EP1528145A2 - Trocken- und Glättvorrichtung für Kleidungsstücke - Google Patents

Trocken- und Glättvorrichtung für Kleidungsstücke Download PDFInfo

- Publication number

- EP1528145A2 EP1528145A2 EP04025804A EP04025804A EP1528145A2 EP 1528145 A2 EP1528145 A2 EP 1528145A2 EP 04025804 A EP04025804 A EP 04025804A EP 04025804 A EP04025804 A EP 04025804A EP 1528145 A2 EP1528145 A2 EP 1528145A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- handle

- frame

- retracted position

- drying

- extended position

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06F—LAUNDERING, DRYING, IRONING, PRESSING OR FOLDING TEXTILE ARTICLES

- D06F73/00—Apparatus for smoothing or removing creases from garments or other textile articles by formers, cores, stretchers, or internal frames, with the application of heat or steam

Definitions

- the present invention relates to a drying and smoothing device for Garments with a frame and a flexible arranged on the frame Iron-on doll, which is inflatable from the inside with a stream of air.

- Drying and lightening devices for garments with a frame and one on it arranged flexible ironing manikin are commonly used as stationary devices operated.

- a disadvantage of these devices is that they are very cumbersome too are transporting.

- Object of the present invention is therefore a drying and smoothing device for garments with a frame and a flexible one attached thereto Ironing doll to provide, which is easy to transport.

- the device By providing a handle to the garment drying and straightening device is, which is arranged on the frame, the device can be easily transported.

- the device can be easily worn on the handle or, if still

- rollers are provided on the frame, can also be rolled.

- the handle can take a retracted position in which the handle is not is used, and can assume an extended position in which the handle is usable, it ensures that the handle in case of non-use is not is disturbing.

- the handle is merely for the purpose of transporting the device into the brought out extended position and after transport to the retracted position scaled back.

- the handle can only be retracted, if this is wanted by the user.

- the handle in the retracted Receives position and / or in which the unlocking is arranged can the handle can be housed in the retracted position without disturbing and the Unlocking adjacent to the handle in the retracted position be accommodated advantageous manner.

- the guide device is designed as a linear Guiding device formed along the handle in the extended position and / or the retracted position is movable.

- the guide device is designed as a linear Guiding device formed along the handle in the extended position and / or the retracted position is movable.

- the handle is preferably arranged on the same side of the frame, on which also the wheels are arranged, the device by means of the handle in its extended Position are moved like a sack truck in an advantageous manner.

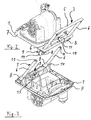

- the garment drying and smoothing device has a frame 1 and a flexible, air-permeable arranged on the top of the frame 1 Ironing doll 2.

- a fan (not shown) and a heater (not shown) arranged around a hot air flow to inflate the Ironing doll 2 to produce.

- a garment such as. a shirt, so this garment by the hot air flow dried and smoothed.

- a handle 3rd arranged to transport the device to an extended position ( Figure 1, Figure 2 and Figure 3) and when not in use a retracted position ( Figure 3 and Figure 5) can take.

- the cuboid frame 1 has at its rear lower portion each one roller 4 arranged on each side of the frame 1 such that the frame 1 to the two wheels 4 can be swiveled.

- the handle 3 is at the upper rear End portion of the frame 1 is arranged and protrudes in its extended position obliquely backwards out of the frame 1 out.

- the device is pivoted about the two wheels 4 by means of the handle 3, so that the front bottom portion of the frame 1 is lifted off the ground and the Frame 1 now contacted only via the wheels 4 the ground. In this position can the device similar to a sack truck or a wheelbarrow in a simple manner be transported.

- the handle 3 is U-shaped and has a cross tube 5 and two lateral longitudinal tubes 6. Die Longitudinal tubes 6 of the handle 3 are in an upper component 7 of the frame 1 in each case one linear guide means 8 slidably mounted, so that the handle 3 a retracted position (see Figure 3 and Figure 5) and an extended position (see Figure 1, Figure 2 and Figure 4) can take.

- the handle 3 has a Locking device 9, with the handle 3 in the extended position is lockable.

