EP1286794B2 - Machine de laminage a froid - Google Patents

Machine de laminage a froid Download PDFInfo

- Publication number

- EP1286794B2 EP1286794B2 EP01955205A EP01955205A EP1286794B2 EP 1286794 B2 EP1286794 B2 EP 1286794B2 EP 01955205 A EP01955205 A EP 01955205A EP 01955205 A EP01955205 A EP 01955205A EP 1286794 B2 EP1286794 B2 EP 1286794B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- rolling

- cold rolling

- rods

- accordance

- guide

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H5/00—Making gear wheels, racks, spline shafts or worms

- B21H5/02—Making gear wheels, racks, spline shafts or worms with cylindrical outline, e.g. by means of die rolls

- B21H5/027—Making gear wheels, racks, spline shafts or worms with cylindrical outline, e.g. by means of die rolls by rolling using reciprocating flat dies, e.g. racks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H3/00—Making helical bodies or bodies having parts of helical shape

- B21H3/02—Making helical bodies or bodies having parts of helical shape external screw-threads ; Making dies for thread rolling

- B21H3/06—Making by means of profiled members other than rolls, e.g. reciprocating flat dies or jaws, moved longitudinally or curvilinearly with respect to each other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H7/00—Making articles not provided for in the preceding groups, e.g. agricultural tools, dinner forks, knives, spoons

- B21H7/14—Making articles not provided for in the preceding groups, e.g. agricultural tools, dinner forks, knives, spoons knurled articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H7/00—Making articles not provided for in the preceding groups, e.g. agricultural tools, dinner forks, knives, spoons

- B21H7/18—Making articles not provided for in the preceding groups, e.g. agricultural tools, dinner forks, knives, spoons grooved pins; Rolling grooves, e.g. oil grooves, in articles

Definitions

- the invention relates to a cold rolling machine according to the preamble of patent claim 1 and a method for cold rolling a workpiece.

- the workpiece to be machined is rotatably tensioned between two tips or other quick-action clamping devices, this workpiece clamping device generally being associated with a feed axis.

- the desired profiling of the workpiece via two synchronously counter-rotating rolling rods, which impinge simultaneously on the workpiece and this initially by frictional engagement and later by positive engagement in rotation.

- the material is in the free spaces of the tool, d. H. displaced by the rolling rods.

- the height of the ground profile of the rolling rod increases in the forming area, so that each tooth of the rolling rod is pressed slightly deeper into the workpiece, as the preceding.

- This non-cutting cold forming of profiles is about thirty times faster than the machining of the profiles.

- Cold rolled workpieces also offer higher strength, better surface finish and high accuracy.

- transverse roll strips provided, which are arranged by linear drives in a direction transverse to the axis of rotation movable.

- the transverse rolling strips are received by an upper support and sub-support, wherein the upper support in a vertical direction above and a sub-support in a vertical direction below the tool chuck are arranged movable.

- the rolling rod For dimensional corrections on the workpiece, it may be necessary to deliver the rolling rod in the radial direction (relative to the workpiece) in order to form the predetermined tread depth. This delivery is done manually via adjusting screws, over which the radial position of the rolling rods is adjustable relative to the workpiece. For this readjustment of the rolling process must be interrupted, so that the productivity of the system is reduced.

- the present invention seeks to provide a cold rolling machine and a method for cold rolling, through which the downtime during production are reduced.

- the cold rolling machine is provided with a feed device with an integrated feed drive, via which the rolling rods can be adjusted during the rolling process in the direction of engagement. That is, each rolling rod is associated with a feed axis, which allows an adjustment of the rolling rods in approximately radial direction with respect to the workpiece to be machined.

- this feed device thus the tread depth can be changed during the rolling process, so that, for example, the desired Endprofiliefe not - as required in the prior art - during a feed movement of the rolling rods, but during several Walzstangenh Claus can be formed, in which the rolling rods are readjusted in the radial direction. This makes it possible to minimize the length of the rolling rod, so that the dimensions of the cold rolling machine remain relatively low.

- the rolling rods can be performed substantially with constant tread depth, so that their production is much easier than in the conventional rolling rods with increasing profile depth in the rolling direction.

- the calibration and relaxation zones described above can be formed by means of small ramps at the end sections of the rolling rods, wherein the region of the rolling rods extending between the ramps is formed essentially with the same profile depth.

- Each of the two rolling rods is in each case assigned a guide carriage, which is displaceable along inclined guides.

- These two inclined guides are employed in a V-shaped manner with respect to one another, so that the radial distance between the rolling rod and the workpiece can be changed by displacing the guide carriage along the associated inclined guide.

