EP1517097B1 - système pour fournir de l'eau chaude sanitaire dans un système de canalisation et soupape pour dudit commander - Google Patents

système pour fournir de l'eau chaude sanitaire dans un système de canalisation et soupape pour dudit commander Download PDFInfo

- Publication number

- EP1517097B1 EP1517097B1 EP04019690A EP04019690A EP1517097B1 EP 1517097 B1 EP1517097 B1 EP 1517097B1 EP 04019690 A EP04019690 A EP 04019690A EP 04019690 A EP04019690 A EP 04019690A EP 1517097 B1 EP1517097 B1 EP 1517097B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- water

- hot

- valve

- cold

- water reservoir

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 title claims abstract description 282

- 238000010438 heat treatment Methods 0.000 claims abstract description 52

- 238000009434 installation Methods 0.000 claims description 5

- 239000012528 membrane Substances 0.000 claims description 5

- 238000010079 rubber tapping Methods 0.000 claims description 4

- 238000000926 separation method Methods 0.000 claims description 4

- 238000009413 insulation Methods 0.000 claims description 3

- 230000002441 reversible effect Effects 0.000 abstract description 3

- 230000004087 circulation Effects 0.000 description 10

- 238000005070 sampling Methods 0.000 description 9

- 238000003809 water extraction Methods 0.000 description 6

- 239000007788 liquid Substances 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 230000001419 dependent effect Effects 0.000 description 3

- 238000010276 construction Methods 0.000 description 2

- 238000000605 extraction Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000005086 pumping Methods 0.000 description 2

- 238000010992 reflux Methods 0.000 description 2

- 238000009420 retrofitting Methods 0.000 description 2

- 230000004913 activation Effects 0.000 description 1

- 230000006978 adaptation Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 239000013589 supplement Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24D—DOMESTIC- OR SPACE-HEATING SYSTEMS, e.g. CENTRAL HEATING SYSTEMS; DOMESTIC HOT-WATER SUPPLY SYSTEMS; ELEMENTS OR COMPONENTS THEREFOR

- F24D17/00—Domestic hot-water supply systems

- F24D17/0078—Recirculation systems

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24D—DOMESTIC- OR SPACE-HEATING SYSTEMS, e.g. CENTRAL HEATING SYSTEMS; DOMESTIC HOT-WATER SUPPLY SYSTEMS; ELEMENTS OR COMPONENTS THEREFOR

- F24D17/00—Domestic hot-water supply systems

Definitions

- the invention relates to a system for substantially permanent or rapid provision of heated by a central heating system water with a first line section, a second line section, at least one connected to the first and second line section, a hot water reservoir and a cold water reservoir having container.

- a system according to the preamble of claim 1 is known from the document DE 334 2 273 known.

- Circulation ducts in turn emit enormous thermal energy due to permanent maximum temperature difference and about twice the duct length. Time switches and demand switches reduce this only to a limited extent, because in the rest periods the approximately double amount of hot water also cools down and then has to be completely replaced again. The desired comfort is again severely limited in time-controlled circulations during rest periods. Circulation lines also mean about twice the assembly and material costs.

- a system is made available which is able to provide heated service water at the removal point almost permanently available and / or to ensure the supply and removal of heated or cold service water safely and energy-saving.

- the system according to the present invention can be installed in new buildings as well as created by retrofitting already existing piping systems.

- any number of water taps may be provided or an existing system may be extended by subsystems utilizing parts of the main system.

- the line system according to the invention is particularly simple in design, designed maintenance-friendly and is therefore particularly suitable for use in private households.

- the demand sensor starts the pump, which pumps hot water from the heating system to the water tap.

- the sensor opens the valve which connects the first line section to the second line section, which in turn is connected to the heating system.

- the still cold water in the first line section can thus be returned to the heating system.

- the valve is closed and hot water can be removed from the sampling point.

- the system of the invention consists essentially of a central heating system for heating the service water, a first line section for supplying the heated service water to a hot water reservoir, one of the hot water reservoir although thermally insulated, but not pressure-insulated arranged cold water reservoir and one of the cold water reservoir to the first Line section leading second line section for returning excess cold service water.

- the water tap is located at the hot water reservoir or at least in its vicinity, so that when opening the water tap anywhere and almost directly heated hot water is available.