- the handle 3 at the end of each longitudinal tube 6 a Stop pin 10, with which the handle 3 in the extended position against a bottom portion of the respective linear guide device 8 abuts.

- a trough 11 is formed, the handle 3 and in particular receives its cross tube 5 in the retracted position.

- the trough 11 has in a central portion a trough extension 12 to the cross tube 5 in the retracted position better.

- the locking device 9 has a rotatable about a rotation axis 1 latch 14th (Arrow 13), which is biased by a spring 16 in the direction of the longitudinal tube 6 out.

- the latch 14 pivots from the Position according to Figure 5 in the position shown in Figure 4, in which the bolt under the bottom end of each longitudinal tube 6 engages.

- an unlocking device 17 is arranged at Actuation (arrow 18) the latch 14 from the locked position according to Figure 4 in the unlocked position moves according to Figure 5.

- the unlocking mechanism 17 has a pivotally mounted key 19, which upon actuation on the pivotable Latch 14 acts, that the bolt 14 its unlocked position according to FIG occupies.

- the handle on the frame can also be arranged on the frame 1 via a rotation axis be and out about the axis of rotation and be folded into it.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Handcart (AREA)

- Treatment Of Fiber Materials (AREA)

Abstract

Description

- Figur 1

- eine Schrägansicht der Trocken- und Glättvorrichtung für Kleidungsstücke;

- Figur 2

- eine Schrägansicht von oben des Bauteils der Trocken- und Glättvorrichtung, welches einen Griff aufnimmt;

- Figur 3

- eine Schrägansicht des Bauteils nach Figur 2 von unten;

- Figur 4

- eine detaillierte Schnittansicht mit dem Griff in der ausgefahrenen Position;

- Figur 5

- eine detaillierte Schnittansicht mit dem Griff in der eingefahrenen Position.

Claims (10)

- Trocken- und Glättvorrichtung für Kleidungsstücke mit einem Gestell (1) und einer am Gestell (1) angeordneten, flexiblen Bügelpuppe (2), die von innen mit einem Luftstrom aufblähbar ist, dadurch gekennzeichnet, dass wenigstens ein Griff (3) am Gestell (1) angeordnet ist, um die Vorrichtung zu transportieren.

- Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, dass der Griff (3) mittels einer Führungseinrichtung (8) eine eingefahrene Position einnehmen kann, in der der Griff (3) nicht benutzt wird, und eine ausgefahrene Position einnehmen kann, in der der Griff (3) benutzbar ist

- Vorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass der Griff (3) mittels einer Verriegelungseinrichtung (9) in der ausgefahrenen Position verriegelbar ist.

- Vorrichtung nach Anspruch 3, dadurch gekennzeichnet, dass die Verriegelungseinrichtung (9) bei Erreichen der ausgefahrenen Position selbsttätig verriegelt.

- Vorrichtung nach Anspruch 3 oder 4, dadurch gekennzeichnet, dass eine Entriegelungseinrichtung (17) vorgesehen ist, mit der die Verriegelungseinrichtung (9) entriegelbar ist, so dass der Griff (3) in die eingefahrene Position einfahrbar ist

- Vorrichtung nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass am Gestell eine Mude (11) vorgesehen ist, die den Griff (3) in der eingefahrenen Position aufnimmt.

- Vorrichtung nach Anspruch 5 und 6, dadurch gekennzeichnet, dass die Entriegelungseinrichtung (17) in der Mulde (11) angeordnet ist.

- Vorrichtung nach Anspruch 2, dadurch gekennzeichnet, dass die Führungseinrichtung (8) eine lineare Führungseinrichtung hat, längs der der Griff (3) in die ausgefahrene und/oder eingefahrene Position beweglich ist

- Vorrichtung nach einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, dass das Gestell (1) wenigstens an einer Seite mit Rädern (4) versehen ist.

