EP1041602A2 - Kühlsystem für eine dielektrisch behinderte Entladungslampe - Google Patents

Kühlsystem für eine dielektrisch behinderte Entladungslampe Download PDFInfo

- Publication number

- EP1041602A2 EP1041602A2 EP00106471A EP00106471A EP1041602A2 EP 1041602 A2 EP1041602 A2 EP 1041602A2 EP 00106471 A EP00106471 A EP 00106471A EP 00106471 A EP00106471 A EP 00106471A EP 1041602 A2 EP1041602 A2 EP 1041602A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- dielectric

- discharge lamp

- barrier discharge

- tube

- lamp device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J61/00—Gas-discharge or vapour-discharge lamps

- H01J61/02—Details

- H01J61/52—Cooling arrangements; Heating arrangements; Means for circulating gas or vapour within the discharge space

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J65/00—Lamps without any electrode inside the vessel; Lamps with at least one main electrode outside the vessel

- H01J65/04—Lamps in which a gas filling is excited to luminesce by an external electromagnetic field or by external corpuscular radiation, e.g. for indicating plasma display panels

- H01J65/042—Lamps in which a gas filling is excited to luminesce by an external electromagnetic field or by external corpuscular radiation, e.g. for indicating plasma display panels by an external electromagnetic field

- H01J65/046—Lamps in which a gas filling is excited to luminesce by an external electromagnetic field or by external corpuscular radiation, e.g. for indicating plasma display panels by an external electromagnetic field the field being produced by using capacitive means around the vessel

Definitions

- This invention concerns a dielectric-barrier discharge lamp device.

- the lamps conventionally used to provide such treatment have been low-pressure mercury lamps that emit vacuum ultraviolet radiation at a wavelength of 185 nm, which is the resonant line of mercury.

- dielectric-barrier discharge lamps have come to be used. These are lamps that produce excimer emissions by containing a gas for excimer emissions in a discharge vessel made up of a dielectric and bringing about a dielectric-barrier discharge (also called "ozonizer discharge” or "silent discharge.” See Discharge Handbook , Association of Electrical Studies, rev. ed. June 1989, p. 263).

- Such dielectric-barrier discharge lamps are described in, for example, U.S. Patent No. 4,945,290 (Japanese Kokai Patent H1-144560). That patent document describes a dielectric-barrier discharge lamp in which a hollow-cylinder-shaped discharge space, made up of quartz glass of which at least a part is dielectric, is filled with a gas for excimer emissions.

- a problem of dielectric-barrier discharge lamps of that type is that the lighting efficiency of the lamp (the ratio of area lighted to input power) decreases as the power input to the lamp is increased.

- the cause is thought to be that the temperature of the gas in the lamp increases with the input power, and the lighting efficiency decreases as a result.

- the transmissivity at a wavelength of 172 nm is about 85% at 25°C, but it falls to about 83% at 100°C and about 73% at 300°C.

- FIG. 3 is an explanatory drawing of a conventional dielectric-barrier discharge lamp device fitted with a cooling mechanism.

- the discharge lamp 1 has two coaxial tubes, an inner tube 2 and an outer tube 3, forming a hollow-cylinder-shaped discharge space 4 between the inner tube 2 and the outer tube 3.

- the inner tube 2 and the outer tube 3 are made up of a dielectric, at least in part.

- the inner tube 2 and the outer tube 3 are made up of quartz glass that allows light at a wavelength of 172 nm to pass.

- a roughly cylindrical electrode 5 is placed in close contact with the inner surface of inner tube 2.

- This internal electrode 5 is made up by joining two half cylinders formed by bending aluminum sheets.

- an external electrode 6 Around the outer surface of the outer tube 3 is placed an external electrode 6 that allows the light to pass through it.

- the external electrode 6 comprises a mesh electrode that allows the passage of ultraviolet light.

- the internal electrode 5 and external electrode 6 are connected to an alternating current power supply that is not illustrated.

- An inert gas or a mixture of an inert gas and a halogen is placed in the discharge space 4 as a discharge gas.

- a ring-shaped gasket 7 is located that has a through-hole 7A and that is aligned with the end 1A, 1B of lamp 1.

- the diameter of the through-holes 7A is the same as the diameter of the inner space P that is formed by the inner tube 2.

- a coupler fitting 8 has the gasket 7 on its inner face; by rotating this coupler fitting 8, the gaskets 7 are pressed against the ends 1A, 1B of the dielectric-barrier discharge lamp 1, creating a tight seal between the gaskets 7 and the ends 1A, 1B.