- thermo valve upstream of the container causes hot water flowing in from the heating system to flow into the hot water reservoir after the hot water has been drawn, while cold water is directed to the cold water reservoir.

- cold water is not directed into the hot water reservoir.

- the hot water reservoir preferably contains at least the same amount of warm water as the inlet between the central heating system and the hot water reservoir can accommodate.

- the warm water flows directly from the hot water reservoir.

- warm water flows out of the heating system through the first line section in the direction of the hot water reservoir.

- the cooled water pressed by the inflowing warm water, flows out of the line or passages into the cold water reservoir.

- the warm water reaches the sensor, it switches the valve and directs the subsequent warm water into the hot water reservoir.

- the sensor near the sampling point can be any sensor.

- it is a temperature sensor and / or a flow meter that switches as soon as a certain volume, preferably the volume of the first line section has flowed into the second line section.

- a pump is activated, which nach textilet cold water and thus also transfers the present in the first line section of warm water in the hot water reservoir.

- the pump preferably operates at least until only cold water is stored in the line sections.

- the pump is activated by any demand sensor known to those skilled in the art.

- This demand sensor can be a simple switch or by a Pressure sensor that starts the pump when the pressure drops.

- the pump can be started before the actual water removal is to take place.

- the pump is controlled via one or more flow sensors. These flow sensors are preferably able to detect the removal of hot water from the hot water reservoir and deliver a control signal to the pump.

- the system has at least one, preferably two demand sensors, wherein the first preferably at least in the vicinity of the heating system, each further arranged in the cold water line, preferably before the branch to the pump or behind the branch.

- All sensors are preferably arranged close to the pump / regulation of the pump, whereby the technical complexity is minimized.

- the circulatory system can be arranged an almost arbitrary amount of containers with a hot and a cold water reservoir.

- a first hot water reservoir can also serve as a heating system, also as a sub-central heating, for both a conventional hot water circuit and for another system according to the invention.

- warm water can preferably be pumped through the system during longer periods of rest without hot water removal. This can preferably be done when no additional heating elements are arranged in the hot water reservoir and the warm water within the hot water reservoir drops despite the heat insulation below a preferably predefined temperature level. Likewise, the warm water used for this purpose can be removed from the central heating system.

- the second line section usually used as a cold water line, line section as the return line of the circulatory system.

- the second line section with respect to a hot water extraction used exclusively as a return line is stored in the only cold water.

- the valve for controlling the mass flows preferably within a system described above for preferably permanently providing hot water at a hot water tap.

- the valve has a container preferably arranged within a housing for receiving and storing water and / or air, and a closure plate which reversibly seals the container and the connection between the line sections and has at least three active surfaces, the water pressure prevailing in the first line section a first active surface, which presses in the second line section prevailing water pressure on a second active surface and the pressure prevailing in the container water and / or air pressure on a third active surface, wherein acting on the third effective surface pressure before the valve in pressure equality to the line section or holds behind the valve in the closed state and the size ratio of the first effective area to the second effective area is coordinated such that an opening or closing of the valve substantially independent of the pressure difference in the line sections un d is substantially dependent on the pressure in the first conduit section or in the second conduit section.

- a valve which is capable of opening substantially only at an elevated pressure in one of the two line sections or substantially only when it falls below a preferably predefined negative pressure in one of the two line sections.

- the valve according to the invention is also coarsely adjusted during assembly by storing a water / air mixture in a container disposed within the valve. Any necessary adaptation to changing pressure conditions, for example, when changing the water pressure provided by the utilities, thus takes place automatically after activation of the valve.

- the valve can be tuned in advance by the choice of a suitable size ratio between the individual active surfaces of the closure plate of the valve to the usual in the line sections pressure differences.

- a fine adjustment of the valve can be achieved by changing the force acting on the third effective surface of the closure plate spring force.

- the valve is particularly simple in construction and very flexible adjustable and used.

- FIG. 1 a schematic representation of a first system according to the invention is shown.

- the system comprises a heating system 15 having an inlet 16, a hot water pipe 1 connecting the heating plant 15 to the hot water reservoir W, and a cold water pipe 2 reaching from the cold water reservoir K to the hot water pipe 1.

- a heating element 13 for heating the hot water reservoir as required W stored water arranged.

- the feed to the individual water reservoirs W, K is controlled by the thermo valve 7, the drain from the hot water reservoir W via the hot water tapping point 12.

