EP0716722B1 - Klettende umhüllung - Google Patents

Klettende umhüllung Download PDFInfo

- Publication number

- EP0716722B1 EP0716722B1 EP94926194A EP94926194A EP0716722B1 EP 0716722 B1 EP0716722 B1 EP 0716722B1 EP 94926194 A EP94926194 A EP 94926194A EP 94926194 A EP94926194 A EP 94926194A EP 0716722 B1 EP0716722 B1 EP 0716722B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- elements

- covering

- touch

- close

- connection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011248 coating agent Substances 0.000 claims description 7

- 238000000576 coating method Methods 0.000 claims description 7

- 239000000853 adhesive Substances 0.000 claims description 5

- 230000001070 adhesive effect Effects 0.000 claims description 5

- 229910052751 metal Inorganic materials 0.000 claims description 5

- 239000002184 metal Substances 0.000 claims description 5

- 229920002994 synthetic fiber Polymers 0.000 claims description 5

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 claims description 4

- 239000004744 fabric Substances 0.000 claims description 3

- 239000000835 fiber Substances 0.000 claims description 2

- 229910001092 metal group alloy Inorganic materials 0.000 claims 2

- 238000010276 construction Methods 0.000 description 9

- 230000001681 protective effect Effects 0.000 description 8

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 5

- 230000004888 barrier function Effects 0.000 description 3

- 230000009194 climbing Effects 0.000 description 3

- 239000004576 sand Substances 0.000 description 3

- 235000001674 Agaricus brunnescens Nutrition 0.000 description 2

- 241001295925 Gegenes Species 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 230000009969 flowable effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229920000049 Carbon (fiber) Polymers 0.000 description 1

- 241000270295 Serpentes Species 0.000 description 1

- 208000000260 Warts Diseases 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- WYTGDNHDOZPMIW-RCBQFDQVSA-N alstonine Natural products C1=CC2=C3C=CC=CC3=NC2=C2N1C[C@H]1[C@H](C)OC=C(C(=O)OC)[C@H]1C2 WYTGDNHDOZPMIW-RCBQFDQVSA-N 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000011449 brick Substances 0.000 description 1

- 239000004917 carbon fiber Substances 0.000 description 1

- 238000005253 cladding Methods 0.000 description 1

- 230000007123 defense Effects 0.000 description 1

- -1 ferrous metals Chemical class 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 1

- 230000008439 repair process Effects 0.000 description 1

- 238000009958 sewing Methods 0.000 description 1

- 201000010153 skin papilloma Diseases 0.000 description 1

- 230000007480 spreading Effects 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 238000010025 steaming Methods 0.000 description 1

- 239000002352 surface water Substances 0.000 description 1

- 239000012209 synthetic fiber Substances 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B65D33/005—Anti-slip or anti-skid bags, e.g. bags provided with anti-slip coating, ribs, strips

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2313/00—Connecting or fastening means

- B65D2313/02—Connecting or fastening means of hook-and-loop type

Definitions

- the invention relates to a wrapping bag-shaped or tubular Formation of containers for holding a pourable or flowable medium.

- a sack-shaped wrapper for erection of ramparts is further in US-A-4 362 433.

- These surveys do not touch each other over a large area, so that there are always gaps are present, by which past the surveys Water from one side to the other from these known containers built protective wall flow can.

- the object of the invention is now a bag or tubular with a pourable or flowable medium filled casing for the construction of protective walls, barriers and / or provisional structures with a defined geometric shape that these protective walls and structures not only tight, but also remain steadfast.

- This cladding and mats according to the invention can be reliable for everyone Areas are used where previously sandbags Found application. Compared to sandbags, the climbing ones Envelopes according to the invention but the advantage that they are similar to stuck bricks can be stacked. This results in a comparison to the conventional sandbag system through increased Bond strength a 20 to 30-fold protection improvement, the handling of the invention Enclosures also for untrained people is simple. Leave with these wrappers the most diverse building systems are extraordinary simple and easy to manufacture, dismantle and to Transport location or away from it. The surfaces of the Velcro fastenings can also be worn e.g. Steaming coated with a thin coating become.

- This coating can be heat-resistant and acid-proof be trained and plastic or specific Alloys of non-ferrous metals exist.

