EP0561266B1 - Store à lamelles - Google Patents

Store à lamelles Download PDFInfo

- Publication number

- EP0561266B1 EP0561266B1 EP93103862A EP93103862A EP0561266B1 EP 0561266 B1 EP0561266 B1 EP 0561266B1 EP 93103862 A EP93103862 A EP 93103862A EP 93103862 A EP93103862 A EP 93103862A EP 0561266 B1 EP0561266 B1 EP 0561266B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- slats

- blind

- winder

- cord

- rocker arm

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004804 winding Methods 0.000 abstract description 5

- 241001484259 Lacuna Species 0.000 abstract 1

- 238000010276 construction Methods 0.000 abstract 1

- 241000446313 Lamella Species 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000002184 metal Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000000284 resting effect Effects 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E06—DOORS, WINDOWS, SHUTTERS, OR ROLLER BLINDS IN GENERAL; LADDERS

- E06B—FIXED OR MOVABLE CLOSURES FOR OPENINGS IN BUILDINGS, VEHICLES, FENCES OR LIKE ENCLOSURES IN GENERAL, e.g. DOORS, WINDOWS, BLINDS, GATES

- E06B9/00—Screening or protective devices for wall or similar openings, with or without operating or securing mechanisms; Closures of similar construction

- E06B9/24—Screens or other constructions affording protection against light, especially against sunshine; Similar screens for privacy or appearance; Slat blinds

- E06B9/26—Lamellar or like blinds, e.g. venetian blinds

- E06B9/28—Lamellar or like blinds, e.g. venetian blinds with horizontal lamellae, e.g. non-liftable

- E06B9/30—Lamellar or like blinds, e.g. venetian blinds with horizontal lamellae, e.g. non-liftable liftable

- E06B9/32—Operating, guiding, or securing devices therefor

- E06B9/322—Details of operating devices, e.g. pulleys, brakes, spring drums, drives

Definitions

- the present invention relates to a slat blind according to the preamble of independent claim 1.

- slat blind includes both roman blinds and all-metal blinds. These serve to secure the windows and shade rooms.

- the slats are laterally provided with pins that protrude through vertical slots in the side guide rails and engage in a link plate.

- the link plates are rotatably connected to one another at their two ends by support members, so that the position of the link plates can be changed by changing the position of the pairs of support members. This can usually have the effect that the slats can be pivoted from the normal vertical position into a horizontal position in the completely lowered position of the store. These two positions are automatically assumed by the movement of the store.

- the slats When lowering, the slats remain in the closed or vertical position and can be brought into the open or horizontal position by means of a small counter-movement, as when pulling up the store.

- the respective room is either completely shaded or completely dark or the solar radiation cannot be shaded to the desired extent.

- DE-A-37 22 604 also describes a turning device for Roman blinds. With this arrangement, it is desirable that the slats in the lowered position are not necessarily brought into the closed position, but remain in a semi-open position. Special operating cords are also provided here for turning or for pre-setting the slat position.

- a Roman blind in which the slats can assume three positions, namely an open, a partially open and a closed position. It is envisaged that the semi-open position when lowering can only be maintained as long as the store is not fully lowered. When the store is completely lowered, the slats automatically assume the closed position.

- the object of the invention is to provide a Roman blind, in which an additional factory-set position of the slats is possible according to the need for shading without additional adjustment ropes or cords or the like, and in which this additional position over the entire stroke length, also in completely lowered position is maintained.

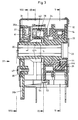

- Fig. 1 and 2 show a Roman blind in frontal view and in sectional view. According to the frontal view, a number of slats 2 are guided on both sides in guide rails 1 in the usual way.

- the two ends of the two-armed lever 5 hold a chain, formed from articulated support members 17, 18, of which the respective upper support member 17 has bearing openings 11 on both sides for connection to the respective lower support member 18, which has a stop 13 for determining the stretched state the chain.

- a drawstring 14 on the left and right of the slats 2 is fastened at its lower free end to a slide support 12 and this slide support 12 pushes the two slides 7, 8 right and left of the slats downwards or upwards.

- a locking lever 9 is attached to the carriage 7, 8 itself, with which the store located in the lower end position can be secured. As far as this or a modification of this store is well known in specialist circles, it does not need to be described further here.