- the cold water line 2 is also arranged via a flow sensor 8 adjustable designed pump 4, which controls the circulation of water within the system.

- FIG. 2 a schematic representation of a second system according to the invention is shown.

- two series-connected containers 5 are arranged on the first line section 1, each having a hot water reservoir W and a separated by a membrane 6 cold water reservoir K, a hot water outlet 12 and a heating element 13.

- Both containers 5 are supplied via a respective thermo valve 7a, 7b with cold and warm water.

- a bypass Valve 43 is disposed between the leading from the thermo valve 7a to the cold water reservoir K and the hot water reservoir W inlets.

- the aforementioned feeds are connected to each other and also ensures a hot water supply to the second thermo valve 7b.

- bypass valve 43 may be provided with a strong spring that allows the bypass valve 43 to open only as a secondary alternative when the primary path for the water is blocked.

- a pump-valve sequence 4, 9 is arranged, which is adjustable via a arranged in the cold water supply line 3 flow sensor 8.

- FIG. 3 a third circulatory system according to the invention is shown.

- the system has a central heating system 15, which is connected to the general water network via the supply line 3, 16, on. With the heating system 15 also the line sections 1 and 2 are connected via the supply line 16. A connection between the line sections 1 and 2 is arranged in the vicinity of the heating system 15. The connection is made via a valve 9, which opens, provided that the downstream pump 4 operates. Both the valve 9 and the pump 4 are controlled by control signals transmitted by flow sensors 8.

- At the first line section 1 two branches 14 are arranged, from which, in the form of subsystems, further first line sections 1 lead to further containers 5.

- the heating system 15 next arranged container 5, the filling of the various reservoirs W, K takes place in the under FIG.

- FIG. 4 A fourth system according to the invention for providing warm water at a plurality of hot water taps 12 is shown.

- the system has three containers 5 arranged one behind the other in the first line section 1. From the hot water reservoir W of the middle container 5 is a circulating line 17, at the three hot water tapping points 12 are arranged.

- the hot water reservoir W is used in this case as a sub-heating system for a conventional hot water supply.

- a subsystem 18, consisting of a line circuit and arranged on this circuit two containers 5 is shown at the downstream within the system shown hot water reservoir W.

- the container 5 serves as a sub-heating system for a further system according to the invention the two containers 5 are arranged.

- FIG. 5 a fifth system according to the invention is shown.

- two containers 5 are arranged starting from the heating system 15.

- the first container 5 is fed with hot and cold water in the manner already described above.

- the downstream second container 5, however, is filled only after filling the first container 5 with water.

- two valves 32, 37 are arranged on the output side of the first container 5.

- the valve 32 opens at a higher pressure at the inlet, but not at lower pressure at the outlet of the valve 32.

- the valve 37 opens only at lower pressure at the outlet, but not at higher pressure at the inlet of the valve 37.

- FIG. 6 a sixth system according to the invention for the provision of hot water at a plurality of hot water tapping points 12 is shown.

- two parallel connected container 5 are arranged, which are supplied at the same time or independently of each other via a common thermo valve 7 both with cold and with warm water.

- Both parallel connected container 5 supply in the under FIG. 6 illustrated manner depending on a downstream container. 5

- FIG. 7 a simplified embodiment of a system without container 5 is shown.

- the pump 4 starts as soon as the flow sensor 8 detects a water removal, which can be done for example by a very short removal of water as a signal.

- the pump 4 can also be activated by means of a switch in the vicinity of the removal points 11 or 12.

- the sensor 7 detects cold water, the water is diverted from the line 1 into the line 2 and thus flows back to the heating system.

- the flow process from the hot water pipe 1 via the valve 32 into the cold water pipe 2 is stopped and warm water can be removed at the removal point 12.

- FIG. 8 corresponds to the line content of the hot water pipe 1 substantially, preferably exactly the content of Container 5, if this is filled only with warm water.

- the valve 9, which may be designed, for example, as an electric valve, is used only as described below to supplement the amount of cold water that may be necessary. Flows namely water from the sampling point 12 before the hot water column from the hot water reservoir W arrives at the sampling point 12, so this cold amount is missing to fill the cold water reservoir K and the hot water column shoots over, ie it flows at least partially into the line 2, which is undesirable.