- Through-holes 8A are formed in the coupler fittings 8 to align with the through-holes 7A in the gaskets 7.

- the coupler fittings 8 are held in casings 9 by O-rings 10.

- This casing 9 is formed with through-holes 9A aligned to allow the passage of a coolant fluid through through-holes 8A.

- the inner space P formed by the inner tube 2 forms a passage along with the through-holes 8A of the coupler fittings 8 and the through-holes 9A of the casing 9.

- the coolant fluid leaving one side of the casing 9 through through-hole 9A then passes through the through-holes 8A and 7A into the inner space P formed by the inner tube 2, to cool the dielectric-baffler discharge lamp 1 from the inner tube 2.

- the dielectric-baffler discharge lamp 1 is made by welding together the inner tube 2 and the outer tube 3 in order to form the discharge space 4. For that reason, there will be irregularities where the ends 1A, 1B face gaskets 7. That is, when the gaskets 7 are pushed tightly against the ends 1A, 1B, gaps may be left between the gaskets 7 and the ends 1A, 1B if they are not pushed hard enough, and the coolant fluid is liable to leak from those gaps. Also, there is the problem that, if the coolant fluid leaks, it will not be possible to cool the dielectric-barrier discharge lamp 1.

- vacuum ultraviolet radiation is emitted by the dielectric-barrier discharge lamp 1, and the gaskets 7 are directly illuminated by that vacuum ultraviolet radiation.

- the gaskets 7 deteriorate because of the vacuum ultraviolet radiation.

- gaps occur between the gaskets 7 and the ends 1A, 1B in the course of deterioration of the gaskets 7, causing leakage of the coolant fluid from the gaps.

- a primary object of this invention is to provide a dielectric-barrier discharge lamp device in which leakage of the coolant fluid used to cool the dielectric-barrier discharge lamp can be reliably prevented, and in which the dielectric-barrier discharge lamp can be reliably cooled.

- this invention provides a dielectric-barrier discharge lamp device having a dielectric-barrier discharge lamp with a hollow-cylinder-shaped discharge space formed by an outer tube that is roughly cylindrical in external shape and a co-axial inner tube, in which the inner tube has a cylindrical tube extension that extends outward from the discharge space, and in which the outer periphery of the end of the tube extension is held tightly by a coupler fitting connected to a guide tube through which a coolant fluid flows.

- a dielectric-barrier discharge lamp device 1 in accordance with the present invention which comprises a co-axial, overlapping structure of an inner tube 2 and an outer tube 3 made of quartz glass, a dielectric that passes light with a wavelength of 172 nm.

- the ends of the inner tube 2 and the outer tube 3 are welded together to form a hollow-cylinder-shaped discharge space 4.

- the inner space P formed by the inner tube 2 has a diameter of 12 to 15 mm, the thickness of the inner tube 2 is 1 mm, the outer diameter of the outer tube 3 is 24 to 27 mm, and the thickness of the outer tube 3 is 1 mm.

- the length of the discharge space 4 is 260 mm, and the discharge space 4 is filled with xenon, as an inert gas, at a pressure of 3 to 5 KPa.

- a part of the inner tube 2 forms a cylindrical tube extension 2A that projects beyond the discharge space 4 formed by the inner tube 2 and the outer tube 3. That is, the central space 2P of tube extension 2A connects with the inner space P.

- the tube extension 2A comprises a part of the inner tube 2; but it may also be a separate piece welded to the end 1A or 1B of the inner tube 2 in the direction of the axis of the dielectric-barrier discharge lamp 1, such that its central space connects with the inner space P.

- a roughly cylindrical electrode 5 is closely adhered to the inner surface of the inner tube 2.

- This internal electrode 5 can be formed, for example, by joining two half cylinders made by bending aluminum sheet 0.5 mm thick.

- an external electrode 6 Around the outer surface of the outer tube 3 is placed an external electrode 6 that allows the light to pass through.

- This external electrode 6 comprises a mesh electrode that allows the passage of ultraviolet light.

- the internal electrode 5 and external electrode 6 are connected to an alternating current power supply (not illustrated).

- the end 2A1 of the tube extension 2A is attached to a coupler fitting 8, which connects to a guide tube 11 through which the coolant fluid flows. Specifically, the outer periphery of the end 2A1 is held tightly by the coupler fitting 8.

- the coupler fitting 8 that attaches to the other tube extension 2A is not shown but is the same in construction.

- the guide tube 11 is an inlet or outlet tube for the coolant fluid, and either projects from or is contained in the casing that holds the dielectric-barrier discharge lamp 1 in place.

