EP1520929A1 - Verfahren und Vorrichtung zur Herstellung von Sicherheitsfolien - Google Patents

Verfahren und Vorrichtung zur Herstellung von Sicherheitsfolien Download PDFInfo

- Publication number

- EP1520929A1 EP1520929A1 EP04015119A EP04015119A EP1520929A1 EP 1520929 A1 EP1520929 A1 EP 1520929A1 EP 04015119 A EP04015119 A EP 04015119A EP 04015119 A EP04015119 A EP 04015119A EP 1520929 A1 EP1520929 A1 EP 1520929A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- film

- solvent

- sheet

- fabric

- carrier film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 45

- 238000004519 manufacturing process Methods 0.000 title description 10

- 239000002904 solvent Substances 0.000 claims abstract description 45

- 238000005406 washing Methods 0.000 claims abstract description 33

- 238000007639 printing Methods 0.000 claims abstract description 16

- 239000000049 pigment Substances 0.000 claims abstract description 12

- 238000001035 drying Methods 0.000 claims abstract description 10

- 230000008569 process Effects 0.000 claims abstract description 9

- 239000004753 textile Substances 0.000 claims abstract description 9

- 230000009471 action Effects 0.000 claims abstract description 8

- 238000004140 cleaning Methods 0.000 claims description 36

- 239000003973 paint Substances 0.000 claims description 35

- 239000004744 fabric Substances 0.000 claims description 33

- 229910052751 metal Inorganic materials 0.000 claims description 15

- 239000002184 metal Substances 0.000 claims description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 7

- 239000007788 liquid Substances 0.000 claims description 5

- 229910052782 aluminium Inorganic materials 0.000 claims description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 4

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 3

- 229910052802 copper Inorganic materials 0.000 claims description 3

- 239000010949 copper Substances 0.000 claims description 3

- 210000002268 wool Anatomy 0.000 claims description 3

- 241001494479 Pecora Species 0.000 claims description 2

- FGUUSXIOTUKUDN-IBGZPJMESA-N C1(=CC=CC=C1)N1C2=C(NC([C@H](C1)NC=1OC(=NN=1)C1=CC=CC=C1)=O)C=CC=C2 Chemical compound C1(=CC=CC=C1)N1C2=C(NC([C@H](C1)NC=1OC(=NN=1)C1=CC=CC=C1)=O)C=CC=C2 FGUUSXIOTUKUDN-IBGZPJMESA-N 0.000 claims 4

- 238000000576 coating method Methods 0.000 abstract description 17

- 239000011248 coating agent Substances 0.000 abstract description 14

- 238000002360 preparation method Methods 0.000 abstract description 3

- 230000015572 biosynthetic process Effects 0.000 abstract 1

- 238000009966 trimming Methods 0.000 abstract 1

- 239000010408 film Substances 0.000 description 68

- 239000002245 particle Substances 0.000 description 19

- 239000000835 fiber Substances 0.000 description 11

- 230000008901 benefit Effects 0.000 description 8

- 239000011230 binding agent Substances 0.000 description 6

- 239000011888 foil Substances 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- 230000032258 transport Effects 0.000 description 5

- 229920002451 polyvinyl alcohol Polymers 0.000 description 4

- 230000001427 coherent effect Effects 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 3

- 229920002994 synthetic fiber Polymers 0.000 description 3

- 239000012209 synthetic fiber Substances 0.000 description 3

- 229910002012 Aerosil® Inorganic materials 0.000 description 2

- 241000252254 Catostomidae Species 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- -1 Polyethylene Terephthalate Polymers 0.000 description 2

- 239000004743 Polypropylene Substances 0.000 description 2

- 239000004372 Polyvinyl alcohol Substances 0.000 description 2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 2

- 229920002472 Starch Polymers 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- 210000003323 beak Anatomy 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 239000006260 foam Substances 0.000 description 2

- 238000010438 heat treatment Methods 0.000 description 2

- 238000010030 laminating Methods 0.000 description 2

- 239000002923 metal particle Substances 0.000 description 2

- 230000003287 optical effect Effects 0.000 description 2

- 239000003960 organic solvent Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 229920003023 plastic Polymers 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229920000139 polyethylene terephthalate Polymers 0.000 description 2

- 239000005020 polyethylene terephthalate Substances 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 239000007921 spray Substances 0.000 description 2

- 239000008107 starch Substances 0.000 description 2

- 235000019698 starch Nutrition 0.000 description 2

- 238000002604 ultrasonography Methods 0.000 description 2

- 239000003232 water-soluble binding agent Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229920002134 Carboxymethyl cellulose Polymers 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 229920001875 Ebonite Polymers 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 229920000297 Rayon Polymers 0.000 description 1