- the feed movement is carried out by moving the rolling rod along the wedge-shaped inclined guides, so that by adjusting the rolling rods without tool change a variation of the number of teeth, the rolling of even and odd numbers of teeth, a positioned rolling and the quality optimization of the profile by division correction is possible.

- each guide carriage is assigned its own feed drive, for example a planetary spindle drive.

- feed drive for example a planetary spindle drive.

- suitable drives such as rack drives, ball screw drives or hydraulic drives can be used.

- the structure of the cold rolling machine according to the invention can be further simplified if the free end portions of the guide slide displaceable along the inclined guides are connected via a console on which the drives for the rolling rod device are mounted.

- the inventive concept can be used particularly advantageously in cold rolling machines, the rolling rods are driven in the vertical direction, so that the footprint of the machine according to the invention is minimal.

- the height can be minimized by driving the rolling rods in the horizontal direction.

- the workpiece can be driven via the rolling rods transmitted forces or via its own rotary drive, which is synchronized with the drive of the rolling rods.

- the forming area of the workpiece is subjected to ultrasound.

- ultrasound the flow limit is lowered during the forming process, so that the forming forces are reduced compared to conventional solutions.

- the guide rails supporting the inclined guides are advantageously supported on two spaced support legs of a machine bed, these two support legs are connected to increase the rigidity over cross straps.

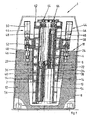

- FIG. 1 shows a section through a cold rolling machine 1, in which two rolling rods 2, 4 in the vertical direction: (with respect to the footprint) are arranged, while a workpiece, not shown, the bearing headstock 6 (only indicated in FIG FIG. 1 ) in the horizontal direction, that is arranged parallel to the support surface.

- the workpiece is rotatably mounted in this headstock 6, wherein via an NC drive, not shown, for example, for feeding or removal of the workpiece from the processing area, before or after the rolling, a shift in the axial direction (perpendicular to the plane) is possible.

- the design of the headstock with a quill and a rear centering differs essentially not from conventional solutions, so that reference is made to the above-mentioned prospectus of the applicant with regard to further details for the sake of simplicity.

- cold rolling machine can be a variety of profiles, such as serrations, threads, running gears, oil grooves, annular grooves, knurls or other special forms in reversing train.

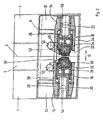

- the control of the cold rolling machine 1 is according to FIG. 2 housed in laterally arranged cabinets 7.

- This extremely compact design with minimal footprint makes it possible to perform the cold rolling machine 1 as a so-called hook machine, which is practically pre-assembled and delivered as a functional unit.

- the illustrated cold rolling machine 1 has a base made of mineral cast, the two upwards (see FIG. 1 ) projecting support legs 10, 12 has. These each have a stepped recess with an in FIG. 1 visible horizontal support surface 14 and a vertical support surface ( FIG. 2 ) 16, on which one of the two support legs 10, 12 overstretching bridge structure 18 is supported. This is in FIG. 2 shown cut and contains essentially the guides and drives for the reciprocating movement of the rolling rods 2, 4th

- the bridge structure 18 carrying the rolling rods 2, 4 has in each case one supporting body 20, 22 attached to the supporting legs 10, 12, which essentially consists of a cast-supporting structure 24, which is designed with a mineral casting filling.

- FIG. 2 can be removed, the two support bodies 20, 22 via a rear transverse tab 26 and a front transverse flap 28 are connected to each other, which extend beyond the area between the two support legs 10, 12.

- the end portions of the front cross-bar 28 are secured to the bearing surfaces of the support legs 10 and 12 formed by the horizontal support surface 14 and the vertical support surface 16.

- Both transverse straps 26, 28 each have a recess 30, 32, through which the workpiece with the associated clamping devices of the headstock 6 (indicated in FIG FIG. 2 ) can be feasible in the editing area.

- FIG. 2 can be removed, are formed on the opposite end surfaces of the two support bodies 20, 22 and the cast-support structure 24 oblique track guides 34, 36 in the form of flat track guides made of plastic, characterized by low friction, high accuracy, long life and optimum Characterize damping behavior.

- oblique track guides 34, 36 in the form of flat track guides made of plastic, characterized by low friction, high accuracy, long life and optimum Characterize damping behavior.

- a guide carriage 38, 40 guided which is designed in the contact area with the two support members 20, 22 with guide legs which engage around the inclined track guide 34, 36.

- the determination of the guide carriage 38, 40 in the transverse direction takes place via a counter guide 42, which engage behind the side surfaces of the flat track guide 36.

- each flat track guide 34, 36 may be, for example, 3 °.

- NC drive 44 which can be embodied, for example, as a planetary spindle drive with servomotor 50.

- a spindle nut 46 is rotatably supported in the support body 22 and 24, while the planetary spindle 48 is mounted in a console of the guide carriage 38 and 40 and connected via a toothed belt with the servo motor 50.