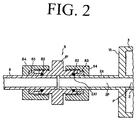

- FIG. 2 is an enlarged view showing the relationship between the tube extension 2A and the coupler fitting 8.

- the coupler fitting 8 comprises a stainless steel body 81, fluorine polymer O-rings 82, iron-nickel alloy ferrules 83 and stainless steel cap nuts 84. This coupler fitting 8 connects the tube extension 2A to the guide tube 11 through which the coolant fluid flows.

- the method of connecting the tube extension 2A and the coupler fitting 8 is as follows.

- the cap nut 84 is placed on the tube extension 2A in advance, and then the ferrule 83 is placed on the tube extension 2A so as to fit into the front of the cap nut 84.

- the O-ring 82 is placed in front of the ferrule 83 so that it is in contact with the entire circumference of the tube extension 2A, after which the end 2A1 of the tube extension 2A is slid into the body 81 to which the guide tube 11 is connected.

- the cap nut 84 is pushed onto the body 81 and rotated so that the threads of the cap nut 84 engage the threads of the body 81.

- the O-ring 82 is deformed to create a tight fit between body 81 and ferrule 83, providing a tight hold on the outer periphery of the end 2A1 of the tube extension 2A.

- this is a structure in which the coupler fitting 8 holds tightly to the very smooth surface of the tube extension 2A that connects to the inner space P, it is possible to reliably prevent leakage of the coolant fluid used to cool the dielectric-barrier discharge lamp 1, and to reliably cool the dielectric-barrier discharge lamp 1.

- the fluorine polymer O-ring 82 is completely enclosed by the stainless steel body 81, the iron-nickel alloy ferrule 83 and stainless steel cap nut 84. Therefore, the O-ring 2 is not directly illuminated by the vacuum ultraviolet radiation, which makes it possible to prevent deterioration of the O-ring 82 due to vacuum ultraviolet radiation. As a result, it is possible to prevent, over a long period, the leakage of the coolant fluid that cools the dielectric-barrier discharge lamp 1.

- the coupler fitting 8 is located on the tube extension 2A such that it is separated from the nearest end 1A by a distance L of, e.g., 10 mm, as shown.

- L e.g. 10 mm

- the fixed space L is left between the coupler fitting 8 and the end 1A of the discharge space 4 of the dielectric-barrier discharge lamp 1 that is nearest to the coupler fitting 8.

- the minimum distance between the coupler fitting 8 and the end 1A that forms the discharge space 4 be at least 0.2 mm/W. If this distance is less than 0.2 mm/W, there is an increased possibility that the coupler fitting 8 and the end 1A that forms the discharge space 4 will be too close, thus causing the problems described above.

- this invention provides a dielectric-barrier discharge lamp device having a dielectric-barrier discharge lamp with a hollow-cylinder-shaped discharge space formed by an outer tube that is roughly cylindrical in external shape and a co-axial inner tube, in which the inner tube has a cylindrical tube extension that extends outward from the discharge space, and in which the outer periphery of the end of the tube extension is held tightly by a coupler fitting connected to a guide tube through which a coolant fluid flows.

- the invention provides a dielectric-barrier discharge lamp device that can reliably prevent leakage of the coolant fluid used to cool the dielectric-barrier discharge lamp, and that can reliably cool the dielectric-barrier discharge lamp.

Landscapes

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Engineering & Computer Science (AREA)

- Plasma & Fusion (AREA)

- Discharge Lamps And Accessories Thereof (AREA)

- Vessels And Coating Films For Discharge Lamps (AREA)

- Common Detailed Techniques For Electron Tubes Or Discharge Tubes (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP08828399A JP3458757B2 (ja) | 1999-03-30 | 1999-03-30 | 誘電体バリア放電ランプ装置 |

| JP8828399 | 1999-03-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1041602A2 true EP1041602A2 (de) | 2000-10-04 |

| EP1041602A3 EP1041602A3 (de) | 2003-05-28 |

Family

ID=13938589

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP00106471A Withdrawn EP1041602A3 (de) | 1999-03-30 | 2000-03-24 | Kühlsystem für eine dielektrisch behinderte Entladungslampe |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US6570301B1 (de) |

| EP (1) | EP1041602A3 (de) |

| JP (1) | JP3458757B2 (de) |

| KR (1) | KR20000063054A (de) |

| CN (1) | CN1229851C (de) |

| TW (1) | TW452824B (de) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6628078B2 (en) * | 2000-03-15 | 2003-09-30 | M.D.Com Inc. | Dielectric barrier discharge lamp and dry cleaning device using the same |

| US7855492B2 (en) | 2005-02-21 | 2010-12-21 | Koninklijke Philips Electronics N.V. | Lamp holder for a dielectric barrier discharge lamp |