- AZDRQVAHHNSJOQ-UHFFFAOYSA-N alumane Chemical compound [AlH3] AZDRQVAHHNSJOQ-UHFFFAOYSA-N 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 230000000454 anti-cipatory effect Effects 0.000 description 1

- 239000003125 aqueous solvent Substances 0.000 description 1

- 239000004760 aramid Substances 0.000 description 1

- 229920003235 aromatic polyamide Polymers 0.000 description 1

- 239000000440 bentonite Substances 0.000 description 1

- 229910000278 bentonite Inorganic materials 0.000 description 1

- SVPXDRXYRYOSEX-UHFFFAOYSA-N bentoquatam Chemical compound O.O=[Si]=O.O=[Al]O[Al]=O SVPXDRXYRYOSEX-UHFFFAOYSA-N 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000012876 carrier material Substances 0.000 description 1

- 229920002678 cellulose Polymers 0.000 description 1

- 239000001913 cellulose Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 239000013039 cover film Substances 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 238000007646 gravure printing Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 239000005445 natural material Substances 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 239000004745 nonwoven fabric Substances 0.000 description 1

- 230000001151 other effect Effects 0.000 description 1

- 230000035515 penetration Effects 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000007790 scraping Methods 0.000 description 1

- 238000006748 scratching Methods 0.000 description 1

- 230000002393 scratching effect Effects 0.000 description 1

- 239000010865 sewage Substances 0.000 description 1

- 239000011877 solvent mixture Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 239000000758 substrate Substances 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000007740 vapor deposition Methods 0.000 description 1

- 235000013311 vegetables Nutrition 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21H—PULP COMPOSITIONS; PREPARATION THEREOF NOT COVERED BY SUBCLASSES D21C OR D21D; IMPREGNATING OR COATING OF PAPER; TREATMENT OF FINISHED PAPER NOT COVERED BY CLASS B31 OR SUBCLASS D21G; PAPER NOT OTHERWISE PROVIDED FOR

- D21H21/00—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties

- D21H21/14—Non-fibrous material added to the pulp, characterised by its function, form or properties; Paper-impregnating or coating material, characterised by its function, form or properties characterised by function or properties in or on the paper

- D21H21/40—Agents facilitating proof of genuineness or preventing fraudulent alteration, e.g. for security paper

- D21H21/44—Latent security elements, i.e. detectable or becoming apparent only by use of special verification or tampering devices or methods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B42—BOOKBINDING; ALBUMS; FILES; SPECIAL PRINTED MATTER

- B42D—BOOKS; BOOK COVERS; LOOSE LEAVES; PRINTED MATTER CHARACTERISED BY IDENTIFICATION OR SECURITY FEATURES; PRINTED MATTER OF SPECIAL FORMAT OR STYLE NOT OTHERWISE PROVIDED FOR; DEVICES FOR USE THEREWITH AND NOT OTHERWISE PROVIDED FOR; MOVABLE-STRIP WRITING OR READING APPARATUS

- B42D25/00—Information-bearing cards or sheet-like structures characterised by identification or security features; Manufacture thereof

- B42D25/30—Identification or security features, e.g. for preventing forgery

- B42D25/355—Security threads

Definitions

- the invention relates to a method and an apparatus for producing of security films stored or applied in or on securities be and from a translucent carrier film and a deposited thereon Covering layer with coating-free areas in the form of Letters, numbers, signs, points and / or patterns, in particular are clearly visible in transmitted light exist.

- WO 99/13157 describes a process for producing a negative typeface described in the first color with high pigment content on a carrier film is printed. Thereafter, the printed carrier film with a thin cover layer, for example, with vapor-deposited aluminum, covered. Following is the paint application and the overlying or in removed the paint penetration penetrated cover, so that to this Make the negative writing visible.

- the invention is therefore based on the object, a method and a To provide apparatus that produce negative images on transparencies can be, which are characterized by a high contour sharpness.

- “Negative representation” in the sense of the invention is coating-free Areas in any form in the cover layer according to the invention Understood. Preferably, these are areas in the form of letters, Numbers, signs, points and / or patterns.

- a carrier film with a printing ink with high pigment content in the form of the later desired Negative representation printed first a carrier film with a printing ink with high pigment content in the form of the later desired Negative representation printed.

- the misprinted color with a high pigment content forms on the printing substrate after drying sublime paint application, of a porous, porous structure with large Has surface.

- An applied on such a paint cover layer preferably small thickness leads to no continuous, nationwide Coating, but covers the dried color body because of its large surface and porous structure only partially off, so that the color body at least partially from the outside for solvent easily remains accessible.

- If one uses a soluble binder for the paint then can the paint application and with the paint application and the deposited thereon Covering layer by exposure to a suitable solvent be washed out.