- the new Wrapping can consist of carbon fiber fabric, to ensure high temperature resistance. It is also possible to use the envelopes according to the invention rot-proof UV-resistant synthetic fibers such as Manufacture polyacrylic.

- the top and bottom each wrapper can be identified by a letter O and U should be marked, preferably is formed fluorescent. As a result, these are Letters on the wrappings even in the dark visible. This will turn on even in the dark safe stacking and building of new wrappings guaranteed. It is useful on the surface of these envelopes or To develop serpentine lines also fluorescent.

- Velcro elements are used to form the Velcro fasteners and Velcro fasteners provided.

- the Velcro elements can be used as hooks or mushroom heads and the Velcro fasteners as fleece, fleece loops or fleece felt. you will be e.g. by gluing, sewing, heat welding or Ultrasonic welding cannot be removed with the coating connected. Their size depends on the respective area of application. For storm surge protection or to secure a steep slope, e.g. invention Wraps with extremely large dimensions can be used.

- the surface pattern of the Velcro elements or Velcro fasteners can be different be trained. It is possible to have diagonal patterns in Stripe shape, diagonal pattern in snake shape, grid pattern or circular pattern. This surface pattern are for the fleece and Velcro areas interchangeable. This surface pattern can also be used for double-sided Velcro and fleece mats as well as used for Velcro and fleece strips become.

- Envelopes also as a triangular tube system to contain contaminated extinguishing water in fire service operations etc. be formed. Further Possible uses of the new wrapping result against the slipping of loads during transport by ships, airplanes, trucks and others Transport systems (e.g. railways).

- the envelope 1 shown in FIGS. 1 and 2 is after filling with a not shown Medium cuboid.

- a closure 6 through which the medium like e.g. Sand or water introduced into the casing 1 has been.

- the casing 1 Three abutting surfaces the casing 1 are provided with Velcro 3 (Fig. 1), which form the Velcro elements. This can also be designed as a mushroom head.

- the others three abutting surfaces of the Wrapping 1 are with Velcro or Velcro loop felt 4 coated (Fig. 2), the Velcro fasteners form. This makes it possible to stack them the one filled with the medium Envelopes 1 each have an outer surface 2 with Velcro hooks 3 one covering with the outer surface 2 with Velcro or Velcro 4 another To bring envelope 1 into engagement.

- the Velcro hook 3 and the Velcro felt or Velcro loop felt 4 can be made of metal including non-ferrous metal, Plastic or natural fibers exist.

- the Velcro felt or Velcro loop felt 4 can cover the entire surface arranged on the relevant outer surfaces 2 become. But it is also possible to use Velcro or Velcro loop felt 4 only in sections or to be provided point by point. So the Velcro felt or Velcro loop felt 4 e.g. striped or punctiform crossed diagonally or wavy on each Outer surface 2 of the casing 1 is provided become. Examples of this are shown in FIGS. 3 to 11 shown.

- the Velcro elements and the Velcro fasteners are so on the envelope 1 aligned that when stacking Envelopes 1 always an intervention takes place.

- each envelope 1 It is useful to have the top and bottom outer surface 2 of each envelope 1 with area-specific To provide symbols 11, as in Fig. 1st and Figure 2 is shown schematically.

- the symbols O and U identify the respective top or bottom a wrapping 1.

- the others area-specific symbols 11 which are punctiform or are snake-shaped, characterize the Outer surfaces 2, the Velcro hooks 3 or Velcro felt or Velcro loop felt 4. This allows you to simple way when creating a union of Envelopes 1 which each engage with each other external surfaces to be brought 2 Envelopes 1 are assigned to each other.

- FIG. 12 to 14 show the formation of a closure 6 of an envelope 1.

- a closure 6 of an envelope 1 In one end face 5 of the climbing covering 1 is an opening 12 trained.

- a flap 13 is formed on this, Velcro elements such as Velcro hooks on the outer surface 3 are arranged.

- the inner wall 14 of the Envelope 1 is on the opposite of the tab 13 Edge of the opening 12 with Velcro fasteners like Velcro felt or Velcro loop felt 4 coated.