Families Citing this family (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3576100B2 (ja) * | 2000-12-28 | 2004-10-13 | 株式会社オーク製作所 | 高輝度光照射装置 |

| US6762556B2 (en) * | 2001-02-27 | 2004-07-13 | Winsor Corporation | Open chamber photoluminescent lamp |

| JP2004087270A (ja) * | 2002-08-26 | 2004-03-18 | Orc Mfg Co Ltd | エキシマランプおよびエキシマランプ装置 |

| JP4461707B2 (ja) * | 2003-05-06 | 2010-05-12 | ウシオ電機株式会社 | エキシマランプ |

| US7781947B2 (en) | 2004-02-12 | 2010-08-24 | Mattson Technology Canada, Inc. | Apparatus and methods for producing electromagnetic radiation |

| CN1926658B (zh) * | 2004-02-12 | 2012-10-10 | 加拿大马特森技术有限公司 | 高强度电磁辐射装置与方法 |

| JP5103728B2 (ja) * | 2005-11-24 | 2012-12-19 | ウシオ電機株式会社 | 放電ランプ点灯装置 |

| DE602007004732D1 (de) * | 2006-07-13 | 2010-03-25 | Philips Intellectual Property | Flüssigkeitsverarbeitungssystem mit einem strahlungsquellenmodul und einem kühlmittel |

| DE202007004236U1 (de) * | 2007-03-22 | 2007-06-14 | Patent-Treuhand-Gesellschaft für elektrische Glühlampen mbH | Dielektrische Barriere-Entladungslampe mit Zündhilfe |

| JP5186823B2 (ja) * | 2007-07-17 | 2013-04-24 | ウシオ電機株式会社 | 高圧放電ランプ及び高圧放電ランプを用いた光照射装置 |

| US20090246101A1 (en) * | 2008-04-01 | 2009-10-01 | Pochy Rocco D | Apparatus for Rapid Oxidation using UV Radiation |

| WO2011153388A2 (en) | 2010-06-04 | 2011-12-08 | Access Business Group International Llc | Inductively coupled dielectric barrier discharge lamp |

| US9159545B2 (en) * | 2011-12-02 | 2015-10-13 | Ushio Denki Kabushiki Kaisha | Excimer lamp |

| CN102500451A (zh) * | 2011-12-23 | 2012-06-20 | 华南理工大学 | 辅助球磨介质阻挡放电电极 |

| CN103237404A (zh) * | 2013-05-14 | 2013-08-07 | 哈尔滨工业大学 | 同轴放电模式的大气等离子体发生装置 |

| JP6036740B2 (ja) * | 2014-04-08 | 2016-11-30 | ウシオ電機株式会社 | 光照射装置 |

| CN110797254A (zh) * | 2019-10-30 | 2020-02-14 | 深圳市嘉光科技有限公司 | 一种单面发均匀平行光的长方形准分子灯 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3486775A (en) * | 1968-07-31 | 1969-12-30 | Cajon Co | Fitting |

| CH675178A5 (de) | 1987-10-23 | 1990-08-31 | Bbc Brown Boveri & Cie | |

| JPH0727168B2 (ja) * | 1989-06-21 | 1995-03-29 | 株式会社オーク製作所 | 放電灯の冷却液循環システム |

| US5039904A (en) * | 1989-09-28 | 1991-08-13 | General Electric Company | Mount for miniature arc lamp |

| DE59105798D1 (de) * | 1991-04-15 | 1995-07-27 | Heraeus Noblelight Gmbh | Bestrahlungseinrichtung. |

| US5104151A (en) * | 1991-05-15 | 1992-04-14 | Adams Don L | Coupler apparatus for connecting a conduit to an equipment opening having damaged threads |

| JPH07169443A (ja) * | 1993-12-17 | 1995-07-04 | Ushio Inc | 誘電体バリヤ放電ランプ装置 |

| JPH07288112A (ja) * | 1994-04-15 | 1995-10-31 | Ushio Inc | 誘電体バリヤ放電ランプ装置 |

| JPH09274893A (ja) * | 1996-04-04 | 1997-10-21 | Ushio Inc | 誘電体バリア放電ランプ |

| US5871239A (en) * | 1996-10-31 | 1999-02-16 | Stanley Aviation Corporation | Positive lock coupling |