- the valve 9 the shortage of hot water can be supplemented, ie the valve 9 is open only during the first supporting pumping operation. If no more warm water in the container 5, due to the design, no cold water flows from the cold water reservoir K from the container 5 in the hot water pipe and vice versa.

- FIG. 9 shows another variant of a system.

- No sensor for example a thermal sensor, needs to be arranged in front of the valve 32, since the line contents of the hot water line 1 up to the valve 32 correspond to the contents of the hot water reservoir in the container 5.

- the pump 4 pumps the cold water from the cold water reservoir K of the container 5 via the cold water line 2 the other valve 32 in the hot water pipe and the warm water from the hot water pipe 1 is pumped into the hot water reservoir W of the container 5 until the container 5 is completely filled with warm water.

- this system is particularly suitable for a spatial proximity of the two removal points 12.

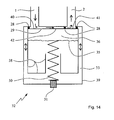

- FIG. 12 schematic representation of a valve 32 is shown. Shown is a valve 32, which opens only at positive pressure from line 1, but not by a negative pressure in line 2.

- the valve 32 is particularly for an arrangement behind the last container 5 in the Figures 3 . 5 . 6 . 7 . 9 . 10 and 11 illustrated embodiment, in which the cold water line is used as a return line suitable.

- the power of the circulation pump 4 and the execution and adjustment of the valve 32 by the adjusting screw 31 are preferably coordinated.

- the active surface 40 for the liquid from line section 1 on the closure plate 29 is comparatively large, that of the liquid from line section 2 comparatively small.

- the shape of the piston housing 38 shown here also allows a non-vertical installation of the valve 32, which also can be dispensed with a membrane ,

- the adjustment of the valve 32 by running the water into the piston housing 38 and / or the spring housing 33 is preferably carried out only after assembly after the valve 32 has reached its final position.

- the piston housing 38 and the spring housing 33 are preferably filled with air under atmospheric pressure prior to assembly. In this case, after entering the water into the valve 32, the air / water level described above is formed, which allows adjustment of the valve 32.

- FIG. 13 a schematic representation of a second valve 37 is shown.

- the valve 37 opens even at a low relative negative pressure in line 1, but not at an overpressure on the opposite side of the valve 37.

- This overpressure for example, by inflow from a hot water reservoir (not shown), such as in FIG. 5 is shown done.

- the closure plate 29 has on the line section 1 side facing a large effective area 40 for the water, whereas the active surface on the side facing away from the line 1 a relatively small attack surface for the water. If the piston cover 29 is raised, the water in line 1 can flow in, since the spring housing 33 and the piston housing 38 are not sealed against each other. It thus finds an adjustment of the valve 37 by influencing the air / water level 35th instead of.

- the air trapped in the valve 37 also ensures by its compressibility that the piston cover 29 can detach from the seals 28.

- the pressure, which occurs during the flow of water within the piston housing 38 and the spring housing 33, is preferably slightly below the static pressure and above the release vacuum in line 1 to open the valve 37.

- the spring 34 in this case still provides up to one with the adjustment screw 31 adjustable limit value of the negative pressure for the concern of the closure plate 29 to the seals 28.

- the shape of the piston housing 38 shown here also allows a non-vertical installation of the valve 32, which also can be dispensed with a membrane.

- the adjustment of the valve 37 by running the water into the piston housing 38 and / or the spring housing 33 is preferably carried out only after assembly after the valve 37 has reached its final position.

- the piston housing 38 and the spring housing 33 are preferably filled with air under atmospheric pressure prior to assembly. In this case forms after entering the water in the valve 37, the above-described air / water level, which allows adjustment of the valve 37.

- FIG. 14 shows an embodiment of the valve according to FIG. 12 , wherein the spring housing and the valve housing are made in one piece.

- FIG. 15 shows an embodiment of the valve according to FIG. 13 , wherein the spring housing and the valve housing are made in one piece.

- FIG. 16 a combination of the valves 32 and 37 is shown.

- the pressure in the valve relaxes. Even a slight overpressure in the hot water pipe 1 pushes the piston down because it has a large attack surface due to its depression.