- the washing out becomes mechanically according to the invention supported, namely by means of a textile fabric, preferably by means of a felt.

- the film web After washing out the paint, the film web is dried and cut, for example, to form security threads that are then in paper can be stored for banknotes.

- the film web can also be designed as a transfer film, with the help of security elements any form on security documents or any other securing products can be transferred. Also the use as label material is possible.

- any other effect layer e.g. a print pattern, a diffractive optical effective layer (liquid crystal pigments or layers, interference layers, holograms, etc.).

- a diffractive optical effective layer liquid crystal pigments or layers, interference layers, holograms, etc.

- a plastic film is preferably used as a carrier film. Especially preferred material is polyester. Other plastics can also used, provided they are translucent, have one sufficient strength and a surface that can be printed with and with a cover layer, in particular metal coat. The thickness of the Film is preferably about 6 to 36 microns.

- the film is usually used in the form of endless belts, as the Process is preferably carried out continuously.

- the bands are after tailored to their completion.

- the ink used is a high-pigment color.

- the pigment content, based on the dry weight of the paint should be for Generation of the porous structure about between 10% and 80%, preferably at about 30%, more preferably at about 20%.

- pigments preference is given to choosing natural raw materials, preferably Chalk, but also bentonite, aerosil, alumina and titania.

- Suitable pigments are sold by Martinswerke under the name Pergopak, by Rohm & Haas under the name Rhopaque and by the Degussa offered under the name Aerosil.

- organic can also Particles, such as uncooked starch, are used.

- water-soluble binders are used for the printing ink, so that the paint application with water again dissolved and washed off can be.

- a binder is for example cooked or dissolved starch, polyvinyl alcohol (PVA) or carboxymethylcellulose (CMC).

- solvent used depends inter alia on the used Binders off.

- Useful are aqueous and / or organic Solvents or solvent mixtures, e.g. Water / isopropanol in any suitable mixing ratio.

- water-soluble binder When using a water-soluble binder for the paint, water be used as a solvent. When using other binders a suitable organic solvent must be used.

- any opaque coatings can be used as the cover layer.

- metal coatings such as e.g. Aluminum-, Iron, cobalt, copper or nickel coatings used.

- the film is e.g. with a about 30 nm thick layer of aluminum vaporized.

- aluminum can also copper or another suitable metal can be used.

- the metal may also be replaced by another opaque material, provided that: it can be applied by a similar method to vapor deposition and has an optical at layer thicknesses of about 30 nm Density above 1.8, making the layer substantially opaque is.

- the layer thicknesses can also vary depending on the application in one area vary from 0.01 to 1 micron.

- Such a method leads to surprisingly sharp and defined edge contours and is therefore particularly suitable for the production of negative writing for security threads stored in securities, such as banknotes become.

- the textile fabric is in particular a fabric, a knitted fabric, a knitted fabric, a felt or a fleece. According to the invention Under textile fabric also a sponge and foam to understand.

- it is a felt.

- the fabrics can, as in felts or fleeces, directly from the Fibers, or, as in woven, knitted, crocheted or braided Be formed yarns.

- a tissue indicates a by crossing produced by at least two different thread systems (warp and weft) Fabrics, while in knitted fabrics and crocheted the or swallow the threads in mesh loops.

- Felts are mechanical solidified woven surfaces or fibrous webs. As a nonwoven are not woven Textiles with mostly confused fibers called, their cohesion may already be given by the fibers own liability. In addition, the nonwovens can also be consolidated mechanically or chemically be.

- the sponges and foams can be made of natural material or also made of plastic.

- the textile comprises Fabrics of synthetic fibers, in particular selected from Group Viscose, Aramid, PVAL (Polyvinyl Alcohols), PET (Polyethylene Terephthalate), PA (polyamides) and PP (polypropylenes).

- PVAL Polyvinyl Alcohols

- PET Polyethylene Terephthalate

- PA polyamides

- PP polypropylenes

- Fabrics natural fibers in particular selected from the group wool, Silk, cotton, vegetable fibers, paper fibers and cellulose.

- the fiber coating may also include bi-component fibers or multicomponent fibers, in particular from the said synthetic fiber raw materials or Natural fibers.

- fibers mentioned also occur in combination can, i.e., e.g. as a mixture or in different areas of the fabric.

- the sheet is preferably tubular and is mounted on a corresponding roll.

- the tube has no seam and is therefore characterized by an undisturbed, smooth surface.

- little to no unwanted color particle deposits accumulate on the sheet.

- a felt is used, the preferred material for the felt being pure sheep's wool; other materials such as synthetic fiber felts may also be used.

- the sheet has a thickness of 1 to 30 mm, preferably 10 mm.