- the flap 13 is used to close the closure 6 inserted through the opening 12 and with his Velcro elements on the Velcro fasteners brought to the plant (Fig. 13).

- This closure 6 is for manual or mechanical hopper filling suitable. When the casing is filled 1, the filled medium lies on the tab 13, which makes the closure 6 optimal compressive strength has and does not open automatically.

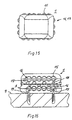

- the side 1 it is also possible to cover the side 1 to be provided with circumferential loops 15 (Fig. 15).

- the loops 15 become an upper one Loop band 16 and a lower loop band 17 arranged (Fig. 16).

- the side loops 15 of the Wrapping 1 have the function that Cover 1 on the floor surface 9 by means of ground anchors 19 to be anchored and thus reliably attached.

- those in the bottom surface 9 are fixed anchored ground anchor 19 by means of a rope 18 the loops 15 of the loop bands 16, 17 connected.

- Another function of the side loops 15 is in it, with Velcro and / or Velcro fasteners equipped coverings 1 by means of to reliably tie or connect a rope 18 to be able to. This turns these wrappings into one stable stackable position.

- recessed anchorages can be folded Brackets or rings embedded in the floor surface 9 become. If necessary, the climbing ones can Enclosures 1 are attached.

- wrappings according to the invention with different Cross sections are available after filling can also be stacked in a bandage with a medium. This is particularly advantageous if, for example, a Protection of a floor surface 9 against one-sided Water should be achieved.

- An example of one Protective wall is shown in Fig. 17.

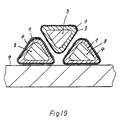

- Fig. 19 shows envelopes 1 which are tubular can be trained and e.g. as a provisional Can serve as a barrier against spreading liquid.

- These envelopes 1 are in the medium filled state in cross section generally triangular educated.

- the outer surfaces are alternating all over with Velcro hook 3 or Velcro felt or Velcro loop felt 4 so that the Envelopes 1 stacked against each other are sealed together.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Revetment (AREA)

- Wrappers (AREA)

- Protection Of Pipes Against Damage, Friction, And Corrosion (AREA)

- Buffer Packaging (AREA)

- Slide Fasteners, Snap Fasteners, And Hook Fasteners (AREA)

- Hooks, Suction Cups, And Attachment By Adhesive Means (AREA)

- Materials For Medical Uses (AREA)

- Transition And Organic Metals Composition Catalysts For Addition Polymerization (AREA)

- Laminated Bodies (AREA)

Description

- Bau von Schutzwällen zur Deichverteidigung bei Hochwasser oder Sturmflut

- Bau von provisorischen Häusern und Unterständen in Katastrophengebieten, z.B. durch Iglu-Bauweise

- Bau von behelfsmäßigen Brückenpfeilern oder Brükken durch Viadukt-Bauweise

- stabilen Abstützen von einsturzgefährdeten Gebäuden bei Erdbeben

- Bau von Schutzwällen gegen hohe Windgeschwindigkeiten, wie sie z.B. bei Hurricanes und Tornados auftreten

- Errichten von Schutzwällen gegen Feuersbrünste durch feuerfeste Sandsäcke.

- Fig. 1 und 2

- eine gefüllte sackförmige Umhüllung in zwei perspektivischen Ansichten,

- Fig. 3 bis 11

- Beispiele für die Anordnung von Klettfilz oder Klettschlingenfilz auf einer Fläche der sackförmigen Umhüllungen,

- Fig. 12 bis 14

- eine Umhüllung in zwei Queransichten im Schnitt und in der Draufsicht,

- Fig. 15

- eine weitere Ausbildung einer Umhüllung in der Draufsicht,

- Fig. 16 bis 19

- Beispiele für den Einsatz von Umhüllungen in schematischen Seitenansichten.

Claims (15)

- Sack- oder schlauchförmige Umhüllung (1) zur Bildung von Behältnissen die für Aufnahme von schüttfähigem oder fließfähigem Medium (8), deren Außenfläche(n) (2) mit Elementen (3, 4) zur Lagesicherung aufeinander und/oder nebeneinander gestapelter gefüllter Behältnisse versehen ist (sind), dadurch gekennzeichnet, daß die Elemente (3, 4) Kletthaft- (3) und/oder Klettverbindungselemente (4) einer an sich bekannten Klettverbindung sind, wobei die Kletthaft- (3) bzw. die Klettverbindungselemente (4) derart angeordnet sind, daß sie bei aufeinander und/oder nebeneinander gestapelten gefüllten Behältnissen mit den Kletthaft- (3) bzw. Klettverbindungselementen (4) von benachbarten Behältnissen eine lösbare Haftverbindung eingehen.