- Cold water flows past the thermocouple / valve until incoming warm water closes the cold water outlet 46 and cold water inlet 47 opens. Due to the still existing pressure of the pump, the entire valve 45 is pressurized again. Since the thermocouple is down, the cold water inlet 47 is opened from the cold water line 2 via a valve 32, so that reflux of cold Water from the line section 2 in the line section 1 is now possible. This displaces the warm water from the line section 1.

- a cooling rate at 7 in 45 which corresponds to the cooling rate of the warm water in the line 1, is advantageous.

- FIG. 17 a schematic representation of a second valve 22 is shown.

- the clamping bolt 25 In the initial position of the clamping bolt 25 is provided with lever arm 23 in the middle position with balanced voltage of both valves 22.

- the right clamping bolt 25 Upon removal of water from the line 26, the right clamping bolt 25 is pushed up the right valve 22, whereby the left clamping pin 25 is pressed down on the valve 22 of line 27 via the lever arm 23.

- the clamping bolt 25 and the lever arm 23 remain first, even in the case of removal of water from line 27.

- the left valve 22 can be opened solely by the water pressure, however, the operation of the left valve 22 is due to the design of the valves 22 with lever arms 23 heavier than the right valve 22. After completion of each removal starts the circulation.

- the higher pressure in the line is measured, or it can be an acoustic or electrical, but preferably not audible signal can be used.

- the lever arm 23 controlled by the control and support member 24 to.

- the right valve 22 is now stretched more than the left valve 22, whereby the circulation of water from now on via line 27 takes place.

- the control / influence of the lever arm 23 ends by the control and support member 24.

- the current status of the system can preferably by three temperature sensors, which at Inlet, line 26 and arranged on line 27 are registered.

- the clamping bolt 25 and the lever arm 23 then go back to the starting position.

- an electrically controlled opening and closing of the valves 22 can also take place.

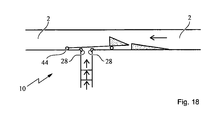

- FIG. 18 is a schematic representation of the principle of action of a flow valve 10 for a water pipe 1, 2 shown.

- the Flow valve has a hinged to a bearing 44 sealing plate, which is located above the junction between line 2 and line 1 and 1 line closes against the line 2 reversible.

- the flow valve 10 serves to close the connection between line 1 and line 2 when a predefined mass flow in line 2 is exceeded. If there is a certain water pressure both in line 1 and in line 2, then the ratio of the two water pressures is decisive for whether the flow valve 10 closes the two lines against each other or connects the lines together.

- the water stored in line 1 presses from below against the flow valve and against the water pressure present in line 2.

- the water flowing in line 2 flows over a slope arranged inside the line 2 in front of the connection point and impinges on the inclined plane arranged on the flow valve 10. If the water also flows over the inclined plane, then the closure plate 29 of the flow valve 10 is additionally pressed onto the connection point between line 1 and line 2 and thus closes line 1 with respect to line 2.

- a circumferential seal arranged to seal the line 1 is at the edge of the connection point between line 1 and 2, a circumferential seal arranged.

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Thermal Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Physics & Mathematics (AREA)

- Domestic Hot-Water Supply Systems And Details Of Heating Systems (AREA)

- Devices For Dispensing Beverages (AREA)

- Cookers (AREA)

- Multiple-Way Valves (AREA)

- Water Treatment By Sorption (AREA)

- Steam Or Hot-Water Central Heating Systems (AREA)

Claims (14)

- Système d'approvisionnement en eau chauffée fonctionnant par l'intermédiaire d'une installation de chauffage (15) sur au moins un point d'eau (12) disposé le plus près possible d'un réservoir d'eau chaude (W) avec au minimum : un conteneur (5) comprenant le réservoir d'eau chaude (W), un premier tronçon de canalisation (1) aménageable entre le conteneur (5) et l'installation de chauffage (15) et un second tronçon de canalisation (2) aménageable entre le conteneur (5) et le premier tronçon (1). Le système est caractérisé en ce que le conteneur renferme également un réservoir d'eau froide (K), que le réservoir d'eau chaude (W) est séparé principalement du réservoir d'eau froide (K) par une isolation thermique mais pas contre la pression et que le remplissage du réservoir d'eau chaude (W) avec de l'eau chaude doit se faire exclusivement par une thermovalve (7) incluse dans le premier tronçon de canalisation (1).

- Système selon la revendication 1, caractérisé en ce que le réservoir d'eau chaude (W) et le réservoir d'eau froide (K) sont séparés par une membrane thermo-isolante (6).