- the density is between 0.15 and 0.8 g / cm 3 , preferably about 0.5 g / cm 3 .

- the wrap angle and the contact pressure of Slides to the roller can be made by simple devices for the process be set optimally.

- the wrap angle is in a range of 0 to 360 ° and is preferably inter alia dependent the subject to be washed, the transport speed the film, the diameter of the washing roller, the surface structure of the Set sheet.

- the washing roller can be used with a separate drive be equipped.

- the rotational speed of the rotating roller is preferably adjusted so that between the roll surface and the film a Relative speed of ⁇ 400% results.

- the roller is in Advance run, that is, the peripheral speed of the roller is greater than the transport speed of the film.

- the ratio of peripheral speed to transport speed is preferably + 200%.

- the roll diameter depends on the desired machine speed and is between 100 and 2000 mm, preferably between 500 and 1500 mm, more preferably at 1200 mm.

- the direction of rotation can be the roller equal or opposite to the direction of movement of the film be in opposite directions. If it is the same, it may be leading or trailing be. If the relative movement of the washing roller with respect to the film is anticipatory, so that has the advantage that the already detached color particles not the remainder of the wrap angle on the metal coated Foil must be transported before and possibly the thin Hurt metal layer.

- the fabric not only dissolves the paint particles from the film, but also Under certain circumstances she also picks up and transports her.

- the fabric is therefore cleaned regularly. This is between the production of individual batches possible, the sheet is preferred continuously cleaned during the washing process.

- Various Cleaning devices are conceivable, e.g. can a squeegee be used scraping off the paint particles from the surface.

- a more thorough Cleaning can be carried out by means of one or more directed liquid jets, especially at high pressure, done. The pressure is preferably in one Range from 2 to 500 bar.

- Another option is one or more Use brushes which are arranged parallel to the washing roller and e.g. parallel to this, reciprocate or rotate so that the paint particles be brushed off the surface of the fabric.

- the length and stiffness of the bristles are chosen to match the structure of the Do not hurt the fabric.

- the cleaning process can be done by additional Rinsing be supported.

- a suction device For example, a so-called beak suckers, as he from paper production is known. It can support a pressure roller against Press the fabric and at least part of it in it Press out the liquid present. This will then be together with the contained therein color particles of the beak suckers, usually one under vacuum standing gap-shaped nozzle, sucked up.

- the improved wash result is probably due to a solvent film extending between the film and the surface of the fabric can train.

- This solvent film can act as a lubricating film and thereby prevents scratching of the opaque layer. on the other hand he is probably so thin that the friction is large enough to be solved Completely remove paint particles.

- devices are used with which the thickness of the solvent film can be varied.

- a simple measure to extract water from the fabric is e.g. a wiper lip or squeegee, which is on the surface of the fabric suppressed.

- Another possibility is a pressure roller, which with a Suction device can be combined.

- the step of mechanical action by means of sheet preceded by a pre-cleaning.

- pre-cleaning lies in the fact that a part of the printing ink and the cover layer to be removed already before the film hits the fabric has been removed and can not deposit on its surface.

- pre-cleaning is the printed and provided with the cover film with a solvent wetted by, for example, sprayed with it, or in a tub of solvent is dipped. This penetrates into the highly pigmented Ink and dissolves it.

- the film on mechanical aids such as a brush, rotating or oscillating Brushes or the like, be passed.

- the film can by a sonicated tub with Be guided solvent.

- pre-clean by means of one or more directed liquid jets, preferably under pressure, more preferably below 2 to 3 bar perform.

- the temperature of the solvent e.g. by means of a Heating coil, controlled to set optimum cleaning conditions.

- the temperature of the solvent is in the range of 10 and 50 ° C, more preferably in the range of 20 and 40 ° C. All Measures should be designed so as not to injure the covering layer or scratch.

- the degree of pre-cleaning can, among other things by the time during which the solvent can act, the contact pressure the mechanical aid and the temperature of the solvent be set.

- a Cleaning device which means the step of mechanical action Flat fabric is connected downstream.

- Flat fabric is connected downstream.

- this post-cleaning can all Measures that were described during the pre-cleaning, are used come.

- the last particles of the film surface removed in any subsequent manufacturing steps, such as laminating with a second film, disturbing effect could be used.

- the pre-cleaning, the mechanical action of the fabric and the post-cleaning in a suitable device connected in series, which has the advantage that the film is unwound only once and has to be wound up again.

- Using the method according to the invention can be particularly contour sharp Create negative representations.

- the use allows a fabric for the cover layer gentle removal of the paint job.