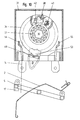

- the reel shaft 29 ends in a hexagonal shaft section 30.

- the band reel 33 which is installed in a housing 31 with a cover 32.

- the tension band 14 (FIGS. 5 to 7) is wound on this band reel 33.

- a rocker 36 (FIG. 4) is rotatably mounted on the hexagonal shaft section 30 and comprises a rocker arm 36a and a control arm 36b, which two parts 36a and 36b are arranged diametrically.

- the rocker arm 36a is provided with an adjustment pocket 36c which protrudes outwards through a slot in the housing and can thus be adjusted from outside the housing but within the cover of the box.

- a locking screw 47 the rocker 36 can be rotated in several discrete positions, e.g.

- a toothed segment 38 (FIG. 8) meshes with a toothed ring 51 held in a rotationally fixed manner on the shaft part 30. By rotating the shaft part 30, the toothed segment 38 is moved to the left or to the right for lowering and pulling up the store and is disengaged from the toothed ring 51 .

- the pivoting device is locked by means of locking bolts 42, 43, which are pressed against the flanks of the toothed segment 38 by springs 41, and the band 14 can be unrolled or rolled up.

- the mode of operation will be explained below in the description of the mode of operation.

- the tape reel 33 is equipped with a wedge 39 which slides radially into its hub when the tape is wound up (Fig. 5), and when that Band 14 is completely unwound, protrudes from the hub into a locking position (Fig. 6).

- a pawl 45 is rotatably mounted on the housing on a bolt 46. Due to its own weight, this pawl 45 rests on the belt 14 and comes to a stop at a locking surface 52 when the belt 14 is unwound. (Fig. 6)

- Fig. 7 shows the winding phase.

- the pawl 45 is accordingly lifted by the wound band 14 from the pawl stop 48 and half a turn further the wedge 34 is then pressed into the hub of the reel and the store can thus be lifted up.

- the store is stacked in the lintel.

- the cam 53 of the swivel plate 34 is locked in the catch 54 (FIG. 9).

- the fixed cam 37 locks the locking bolt 42 so that the toothed segment 38 remains in position outside of the engagement with the ring gear 51.

- the pawl 45 (FIG. 5) rests on the band 14 wound on the band reel 33 and slides on the band 14 during rotation.

- the further rotation of the reel shaft 29 has the effect that the toothed segment 38 is further rotated counterclockwise by the ring gear 51 and the locking bolt 42 is thereby lifted off the control curve 37.

- the toothed segment 38 is carried along until it is no longer in engagement with the ring gear 51. This causes the spring 41 to be tensioned and press the toothed segment 38 against the ring gear 51.

- the swivel plate 34 is locked and uncoupled by the engagement of the cam 53 in the catch 49, the tape 14 is unrolled by the further winding of the reel 33 and the store lowers with the slats 49 opened by the set angle of the catch 49.

- the band 14 releases the pawl 45, which thereby comes to rest and by which the wedge 44 is released so that it can be pressed outwards by the wedge spring 44a.

- the wedge 44 engages in a groove in the swivel disk 34 and takes it with it. After a rotation of 180 °, the swivel disk 34 is locked by the pawl 45 and the store is in the closed position of the slats.

- the hexagonal shaft 30 and thus the tape reel 33 are rotated clockwise.

- the ring gear 51 takes the toothed segment 38 with it. This makes a counterclockwise rotation and abuts the locking bolt 43. Torque is thus transmitted to the swivel plate 34 via ring gear 51, toothed segment 38 and locking bolt 43. This now turns together with the reel 33 in a clockwise direction.

- the cam 53 is thus pressed out of the detent and the locking bolt 43 slides on the control cam 37.

- the locking bolt 42 thus relieved is pressed down by the spring 41 against the swivel plate 34 and the cam 53 engages in the detent 49 on the adjustment pocket 36c and the locking bolt 42 is released. In the meantime, the locking bolt 43 slides on the cam 37 and is held down.

- the released locking bolt 42 is pushed upwards by the rotating swivel disk 34.

- the toothed segment 38 continues to rotate counterclockwise until it no longer meshes with the ring gear 51. However, it is pressed against the ring gear 51 by its own weight. Because the swivel plate 34 is locked but uncoupled, the further winding of the reel 33 causes the band 14 to be wound up.