- Système selon la revendication 1, caractérisé en ce que le réservoir d'eau chaude (W) et le réservoir d'eau froide (K) sont séparés au moins par la paroi d'un piston se déplaçant dans un cylindre.

- Système selon l'une des revendications 1 à 3, caractérisé en ce que la commande du remplissage d'eau froide dans le réservoir d'eau froide (K) et de l'eau chaude dans le réservoir d'eau chaude (W) se fait par un capteur (7).

- Système selon la revendication 4, caractérisé en ce que le capteur (7) commande une vanne laissant circuler l'eau chaude dans le réservoir d'eau chaude (W) via le premier tronçon de canalisation (1) et l'eau froide dans le réservoir d'eau froide (K) via une dérivation reliant le premier tronçon de canalisation (1) au réservoir d'eau froide (K).

- Système selon l'une des revendications 1 à 5, caractérisé en ce que, une fois que le réservoir d'eau froide (K) est rempli, le trop-plein d'eau froide est redirigé dans le second tronçon de canalisation (2).

- Système selon l'une des revendications susmentionnées, caractérisé en ce que l'eau chaude a été prélevée, l'eau chaude encore présente dans le premier tronçon de canalisation (1) peut être amenée vers le réservoir d'eau chaude (W) à l'aide d'une pompe (4).

- Système selon la revendication 7 caractérisé en ce que la pompe (4) est disposée à l'intérieur du premier ou du second tronçon de canalisation (2) et que le réglage de ladite pompe se fait de préférence à l'aide d'un capteur de demande que l'on apposera plutôt dans le premier tronçon de canalisation (1).

- Système selon l'une des revendications 1 à 8, caractérisé en ce qu'un dispositif de chauffage (13) est disposé à l'intérieur du réservoir d'eau chaude (W).

- Système selon l'une des revendications 1 à 9, caractérisé en ce que plusieurs réservoirs d'eau chaude (W) et réservoirs d'eau froide (K) sont raccordés en série au premier tronçon de canalisation (1).

- Système selon l'une des revendications 1 à 10, caractérisé en ce que le réservoir d'eau chaude (W) est relié avec un autre système constitué d'un premier tronçon de canalisation (1) et d'un second tronçon de canalisation (2) sur lesquels sont reliés un second réservoir d'eau chaude (W) et un second réservoir d'eau froide (K).

- Système selon l'une des revendications 10 à 11, caractérisé en ce que le réglage de l'arrivée et de la sortie d'eau chaude et d'eau froide dans les tronçons de canalisation vers les différents réservoirs d'eau chaude (W) et d'eau froide (K) se fait respectivement par au minimum une vanne, de préférence un clapet anti-retour.

- Système selon l'une des revendications 1.0 à 12, caractérisé en ce que la régulation de l'arrivée et de la sortie d'eau aux réservoirs d'eau chaude (W) et d'eau froide (K) se fait par l'intermédiaire de vannes disposées de part et d'autre de chaque dérivation (14) et fonctionnant indépendamment l'une de l'autre.

- Installation de chauffage avec système selon l'une des revendications 1 à 13, caractérisée en ce que le conteneur (5) est disposé à proximité, de préférence au niveau de l'amenée de l'installation de chauffage (15).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10343700 | 2003-09-18 | ||

| DE10343700A DE10343700A1 (de) | 2003-09-18 | 2003-09-18 | System zur Bereitstellung von erwärmtem Brauchwasser in einem Leitungssystem und Ventil zu dessen Steuerung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1517097A2 EP1517097A2 (fr) | 2005-03-23 |

| EP1517097A3 EP1517097A3 (fr) | 2005-07-06 |

| EP1517097B1 true EP1517097B1 (fr) | 2011-02-09 |

Family

ID=34177867

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04019690A Expired - Lifetime EP1517097B1 (fr) | 2003-09-18 | 2004-08-19 | système pour fournir de l'eau chaude sanitaire dans un système de canalisation et soupape pour dudit commander |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP1517097B1 (fr) |

| AT (1) | ATE498097T1 (fr) |

| DE (2) | DE10343700A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102011014527A1 (de) | 2011-03-18 | 2012-09-20 | Markus Keitsch | System zur Bereitstellung erwärmten Brauchwassers in einem Leitungssystem |