- the sheet has the advantage of being preferably is easily deformable and conforms to the surface of the film and thereby reach all color particles and thus can remove. In addition, it is so soft that it does not scratch the remaining metal layer. Scratch marks, especially in a metallic cover layer and at Using mechanically strong acting agent could occur be almost or even avoided altogether. Also in the production filigree structures, such as fine lines or points, is when using a Sheet produced significantly less rejects.

- Another advantage of using a fabric are the small ones mechanical stresses that the carrier film during the mechanical Exposure is exposed by the fabric. Strains and Shrinkage in the longitudinal or transverse direction of the film can during so the production restricted or even avoided.

- Another advantage of the inventive method lies in its environmental compatibility. It does not need any harmful chemicals to become. When using water-soluble paints, the washed out Pigments with known methods removed from the sewage become. It has also been shown that the inventive method compared less time consuming with other methods.

- a translucent transparent carrier sheet 1 made of polyester provided.

- the slide is in a first step with characters, symbols or patterns printed.

- Printing can be done with a common printing process take place, however, a gravure cylinder is preferably used because in gravure printing, especially clear edge contours and a corresponding high paint can be achieved.

- the paint has a porous, porous structure and a raised Profile.

- a cross section through such a paint application 3 shows Fig.1.

- the paint application is a suitable, preferably opaque Covering layer 2 applied in the areas of the paint job again can be removed.

- the printed with the high-pigmented ink carrier sheet is then subjected to a washing process.

- the solvent can easily disperse the discontinuous coating penetrate. It is thus easy, the print characters together with the to wash off any contiguous metal layer.

- the effect of the solvent is through the Supported sheet as a mechanical means.

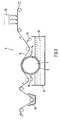

- FIG. 3 A washing device 6 for removing the covering layer is shown in FIG. 3 shown schematically.

- the roller 7 can at least partially into a trough 9 with solvent 10, preferably water, immerse so that this can absorb the felt or even soak in it.

- the film 11 is attached to the washing roller 7 passed and at the contact of the sucked felt with the to be washed Surface forms advantageously a sliding film, whereby a scratch-free surface contact is made possible.

- the film may optionally be pre-cleaned prior to contact with the felt be subjected.

- the binder of the printing ink is at least dissolved, so that with the main cleaning by means of felt the color particles be solved more easily.

- the main cleaning with the felt can be an extra follow cleaning of the film.

- the wash felt is shown in Fig. 3 on the one hand by means of a doctor blade 14 and / or a high pressure solvent jet. Prefers For this purpose, high-pressure nozzles 15 are used.

- the pre-, main- and / or postcleaning are controlled so that the recycled solvent is recycled.

- the film is before further processing in a drying station 16 dried.

- Fig. 4 shows another possible arrangement of the washing device consisting from a two-stage pre-cleaning, the main cleaning and a Post-cleaning.

- the security film 11 is for pre-cleaning by a trough 12 with solvent guided. This is the complete surface of the security film 11 wetted with solvent and dissolved the binder of the ink.

- the temperature of the solvent may optionally be via a heating element 18 are set, preferably in a temperature range from 20 to 40 ° C.

- the solvent bath may alternatively or additionally with Ultrasound to be applied.

- a rotating Brush 17 may be attached to the already dissolved paint particles of the security foil removed. Another advantage of the brush is that the still sticking paint is roughened and thus the attack surface for the solvent is increased. Also other versions a mechanical action, such as a brush or an oscillating Brush are possible.

- a solvent jet rinsed by the security film In the second stage of pre-cleaning, more paint particles are used a solvent jet rinsed by the security film.

- printing nozzles 20 To be favoured used for this purpose printing nozzles 20. There may also be several of these nozzles be mounted one behind the other.

- the pressure in the pressure nozzles is preferably in a range of 2 to 3 bar.

- the downflowing solvent can be collected in a tub 19 and optionally a cleaning device be supplied.

- the security film 11 is a deflection roller 27 brought to the occupied with a felt 8 washing roller 7.

- the washing roller 7 has its own controllable drive, not shown is.

- the washing roller 7 is operated in advance, that is, the peripheral speed at the felt surface is greater than the transport speed the slide 11 and goes in the same direction.

- Between foil 11 and felt surface solvent is introduced and it is preferably formed a solvent film.

- the contact pressure of the film 11 is about the web tension and the wrap angle affected.

- the wrapping angle of the security film around the washing roller 7 can be adjusted via the guide rollers 27 and 28 be faced with a suitable device in position the washing roller 7 are changed.

- the film 11 is fed to the Nachthesesstation.

- Particularly preferred for this purpose are high-pressure nozzles 15, 22 used, which work at about 150 bar.

- the felt surface becomes by a transverse to the direction of rotation brush strip 21st brushed off.

- the contaminated water is through a flexible lip, for example made of hard rubber, stripped off.