- the wedge 44 is pressed inwards by the band 14 and by the groove in the swivel plate 34.

Landscapes

- Engineering & Computer Science (AREA)

- Structural Engineering (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Blinds (AREA)

- Emergency Lowering Means (AREA)

- Iron Core Of Rotating Electric Machines (AREA)

- Exhaust Silencers (AREA)

- Central Air Conditioning (AREA)

Claims (5)

- Store à lamelles comportant un dispositif prévu sur l'arbre d'enroulement (29) pour remonter ou descendre le store ainsi que des moyens pour faire pivoter des lamelles (2) entre une première position dans laquelle les lamelles (2) sont fermées en s'appliquant les unes contre les autres pratiquement verticalement, et une seconde position avec les lamelles (2) horizontales les unes par rapport aux autres,

caractérisé en ce qu'• une couronne dentée (51) est fixée solidairement en rotation sur l'arbre (29), et est fixée à rotation avec un segment denté (38) d'actionnement par un goujon de verrouillage (42, 43) poussé par un ressort (41) contre les flancs dentés et engrène pour limiter l'angle de pivotement, et• le segment denté (38) est fixé solidairement en rotation sur un disque de pivotement (34), et les goujons de verrouillage (42, 43) d'une bascule (36) qui est réalisée sous la forme d'un levier à deux bras à pivot central, comportant un bras de bascule (36a) et un bras de commande (36b), servent de butées, et• le bras de bascule (36a) comporte une came (53) servant à prendre dans une encoche (49) du bras de bascule (36a) et dans des encoches à suspension (54, 55) solidaires du boîtier, pour les deux positions d'ouverture ou de fermeture. - Store selon la revendication 1,

caractérisé en ce que

le bras de bascule (36a) est muni d'une patte de réglage (36c) et d'une vis de blocage (47) pour fixer le bras de bascule (36a) dans une position prédéterminée entre les positions d'ouverture et de fermeture des lamelles, et pour bloquer ainsi la position du moyen d'encliquetage (49). - Store selon la revendication 2,

caractérisé en ce que

le bras de bascule (36a) peut se régler par rapport aux encoches (54, 55) d'un angle compris entre 30° et 90° et, de préférence, un angle compris entre 40° et 65°. - Store selon l'une des revendications 1 à 3,

caractérisé en ce que

l'axe d'enroulement (29, 30) comprend une bobine (33) pour enrouler le ruban (14) servant à descendre et remonter le store, et qui est maintenue par le ruban (14) hors de prise d'une butée de verrouillage (48) existant à la périphérie de la bobine à ruban (33), et ce n'est que lorsque le ruban (14) est complètement dévidé qu'elle est libérée pour venir en prise dans la butée de verrouillage (48) pour bloquer la position de fin de course inférieure. - Store selon l'une des revendications 1 à 4,

caractérisé en ce que

la bobine à ruban (13) est reliée à un axe à six pans (30) solidaire de l'axe d'enroulement (29) et comporte un moyeu prolongé sur lequel est fixée la couronne dentée (51) pour entraîner le segment denté (38).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH825/92A CH685402A5 (de) | 1992-03-16 | 1992-03-16 | Rafflamellenstore. |

| CH825/92 | 1992-03-16 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0561266A2 EP0561266A2 (fr) | 1993-09-22 |

| EP0561266A3 EP0561266A3 (fr) | 1994-01-05 |

| EP0561266B1 true EP0561266B1 (fr) | 1997-11-05 |

Family

ID=4196079

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93103862A Expired - Lifetime EP0561266B1 (fr) | 1992-03-16 | 1993-03-10 | Store à lamelles |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0561266B1 (fr) |

| AT (1) | ATE159998T1 (fr) |

| CH (1) | CH685402A5 (fr) |

| DE (1) | DE59307618D1 (fr) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH696498A5 (de) * | 2003-07-11 | 2007-07-13 | Griesser Holding Ag | Lamellenstore. |

| JP4561268B2 (ja) * | 2004-09-16 | 2010-10-13 | オイレスEco株式会社 | ブラインド装置 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH503885A (de) * | 1969-08-25 | 1971-02-28 | Griesser Ag | Raffstore |

| CH523418A (fr) * | 1970-05-12 | 1972-05-31 | Fiblex S A | Mécanisme d'orientation pour stores à lamelles |

| CH608563A5 (fr) * | 1976-04-30 | 1979-01-15 | Schenker Emil Storen Und Masch | |

| CH650311A5 (de) * | 1981-05-19 | 1985-07-15 | Baumann Rolladen | Rafflamellenstore. |

| SE8203812L (sv) * | 1982-06-18 | 1983-12-19 | Perma System Ab | Lagerbock for fasadpersienner |

| DE3511246A1 (de) * | 1985-03-28 | 1986-10-02 | Theophil Dipl.-Ing. 7300 Esslingen Pfeffer | Abschirm- oder schutzvorrichtung fuer wandoeffnungen o.dgl., insbesondere ein rolladen oder eine jalousie |

| DE3610028C2 (de) * | 1986-03-25 | 1996-07-25 | Rau Metall Gmbh & Co | Wendevorrichtung für Rafflamellenstores |

-

1992

- 1992-03-16 CH CH825/92A patent/CH685402A5/de not_active IP Right Cessation

-

1993

- 1993-03-10 DE DE59307618T patent/DE59307618D1/de not_active Expired - Fee Related

- 1993-03-10 EP EP93103862A patent/EP0561266B1/fr not_active Expired - Lifetime

- 1993-03-10 AT AT93103862T patent/ATE159998T1/de active

Also Published As

| Publication number | Publication date |

|---|---|

| DE59307618D1 (de) | 1997-12-11 |

| EP0561266A2 (fr) | 1993-09-22 |

| EP0561266A3 (fr) | 1994-01-05 |

| ATE159998T1 (de) | 1997-11-15 |

| CH685402A5 (de) | 1995-06-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69826566T2 (de) | Wendemechanismus für eine Jalousie | |

| DE7529767U (de) | Stabbetaetigte jalousie | |

| DE10316836B4 (de) | Elektrisch betätigbare Jalousie | |

| DE3037701A1 (de) | Rafflamellenstore, rolladen o.dgl. | |

| DE2805836C2 (de) | Rafflamellenstore | |

| DE2312661A1 (de) | Faltjalousie | |

| AT394880B (de) | Rafflamellenstore | |

| DE3037759A1 (de) | Rafflamellenstore | |

| EP0050677B1 (fr) | Store vénitien | |

| DE3625365A1 (de) | Wendevorrichtung fuer eine raffbare lamellenjalousie mit drei lamellenstellungen | |

| CH650311A5 (de) | Rafflamellenstore. | |

| EP0561266B1 (fr) | Store à lamelles | |

| DE9117067U1 (de) | Fensterjalousie | |

| EP1072753A2 (fr) | Store vénitien | |

| DE2452549C3 (de) | Lamellenjalousie | |

| CH679689A5 (fr) | ||

| EP0383067B1 (fr) | Volet roulant pour ouvertures dans les toitures ou les murs, particulièrement avec une fenêtre de toiture basculante | |

| AT502509B1 (de) | Jalousie | |

| DE1683177A1 (de) | Kordelantriebsvorrichtung fuer Jalousien mit Lamellen | |

| EP1213437A2 (fr) | Store à lamelles avec mécanisme d'inclinaison | |

| EP1213439A2 (fr) | Dispositif de couverture | |

| EP0322355B1 (fr) | Store vénitien | |

| DE3037733A1 (de) | Rafflamellenstore | |

| DE2201056B1 (de) | Wendevorrichtung fuer eine raffbare Lamellenjalousie | |

| DE3037703A1 (de) | Rafflamellenstore mit an den lamellenenden angeordneten fuehrungsgliedern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19931224 |

|

| 17Q | First examination report despatched |

Effective date: 19951102 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971105 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971105 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19971105 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971105 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19971105 |

|

| REF | Corresponds to: |

Ref document number: 159998 Country of ref document: AT Date of ref document: 19971115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: NOVATOR AG Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59307618 Country of ref document: DE Date of ref document: 19971211 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19980205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980310 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19971105 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20000320 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20000329 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20000330 Year of fee payment: 8 Ref country code: AT Payment date: 20000330 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20000517 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010310 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010331 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010331 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010331 |

|

| BERE | Be: lapsed |

Owner name: E. KINDT A.G. VORMALS HANS KIEFER A.G. Effective date: 20010331 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011130 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050310 |