| EP2503252B1 (fr) * | 2011-03-18 | 2020-04-29 | Markus Keitsch | Système de préparation d'eau chaude non potable dans un système de conduites |

| DE102012011042A1 (de) | 2012-06-05 | 2013-12-05 | Markus Keitsch | Verbessertes System zur Bereitstellung von erwärmtem Wasser in einem Leitungssystem |

| DE102013008991A1 (de) | 2013-03-14 | 2014-09-18 | Markus Keitsch | Effizientes, vielseitig einsetzbares, einfach steuerbares und leicht nachrüstbares System zur Bereitstellung warmen Wassers, oder anderer Medien mit einer Temperaturdifferenz zur Umgebung, in einem Leitungssystem |

| DE102014006539A1 (de) | 2014-05-05 | 2015-11-05 | Markus Keitsch | Ein besonders leicht nachrüstbares, besonders vielseitig einsetzbares, sehr energiesparendes und einfach steuerbares System zur Bereitstellung warmen Wassers, oder anderer Medien mit einer Temperaturdifferenz zur Umgebung in einem Leitungssystem |

| DE102015001450A1 (de) | 2014-07-02 | 2016-01-07 | Markus Keitsch | System zum energiesparenden Betrieb nicht permanent genutzter oder nicht permanent ausgelasteter Wärmetauscher in einem Leitungssystem, insbesondere zur Trinkwassererwärmung |

| DE102015006945A1 (de) | 2015-06-05 | 2016-12-08 | Markus Keitsch | System zur beschleunigten Beförderung warmer Flüssigkeit in einem kälteren Leitungssystem bei spontan einsetzendem Bedarf an warmer Flüssigkeit bei dezentralen Wärmetauschern oder dezentralen Zwischenspeichern |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5277219A (en) * | 1991-05-03 | 1994-01-11 | Metlund Enterprises | Hot water demand system suitable for retrofit |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2244289A1 (de) * | 1972-09-09 | 1974-03-21 | Franz Gonsior | Durchlaufventil |

| AT377598B (de) * | 1981-07-03 | 1985-04-10 | Azote Sa Cie Neerlandaise | Warmwasserleitungssystem |

| DE3126883C2 (de) * | 1981-07-08 | 1985-12-05 | Stiebel Eltron Gmbh & Co Kg, 3450 Holzminden | Heizungsanlage für die Brauchwasserbereitung |

| DE3342273A1 (de) * | 1983-11-23 | 1985-05-30 | kabelmetal electro GmbH, 3000 Hannover | Verfahren und vorrichtung zur erzeugung und bereitstellung von erwaermtem brauchwasser |

| DE3522344A1 (de) * | 1985-06-22 | 1987-01-02 | Meyer Fa Rud Otto | Verfahren zur regelung der temperatur des an ein warmwasser-versorgungssystem mit zirkulationsleitung angeschlossenen verbrauchern zufliessenden warmwassers und warmwasserversorgungssystem zur durchfuehrung des verfahrens |

| DE9100283U1 (de) * | 1991-01-11 | 1991-04-04 | Wienandt, Reinhold, 4600 Dortmund | Niederdruck-Selbstschlußventil für die Aquaristik |

| US5181656A (en) * | 1991-12-16 | 1993-01-26 | Schwerdt Gerald N | Water recirculating apparatus |

| JPH11248181A (ja) * | 1998-02-25 | 1999-09-14 | Hazama Gumi Ltd | 給湯方法及びそのシステム |

| DE19910096C1 (de) * | 1999-03-08 | 2000-05-31 | Guenther Litzba | Verfahren und Vorrichtung zum Wasser- und Energiesparen bei Warmwasser-Versorgungssystemen |

| DE19934627A1 (de) * | 1999-07-23 | 2001-01-25 | Michael Manok | Warmwasserversorgungsanlage |

| DE19934786A1 (de) * | 1999-07-27 | 2001-02-01 | Oliver Kudera | Warmwasserversorgungsanlage |

| GB2366830A (en) * | 2000-07-17 | 2002-03-20 | South Staffordshire Water Plc | Pressure relief valve in mains water supply system |

-

2003

- 2003-09-18 DE DE10343700A patent/DE10343700A1/de not_active Withdrawn

-

2004

- 2004-08-19 AT AT04019690T patent/ATE498097T1/de active

- 2004-08-19 DE DE502004012171T patent/DE502004012171D1/de not_active Expired - Lifetime