- the arrangement and number of individual cleaning devices can be varied as desired.

- the liquid entry between the film 11 and felt 8 can via the facilities Spray nozzle 24, suction device 25 and squeeze roller 26 set become.

- the deflection rollers 27 and 28 positioned so that the film 11 does not touch the washing roller 7.

- the washing roller 7 is driven and the felt 8 with solvent wetted. This can be done via the spray nozzle 24.

- the Deflection rollers 27 and / or 28 adjusted so that the film 11 with the desired wrap around the washing roller 7 sets.

- the descending solvent is collected in a tub 9 and optionally supplied to a cleaning device.

- the main cleaning i. the step with the mechanical action by means of sheet follows an additional post-cleaning.

- the film with a solvent jet from a suitable device 13 rinsed to remove the last adhering paint particles.

- the Device is preferably a pressure nozzle.

- the downflowing solvent is collected in a pan 29 and optionally one Cleaning device supplied.

- the film is before further processing in a drying station 16 dried.

Landscapes

- Printing Methods (AREA)

- Burglar Alarm Systems (AREA)

- Laminated Bodies (AREA)

- Paper (AREA)

- Application Of Or Painting With Fluid Materials (AREA)

Abstract

Description

- Fig.1

- eine schematische Darstellung eines Schnittes durch die bedruckte und metallbeschichtete Folie vor dem Auswaschen;

- Fig. 2

- die gleiche Ansicht, jedoch nach dem Auswaschen;

- Fig. 3 und 4

- eine schematische Darstellung einer Ausführungsform der Waschvorrichtung.

Claims (22)

- Verfahren zur Herstellung von Sicherheitsfolien für Wertpapiere, bestehend aus einer transluzenten Trägerfolie und einer darauf aufgebrachten Abdeckschicht , die beschichtungsfreie Bereiche in Form von Buchstaben, Zahlen, Zeichen, Punkten und/oder Muster etc. aufweist, die insbesondere im Durchlicht klar zu erkennen sind mit folgenden Schritten:dadurch gekennzeichnet, dass bei Schritt f) die mechanische Einwirkung mittels eines textilen Flächengebildes erfolgt.a) Bereitstellen der Trägerfolie;b) Bedrucken der Trägerfolie mit Buchstaben, Zahlen, Zeichen, Punkten und/oder Mustern etc.;c) Verwendung einer Druckfarbe mit einem hohen Pigmentanteil;d) Trocknen der Druckfarbe zur Bildung eines porigen, erhabenen Farbauftrags;e) Bilden einer dünnen Abdeckschicht auf der bedruckten Trägerfolie;f) Entfernen des Farbauftrags und der darüber liegenden bzw. in den Farbauftrag eingedrungenen Abdeckschicht durch Auswaschen mit einem Lösungsmittel, kombiniert mit mechanischer Einwirkung;g) Trocknen und gegebenenfalls Zuschneiden der Trägerfolie,

- Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass die Abdeckschicht eine Metallschicht, vorzugsweise eine Aluminium- oder Kupferschicht, ist.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass die Trägerfolie in Form eines endlosen Bandes bereitgestellt wird und das Verfahren kontinuierlich durchgeführt wird.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass die Druckfarbe wasserlöslich ist und zum Auswaschen Wasser verwendet wird.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, dass in Schritt f) eine mit Filz belegte Walze verwendet wird.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, dass die Oberfläche des Flächengebildes gegenüber der Folie eine Relativbewegung ausführt.

- Verfahren nach Anspruch 6, dadurch gekennzeichnet, dass die Relativgeschwindigkeit ± 400 % beträgt.

- Verfahren nach Anspruch 7, dadurch gekennzeichnet, dass die Relativgeschwindigkeit vorlaufend oder nachlaufend ist.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, dass das Flächengebilde einen Filz, vorzugsweise einen Filz aus reiner Schafwolle, umfasst.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 9, dadurch gekennzeichnet, dass das Flächengebilde eine Dicke von 1 bis 30 mm hat.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 10, dadurch gekennzeichnet, dass das Flächengebilde eine Dichte von 0,15 bis 0,8 g/cm3 hat.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 11, dadurch gekennzeichnet, dass das Flächengebilde schlauchförmig ist.

- Verfahren nach wenigstens einem der Ansprüche 5 bis 12, dadurch gekennzeichnet, dass der Durchmesser der Walze 100 bis 2000 mm, vorzugsweise 500 bis 1500 mm, beträgt.