| DE19744940A1 (de) * | 1997-02-28 | 1998-09-03 | Umex Ges Fuer Umweltberatung U | Vorrichtung zur Durchführung fotochemischer Reaktionen, vorzugsweise von Aufschlüssen im Labor |

| US5834784A (en) * | 1997-05-02 | 1998-11-10 | Triton Thalassic Technologies, Inc. | Lamp for generating high power ultraviolet radiation |

| DE19728646C2 (de) * | 1997-07-04 | 2001-10-18 | Heraeus Noblelight Gmbh | Tauchlampe für die Anregung photochemischer Reaktionen |

| JP3439679B2 (ja) * | 1999-02-01 | 2003-08-25 | 株式会社オーク製作所 | 高輝度光照射装置 |

-

1999

- 1999-03-30 JP JP08828399A patent/JP3458757B2/ja not_active Expired - Lifetime

-

2000

- 2000-01-21 TW TW089101019A patent/TW452824B/zh not_active IP Right Cessation

- 2000-03-24 EP EP00106471A patent/EP1041602A3/de not_active Withdrawn

- 2000-03-29 KR KR1020000016197A patent/KR20000063054A/ko not_active Withdrawn

- 2000-03-30 US US09/537,715 patent/US6570301B1/en not_active Expired - Fee Related

- 2000-03-30 CN CNB001049216A patent/CN1229851C/zh not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6628078B2 (en) * | 2000-03-15 | 2003-09-30 | M.D.Com Inc. | Dielectric barrier discharge lamp and dry cleaning device using the same |

| US7855492B2 (en) | 2005-02-21 | 2010-12-21 | Koninklijke Philips Electronics N.V. | Lamp holder for a dielectric barrier discharge lamp |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1269597A (zh) | 2000-10-11 |

| KR20000063054A (ko) | 2000-10-25 |

| CN1229851C (zh) | 2005-11-30 |

| TW452824B (en) | 2001-09-01 |

| US6570301B1 (en) | 2003-05-27 |

| JP3458757B2 (ja) | 2003-10-20 |

| JP2000285866A (ja) | 2000-10-13 |

| EP1041602A3 (de) | 2003-05-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US6570301B1 (en) | Dielectric barrier discharge lamp device with coupler for coolant fluid flow | |

| EP0703603B1 (de) | Dielektrikumbegrenzte Entladungslampe | |

| JP3580233B2 (ja) | 誘電体バリア放電ランプ装置 | |

| JP2019164994A (ja) | レーザ維持プラズマランプ用の機械的密封管及びその製造方法 | |

| US6316877B1 (en) | Lamp device and a method of regulating the lamp intensity | |

| KR100404382B1 (ko) | 고휘도 광조사 장치 | |

| TWI399784B (zh) | A high pressure discharge lamp, a manufacturing method thereof, and a light irradiation device | |

| JP2000306549A (ja) | ショートアーク型放電ランプ | |

| US8143787B2 (en) | Xenon lamp | |

| JP2003165711A (ja) | オゾン発生装置 | |

| JPH07169443A (ja) | 誘電体バリヤ放電ランプ装置 | |

| CN101533753B (zh) | 高压放电灯以及光照射装置 | |

| TWI269344B (en) | Excimer lamp | |

| JP5186823B2 (ja) | 高圧放電ランプ及び高圧放電ランプを用いた光照射装置 | |

| JP5800189B2 (ja) | ショートアーク型放電ランプ | |

| JP2000173544A (ja) | ショートアーク水銀ランプ | |

| JP3264046B2 (ja) | 高圧放電灯およびこれを含む半導体露光装置ならびに映写装置 | |

| JP2002170527A (ja) | 誘電体バリア放電ランプ装置 | |

| JP3629227B2 (ja) | エキシマランプ装置 | |

| JP2001283784A (ja) | 誘電体バリア放電ランプ装置 | |

| US7514873B2 (en) | Electric lamp having an outer bulb | |

| RU214286U1 (ru) | Газоразрядный импульсный источник высокоинтенсивного ультрафиолетового излучения | |

| CN111229133B (zh) | 一种用于光热协同反应的恒温炉 | |

| JP2001126665A (ja) | 誘電体バリア放電ランプ | |

| KR100268706B1 (ko) | 유전체 배리어 방전램프 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: 7F 16L 19/06 B Ipc: 7H 01J 65/04 B Ipc: 7H 01J 61/52 A |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK RO SI |

|

| AKX | Designation fees paid | ||

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: 8566 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20031129 |