- Vorrichtung nach Anspruch 8, dadurch gekennzeichnet, dass der Griff (3) an der gleichen Seite am Gestell (1) angeordnet ist, an der die Räder (4) angeordnet sind.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE2003150497 DE10350497A1 (de) | 2003-10-29 | 2003-10-29 | Trocken- und Glättvorrichtung für Kleidungsstücke |

| DE10350497 | 2003-10-29 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1528145A2 true EP1528145A2 (de) | 2005-05-04 |

| EP1528145A3 EP1528145A3 (de) | 2008-11-12 |

Family

ID=34399594

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04025804A Withdrawn EP1528145A3 (de) | 2003-10-29 | 2004-10-29 | Trocken- und Glättvorrichtung für Kleidungsstücke |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1528145A3 (de) |

| DE (1) | DE10350497A1 (de) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8407914B2 (en) | 2009-06-01 | 2013-04-02 | The Procter & Gamble Company | Passive heat management system |

| US8484867B2 (en) | 2009-06-01 | 2013-07-16 | The Procter & Gamble Company | Fabric refreshing cabinet device for increasing flexural rigidity |

| US8783070B2 (en) | 2009-03-27 | 2014-07-22 | The Procter & Gamble Company | Fluid dispensing system for fabric refreshing cabinet device |

| US8931667B2 (en) | 2008-09-24 | 2015-01-13 | The Procter & Gamble Company | Methods and apparatuses for dispensing fluids |

| US9410281B2 (en) | 2009-05-01 | 2016-08-09 | Whirlpool Corporation | Fabric treating systems and accessories |

| US10208424B2 (en) | 2009-06-01 | 2019-02-19 | Whirlpool Corporation | Fabric refreshing cabinet device |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1574306A (en) * | 1925-08-06 | 1926-02-23 | Ramsey William Albert | Garment drier |

| US3085350A (en) * | 1960-12-01 | 1963-04-16 | Westinghouse Electric Corp | Portable heater |

| US3165244A (en) * | 1962-05-18 | 1965-01-12 | Dosal Martin Roberto | Inflatable apparatus for pressing shirts |

| DE1262204B (de) * | 1964-11-12 | 1968-03-07 | Masch App Werkzeuge & Co | Daempf- und Blaspuppe zur Behandlung von Roecken od. dgl. |

| US3559427A (en) * | 1969-03-19 | 1971-02-02 | Norman J Baker | Clothes steaming device |

| US4254850A (en) * | 1979-10-29 | 1981-03-10 | Knowles Harford E | Luggage case |

| IT1169275B (it) * | 1981-11-09 | 1987-05-27 | Omar Hakim | Apparecchiatura per la stiratura rapida di capi di abbigliamento in genere |

| DE9011019U1 (de) * | 1990-07-26 | 1990-09-27 | Richard Tscherwitschke GmbH Kunststoff-Apparatebau und Ablufttechnik, 7022 Leinfelden-Echterdingen | Vorrichtung zum Trocknen von einteiligen Schutzanzügen |

| US5414895A (en) * | 1993-05-26 | 1995-05-16 | Remin Laboratories, Inc. | Cart and luggage handle assembly with a push button actuator |

| JP3070363B2 (ja) * | 1993-11-02 | 2000-07-31 | 松下電器産業株式会社 | 縦型衣類プレス器 |

| US5609047A (en) * | 1995-06-06 | 1997-03-11 | Nadia Wechsler | Garment steaming device with safety nozzle |

| US5868406A (en) * | 1997-07-01 | 1999-02-09 | Outrigger, Inc. | Inclined handle for wheeled case |

| US5864921A (en) * | 1997-12-10 | 1999-02-02 | Chou; Cheng-Tsan | Extensible handle assembly |

| AU2956599A (en) * | 1998-03-23 | 1999-10-18 | Capecchi, Carla | Small home equipment for drying and ironing clothes, in standing position |

| US6393660B1 (en) * | 1999-04-26 | 2002-05-28 | Chaw Khong Technology Co., Ltd. | Handle for a luggage |

| DE10063671A1 (de) * | 2000-12-20 | 2002-06-27 | Bsh Bosch Siemens Hausgeraete | Vorrichtung zum Glätten von Hemden |

| DE10128939B4 (de) * | 2001-06-18 | 2006-01-26 | Volker Weiss | Vorrichtung zum Trocknen und Glätten von Kleidungsstücken |

| JP2003199996A (ja) * | 2002-01-10 | 2003-07-15 | Matsushita Electric Ind Co Ltd | 衣類仕上げ装置 |