- 2004-08-19 EP EP04019690A patent/EP1517097B1/fr not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5277219A (en) * | 1991-05-03 | 1994-01-11 | Metlund Enterprises | Hot water demand system suitable for retrofit |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE498097T1 (de) | 2011-02-15 |

| DE502004012171D1 (de) | 2011-03-24 |

| EP1517097A3 (fr) | 2005-07-06 |

| EP1517097A2 (fr) | 2005-03-23 |

| DE10343700A1 (de) | 2005-05-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1884720B1 (fr) | Ensemble pour installation de chauffage compact | |

| DE2933606C2 (de) | Heißwasserbereiter | |

| EP2397777A1 (fr) | Unité de boîtier pour une installation de chauffage | |

| EP2503252B1 (fr) | Système de préparation d'eau chaude non potable dans un système de conduites | |

| EP1517097B1 (fr) | système pour fournir de l'eau chaude sanitaire dans un système de canalisation et soupape pour dudit commander | |

| DE102007048728B4 (de) | Heizkessel, Heizungsanlage sowie Verfahren zum Betreiben einer Heizungsanlage, insbesondere zur solaren Heizungsunterstützung | |

| DE630658C (de) | Elektrischer Durchlauferhitzer mit selbsttaetiger Schaltung mittels einer dem vollen Fluessigkeitsdruck ausgesetzten Membran | |

| DE102011014527A1 (de) | System zur Bereitstellung erwärmten Brauchwassers in einem Leitungssystem | |

| EP2413047B2 (fr) | Unité de chauffage d'eau potable | |

| DE19518910C1 (de) | Warmwasserversorgung | |

| EP0981784A1 (fr) | Dispositif de commande d'eau | |

| DE3145636C2 (fr) | ||

| DE19642179A1 (de) | Vorrichtung für die Bereitung von Brauchwarmwasser | |

| AT402575B (de) | Verfahren zur steuerung eines volumenstrombegrenzers | |

| AT501612B1 (de) | Verfahren zum betreiben einer warmwasserbereitungsanlage und warmwasserbereitungsanlage | |

| DE4308941C2 (de) | Anordnung zur Warmwasserbereitstellung für mit Gaswandgeräten beheizte Durchlaufspeicher | |

| EP3800403B1 (fr) | Procédé de fonctionnement d'un dispositif de chauffage, dispositif de chauffage | |

| DE2451544A1 (de) | Waermepumpe | |

| DE102019003716A1 (de) | Verbessertes System zur koordiniereten Beschleunigung von Flüssigkeit in einem Leitungssystem, insbesondere von Heizungswasser zum Erwärmen von Trinkwasser über Wärmetauscher | |

| DE60012963T2 (de) | Heisswasserentnahmeleitung | |

| DE310254C (fr) | ||

| DE102022127744A1 (de) | Zentralheizungssystem und Verfahren zum Betrieb und/oder zur Steuerung und/oder zur Regelung eines Zentralheizungssystems | |

| DE684453C (de) | Gasbeheizter Durchlaufwassererhitzer zur Versorgung mehrerer entfernt liegender Zapfstellen | |

| DE3100121C2 (de) | Verfahren zum Aufheizen von Brauchwasser in einem doppelwandigen Speicher mit einem Brauchwasser- und einem Heizwasserteil und Warmwasserheizvorrichtung mit einer Wärmepumpe | |

| DE102020112355A1 (de) | Warmwasserspeichersystem |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20060106 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| 17Q | First examination report despatched |

Effective date: 20061130 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: KEITSCH, MARKUS |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KEITSCH, MARKUS |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004012171 Country of ref document: DE Date of ref document: 20110324 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502004012171 Country of ref document: DE Effective date: 20110324 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20110209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110520 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110510 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110609 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110509 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20111110 |

|

| BERE | Be: lapsed |

Owner name: KEITSCH, MARKUS Effective date: 20110831 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004012171 Country of ref document: DE Effective date: 20111110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20110819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110831 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20120430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110831 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110831 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110819 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 498097 Country of ref document: AT Kind code of ref document: T Effective date: 20110819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110209 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20230831 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502004012171 Country of ref document: DE |