- Verfahren nach einem der Ansprüche 5 bis 13, dadurch gekennzeichnet, dass der Umschlingungswinkel der Folie um die Waschwalze 0 bis 360° beträgt.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 14, dadurch gekennzeichnet, dass das Flächengebilde zumindest teilweise in ein Bad mit Lösungsmittel taucht.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 15, dadurch gekennzeichnet, dass das Lösungsmittel eine Temperatur von 10 bis 50 °C, vorzugsweise 20 bis 40 °C hat.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 16, dadurch gekennzeichnet, dass zum Reinigen das Flächengebilde mit einer Rakel kontinuierlich abgeschabt wird.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 17, dadurch gekennzeichnet, dass das Flächengebilde zum Reinigen mit einem gerichteten Flüssigkeitsstrahl gespült wird.

- Verfahren nach Anspruch 18, dadurch gekennzeichnet, dass der gerichtete Strahl unter einem Druck von etwa 0 bis 500 bar, vorzugsweise etwa 150 bar, steht.

- Verfahren nach wenigstens einem der Ansprüche 1 bis 19, dadurch gekennzeichnet, dass die bedruckte und mit einer Abdeckschicht versehene Trägerfolie vor Schritt f) und/oder die mit dem Flächengebilde gereinigte Trägerfolie nach Schritt f) zusätzlich mit Lösungsmittel gewaschen wird.

- Sicherheitsfolie, hergestellt nach dem Verfahren gemäß wenigstens einem der Ansprüche 1 bis 20.

- Vorrichtung zur Durchführung des Verfahrens gemäß wenigstens einem der Ansprüche 1 bis 20, mit einer Druckeinrichtung, einer Einrichtung zum Aufbringen einer Abdeckschicht und einer Waschvorrichtung, dadurch gekennzeichnet, dass die Waschvorrichtung ein textiles Flächengebilde umfasst.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10333468 | 2003-07-22 | ||

| DE10333468A DE10333468A1 (de) | 2003-07-22 | 2003-07-22 | Verfahren und Vorrichtung zur Herstellung von Sicherheitsfolien |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1520929A1 true EP1520929A1 (de) | 2005-04-06 |

| EP1520929B1 EP1520929B1 (de) | 2009-03-04 |

Family

ID=34042047

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04015119A Expired - Lifetime EP1520929B1 (de) | 2003-07-22 | 2004-06-28 | Verfahren und Vorrichtung zur Herstellung von Sicherheitsfolien |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1520929B1 (de) |

| AT (1) | ATE424479T1 (de) |

| DE (2) | DE10333468A1 (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009052538A1 (de) | 2009-11-11 | 2011-05-12 | Giesecke & Devrient Gmbh | Herstellung eines mit gefärbten Mikrovertiefungen versehenen Sicherheitselementes |

| DE102012010908A1 (de) | 2012-06-01 | 2013-12-05 | Giesecke & Devrient Gmbh | Verifikation von Wertdokumenten mit einem Fenster mit diffraktiven Strukturen |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0330733A1 (de) * | 1988-03-04 | 1989-09-06 | GAO Gesellschaft für Automation und Organisation mbH | Sicherheitselement in Form eines Fadens oder Bandes zur Einbettung in Sicherheitsdokumente sowie Verfahren zur Herstellung desselben |

| WO1999013157A1 (de) * | 1997-09-08 | 1999-03-18 | Giesecke & Devrient Gmbh | Sicherheitsfolien für wertpapiere und verfahren zu ihrer herstellung |

-

2003

- 2003-07-22 DE DE10333468A patent/DE10333468A1/de not_active Withdrawn

-

2004

- 2004-06-28 EP EP04015119A patent/EP1520929B1/de not_active Expired - Lifetime

- 2004-06-28 DE DE502004009070T patent/DE502004009070D1/de not_active Expired - Lifetime

- 2004-06-28 AT AT04015119T patent/ATE424479T1/de not_active IP Right Cessation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0330733A1 (de) * | 1988-03-04 | 1989-09-06 | GAO Gesellschaft für Automation und Organisation mbH | Sicherheitselement in Form eines Fadens oder Bandes zur Einbettung in Sicherheitsdokumente sowie Verfahren zur Herstellung desselben |

| WO1999013157A1 (de) * | 1997-09-08 | 1999-03-18 | Giesecke & Devrient Gmbh | Sicherheitsfolien für wertpapiere und verfahren zu ihrer herstellung |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102009052538A1 (de) | 2009-11-11 | 2011-05-12 | Giesecke & Devrient Gmbh | Herstellung eines mit gefärbten Mikrovertiefungen versehenen Sicherheitselementes |

| WO2011057739A1 (de) | 2009-11-11 | 2011-05-19 | Giesecke & Devrient Gmbh | Herstellung eines mit gefärbten mikrovertiefungen versehenen sicherheitselementes |

| US8920663B2 (en) | 2009-11-11 | 2014-12-30 | Giesecke & Devrient Gmbh | Production of a security element provided with colored micro-depressions |