- Bausatz bestehend aus mindestens zwei sack- oder schlauchförmigen Umhüllungen (1) zur Aufnahme von schüttfähigem oder fließfähigem Medium (8) und einer Matte (7), wobei die Außenflächen der Umhüllungen (1) und der Matte (7) mit Elementen (3, 4) zur Lagesicherung aufeinander und/oder nebeneinander versehen sind, dadurch gekennzeichnet, daß die Elemente (3, 4) Kletthaft- (3) und/oder Klettverbindungselemente (4) einer an sich bekannten Klettverbindung sind, wobei auf den Außenflächen (2) der Umhüllung (1) eine Art der Elemente (3, 4) der Klettverbindung angebracht ist, die Matte (7) beidseitig mit der anderen Art der Elemente (3, 4) der Klettverbindung versehenen ist und die Kletthaft- (3) bzw. die Klettverbindungselemente (4) der Umhüllungen derart vorgesehen sind, daß sie bei aufeinander und/oder nebeneinander gestapelten gefüllten Behältnissen mit den Kletthaft- (3) bzw. Klettverbindungselementen (4) von benachbarten Matten (7) eine lösbare Haftverbindung eingehen.

- Umhüllung nach Anspruch 1, dadurch gekennzeichnet, daß die Kletthaftelemente und Klettverbindungselemente mit einem dünnen Überzug aus Kunststoff oder einer NE-Metallegierung beschichtet sind.

- Umhüllung nach Anspruch 1, dadurch gekennzeichnet, daß die Kletthaftelemente und Klettverbindungselemente abschnittsweise mit einem dünnen Überzug aus Kunststoff oder einer NE-Metallegierung beschichtet sind.

- Umhüllung nach Anspruch 1, dadurch gekennzeichnet, daß die Umhüllung (1) aus Kohlefasergewebe oder einem Gewebe aus UV-beständigen Kunststoffasern besteht.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 5, dadurch gekennzeichnet, daß die Kletthaftelemente pilzkopfartig oder als Kletthaken (3) und Klettverbindungselemente als Klettfilz bzw. Klettschlingenfilz (4) oder als Flausch, Flausch-Schlingen, Flausch-Filz ausgebildet sind.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 6, dadurch gekennzeichnet, daß die Umhüllung (1) im Gebrauchszustand, wenn sie mit einem Medium (8) gefüllt ist, im Querschnitt rund, quadratisch, rechteckförmig, dreieckförmig oder oval ausgebildet ist.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 7, dadurch gekennzeichnet, daß die Kletthaftelemente und die Klettverbindungselemente auf der Außenfläche (2) der Umhüllung (1) ganzflächig, abschnittsweise streifen-, kreis- oder punktförmig angeordnet sind.

- Umhüllung nach Anspruch 1, dadurch gekennzeichnet, daß an einer Stirnfläche (5) der mit einem Medium (8) gefüllten Umhüllung (1) ein Verschluß (6) angeordnet ist.

- Umhüllung nach Anspruch 9, dadurch gekennzeichnet, daß in der Stirnfläche (5) eine Durchbrechung (12) ausgebildet ist, an der ein Lappen (13) mit einer äußeren Beschichtung mit Kletthaftelementen oder Klettverschlußelementen ausgebildet ist, die mit einer auf der Innenwand (14) der Umhüllung (1) am Rande der Durchbrechung (12) angeordneten Schicht von Klettverbindungselementen oder Kletthaftelementen zur Ausbildung des Verschlusses (6) in Eingriff bringbar ist.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 10, dadurch gekennzeichnet, daß an den an die Außenflächen (2) angrenzenden Außenflächen der Umhüllung (1) mindestens ein aus Schlaufen (15) bestehendes umlaufendes Schlaufenband (16; 17) ausgebildet ist.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 11, dadurch gekennzeichnet, daß auf der ober- und unterseitigen Außenfläche (2) einer jeden Umhüllung (1) flächenspezifische Symbole (11) zur Kennzeichnung der Außenflächen (2) angeordnet sind.