- the planetary spindle 48 is rotated by the fixed spindle nut 46 and transmitted as axial displacement on the guide carriage 38,40 so that they are moved along the inclined track guides 34 and 36, respectively.

- the end faces of the guide carriage 38, 40 remote from the inclined track guides 34, 36 run parallel to the feed axis of the two rolling rods 2, 4, so that the guide slides, 38, 40 in the illustration according to FIG FIG. 1 have an approximately wedge-shaped cross-section.

- the rolling rods 2, 4 facing end surfaces of the guide carriage 38, 40 are also formed as guides 52, 54, along which slides 56, 58 are guided, on which the Wälzstangen 2, 4 are fixed.

- the guides 52, 54 are also executed again as a cast flat rail guides and correspond in terms of structure substantially the inclined guides 34, 36. D. h., The carriages 56, 58 dive with their end face in a U-shaped recess of the associated guide carriage 38, 40, wherein this recess is designed as a sliding guide. The determination of the carriages 56, 58 on the associated guide carriage 38, 40 takes place via a counter guide 60.

- FIG. 1 via the two support legs 10, 12 also extending end portions of the two guide slides 38, 40 each have a bracket 62, in each of which a NC drives 64, 66 is mounted.

- a planetary spindle 48 is (here via a toothed belt 68) ( FIG. 2 ) connected to a servomotor 50 and rotatably mounted in the bracket 62.

- the cooperating with the planetary spindle 48 spindle nut 46 is rotatably mounted in a respective carriage 56, 58, so that upon rotation of the planetary spindle 48, the spindle nut 46 and the associated carriage 56 and 58 along the guide 52 and 54 is moved.

- the planetary spindle 48 passes through an inner bore of the associated carriage 56, 58.

- the two NC drives 64, 66 are driven in such a way that the two rolling rods 2, 4 are offset in the counter-synchronized movements.

- FIG. 3 shows a schematic representation of a rolling rod 2, as used in the cold rolling machine 1 according to the invention FIG. 1 can be used.

- This rolling rod 2 is conventionally made of hardened and ground cold work steel and carries a profiling 70 whose tread depth S is substantially constant along a region T. At the two end portions of the profiling 70 ramps 72 are formed whose length U is substantially less than the length T with constant profiling 70. Due to the substantially constant profiling can be in FIG. 3 shown rolling rod much easier to produce than conventional rolling rods, where the tread depth in the range T is variable. Also the regrinding of in FIG. 3 shown rolling rod is due to the substantially constant tread depth much easier than in the conventional solutions.

- FIG. 1 shows the basic position of the cold rolling machine 1, in which the carriage 58 is in its upper and the carriage 56 in its lower end position.

- the two guide slides 38, 40 are moved via the NC drives 44 into their upper end position, so that the distance between the rolling rods 2, 4 is maximum (minimum profile depth).

- the workpiece is brought over the headstock 6 in its processing position between the two rolling rods 2, 4.

- the two NC drives 64, 66 controlled synchronously and in opposite directions, so that the two rolling rods 2, 4 accumulate in opposite directions on the workpiece and this offset by frictional and positive locking in rotation, wherein the engagement between the workpiece and the two rolling rods. 2 , 4 the forming process takes place.

- the tread depth can be adjusted by a synchronous displacement of the two guide slides 38, 40 along the inclined surfaces 34, 36, wherein the maximum tread depth during a stroke of the rolling rods 2, 4 or during several successive strokes (also in reversing) is formed.

- suitable inclination of the inclined guide 34, 36 and corresponding stroke of the NC drives for example, a tread depth of up to about 5 mm can be produced.

- the rolling process is constantly monitored, so that the rolling process can be optimized by means of variable speed profiles both for the advance of the guide carriages 34, 36 and the carriages 56, 58.

- the mineral casting substructure 8 and the mineral cast-filled support body 20, 22 cause a much better attenuation than conventional constructions.

- the cast mineral substructure makes it possible to integrate all the supply elements, with virtually no additional processing required after casting the substructure.

- the substructure may be formed in a conventional manner by a welded or cast construction in deviation from the above-described embodiment.

- the adjustability of the guide carriages 38, 40 also makes it possible to carry out a division correction during the rolling process, so that the rolling quality is significantly improved over conventional solutions with rolling rods.

- conventional, non-plastic-coated sliding guides rolling guides, for example roller shoes or flat cage guides could alternatively also be used, but these are less favorable than the molded guideways both in terms of load capacities and costs.

- the workpiece is driven by the engagement with the rolling rods 2, 4.

- the workpiece can be assigned its own rotary drive, which is synchronized with the NC drives 64, 66 of the rolling rods, so that the stroke of the rolling rods 2, 4 is synchronized with the rotation of the workpiece to be rolled.

