and Fig. 4 an enlarged view of the lower portion of the nozzle head 3.

- the longitudinal bore 32 in this embodiment in the region of the nozzle holes 31 an extension 321 on.

- five nozzle holes 31 are provided analogous to the illustration in FIG Fig. 2 ,

- the extension 321 By the extension 321, the flow of the fuel from the longitudinal bore 32 into the nozzle holes 31 can be facilitated and thus reduce the flow resistance, because it is easier to deflect the fuel flow from the larger cross section of the extension 321 out into the nozzle holes. The hydraulic friction when flowing into the nozzle holes 31 is thus reduced.

- the extension also has an additional advantage. Given a given number of nozzle holes 31 with a given diameter and given rounding in the junction region, the distance between the individual junctions of the nozzle holes 31 in the longitudinal bore 32 can be made larger. This larger distance has the advantage of reducing the mechanical stress peaks caused by the internal pressure in the material of the nozzle head.

- extension 321 asymmetrically with respect to the longitudinal axis of the longitudinal bore 32, as in particular Fig. 4 can be seen.

- the longitudinal axis of the longitudinal bore 31 in this embodiment is identical to the longitudinal axis A of the nozzle head 3 and the longitudinal axis of the Fuel injection nozzle 1.

- the longitudinal axis C of the extension 321 is parallel but offset from the longitudinal axis A, so that the extension 321 is asymmetrical or eccentric with respect to the longitudinal bore 32.

- This measure has the advantage that the larger wall thickness of the nozzle head 3 caused by the comparatively small diameter D of the longitudinal bore 32 can be reduced by the extension 321 on the side facing the combustion chamber 20, ie where the nozzle holes 31 are provided.

- a large wall thickness may be advantageous in terms of mechanical strength, it also requires that the nozzle holes 31 become longer in each case. This can have an adverse effect because too great a length of the nozzle holes can lead to a strong concentration of the fuel jet flowing through them, which can have a negative effect on the injection process.

- This can be avoided by the extension 321, because the wall thickness of the nozzle head 3 on the combustion chamber 20 side facing smaller, and thus the nozzle holes 31 are shorter.

- the asymmetrical configuration of the extension 321 is easier to manufacture.

- FIG. 5 shows the longitudinal bore 32 extends obliquely to the longitudinal axis A of the nozzle head.

- the longitudinal bore 32 designated here by A ', at a different angle ⁇ from the longitudinal axis A of the nozzle head 3.

- the passage at the valve seat 8 in the open position of the nozzle needle has a surface which is at least as large as the flow cross section of the longitudinal bore 31. That is, in the open position of the nozzle needle 7, the flow cross section between Nozzle needle and valve seat 8 equal to or greater than the flow cross-section of the longitudinal bore 32. Since the flow cross-section of the longitudinal bore 32nd in turn larger than the total flow cross-section of all nozzle holes 31, the flow cross section downstream of the pressure chamber 6 in the open position of the nozzle needle 7 no longer increases. This means that a reduction in the flow rate of the fuel, which would be caused by an increase in the flow cross-section is excluded. This is advantageous in the case of the fuel injection nozzle, because in this case recovering kinetic energy by widening the flow cross-section (diffuser effect) is inefficient.

- the production of the nozzle head for the inventive fuel injector can be done with all known processing methods.

- the production of the longitudinal bore 32, the nozzle holes 31, the rounding and optionally the extension 321 may be by means of drilling and / or electrochemical machining methods, for. B. Elysieren done.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Fuel-Injection Apparatus (AREA)