| DE102012010908A1 (de) | 2012-06-01 | 2013-12-05 | Giesecke & Devrient Gmbh | Verifikation von Wertdokumenten mit einem Fenster mit diffraktiven Strukturen |

| WO2013178349A1 (de) | 2012-06-01 | 2013-12-05 | Giesecke & Devrient Gmbh | Verifikation von wertdokumenten mit einem fenster mit diffraktiven strukturen |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE424479T1 (de) | 2009-03-15 |

| EP1520929B1 (de) | 2009-03-04 |

| DE10333468A1 (de) | 2005-02-10 |

| DE502004009070D1 (de) | 2009-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1023499B2 (de) | Verfahren zur Herstellung von Sicherheitsfolien | |

| DE69523471T2 (de) | Verfahren zum drucken auf ein einziges substrat in mehreren aufeinanderfolgenden durchgängen und hiernach bedrucktes substrat | |

| DE69233200T2 (de) | Selektive Entmetallisierung von Aluminium | |

| DE69813580T2 (de) | Verfahren und vorrichtung zur streifenförmigen bemusterung von gefärbten geweben mittels wasserstrahlbehandlung | |

| DE69932298T2 (de) | Verfahren zur Behandlung des Flocks einer geflockten Unterlage und das so erhaltene Produkt | |

| DE10342253A1 (de) | Flächiges Sicherheitselement | |

| DE112006003410T5 (de) | Verbesserungen in Verfahren zur Herstellung von Sicherheitssubstraten | |

| DE2457618C3 (de) | Verfahren zum Erzeugen eines Kontrastmusters auf einer Platte und gemusterte Platte | |

| DE69432773T2 (de) | Hochflexibles lederartiges Material und Verfahren zu dessen Herstellung | |

| DE69227241T2 (de) | Blatt aus fasermaterial als informationsträger, verfahren und apparat zu dessen herstellung | |

| EP1520929B1 (de) | Verfahren und Vorrichtung zur Herstellung von Sicherheitsfolien | |

| DE1560759A1 (de) | Verfahren zur Herstellung eines band- oder bahnfoermigen Werkstoffs | |

| DE1933180A1 (de) | Verfahren und Einrichtung zur Herstellung einer zum Einbuegeln bestimmten Harz-Beschichtung auf einer Stoffbahn nach vorbestimmtem Muster | |

| DE1958978C3 (de) | Verfahren zum Undurchsichtigmachen eines textlien Faservlieses | |

| DE860044C (de) | Drucktuch fuer Textil-Rotationsdruckmaschinen und Verfahren zu seiner Herstellung | |

| DE2152657B2 (de) | Als Blattmaterial-Ersatz dienendes Verbundmaterial, Verfahren zu seiner Herstellung sowie dessen Verwendung zum Beschichten | |

| DE2600167A1 (de) | Verfahren zur herstellung von metallisierten papiergeweben | |

| DE60203951T2 (de) | Wärmeempfindliche Druckschablone und deren Herstellungsverfahren | |

| DE10018785C1 (de) | Rotationssiebdruckform und Verfahren zu deren Herstellung | |

| EP1524351B1 (de) | Verfahren zum Verstärken textiler Flächengebilde | |

| DE2435013C3 (de) | Verfahren zur Herstellung von bedrucktem Kunstleder | |

| DE2836996C2 (de) | ||

| DE2855711A1 (de) | Mustertraeger und verfahren zu seiner herstellung | |

| DE2731713A1 (de) | Verfahren und vorrichtung zum behandeln einer seite eines gewebes mit einer fluessigkeit | |

| DE19541817A1 (de) | Verfahren zur Herstellung von Textilfasern oder -endlosfäden und deren Verwendung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20051006 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: LT Payment date: 20051006 Extension state: MK Payment date: 20051006 Extension state: AL Payment date: 20051006 Extension state: HR Payment date: 20051006 Extension state: LV Payment date: 20051006 |

|

| RTI1 | Title (correction) |

Free format text: METHOD AN APPARATUS FOR MANUFACTURING SECURITY FILMS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004009070 Country of ref document: DE Date of ref document: 20090416 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20090304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090604 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20090625 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090819 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090615 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| BERE | Be: lapsed |

Owner name: GIESECKE & DEVRIENT G.M.B.H. Effective date: 20090630 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090604 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| 26N | No opposition filed |

Effective date: 20091207 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090605 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090905 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090304 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004009070 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20140630 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20150623 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150625 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004009070 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20160628 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160628 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160628 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Owner name: GIESECKE+DEVRIENT CURRENCY TECHNOLOGY GMBH, DE Effective date: 20180530 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20210621 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220630 |