- the forming forces can be reduced when the rolled portion of the workpiece is subjected to ultrasound.

- a suitable ultrasonic head can be integrated into the cold rolling machine.

- Another possibility is to overlay the rotational movement of the workpiece during the rolling process with ultrasonic vibrations. This could be done, for example, by the fact that the above-described rotary drive generates a rotary movement for the workpiece, which is superimposed with high-frequency ultrasound oscillations of low amplitude.

- the Schwingungsbeinsselung the forming process the forming forces can be reduced during the rolling process, so that an increase in the process speed is possible. Due to the reduction in the flow limit, materials that are difficult to form can also be cold-rolled using conventional methods.

- a cold rolling machine in which the rolling rods are preferably arranged in the vertical direction and are adjustable via a feed device during the rolling process in the radial direction with respect to the workpiece to be machined.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Metal Rolling (AREA)

- Transmission Devices (AREA)

- Superconductors And Manufacturing Methods Therefor (AREA)

- Lubricants (AREA)

Claims (12)

- Machine de laminage à froid comprenant deux barres de laminage (2, 4), profilées, entraînées en sens opposé, qui sont montées à chaque fois sur un guidage (52, 54) via un chariot (56, 58), et sont en contact avec une pièce d'usinage montée en rotation entre les barres de laminage (2, 4), et un dispositif d'avance (38, 40 ; 20, 22) comprenant au moins un entraînement d'avance (44) grâce auquel les barres de laminage (2, 4), pendant le laminage, sont réglables dans le sens radial par rapport à la pièce d'usinage, le dispositif d'avance ayant pour chaque guidage (52, 54) un chariot de guidage (38, 40), caractérisé en ce que celui-ci est monté en étant mobile sur un guidage oblique (34, 36), où les guidages obliques (34, 36) associés aux deux barres de laminage (2, 4) sont disposés en forme de V l'un par rapport à l'autre.

- Machine de laminage à froid selon la revendication 1, où un entraînement d'avance (44), de préférence un entraînement à commande numérique (NC), est associé à chaque chariot de guidage (38, 40).

- Machine de laminage à froid selon la revendication 1 ou 2, où les parties d'extrémités libres des chariots de guidage (38, 40) ont une console (62) sur laquelle sont montés les entraînements (64, 66) pour les barres de laminage (2, 4).

- Machine de laminage à froid selon l'une quelconque des revendications précédentes, où les guidages (52, 54) pour les barres de laminage (2, 4) sont disposés dans le sens vertical ou dans le sens horizontal.

- Machine de laminage à froid selon l'une quelconque des revendications 1 à 4, où les guidages obliques (34, 36) sont disposés sur deux branches d'appui (10, 12) d'une infrastructure (8).

- Machine de laminage à froid selon la revendication 5, où les deux branches d'appui (10, 12) sont reliées entre elles par des éclisses transversales (26, 28).

- Machine de laminage à froid selon l'une quelconque des revendications 1 à 6, où un entraînement est associé à la pièce d'usinage, lequel entraînement est synchronisé avec l'entraînement des barres de laminage.

- Machine de laminage à froid selon l'une quelconque des revendications 1 à 7, comprenant un dispositif à ultrasons au moyen duquel la zone laminée de la pièce d'usinage peut être sollicitée par des vibrations dans la plage d'ultrasons.

- Machine de laminage à froid selon l'une quelconque des revendications précédentes, caractérisée en qu'il est prévu une barre de laminage (2 ; 4) ayant un profilage (70) qui s'étend en ayant un profil constant pratiquement sur toute la surface active de la barre de laminage (2 ; 4).

- Machine de laminage à froid selon la revendication 9, où des rampes courtes (72), ayant une profondeur de profilé moins importante, sont conformées au niveau des parties d'extrémité du profilage (70).

- Procédé de laminage à froid d'une pièce d'usinage, qui est en contact actif avec deux barres de laminage (2, 4) pouvant être entraînées en sens opposé, où les barres de laminage (2, 4), pendant le laminage, sont réglées dans le sens radial par rapport à la pièce d'usinage, les barres de laminage étant montées à chaque fois en étant mobiles au moyen de chariots de guidage sur un guidage oblique et les guides obliques associés aux deux barres de laminage sont disposés en fourme de V l'un par rapport à l'autre.