- Feeding And Controlling Fuel (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL05405036T PL1566539T3 (pl) | 2004-02-23 | 2005-01-25 | Wtryskiwacz paliwa |

| EP05405036A EP1566539B1 (de) | 2004-02-23 | 2005-01-25 | Brennstoffeinspritzdüse |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04405099 | 2004-02-23 | ||

| EP04405099 | 2004-02-23 | ||

| EP05405036A EP1566539B1 (de) | 2004-02-23 | 2005-01-25 | Brennstoffeinspritzdüse |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1566539A1 EP1566539A1 (de) | 2005-08-24 |

| EP1566539B1 true EP1566539B1 (de) | 2009-01-14 |

Family

ID=34932043

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05405036A Not-in-force EP1566539B1 (de) | 2004-02-23 | 2005-01-25 | Brennstoffeinspritzdüse |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP1566539B1 (zh) |

| JP (1) | JP2005240805A (zh) |

| KR (1) | KR101264814B1 (zh) |

| CN (1) | CN100564865C (zh) |

| AT (1) | ATE421039T1 (zh) |

| DE (1) | DE502005006448D1 (zh) |

| DK (1) | DK1566539T3 (zh) |

| PL (1) | PL1566539T3 (zh) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20080006713A1 (en) * | 2006-07-06 | 2008-01-10 | Parish James R | Fuel injector having an internally mounted cross-flow nozzle for enhanced compressed natural gas jet spray |

| DK2031237T3 (da) * | 2007-08-31 | 2011-01-10 | Waertsilae Nsd Schweiz Ag | Indsprøjtningsdyse til indsprøjtning af brændstof |

| CN101694199B (zh) * | 2009-08-20 | 2011-05-11 | 余姚市舒春机械有限公司 | 低速柴油机喷嘴 |

| EP3267027A1 (de) * | 2016-07-07 | 2018-01-10 | Winterthur Gas & Diesel AG | Düsenkopf für eine brennstoffeinspritzdüse eines grossdieselmotors, sowie verfahren zum herstellen eines solchen |

| DK181318B1 (en) | 2022-02-18 | 2023-08-10 | Man Energy Solutions Filial Af Man Energy Solutions Se Tyskland | A fuel valve for a large turbocharged two-stroke uniflow crosshead internal combustion engine |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE482591C (de) * | 1927-04-30 | 1930-02-03 | Werke Kiel Akt Ges Deutsche | Brennstoffeinspritzventil fuer Brennkraftmaschinen |

| DE2948451A1 (de) * | 1979-12-01 | 1981-06-04 | Robert Bosch Gmbh, 7000 Stuttgart | Kraftstoffeinspritzduese fuer brennkraftmaschinen |

| DE3234829A1 (de) * | 1982-09-21 | 1984-03-22 | Deutsche Forschungs- und Versuchsanstalt für Luft- und Raumfahrt e.V., 5000 Köln | Einspritzvorrichtung fuer einen dieselmotor |

| CS249562B1 (en) * | 1983-08-23 | 1987-04-16 | Vaclav Rysan | Multi-opening injection jet |

| JPH0639095Y2 (ja) * | 1988-03-09 | 1994-10-12 | 住友重機械工業株式会社 | ディーゼル機関用燃料噴射ノズル |

| US5026462A (en) * | 1990-03-06 | 1991-06-25 | Ail Corporation | Method and apparatus for electrochemical machining of spray holes in fuel injection nozzles |

| JPH10176631A (ja) * | 1996-12-18 | 1998-06-30 | Nippon Soken Inc | 燃料噴射弁 |

| JPH11117830A (ja) * | 1997-10-20 | 1999-04-27 | Hitachi Ltd | インジェクタ |

| ATE388322T1 (de) * | 2002-04-11 | 2008-03-15 | Waertsilae Nsd Schweiz Ag | Düsenkopf für eine brennstoffeinspritzdüse |

| KR101307563B1 (ko) * | 2003-07-16 | 2013-09-12 | 베르트질레 슈바이츠 악티엔게젤샤프트 | 실린더부 내의 고압 피스톤용 피스톤 |

-

2005

- 2005-01-25 DK DK05405036T patent/DK1566539T3/da active

- 2005-01-25 AT AT05405036T patent/ATE421039T1/de not_active IP Right Cessation

- 2005-01-25 DE DE502005006448T patent/DE502005006448D1/de active Active

- 2005-01-25 EP EP05405036A patent/EP1566539B1/de not_active Not-in-force

- 2005-01-25 PL PL05405036T patent/PL1566539T3/pl unknown

- 2005-02-22 JP JP2005044914A patent/JP2005240805A/ja active Pending

- 2005-02-22 KR KR1020050014480A patent/KR101264814B1/ko not_active IP Right Cessation