- Umhüllung nach Anspruch 12, dadurch gekennzeichnet, daß die Symbole (11), die Kletthaftelemente und die Klettverbindungselemente fluoreszierend ausgebildet sind.

- Umhüllung nach Anspruch 12 oder 13, dadurch gekennzeichnet, daß die Symbole (11) als Kletthaftelemente bzw. Klettverbindungselemente ausgebildet sind.

- Umhüllung nach einem der Ansprüche 1 und 3 bis 14 oder Bausatz nach Anspruch 2, dadurch gekennzeichnet, daß die Kletthaftelemene und Klettverbindungselemente aus Metall einschließlich NE-Metall, Kunststoff oder Naturfasern bestehen.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE9312749U | 1993-08-26 | ||

| DE9312749U DE9312749U1 (de) | 1993-08-26 | 1993-08-26 | Umhüllung |

| PCT/EP1994/002712 WO1995006169A1 (de) | 1993-08-26 | 1994-08-13 | Klettende umhüllung |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0716722A1 EP0716722A1 (de) | 1996-06-19 |

| EP0716722B1 true EP0716722B1 (de) | 2004-11-24 |

Family

ID=6897226

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP94926194A Expired - Lifetime EP0716722B1 (de) | 1993-08-26 | 1994-08-13 | Klettende umhüllung |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0716722B1 (de) |

| AT (1) | ATE283393T1 (de) |

| AU (1) | AU7613294A (de) |

| DE (3) | DE9312749U1 (de) |

| WO (1) | WO1995006169A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010025305B4 (de) | 2010-06-28 | 2019-10-02 | Admedes Schuessler Gmbh | Implantat zum Implantieren in den menschlichen Körper und Verfahren zum Herstellen desselben |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19738216A1 (de) * | 1997-09-02 | 1999-03-11 | Reinhard Schneider | Deichmodul |

| DE19938828A1 (de) * | 1999-08-19 | 2001-03-01 | F & B Verpackungen Gmbh | Papier- oder Kunststoffsack mit rutschhemmender Beschichtung |

| DE10248374A1 (de) * | 2002-10-17 | 2004-05-06 | Gerd Kellershohn | Sackartiges Behältnis, insbesondere zur Anwendung im Bereich Hochwasserschutz |

| DE102007042641A1 (de) * | 2007-09-07 | 2009-03-12 | Construction Research & Technology Gmbh | Papiersack für pulverförmiges Füllgut |

| DE102017212720A1 (de) * | 2016-09-29 | 2018-03-29 | Dürkopp Fördertechnik GmbH | Transporttasche für eine Hängeförderanlage |

| WO2019197851A1 (en) * | 2018-04-12 | 2019-10-17 | Flexinnova Kft | Process for forming a transportable stack, transportable stack and process for transporting a transportable stack |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE106906C (de) * | ||||

| DE1864678U (de) * | 1962-11-02 | 1962-12-27 | Folipack Kunststoffwerk Max Bo | Aus folienmaterial bestehender sack. |

| DE1882439U (de) * | 1963-05-09 | 1963-11-07 | Etimex Ges Fuer Textil Und Kun | Rutschfester sack aus polyaethylen. |

| US4362433A (en) * | 1980-10-30 | 1982-12-07 | Wagner David R | Flood disaster control bag |

| JPS5998915A (ja) * | 1982-11-29 | 1984-06-07 | Seiji Ichikawa | リングフツク土納袋連結方法 |

| DE8402729U1 (de) * | 1984-01-31 | 1984-04-26 | Gottlieb Binder Gmbh & Co, 7031 Holzgerlingen | Textiler flaechen-haftverschluss |

| DE3530124A1 (de) * | 1985-08-23 | 1987-03-05 | Huesker Synthetic Gmbh & Co | Verfahren zur herstellung einer boeschungswand oder eines walles, insbesondere eines laermschutzwalles |

| US5115916A (en) * | 1988-04-08 | 1992-05-26 | Stuart Jacobson Associates, Inc. | Personal care package |

| US5172980A (en) * | 1992-05-19 | 1992-12-22 | Velcro Industries, B.V. | Reclosable bag having hook and loop sealing strips |