- Procédé selon la revendication 11, où la profondeur de profil prédéterminée est conformée pendant plusieurs courses successives des barres de laminage.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04009469A EP1442808B1 (fr) | 2000-06-09 | 2001-06-08 | Matrice de laminage |

| DE20122205U DE20122205U1 (de) | 2000-06-09 | 2001-06-08 | Kaltwalzmaschine |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10028165A DE10028165A1 (de) | 2000-06-09 | 2000-06-09 | Kaltwalzmaschine |

| DE10028165 | 2000-06-09 | ||

| PCT/DE2001/002119 WO2001094048A1 (fr) | 2000-06-09 | 2001-06-08 | Machine de laminage a froid |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04009469A Division EP1442808B1 (fr) | 2000-06-09 | 2001-06-08 | Matrice de laminage |

| EP04009469.0 Division-Into | 2004-04-22 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1286794A1 EP1286794A1 (fr) | 2003-03-05 |

| EP1286794B1 EP1286794B1 (fr) | 2004-09-22 |

| EP1286794B2 true EP1286794B2 (fr) | 2009-12-30 |

Family

ID=7644977

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP01955205A Expired - Lifetime EP1286794B2 (fr) | 2000-06-09 | 2001-06-08 | Machine de laminage a froid |

| EP04009469A Expired - Lifetime EP1442808B1 (fr) | 2000-06-09 | 2001-06-08 | Matrice de laminage |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04009469A Expired - Lifetime EP1442808B1 (fr) | 2000-06-09 | 2001-06-08 | Matrice de laminage |

Country Status (5)

| Country | Link |

|---|---|

| US (2) | US7051565B2 (fr) |

| EP (2) | EP1286794B2 (fr) |

| AT (1) | ATE276846T1 (fr) |

| DE (4) | DE10028165A1 (fr) |

| WO (1) | WO2001094048A1 (fr) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10259665A1 (de) * | 2002-12-18 | 2004-07-08 | Wemakon Zeulenroda Gmbh | Zweischlitten-Flachbacken-Profilwalzmaschine |

| DE102004035153A1 (de) * | 2004-07-15 | 2006-02-09 | Ex-Cell-O Gmbh | Walzstange, Kaltwalzmaschine und Kaltwalzverfahren |

| DE102004053501B3 (de) | 2004-10-28 | 2006-06-01 | Ex-Cell-O Gmbh | Kaltwalzmaschine und Kaltwalzverfahren |

| US8468863B2 (en) | 2007-08-07 | 2013-06-25 | E.W. Menn Gmbh & Co. Kg | Profile-rolling machine |

| DE102007044283A1 (de) * | 2007-09-07 | 2009-03-12 | Ex-Cell-O Gmbh | Werkzeugmaschine zur Herstellung von Verzahnungen an Werkstücken und Verfahren zur Herstellung einer Verzahnung an einem Werkstück mittels einer Werkzeugmaschine |

| US9403206B2 (en) | 2012-05-23 | 2016-08-02 | U.S. Gear Tools, Inc. | Spline rolling rack and method |

| KR102264766B1 (ko) * | 2013-03-21 | 2021-06-14 | 일리노이즈 툴 워크스 인코포레이티드 | 왕복 다이를 갖는 롤 형성 기계와, 원통형 블랭크 상에 패턴을 형성하는 방법 |

| DE102013106268A1 (de) | 2013-06-17 | 2014-12-18 | Thyssenkrupp Steel Europe Ag | Verfahren und Vorrichtung zur Herstellung rotationssymmetrischer Metallbauteile |

| RU2644837C2 (ru) * | 2015-11-30 | 2018-02-14 | Общество с ограниченной ответственностью "Челябинский трубопрокатный завод-Инжиниринг" | Способ получения конической резьбы на трубах методом пластического деформирования |

| DE102017113382B3 (de) | 2017-06-19 | 2018-10-18 | Ffg Werke Gmbh | Gewindewalzverfahren und Gewindewalzvorrichtung zur Herstellung eines Gewindes |

| DE102017116895A1 (de) | 2017-07-26 | 2019-01-31 | Mag Ias Gmbh | Verfahren und Vorrichtung zur Herstellung einer Verzahnung an einem zylindrischen Werkstück |

| DE102018113978B3 (de) | 2018-06-12 | 2019-09-05 | Mag Ias Gmbh | Kaltwalzmaschine und Verfahren zur Erzeugung eines Profils an einem Werkstück |

| CN112828216A (zh) * | 2020-12-30 | 2021-05-25 | 瑞斯恩智能科技(苏州)有限公司 | 一种高效搓齿机 |

| DE102022110872A1 (de) | 2022-05-03 | 2023-11-09 | Osg Ex-Cell-O Gmbh | Werkzeugeinheit für eine Kaltwalzmaschine |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE708057C (de) † | 1937-06-20 | 1941-07-11 | Pee Wee Maschinen Und Appbau I | Verfahren zur Herstellung von Bolzen- oder Aussengewinden |