- 2005-02-23 CN CNB2005100519828A patent/CN100564865C/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ATE421039T1 (de) | 2009-01-15 |

| KR20060043061A (ko) | 2006-05-15 |

| KR101264814B1 (ko) | 2013-05-15 |

| EP1566539A1 (de) | 2005-08-24 |

| CN100564865C (zh) | 2009-12-02 |

| PL1566539T3 (pl) | 2009-05-29 |

| JP2005240805A (ja) | 2005-09-08 |

| DK1566539T3 (da) | 2009-04-14 |

| DE502005006448D1 (de) | 2009-03-05 |

| CN1661227A (zh) | 2005-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE4039520B4 (de) | Kraftstoff-Einspritzventil | |

| DE10303859B4 (de) | Düsenbaugruppe zur Einspritzung und Verwirbelung von Kraftstoff | |

| EP0657642B1 (de) | Kraftstoffeinspritzeinrichtung für Brennkraftmaschinen | |

| EP1198672A1 (de) | Kraftstoffeinspritzventil für brennkraftmaschinen | |

| EP0982493B1 (de) | Verfahren zum Herstellen einer Brennstoffeinspritzdüse und Brennstoffeinspritzdüse | |

| EP1656498A1 (de) | Pilotventil gesteuertes brennstoffeinspritzventil | |

| DE602005003824T2 (de) | Einspritzdüse | |

| EP1566539B1 (de) | Brennstoffeinspritzdüse | |

| DE102007021330A1 (de) | Kraftstoffinjektor für eine Brennkraftmaschine mit Common-Rail-Einspritzsystem | |

| EP0961025A1 (de) | Brennstoffeinspritzdüse | |

| EP1649160B1 (de) | Brennstoffeinspritzventil für brennkraftmaschinen | |

| DE102007000095B4 (de) | Kraftstoffeinspritzelement | |

| EP2718558B1 (de) | Einspritzventil für brennkraftmaschinen | |

| DE602005005159T2 (de) | Kraftstoffeinspritzventil | |

| EP0922159B1 (de) | Kraftstoffzuleitungseinrichtung | |

| DE10259799A1 (de) | Brennstoffeinspritzventil | |

| DE102007000670A1 (de) | Fluideinspritzvorrichtung | |

| DE19706661A1 (de) | Kraftstoffeinspritzventil für Brennkraftmaschinen | |

| EP0730089A1 (de) | Kraftstoffeinspritzventil für Brennkraftmaschinen | |

| DE10209527A1 (de) | Einrichtung zur druckmodulierten Formung des Einspritzverlaufes | |

| DE102008041167A1 (de) | Kraftstoffinjektor | |

| EP1281861B1 (de) | Kraftstoff-Einspritzeinrichtung für Brennkraftmaschinen | |

| DE102014220104B3 (de) | Kraftstoffeinspritzventil | |

| DE10348978A1 (de) | Kraftstoff-Einspritzvorrichtung, insbesondere für eine Brennkraftmaschine mit Direkteinspritzung | |

| AT511731B1 (de) | Kavitationsoptimierte drosselbohrungen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060126 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20070417 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: SULZER MANAGEMENT AG PATENTABTEILUNG/0067 Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502005006448 Country of ref document: DE Date of ref document: 20090305 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090425 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090131 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090414 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090615 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090514 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20091030 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 |

|

| 26N | No opposition filed |

Effective date: 20091015 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090414 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20091230 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090414 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090715 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090114 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20120123 Year of fee payment: 8 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: LAPE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110125 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20130122 Year of fee payment: 9 Ref country code: CH Payment date: 20130123 Year of fee payment: 9 Ref country code: DK Payment date: 20130121 Year of fee payment: 9 Ref country code: FI Payment date: 20130111 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: INTELLECTUAL PROPERTY SERVICES GMBH, CH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: NEW ADDRESS: LANGFELDSTRASSE 88, 8500 FRAUENFELD (CH) |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005006448 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP Effective date: 20140131 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502005006448 Country of ref document: DE Effective date: 20140801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140131 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140125 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140801 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140125 |