-

1993

- 1993-08-26 DE DE9312749U patent/DE9312749U1/de not_active Expired - Lifetime

-

1994

- 1994-08-13 EP EP94926194A patent/EP0716722B1/de not_active Expired - Lifetime

- 1994-08-13 DE DE59410395T patent/DE59410395D1/de not_active Expired - Lifetime

- 1994-08-13 AT AT94926194T patent/ATE283393T1/de not_active IP Right Cessation

- 1994-08-13 WO PCT/EP1994/002712 patent/WO1995006169A1/de not_active Ceased

- 1994-08-13 AU AU76132/94A patent/AU7613294A/en not_active Abandoned

- 1994-08-16 DE DE4429021A patent/DE4429021A1/de not_active Ceased

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102010025305B4 (de) | 2010-06-28 | 2019-10-02 | Admedes Schuessler Gmbh | Implantat zum Implantieren in den menschlichen Körper und Verfahren zum Herstellen desselben |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE283393T1 (de) | 2004-12-15 |

| EP0716722A1 (de) | 1996-06-19 |

| DE4429021A1 (de) | 1995-03-16 |

| AU7613294A (en) | 1995-03-21 |

| DE59410395D1 (de) | 2004-12-30 |

| DE9312749U1 (de) | 1993-11-04 |

| WO1995006169A1 (de) | 1995-03-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2040082C3 (de) | Abdeckhaut zum Verkleiden von vertikalen Stirnflächen eines Erdbauwerks | |

| DE69314931T2 (de) | Aus verstärkten Zellen bestehendes Material | |

| US20020090265A1 (en) | Sandbag envelope | |

| EP0716722B1 (de) | Klettende umhüllung | |

| DE2626650A1 (de) | Verfahren zur herstellung von armierten erdbauwerken | |

| DE1634382C3 (de) | Schalungshülle zum Herstellen von Betonplatten im Grundbau | |

| DE20216081U1 (de) | Hilfsdeich-Baukörper | |

| EP1321585A2 (de) | Gittermatte, insbesondere für Gabionenkörbe | |

| DE3037493A1 (de) | System zum zeitweiligen abstuetzen einer ausschachtung | |

| DE4022338C2 (de) | ||

| DE3834701C2 (de) | ||

| DE1811932B2 (de) | Als Raumgitterwand ausgebildete Stützmauer | |

| JPH02261122A (ja) | 補強土擁壁 | |

| DE4012301C2 (de) | Schalungshülle | |

| EP0469008A1 (de) | Mauer. | |

| DE102009012085A1 (de) | Ankermatte für den untertägigen Berg- und Tunnelbau | |

| DE10314314B4 (de) | Einrichtung zum Eindämmen von Hochwasser | |

| DE1970492U (de) | Boeschungsmatte zur sicherung von erdbauwerken. | |

| DE3306632A1 (de) | Drahtverzugmatte mit feinmaschigem netz | |

| DE19609267A1 (de) | Senkrechte Bauwerksabdichtung bei aufsteigenden Wänden gegen Sickerwasser | |

| DE102006039795A1 (de) | Hochwasserschutzvorrichtung | |

| DE4208286A1 (de) | Laermschutz- und hangstuetzwand aus bauchigen drahtgittermatten | |

| DE29601095U1 (de) | Schallabsorptionselement | |

| DE3205383C2 (de) | ||

| DE10354799B4 (de) | Anordnung für eine Deichabdichtung und eine Deicherhöhung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19960124 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19970422 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: WINTER, GEORG |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: MERTEN, HELMUT WOLFGANG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB IT LI NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 20041124 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59410395 Country of ref document: DE Date of ref document: 20041230 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20050306 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20050330 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050813 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050831 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20050825 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| BERE | Be: lapsed |

Owner name: *WINTER GEORG Effective date: 20050831 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080803 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080818 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080820 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20090828 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: V1 Effective date: 20100301 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090813 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100301 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090813 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59410395 Country of ref document: DE Effective date: 20110301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110301 |