| DE751904C (de) † | 1939-10-26 | 1954-03-01 | Pee Wee Maschinen U Appbau Inh | Vorrichtung an Gewindewalzmaschinen mit einer das Werkstueck beim Arbeitsgang abstuetzenden, senkrecht zu den Walzenachsen beweglichen Auflage |

| US3303682A (en) † | 1962-02-01 | 1967-02-14 | Gen Motors Corp | Method and apparatus for cold forming toothed elements |

| US4045988A (en) † | 1976-04-14 | 1977-09-06 | Anderson-Cook Inc. | Rotary forming machine and tool |

| DE3512514A1 (de) † | 1984-07-25 | 1986-01-30 | VEB Kombinat Umformtechnik "Herbert Warnke" Erfurt, DDR 5010 Erfurt | Querwalzmaschine mit geradlinig, hydraulisch angetriebenen walzschlitten |

| EP0123851B1 (fr) † | 1983-03-22 | 1988-01-07 | Osg Mfg. Company | Procédé et appareil pour laminer une ébauche cylindrique |

| DE29616460U1 (de) † | 1996-09-23 | 1996-12-12 | Linnenbrink, Wolfgang, 34414 Warburg | Kaltwalzmaschine |

| EP0894555A2 (fr) † | 1997-07-29 | 1999-02-03 | Revue Thommen AG | Machine à laminer des profilés avec cadre de support |

| US6047581A (en) † | 1998-02-27 | 2000-04-11 | Anderson Cook, Inc. | Drive system for vertical rack spline-forming machine |

| DE19718257C2 (de) † | 1997-04-30 | 2001-06-07 | Bad Dueben Profilwalzmaschinen | Profilwalzmaschine zum Walzen eines rotationssymmetrischen Werkstücks mit einem präzisen Außenprofil |

| DE19728669C2 (de) † | 1997-07-04 | 2001-08-23 | Leico Werkzeugmaschb Gmbh & Co | Verfahren und Querwalzmaschine zum Formen eines rotationssymmetrischen Hohlkörpers |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US408529A (en) * | 1889-08-06 | Island | ||

| US1460061A (en) * | 1922-02-15 | 1923-06-26 | Hamilton Gavin Shearer | Axle mill |

| US2760388A (en) * | 1953-05-18 | 1956-08-28 | Bethlehem Steel Corp | Two-diameter thread rolling device |

| US3945272A (en) * | 1970-01-30 | 1976-03-23 | Nl Industries Inc. | Thread-rolling method, thread-rolling dies, and method of manufacturing the dies |

| US4037281A (en) * | 1975-03-03 | 1977-07-26 | Litton Systems, Inc. | Fastener manufacturing method |

| SU559759A1 (ru) * | 1976-02-23 | 1977-05-30 | Устройство дл поперечно-клиновой прокатки | |

| US4016738A (en) * | 1976-04-27 | 1977-04-12 | Alexandr Vladimirovich Puchko | Traverse wedge forming machine |

| US4487047A (en) * | 1981-03-02 | 1984-12-11 | Anderson-Cook, Inc. | Thin-wall spline forming |

| US4519231A (en) * | 1983-03-11 | 1985-05-28 | Roth Robert G | Forming machine including drive mechanism having rack and gear synchronization |

| JPS60166136A (ja) * | 1984-02-08 | 1985-08-29 | Nissan Motor Co Ltd | 転造盤のダイス取付台 |

| DE3619631A1 (de) * | 1986-06-11 | 1987-12-17 | Ind Systeme Datentechnik | Verfahren und vorrichtung zum querwalzen von profilierten rotationsprofilen |

| DE4123847C2 (de) * | 1991-07-18 | 1994-08-04 | Beche & Grohs Gmbh | Flachbacken-Querwalzmaschine |

| AU4653693A (en) | 1992-07-29 | 1994-03-03 | E.I. Du Pont De Nemours And Company | Herbicidal triazinones |

| DE4306742A1 (de) * | 1993-03-04 | 1994-09-08 | Zahnradfabrik Friedrichshafen | Werkzeug und Verfahren zur spanlosen Herstellung der Außenverzahnung von Getrieberädern |

| US5950471A (en) * | 1998-02-27 | 1999-09-14 | Anderson-Cook, Inc. | Vertical rack spline forming machine |

| US6301945B1 (en) * | 2000-06-01 | 2001-10-16 | Utica Enterprises, Inc. | Rack slide assembly and machine for rolling splines in a round workpiece |

-

2000

- 2000-06-09 DE DE10028165A patent/DE10028165A1/de not_active Withdrawn

-

2001

- 2001-06-08 EP EP01955205A patent/EP1286794B2/fr not_active Expired - Lifetime

- 2001-06-08 US US10/297,195 patent/US7051565B2/en not_active Expired - Lifetime

- 2001-06-08 WO PCT/DE2001/002119 patent/WO2001094048A1/fr active IP Right Grant

- 2001-06-08 DE DE50114694T patent/DE50114694D1/de not_active Expired - Lifetime

- 2001-06-08 AT AT01955205T patent/ATE276846T1/de not_active IP Right Cessation

- 2001-06-08 DE DE20122205U patent/DE20122205U1/de not_active Expired - Lifetime

- 2001-06-08 DE DE50103775T patent/DE50103775D1/de not_active Expired - Lifetime

- 2001-06-08 EP EP04009469A patent/EP1442808B1/fr not_active Expired - Lifetime

-

2006

- 2006-03-27 US US11/389,006 patent/US7353679B2/en not_active Expired - Lifetime

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE708057C (de) † | 1937-06-20 | 1941-07-11 | Pee Wee Maschinen Und Appbau I | Verfahren zur Herstellung von Bolzen- oder Aussengewinden |

| DE751904C (de) † | 1939-10-26 | 1954-03-01 | Pee Wee Maschinen U Appbau Inh | Vorrichtung an Gewindewalzmaschinen mit einer das Werkstueck beim Arbeitsgang abstuetzenden, senkrecht zu den Walzenachsen beweglichen Auflage |

| US3303682A (en) † | 1962-02-01 | 1967-02-14 | Gen Motors Corp | Method and apparatus for cold forming toothed elements |

| US4045988A (en) † | 1976-04-14 | 1977-09-06 | Anderson-Cook Inc. | Rotary forming machine and tool |

| EP0123851B1 (fr) † | 1983-03-22 | 1988-01-07 | Osg Mfg. Company | Procédé et appareil pour laminer une ébauche cylindrique |

| DE3512514A1 (de) † | 1984-07-25 | 1986-01-30 | VEB Kombinat Umformtechnik "Herbert Warnke" Erfurt, DDR 5010 Erfurt | Querwalzmaschine mit geradlinig, hydraulisch angetriebenen walzschlitten |

| DE29616460U1 (de) † | 1996-09-23 | 1996-12-12 | Linnenbrink, Wolfgang, 34414 Warburg | Kaltwalzmaschine |

| DE19718257C2 (de) † | 1997-04-30 | 2001-06-07 | Bad Dueben Profilwalzmaschinen | Profilwalzmaschine zum Walzen eines rotationssymmetrischen Werkstücks mit einem präzisen Außenprofil |

| DE19728669C2 (de) † | 1997-07-04 | 2001-08-23 | Leico Werkzeugmaschb Gmbh & Co | Verfahren und Querwalzmaschine zum Formen eines rotationssymmetrischen Hohlkörpers |

| EP0894555A2 (fr) † | 1997-07-29 | 1999-02-03 | Revue Thommen AG | Machine à laminer des profilés avec cadre de support |

| US6047581A (en) † | 1998-02-27 | 2000-04-11 | Anderson Cook, Inc. | Drive system for vertical rack spline-forming machine |

Non-Patent Citations (4)

| Title |

|---|

| "Fertigungsverfahren Druckumformen Walzen", DEUTSCHE NORMEN, 2 May 1969 (1969-05-02), BERLIN, pages 1 - 7, XP000675285 † |

| "Profilwalzmaschine mit direkter aktiver Regelung des Walzvorganges", UMFORMTECHNIK, 1993, pages 291 † |

| M.WALTHER U. P. STREHMEL U. B. LORENZ: "Verzahnungswalzen in der Gesamtprozesskette beim Herstellen hohler wellenförmiger Antreibsteile", PROFIROLL TECHNOLOGIES BAD DÜBEN/FRAUNHOFER CHEMNITZ, 2000, CHEMNITZ GERMANY † |

| NÄSER/MEICHSNER: "Technologie des gewindewalzens", FACHBUCHVERLAG, 1959, LEIPZIG † |

Also Published As

| Publication number | Publication date |

|---|---|

| US7051565B2 (en) | 2006-05-30 |

| EP1442808B1 (fr) | 2009-02-04 |

| WO2001094048A1 (fr) | 2001-12-13 |

| US7353679B2 (en) | 2008-04-08 |

| DE50103775D1 (de) | 2004-10-28 |

| DE10028165A1 (de) | 2001-12-13 |

| US20040007034A1 (en) | 2004-01-15 |

| EP1286794A1 (fr) | 2003-03-05 |

| US20060162409A1 (en) | 2006-07-27 |

| DE20122205U1 (de) | 2004-09-30 |

| EP1442808A3 (fr) | 2004-09-29 |

| EP1286794B1 (fr) | 2004-09-22 |

| ATE276846T1 (de) | 2004-10-15 |

| EP1442808A2 (fr) | 2004-08-04 |

| DE50114694D1 (de) | 2009-03-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1286794B2 (fr) | Machine de laminage a froid | |

| EP2732895B1 (fr) | Machine-outil pour la fabrication de profilés | |

| EP0492211B1 (fr) | Procédé de pliage de profilés creux en métal et dispositif pour l'exécution du procédé | |

| DE2612174A1 (de) | Schienenschleifmaschine | |

| DE2612173B2 (de) | Fahrbare Schienenschleifmaschine | |

| EP0021329A1 (fr) | Procédé à indexation en développante et dispositif de rectification des dentures | |

| DE3390141C2 (de) | Vorrichtung zur Endbearbeitung eines in ein zylindrisches Stück geschnittenen Schraubenganges durch Glattwalzen | |

| DE3015227C2 (de) | Gleisverfahrbare Maschine zum Abtragen von Unregelmäßigkeiten an der Schienenkopfoberseite eines verlegten Gleises | |

| EP1722912B1 (fr) | Procede pour fabriquer des glissieres profilees pour elements d' articulation | |

| AT395835B (de) | Verfahren zum herstellen einer parallelachsigen rotationskolbenmaschine | |

| DE69211654T2 (de) | Vorrichtung und verfahren zum kaltformen von nuten in die wandung eines rotationskörpers | |

| DE3601425A1 (de) | Verfahren und vorrichtung zum ablaengen von extrudierten kunststoffrohren | |

| DE102018102768B4 (de) | System, mit einem Werkstück in Form einer Gewindespindel und mit einer Feinbearbeitungsvorrichtung | |

| EP3609634B1 (fr) | Outil de roulage en plusieurs parties comprenant un palier flottant et machine de roulage | |

| EP0248983B1 (fr) | Procédé et machine pour le roulage de profils dans des pièces cylindriques | |

| EP0683001B1 (fr) | Méthode et dispositif à usiner des barres, tubes ou bouts de tube | |

| DE10212256A1 (de) | Werkzeug zur Herstellung von Zahnprofilen | |

| CH692382A5 (de) | Profilrollmaschine mit Kraftrahmen. | |

| EP3016771B1 (fr) | Dispositif permettant de lisser une denture et procédé de production d'une denture | |

| DE922045C (de) | Maschine zum Walzen von Innen- oder Aussenprofilen | |

| EP3414030B1 (fr) | Dispositif de galetage de pièces munies d'une denture et procédé afférent | |

| DE19710730B4 (de) | Walzverfahren und Zweiwalzen-Profilwalzmaschine zum Herstellen von Steigungsprofilen mit ungerader Gangzahl auf rotationssymmetrische Werkstücke | |

| DE4340162A1 (de) | Verfahren und Vorrichtung zum Gewindewalzen oder Glattwalzen von hülsen- oder bolzenförmigen Werkstücken | |

| DE102010008027A1 (de) | Werkzeugmaschine | |

| DE202004012067U1 (de) | Walzwerkzeug zum spanlosen Kaltwalzen von Profilen durch Querwalzen mittels paarweise angeordneten Walzstangen oder Rundwalzwerkzeugen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20021205 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17Q | First examination report despatched |

Effective date: 20031217 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KREISSIG, BERND Inventor name: OPHEY, LOTHAR, DR. Inventor name: BRUENTRUP, OTTO |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB IT |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040922 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50103775 Country of ref document: DE Date of ref document: 20041028 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAQ | Examination of admissibility of opposition: information related to despatch of communication + time limit deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE2 |

|

| PLAR | Examination of admissibility of opposition: information related to receipt of reply deleted |

Free format text: ORIGINAL CODE: EPIDOSDOPE4 |

|

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| 26 | Opposition filed |

Opponent name: PROFIROLL TECHNOLOGIES GMBH Effective date: 20050422 |

|

| R26 | Opposition filed (corrected) |

Opponent name: PROFIROLL TECHNOLOGIES GMBH Effective date: 20050422 |

|

| ET | Fr: translation filed | ||

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20091230 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT DE FR GB IT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20100610 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110608 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 276846 Country of ref document: AT Kind code of ref document: T Effective date: 20110608 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50103775 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20180626 Year of fee payment: 18 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50103775 Country of ref document: DE Representative=s name: HOEGER, STELLRECHT & PARTNER PATENTANWAELTE MB, DE |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20190608 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190608 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20200623 Year of fee payment: 20 Ref country code: FR Payment date: 20200623 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20200630 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 50103775 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50103775 Country of ref document: DE Ref country code: DE Ref legal event code: R081 Ref document number: 50103775 Country of ref document: DE Owner name: OSG EX-CELL-O GMBH, DE Free format text: FORMER OWNER: EX-CELL-O GMBH, 73054 EISLINGEN, DE |