-

2003

- 2003-10-29 DE DE2003150497 patent/DE10350497A1/de not_active Withdrawn

-

2004

- 2004-10-29 EP EP04025804A patent/EP1528145A3/de not_active Withdrawn

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US8931667B2 (en) | 2008-09-24 | 2015-01-13 | The Procter & Gamble Company | Methods and apparatuses for dispensing fluids |

| US8783070B2 (en) | 2009-03-27 | 2014-07-22 | The Procter & Gamble Company | Fluid dispensing system for fabric refreshing cabinet device |

| US9410281B2 (en) | 2009-05-01 | 2016-08-09 | Whirlpool Corporation | Fabric treating systems and accessories |

| US10420435B2 (en) | 2009-05-01 | 2019-09-24 | Whirlpool Corporation | Fabric treating systems and accessories |

| US10426284B2 (en) | 2009-05-01 | 2019-10-01 | Whirlpool Corporation | Fabric treating systems and accessories |

| US8407914B2 (en) | 2009-06-01 | 2013-04-02 | The Procter & Gamble Company | Passive heat management system |

| US8484867B2 (en) | 2009-06-01 | 2013-07-16 | The Procter & Gamble Company | Fabric refreshing cabinet device for increasing flexural rigidity |

| US10208424B2 (en) | 2009-06-01 | 2019-02-19 | Whirlpool Corporation | Fabric refreshing cabinet device |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10350497A1 (de) | 2005-06-02 |

| EP1528145A3 (de) | 2008-11-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3423528C2 (de) | Transportwagen | |

| DE19809331C1 (de) | Verfahr- und arretierbare Sammelvorrichtung | |

| DE2627731C2 (de) | Zusammenklappbarer Kinderwagen | |

| DE202016106641U1 (de) | Klappfahrrad | |

| DE20201107U1 (de) | Klappmechanismus für Kinderkarre | |

| DE20010413U1 (de) | Kinderwagen | |

| DE29622226U1 (de) | Kofferkuli | |

| DE202005016709U1 (de) | Vorrichtung zum Zusammenklappen des Rahmens einer Baby-Karre | |

| EP1528145A2 (de) | Trocken- und Glättvorrichtung für Kleidungsstücke | |

| DE102015103844B4 (de) | Aufbewahrungswagen | |

| DE202007014299U1 (de) | Zusammenklappbarer Aufbau eines Kinderwagens | |

| DE29819218U1 (de) | Fahrgestell für einen Kinder- oder Puppenwagen | |

| DE69922187T2 (de) | Golftasche | |

| DE20013742U1 (de) | Trainingswagenstruktur | |

| DE202013005454U1 (de) | Klemmvorrichtung und Kopfstützenholmenhalter | |

| EP1069231B1 (de) | Vorrichtung zum Glätten von Hemden | |

| DE202017100729U1 (de) | Zusammenklappbarer Transportwagen mit Transportkiste sowie zusammenlegbare Transportkiste für einen Transportwagen | |

| DE10156859A1 (de) | Vorrichtung zum Glätten hemdförmiger Kleidungsstücke | |

| DE69815929T2 (de) | Fahrbahrer Träger für eine elektronische Diagnoseeinheit für ein Industriefahrzeug | |

| DE2903781C3 (de) | Klapptritt | |

| DE516062C (de) | Rollvorrichtung fuer Faesser | |

| DE202009002486U1 (de) | Klappvorrichtung für Golfwagen | |

| DE8713696U1 (de) | Ärmelspannvorrichtung für Bügelmaschinen | |

| DE1580744C (de) | Verschluß für Schwenkfenster oder dergleichen, insbesondere für Kraftfahrzeuge | |

| CH342141A (de) | Streckwerk für Spinnereimaschinen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| AKX | Designation fees paid | ||

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20090513 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |